A kind of battery case and preparation method thereof, lithium ion battery and lithium replenishment method thereof

A lithium-ion battery and battery case technology, which is used in the manufacture of electrolyte batteries, charging/discharging of secondary batteries, secondary batteries, etc., can solve the problems of no help in battery safety, influence of electrolyte performance, and inaccurate lithium replenishment. , to achieve the effect of improving operation safety, improving cycle performance and energy density, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

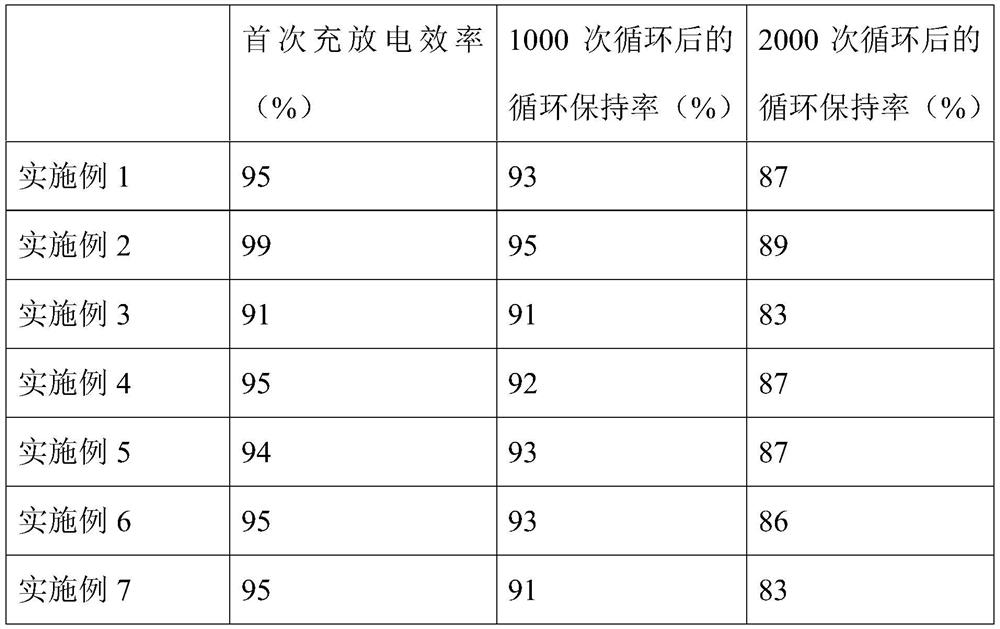

Examples

Embodiment 1

[0067] This embodiment provides a battery case, the battery case includes a case, a lithium-replenishing layer on the inner surface of the case, and a protective layer on the lithium-replenishing layer.

[0068] The shell is an aluminum shell, and its thickness is 0.7mm.

[0069] The lithium supplement layer is composed of lithium powder, acetylene black and polyvinylidene fluoride, wherein the mass ratio of lithium powder, acetylene black and polyvinylidene fluoride is 90:5:5. The thickness of the lithium supplementary layer is 100 μm.

[0070] The protective layer is a high molecular polymer protective layer, and the high molecular polymer is polystyrene. The thickness of the protective layer is 8 μm.

[0071] This embodiment also provides a preparation method of the battery case, and the specific method is as follows:

[0072] Under a nitrogen atmosphere, the formula amounts of lithium powder, acetylene black and polyvinylidene fluoride are mixed in N-methylpyrrolidone t...

Embodiment 2

[0080] This embodiment provides a battery case, the battery case includes a case, a lithium-replenishing layer on the inner surface of the case, and a protective layer on the lithium-replenishing layer.

[0081] The shell is an aluminum shell, and its thickness is 1 mm.

[0082] The lithium supplementing layer is composed of lithium powder, acetylene black and polyvinylidene fluoride, wherein the mass ratio of lithium powder, acetylene black and polyvinylidene fluoride is 88:6:6. The thickness of the lithium supplementary layer is 200 μm.

[0083] The protective layer is a high molecular polymer protective layer, and the high molecular polymer is polyvinyl chloride. The thickness of the protective layer is 10 μm.

[0084] This embodiment also provides a preparation method of the battery case, and the specific method is as follows:

[0085] Under a nitrogen atmosphere, the formula amounts of lithium powder, acetylene black and polyvinylidene fluoride are mixed in N-methylpyr...

Embodiment 3

[0093] This embodiment provides a battery case, the battery case includes a case, a lithium-replenishing layer on the inner surface of the case, and a protective layer on the lithium-replenishing layer.

[0094] The shell is an aluminum shell, and its thickness is 0.5mm.

[0095] The lithium replenishing layer is composed of lithium powder, ketjen black and styrene-butadiene rubber, wherein the mass ratio of lithium powder, ketjen black and styrene-butadiene rubber is 92:4:4. The thickness of the lithium supplementary layer is 10 μm.

[0096] The protective layer is a high molecular polymer protective layer, and the high molecular polymer is a polyethylene-polyvinyl acetate copolymer. The thickness of the protective layer is 5 μm.

[0097] This embodiment also provides a preparation method of the battery case, and the specific method is as follows:

[0098] Under a nitrogen atmosphere, the formula amounts of lithium powder, Ketjen black and styrene-butadiene rubber are mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com