Preservative film cutting device capable of preventing edge from curling during cutting

A technology of cutting device and fresh-keeping film, which is applied in the directions of packaging, sending objects, and packaging protection, etc., can solve the problems of hidden health risks, the end of the fresh-keeping film is not compliant, and the disinfection function of the fresh-keeping film is not perfect, so as to increase the usability and increase the practicability. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

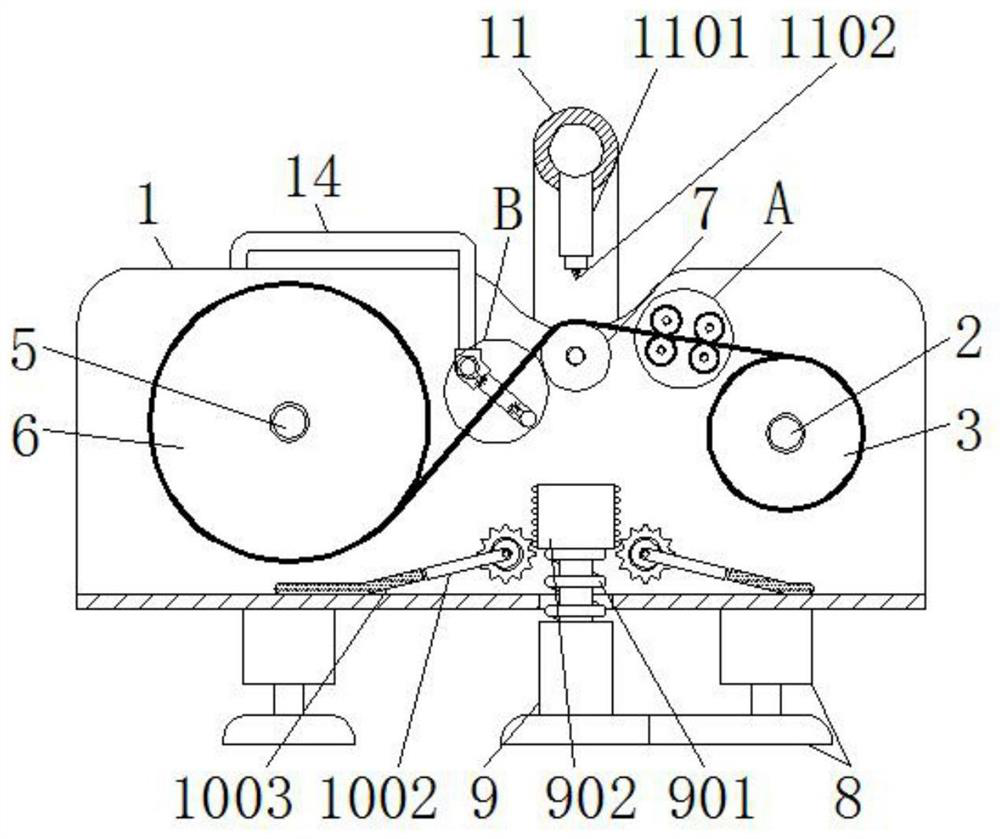

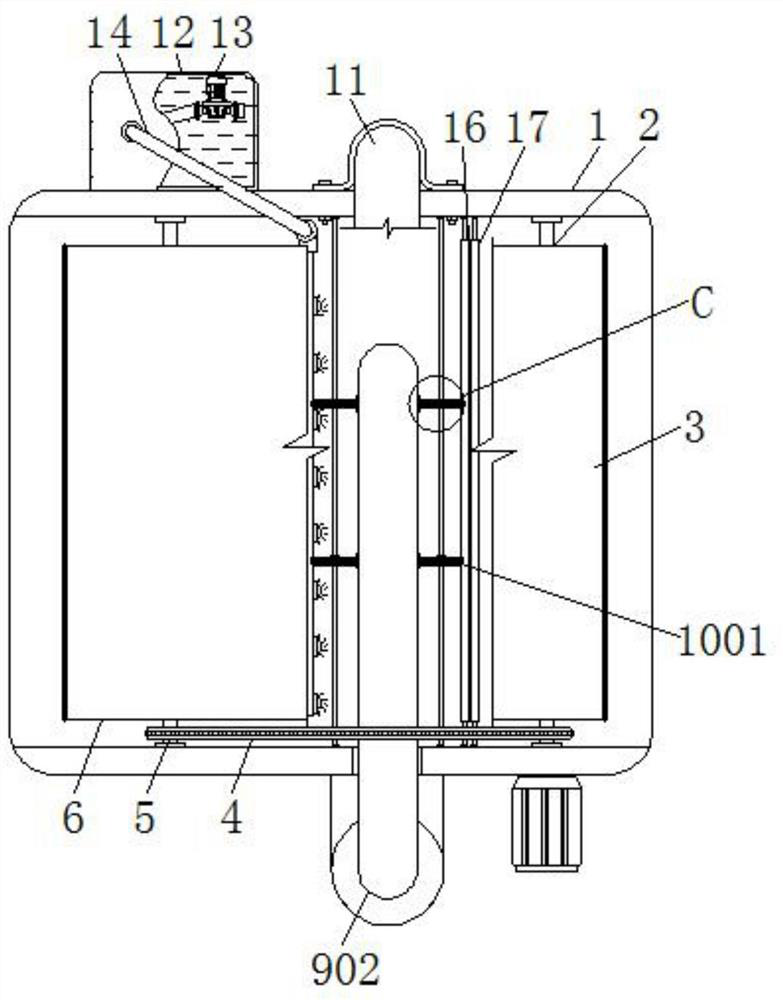

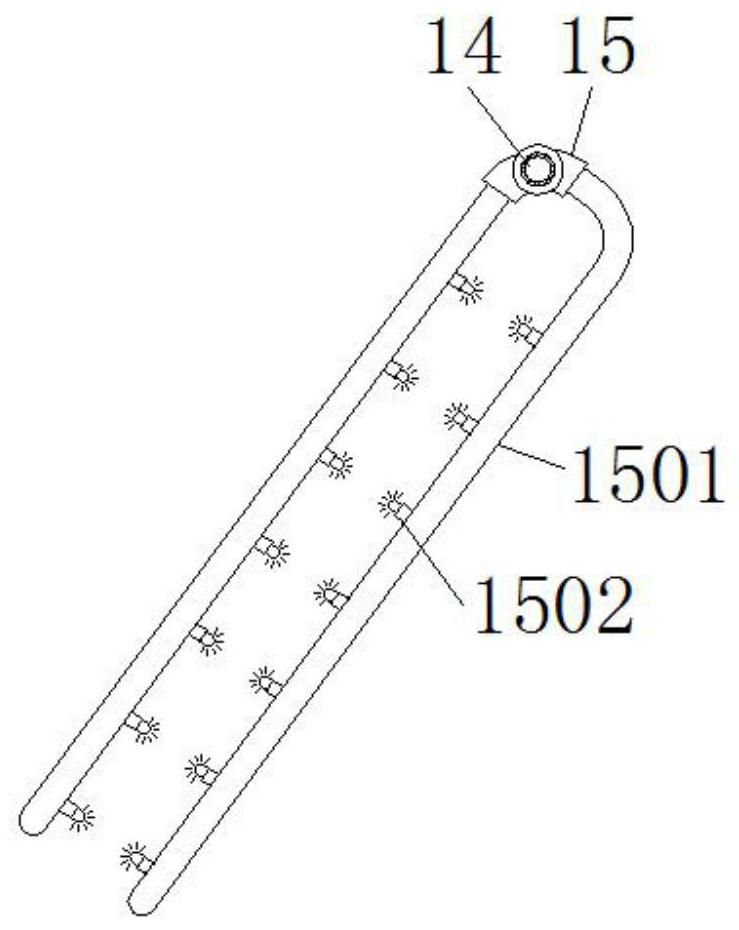

[0030]SeeFigure 1-7 The present invention provides a technical solution: an inter-wrap device for avoiding curling film in the edge of the shear, including the base 1, the main shaft 2, the first winding reel 3, the sprocket 4, the driven shaft 5 The second reel 6, the connection drum 7, the support post 8, the first telescopser 9, the reset spring 901, the pedaling plate 902, the connecting shaft 10, the transmission gear 1001, the connecting rod 1002, sponge 1003, the cylinder 11, the second The telescopic rod 1101, the cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com