Current collector, preparation method thereof, and lithium ion battery

A lithium-ion battery, current collector technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc. Ease of handling, weight reduction, and improved safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

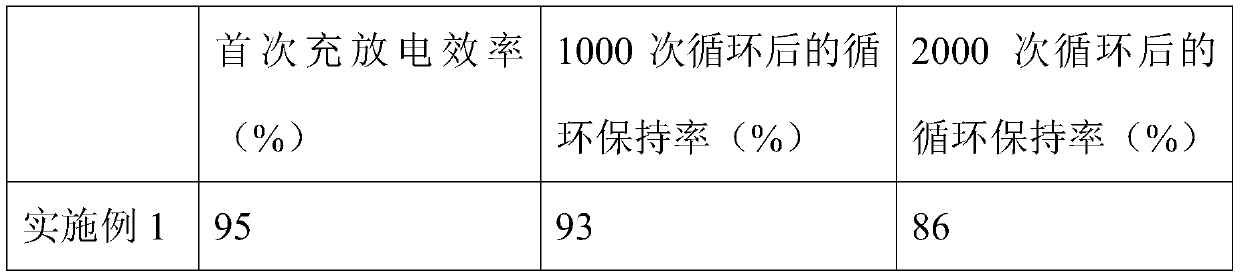

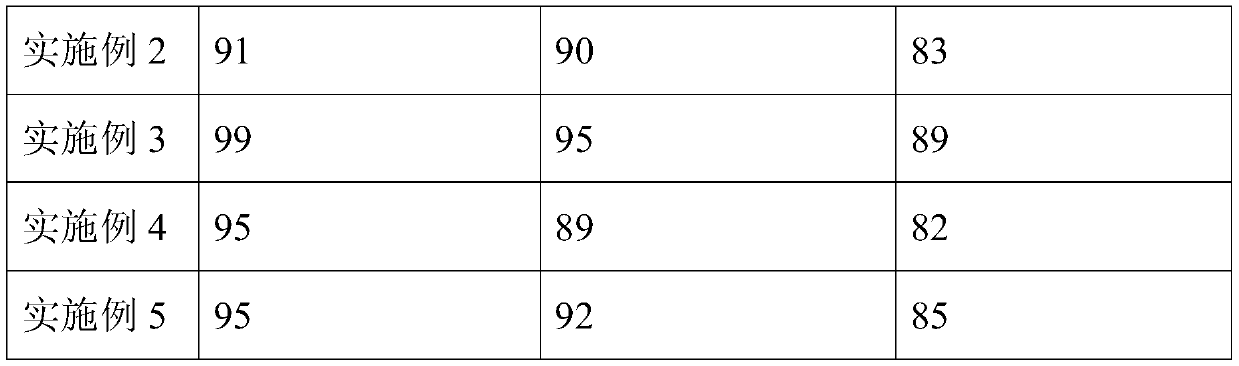

Examples

Embodiment 1

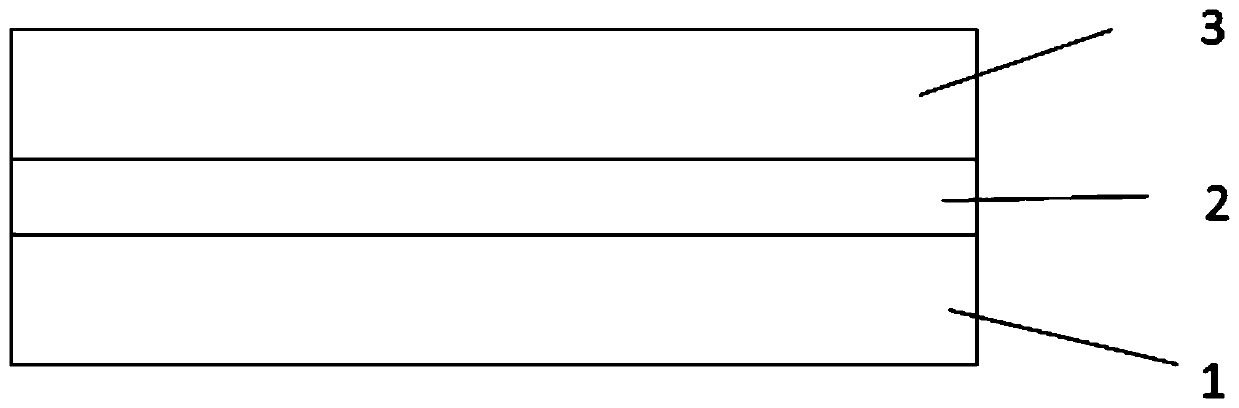

[0059] This embodiment provides a current collector, and the structural schematic diagram of the current collector is as follows figure 1 shown. The current collector comprises a base layer 1, a lithium supplementary layer 2 on the base layer, and a conductive protection layer 3 on the lithium supplementary layer. The base layer 1 is an aluminum layer with a thickness of 8 μm. The lithium replenishing layer 2 is a metal lithium layer with a thickness of 3 μm. The conductive protective layer 3 is an aluminum layer with a thickness of 8 μm.

[0060] This embodiment also provides a method for preparing the current collector, the method comprising the following steps:

[0061] (1) In the evaporation machine, under the vacuum of 5 Pa, metal lithium is used as the plating material, and high-frequency induction is used to generate high temperature, so that lithium metal is heated and evaporated at 1200 ° C for 1.5 hours. After the lithium evaporates, it rises to The upper vapor d...

Embodiment 2

[0065] This embodiment provides a current collector, which includes a base layer, a lithium supplementary layer on the base layer, and a conductive protective layer on the lithium supplementary layer. The base layer is an aluminum layer with a thickness of 5 μm, and the lithium supplement layer is a metal lithium layer with a thickness of 0.1 μm. The conductive protective layer is an aluminum layer with a thickness of 10 μm.

[0066] This embodiment also provides a method for preparing the current collector, the method comprising the following steps:

[0067] (1) In the evaporation machine, under the vacuum of 10Pa, metal lithium is used as the plating material, and high-frequency induction is used to generate high temperature, so that lithium metal is heated and evaporated at 800 ° C for 1 hour. The upper evaporation chamber of the plating machine is cooled by a cooling system at a temperature of -5°C in the evaporation chamber, and the lithium is condensed on the strip of t...

Embodiment 3

[0071] This embodiment provides a current collector, which includes a base layer, a lithium supplementary layer on the base layer, and a conductive protective layer on the lithium supplementary layer. The base layer is an aluminum layer with a thickness of 10 μm. The lithium supplement layer is a metal lithium layer with a thickness of 5 μm. The conductive protective layer is an aluminum layer with a thickness of 5 μm.

[0072] This embodiment also provides a method for preparing the current collector, the method comprising the following steps:

[0073] (1) In the evaporation machine, 10 -5 Under Pa vacuum, metal lithium is used as the plating material, and high-frequency induction is used to generate high temperature, so that lithium metal is heated and evaporated at 1500 ° C for 2 hours. After the lithium evaporates, it rises to the upper evaporation chamber of the evaporation machine through the baffle plate. The evaporation chamber is cooled by a cooling system at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com