Preparation method of hydrothermal synthesis carbon coated lithium iron phosphate

A technology of carbon-coated lithium iron phosphate and hydrothermal synthesis, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of low conductivity and lithium ion diffusion coefficient of lithium iron phosphate, and achieve excellent electrochemical performance and low cost , No environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

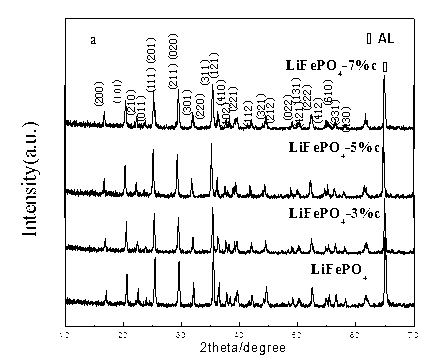

Image

Examples

Embodiment 1

[0030] A hydrothermally synthesized carbon-coated lithium iron phosphate (LiFePO 4 / C composite) synthetic method, comprising the following steps:

[0031] (1) LiFePO 4 Synthesis of precursors: FeSO was weighed at a molar ratio of 1:1:3 4 .7H 2 O, H 3 PO 4 and LiOH.H 2 O, FeSO 4 .7H 2 O, H 3 PO 4 Dissolve in 50 ml of double distilled water, then add 0.2 g of ascorbic acid to prevent Fe 2+ Oxidized to Fe 3+ , and finally added the dissolved LiOH.H 2 O, quickly transfer the solution to a 500 ml stainless steel reaction kettle, place it in a collector type magnetic heating stirrer, set the temperature to 120°C and stir for 2h. After the reactor was cooled to room temperature, the reaction product was centrifuged, washed with double distilled water and dispersed in alcohol, and then dried in a vacuum oven for 2 hours to obtain a light green powder.

[0032] (2) LiFePO 4 Synthesis of / C precursor: the precursor powder obtained in step (1) and ascorbic acid were mixed ...

Embodiment 2

[0035] A hydrothermally synthesized carbon-coated lithium iron phosphate (LiFePO 4 / C composite) synthetic method, comprising the following steps:

[0036] (1) LiFePO 4 Synthesis of precursors: FeSO was weighed at a molar ratio of 1:1:3 4 .7H 2 O, H 3 PO 4 and LiOH.H 2 O, FeSO 4 .7H 2 O, H 3 PO 4 Dissolve in 50 ml of double distilled water, then add 0.2 g of ascorbic acid to prevent Fe 2+ Oxidized to Fe 3+ , and finally added the dissolved LiOH.H 2 O, quickly transfer the solution to a 500 ml stainless steel reaction kettle, place it in a collector type magnetic heating stirrer, set the temperature to 120°C and stir for 2h. After the reactor was cooled to room temperature, the reaction product was centrifuged, washed with double distilled water and dispersed in alcohol, and then dried in a vacuum oven for 2 hours to obtain a light green powder.

[0037] (2) LiFePO 4 Synthesis of / C precursor: the precursor powder obtained in step (1) and ascorbic acid were mixed ...

Embodiment 3

[0040] A hydrothermally synthesized carbon-coated lithium iron phosphate (LiFePO 4 / C composite) synthetic method, comprising the following steps:

[0041] (1) LiFePO 4 Synthesis of precursors: FeSO was weighed at a molar ratio of 1:1:3 4 .7H 2 O, H 3 PO 4 and LiOH.H 2 O, FeSO 4 .7H 2 O, H 3 PO 4 Dissolve in 50 ml of double distilled water, then add 0.2 g of ascorbic acid to prevent Fe 2+ Oxidized to Fe 3+ , and finally added the dissolved LiOH.H 2 O, quickly transfer the solution to a 500 ml stainless steel reaction kettle, place it in a collector type magnetic heating stirrer, set the temperature to 120°C and stir for 2h. After the reactor was cooled to room temperature, the reaction product was centrifuged, washed with double distilled water and dispersed in alcohol, and then dried in a vacuum oven for 2 hours to obtain a light green powder.

[0042] (2) LiFePO 4 Synthesis of / C precursor: the precursor powder obtained in step (1) and ascorbic acid were mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com