High-conductivity polyetheretherketone composite material and preparation method thereof

A technology of polyether ether ketone and composite materials, which is applied in the field of high-conductivity polyether ether ketone composite materials, and can solve the problems of carbon nanotube dispersion, interface problems, performance stability, poor conductivity, and limited application range, etc. problem, achieve the effect of improving the interface effect, increasing the filling amount, and avoiding black spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

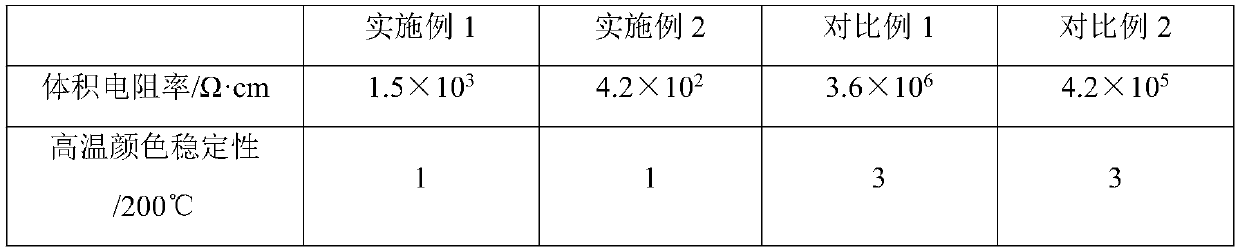

Embodiment 1

[0043] This embodiment provides a highly conductive polyetheretherketone composite material, which consists of the following components in parts by weight:

[0044] 80 parts of PEEK, 10 parts of aramid fiber, 10 parts of grafted modified carbon nanotubes, 5 parts of nano-alumina, 2 parts of silane coupling agent, 0.5 parts of antioxidant, and 1 part of polytetrafluoroethylene.

[0045] Wherein the grafted modified carbon nanotubes are prepared by the following method:

[0046] a. Add coupling agent KH570 to the ethanol aqueous solution with a mass fraction of 50%, adjust the pH to 3.5 with a dilute acid aqueous solution, and prepare a KH570 coupling agent solution with a mass fraction of 30%;

[0047] b. Add 15 parts of carbon nanotubes, 120 parts of acetone, and 15 parts of KH570 silane coupling agent solution into the reaction vessel, stir evenly, and stir and react at 60°C for 6 hours;

[0048] c, after the reaction is finished, filter, wash with anhydrous acetone, and dry...

Embodiment 2

[0059] This embodiment provides a highly conductive polyetheretherketone composite material, which consists of the following components in parts by weight:

[0060] 100 parts of PEEK, 18 parts of carbon fiber, 15 parts of grafted modified carbon nanotubes, 6 parts of nano-silicon carbide, 4 parts of silane coupling agent, 1 part of antioxidant, 0.5 part of molybdenum disulfide, and 0.5 part of graphite.

[0061] Wherein the grafted modified carbon nanotubes are prepared by the following method:

[0062] a. Add coupling agent KH570 to the ethanol aqueous solution with a mass fraction of 50%, adjust the pH to 3.5 with a dilute acid aqueous solution, and prepare a KH570 coupling agent solution with a mass fraction of 30%;

[0063] b. Add 20 parts of carbon nanotubes, 150 parts of acetone, and 20 parts of KH570 silane coupling agent solution into the reaction vessel, stir evenly, and stir and react at 70°C for 5 hours;

[0064] c, after the reaction is finished, filter, wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com