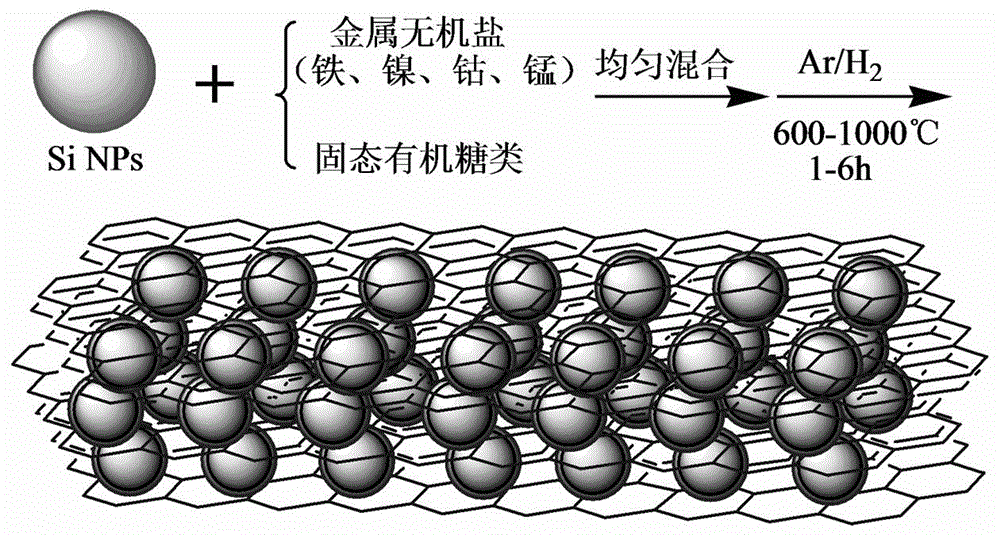

In-situ solid-phase synthesis method of silicon-graphene spheroidal composite material with multilevel structure and application thereof

A composite material, solid-phase synthesis technology, applied in structural parts, sustainable manufacturing/processing, electrical components, etc., can solve the problems of poor electronic conductivity of silicon anode and volume effect, and achieve ultra-light and thin, high reversible capacity, electrical Excellent chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) First weigh 10 g of silicon nanoparticles (with a particle size of 100 nm), then weigh 0.1 g of glucose and 0.1 g of ferric nitrate, and grind the mixture of the three until uniformly dispersed;

[0039] (2) Disperse the above mixture evenly in a crucible or a porcelain boat, and place it in the center of a closed tube furnace. The reaction is carried out in a mixed gas of argon and hydrogen, and the temperature is controlled to rise to 600 °C, and the temperature is kept constant for 1 hour;

[0040] (3) Cool to room temperature in a mixed gas of argon and hydrogen, wash the product three times with nitric acid, centrifuge to obtain the final product, and dry it in vacuum at 60 °C;

[0041] (4) Weigh 10 g of silicon-graphene spherical composite material, add it to the water solvent containing 0.1 g of binder polyacrylic acid, mix and stir, and mill twice with zirconium beads to make a uniform slurry, with a thickness of 9 microns The copper foil is used as a curren...

Embodiment 2

[0045] (1) First weigh 20 g of silicon nanoparticles (with a particle size of 500 nm), then weigh 1 g of sucrose and 0.2 g of nickel nitrate, and grind the mixture of the three until uniformly dispersed;

[0046] (2) Disperse the above mixture evenly in a crucible or a porcelain boat, and place it in the center of a closed tube furnace. The reaction is carried out in a mixed gas of argon and hydrogen, and the temperature is controlled to rise to 800 °C and kept at a constant temperature for 4 hours;

[0047] (3) Cool to room temperature in a mixed gas of argon and hydrogen, wash the product three times with nitric acid, centrifuge to obtain the final product, and dry it in vacuum at 60 °C;

[0048] (4) Weigh 10 g of silicon-graphene spherical composite material, add it into the water solvent containing 0.5 g of binder sodium carboxymethyl cellulose, mix and stir, and mill twice with zirconium beads to make a uniform slurry. Copper foil with a thickness of 9 microns is used as ...

Embodiment 3

[0052] (1) First weigh 50 g of silicon nanoparticles (with a particle size of 800 nm), then weigh 0.5 g of polymethyl methacrylate and 0.25 g of cobalt acetate, and grind the mixture of the three until uniformly dispersed;

[0053] (2) Disperse the above mixture evenly in a crucible or a porcelain boat, and place it in the center of a closed tube furnace. The reaction is carried out in a mixed gas of argon and hydrogen, and the temperature is controlled to rise to 1000 ℃, and the temperature is kept constant for 6 hours;

[0054] (3) Cool to room temperature in a mixed gas of argon and hydrogen, wash the product three times with nitric acid, centrifuge to obtain the final product, and dry it in vacuum at 60 °C;

[0055] (4) Weigh 30 g of the silicon-graphene spherical composite material, add it into the water solvent containing 3 g of the binder styrene-butadiene rubber, mix and stir, and mill twice with zirconium beads to make a uniform slurry. Thick copper foil is used as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com