Cover body, diaphragm and electronic device

A technology of electronic devices and membranes, which is applied to electrical equipment shells/cabinets/drawers, electrical components, chassis/boxes/drawer parts, etc., and can solve the problems of IMT process products being easily scratched and scratched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

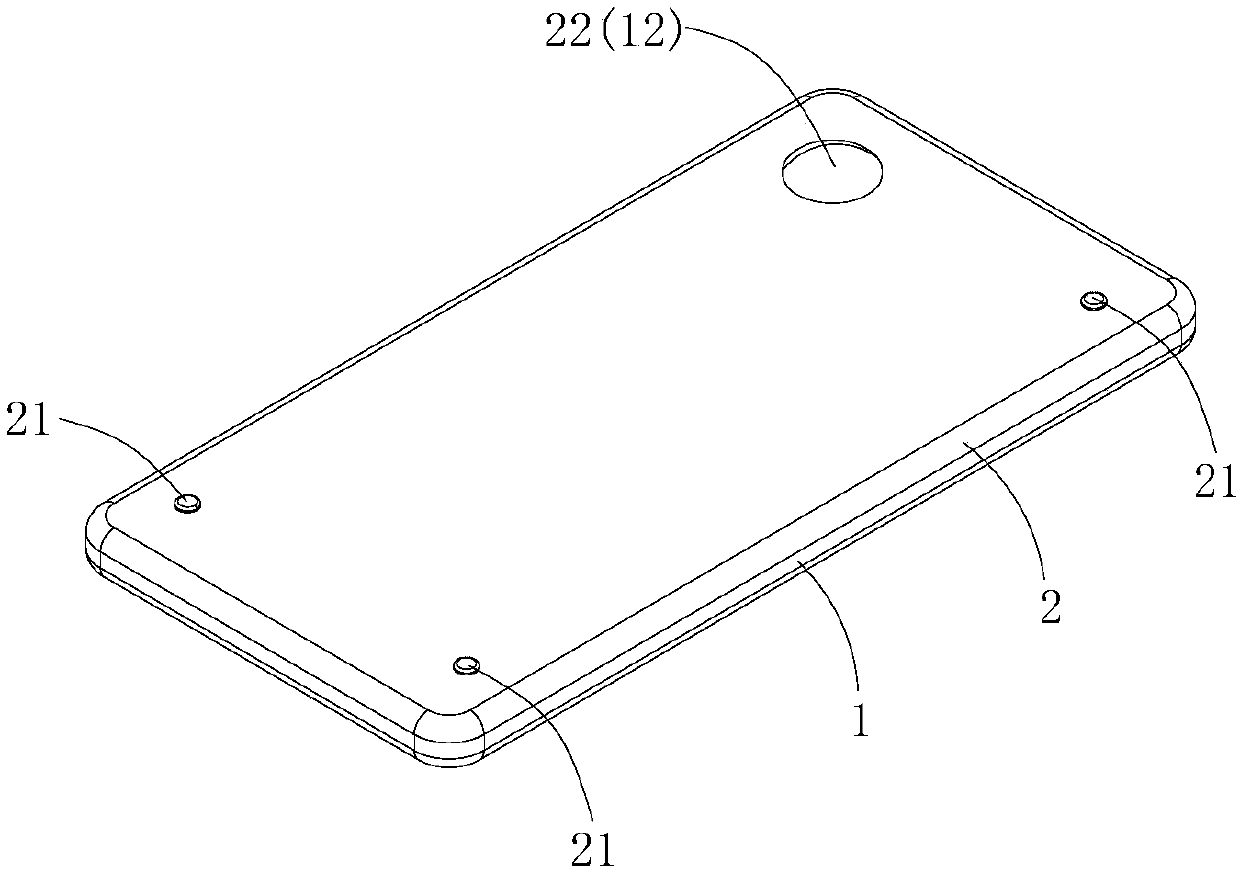

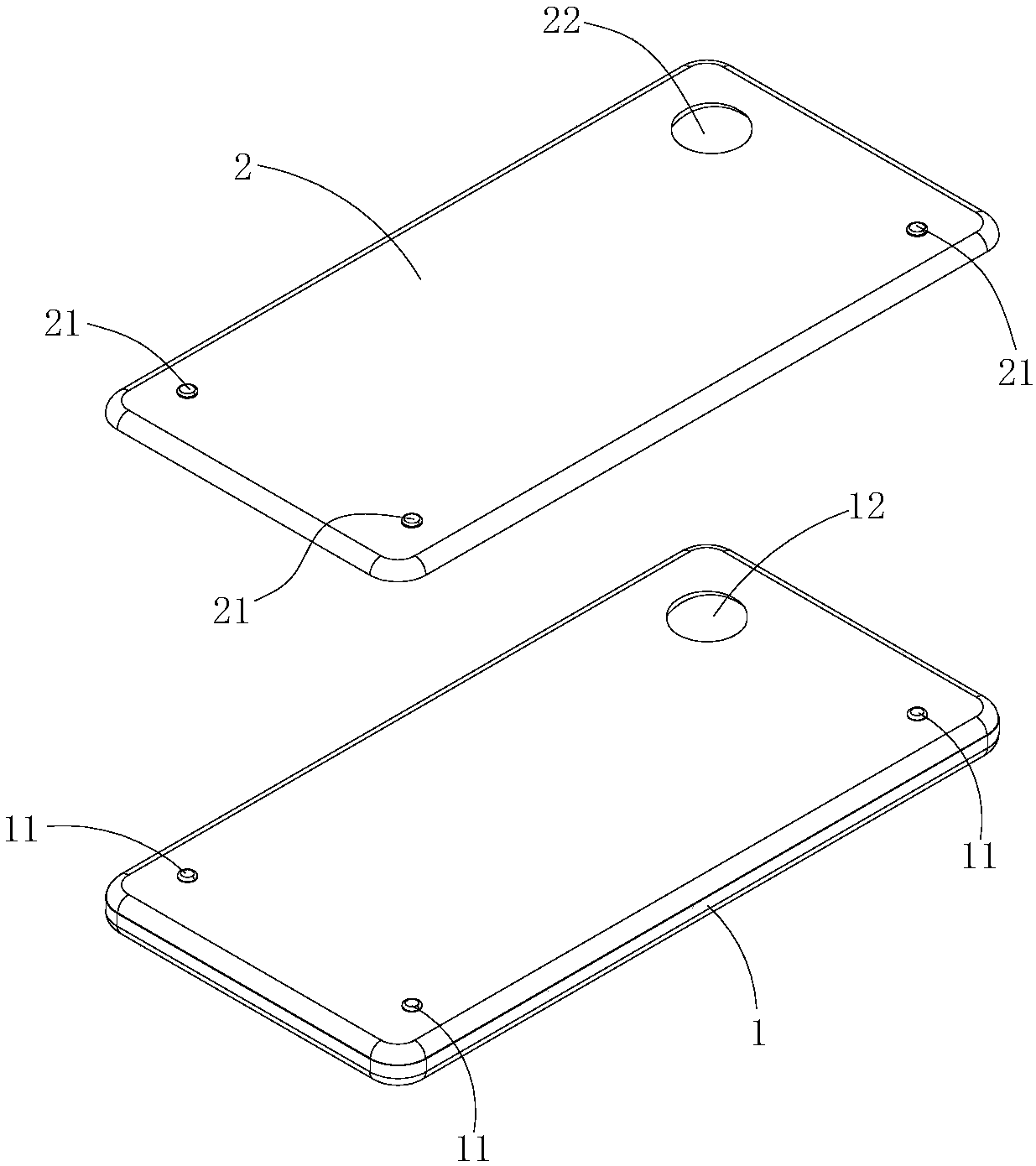

[0027] See Figure 1 to Figure 3 , which is Embodiment 1 of the present invention, shows a cover body, which includes a cover body 1 and a diaphragm 2 .

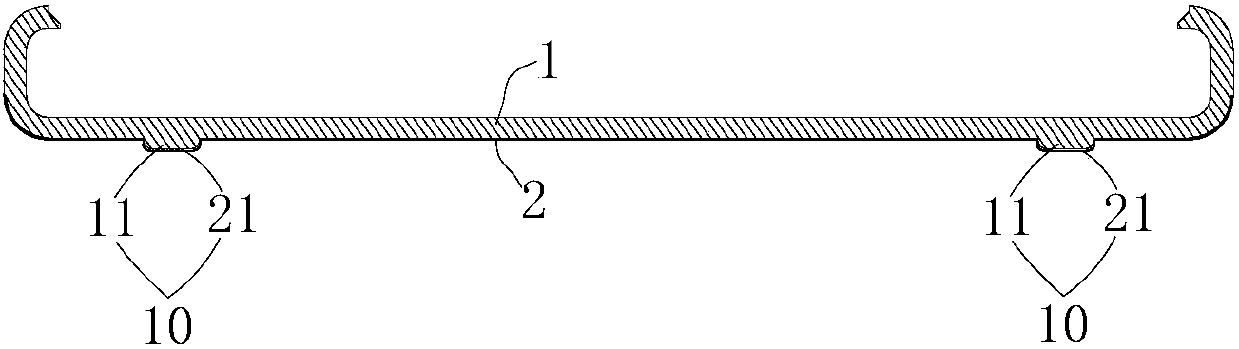

[0028] Wherein, the diaphragm 2 is made by an embedded three-dimensional injection molding process, the diaphragm 2 has a graphic layer, and patterns and / or characters are printed on the graphic layer. A protruding structure 11 is provided on the outer surface of the cover body 1 , and the protruding structure 11 protrudes from the outer surface of the diaphragm 2 . The inner side of the diaphragm 2 is recessed toward the outer side corresponding to the position of the protruding structure 11 , forming a raised area 21 protruding from the outer surface of the diaphragm 2 . The inner surface of the diaphragm 2 is fixedly connected to the outer surface of the cover body 1. When the diaphragm 2 and the cover body 1 are fixedly connected, the raised structure 11 of the cover body 1 is embedded in the raised area 21, so that the...

Embodiment 2

[0037] See Figure 5 and Figure 6 , which is the second embodiment of the present invention, shows a cover body, which includes a cover body 1 and a diaphragm 2 . Except for the following content, this embodiment is the same as the first embodiment.

[0038] A through-hole area 23 is opened on the diaphragm 2 at a position corresponding to the protruding structure 11 , and the protruding structure 11 protrudes from the through-hole area 23 . When the cover body is in contact with a plane such as the desktop, the raised structure 11 lifts the area of the diaphragm 2 that is offset from the raised structure 11. When the cover body slides relative to the plane, it can avoid scratches easily after the surface of the cover body comes into direct contact with the desktop. Problems affecting the appearance of IMT process products due to scratches and scratches.

Embodiment 3

[0040] See Figure 7 and Figure 8, which is the third embodiment of the present invention, shows a cover body, which includes a cover body 1 and a diaphragm 2 . Except for the following content, this embodiment is the same as the first embodiment.

[0041] Such as Figure 7 As shown, the protruding structure 11 is a decorative part. Patterns and / or characters are arranged on the surface of the raised structure 11, and the raised structure 11 is adhered to the outer surface of the cover body 1 through an adhesive 3, and by designing the pattern and / or characters on the raised structure 11, It can increase the beauty of the appearance of the product while preventing the outer surface of the cover from being scratched. See Figure 8 , the shape of the protruding structure itself constitutes a pattern and / or text, so that it can be used as a picture, a logo, a trademark, etc. for publicity.

[0042] When the cover body is in contact with a plane such as the desktop, the rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com