Positive plate, preparation method and lithium-ion battery comprising positive plate

A technology of lithium ion battery and positive electrode sheet is applied in the field of lithium ion, which can solve the problems of polluted air, inability to solve the problem of dissolving lithium supplementary agent, and reducing the battery rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

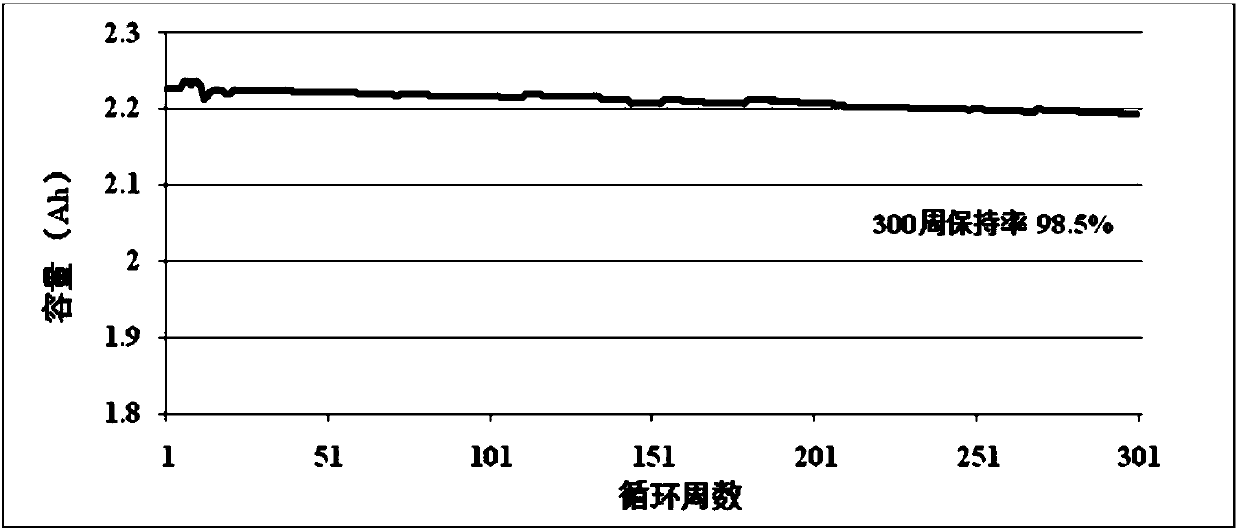

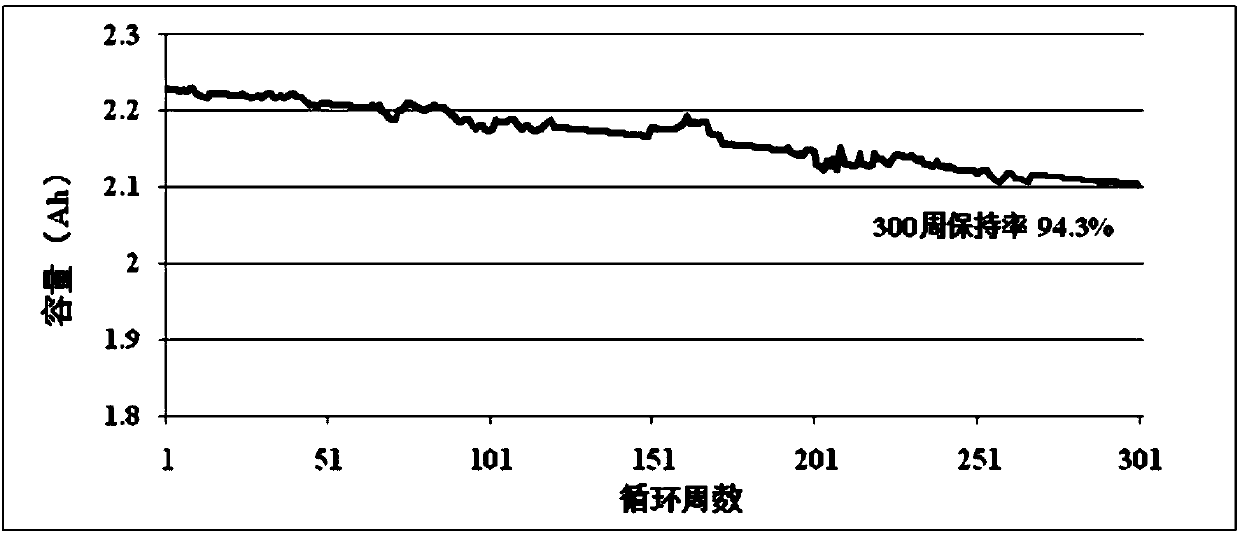

Examples

Embodiment 1

[0056] This embodiment provides a positive electrode sheet, and the preparation method of the positive electrode sheet is as follows:

[0057] 1) LiNi 0.6 co 0.2 mn 0.2 o 2 , SP, PVDF and Co / Li 2 O is mixed and homogenized according to a mass ratio of 95:1.5:1.2:2.3, using NMP as a solvent, the solid content of the solution is 77.5%, and the resulting slurry is coated on an aluminum foil current collector by a coating machine, and the density of one side of the pole piece is 105g / m 2 , drying the resulting pole pieces to form an active layer on the aluminum foil current collector.

[0058] 2) Mix and homogenize PVDF and SP at a mass ratio of 40:60, use NMP as a solvent, and have a solid content of 77.5% in the solution. Use a coating machine to coat the resulting slurry on the pole piece obtained in step 1). 2.1g / m 2 , after drying the resulting pole piece at 80°C, roll pressing to a compacted density of 3.5g / cm 3 .

[0059] 3) Place the pole piece obtained in step 2...

Embodiment 2

[0062] This embodiment provides a positive electrode sheet, and the preparation method of the positive electrode sheet is as follows:

[0063] 1) LiNi 0.815 co 0.135 Al 0.05 o 2 , CNTs, PVDF and Li 6 co 0.95 mn 0.05 o 4 Mix and homogenize according to the mass ratio of 95:1.2:1:2.8, use NMP as solvent, the solid content of the solution is 77.5%, use the coating machine to coat the obtained slurry on the aluminum foil current collector, and the density of one side of the pole piece is 110g / m 2 , drying the resulting pole pieces to form an active layer on the aluminum foil current collector.

[0064] 2) Mix and homogenize PVDF and VGCF at a mass ratio of 20:80, use NMP as a solvent, and the solid content of the solution is 77.5%, and use a coating machine to coat the resulting slurry on the pole piece obtained in step 1), the single-sided loading capacity 2.2g / m 2 , after drying the resulting pole piece at 80°C, roll pressing to a compacted density of 3.5g / cm 3 .

...

Embodiment 3

[0068]1) LiNi 0.7 co 0.2 mn 0.1 o 2 , KS-6, PTFE and Li 3 N is mixed and homogenized according to the mass ratio of 96:1.2:1.0:1.8, NMP is used as the solvent, the solid content of the solution is 70%, and the obtained slurry is coated on the aluminum foil current collector with a coating machine, and the density of one side of the pole piece is 115g / m 2 , drying the resulting pole pieces to form an active layer on the aluminum foil current collector.

[0069] 2) Mix and homogenize PVDF and acetylene black at a mass ratio of 50:50, use NMP as a solvent, and the solid content of the solution is 80%, and use a coating machine to coat the resulting slurry on the pole piece obtained in step 1), and load it on one side Amount 2.3g / m 2 , after drying the resulting pole piece at 75°C, roll pressing to a compacted density of 3.5g / cm 3 .

[0070] 3) Place the pole piece obtained in step 2) in the ALD reaction chamber, inject trimethylaluminum gas into the reaction chamber to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com