Lithium supplementing additive and preparation method thereof and lithium ion battery

A lithium-ion battery and additive technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not easy to be compatible with lithium-ion battery processing and manufacturing technology, and the stability of lithium-replenishing materials needs to be improved, and achieve large-scale industrialization. The effect of production, improved conductivity, and shorter process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

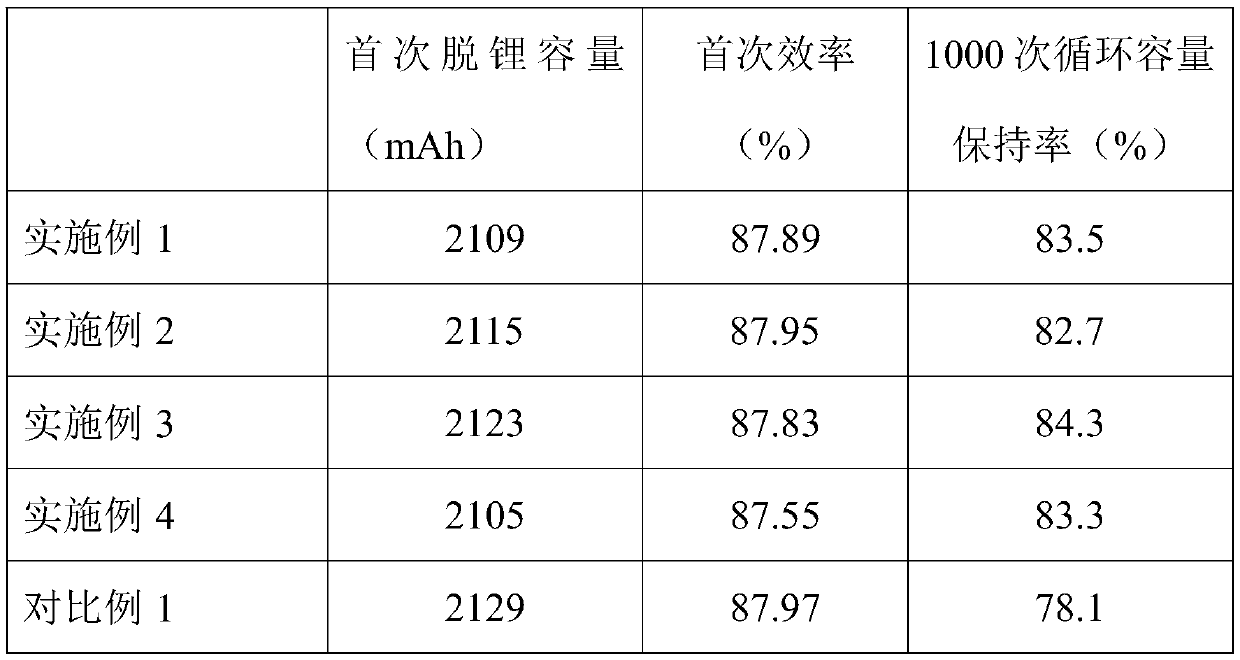

Examples

Embodiment 1

[0057] This embodiment prepares lithium supplement additive according to the following method:

[0058] (1) Under nitrogen protection, use MnO with an average particle size of 5 μm 2 , and lithium metal were heated at 185°C for 30min (the molar ratio of Li to Mn was 4:1), and then heated at 200°C for 3h to obtain the core material.

[0059] (2) Grind the core material described in step (1) and pass through a 325-mesh screen; dissolve 10 g of CTAB in an organic solvent, then ultrasonically disperse 1 g of the core material in 200 g of solvent, then add 0.1 mL of TEOS, and Add 10 mL of ammonia water (mass concentration 25%), react for 2 hours, and then filter to obtain a precursor, which is then sintered at 500° C. for 5 hours under a nitrogen atmosphere to obtain the lithium-supplementing additive.

[0060] The lithium-supplementing additive prepared in this embodiment comprises an inner core and a shell coated on the surface of the inner core, and the inner core includes Li ...

Embodiment 2

[0063] This embodiment prepares lithium supplement additive according to the following method:

[0064] (1) Under nitrogen protection, Fe with an average particle size of 20 μm is used 2 o 3 , after heating with lithium metal at 183°C for 35min (the molar ratio of Li to Fe is 3:1), and then heating at 197°C for 3.2h to obtain the core material.

[0065] (2) Grind the core material described in step (1) and pass through a 325-mesh sieve; dissolve 10 g of CTAB in an organic solvent, then ultrasonically disperse 1 g of the core material in a 200 °C solvent, then add 0.2 mL of TEOS, and Add 10mL ammonia water (mass concentration 25%), react for 2.2h and then filter to obtain the precursor, which is then sintered at 420°C for 5.5h under a nitrogen atmosphere to obtain the lithium supplement additive.

[0066] The lithium-supplementing additive prepared in this embodiment comprises an inner core and a shell coated on the surface of the inner core, and the inner core includes Li 2...

Embodiment 3

[0069] This embodiment prepares lithium supplement additive according to the following method:

[0070] (1) Under the protection of argon, use NiO with an average particle size of 3 μm, heat with lithium metal at 180 °C for 40 min (the molar ratio of Li to Ni is 2:1), and then heat at 195 °C for 3.5 h to obtain core material.

[0071] (2) Grind the core material described in step (1) and pass through a 325 mesh screen; after dissolving 5g of PVP in an organic solvent, ultrasonically disperse 1g of the core material in a 200°C solvent, then add 0.2mL TEOS, and Add 5mL ammonia water (mass concentration 25%), react for 1.5h and then filter to obtain the precursor, which is then sintered at 450°C for 6h under an argon atmosphere to obtain the lithium supplement additive.

[0072] The lithium-supplementing additive prepared in this embodiment comprises an inner core and a shell coated on the surface of the inner core, and the inner core includes Li 2 A mixture of O and metallic N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com