Three-dimensional mesh wall-shaped all-solid-state lithium ion battery negative electrode, preparation method and battery

A lithium-ion battery, three-dimensional mesh technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as lack of promotion value, achieve good cycle performance, high capacity, and solve the effect of volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Antimony sulfide powder with a purity of 99% is used as the evaporation source, the conductive current collector of stainless steel foil is used as the deposition substrate, and the evaporation chamber is evacuated to 1×10 -4 Pa, turn on the evaporation power supply, adjust the current from 0 to 1.5A at a speed of 0.1A / s, and turn off the evaporation power supply after evaporating for 10 minutes. Among them, the antimony sulfide powder is heated evenly by slowly adjusting the current, thereby obtaining uniform Sb on the conductive current collector. 2 S 3 film.

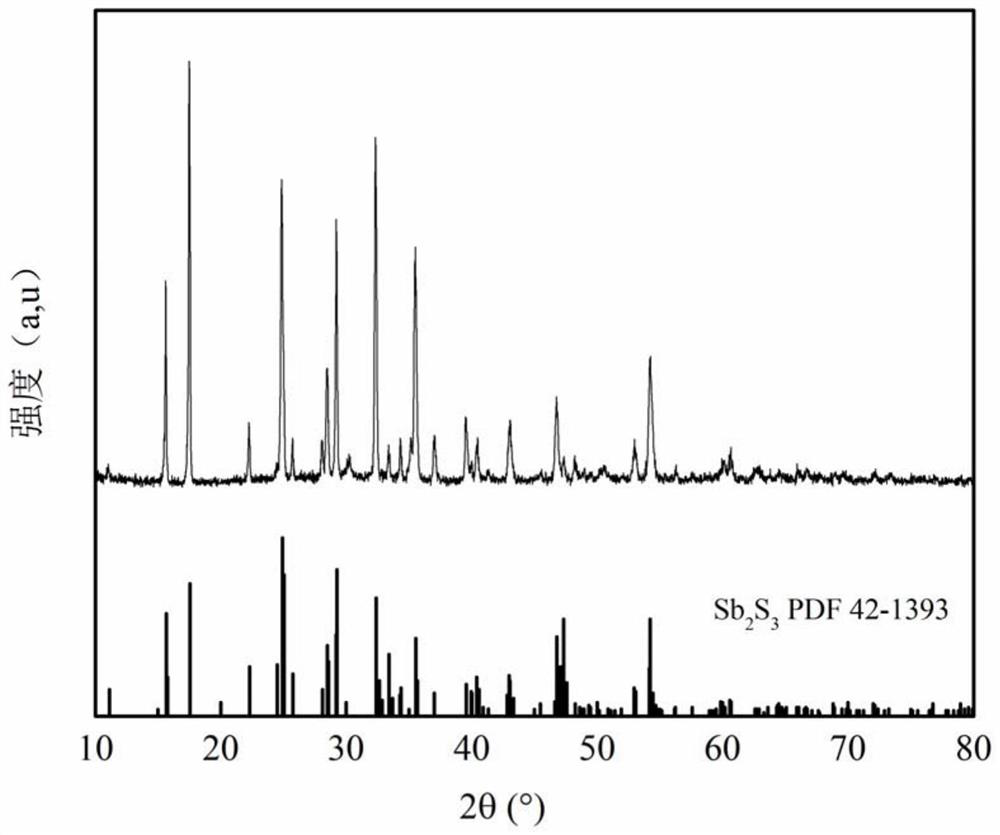

[0024] Please refer to figure 1 , it can be confirmed by X-ray diffraction that the material prepared by the above method is pure Sb 2 S 3 crystals.

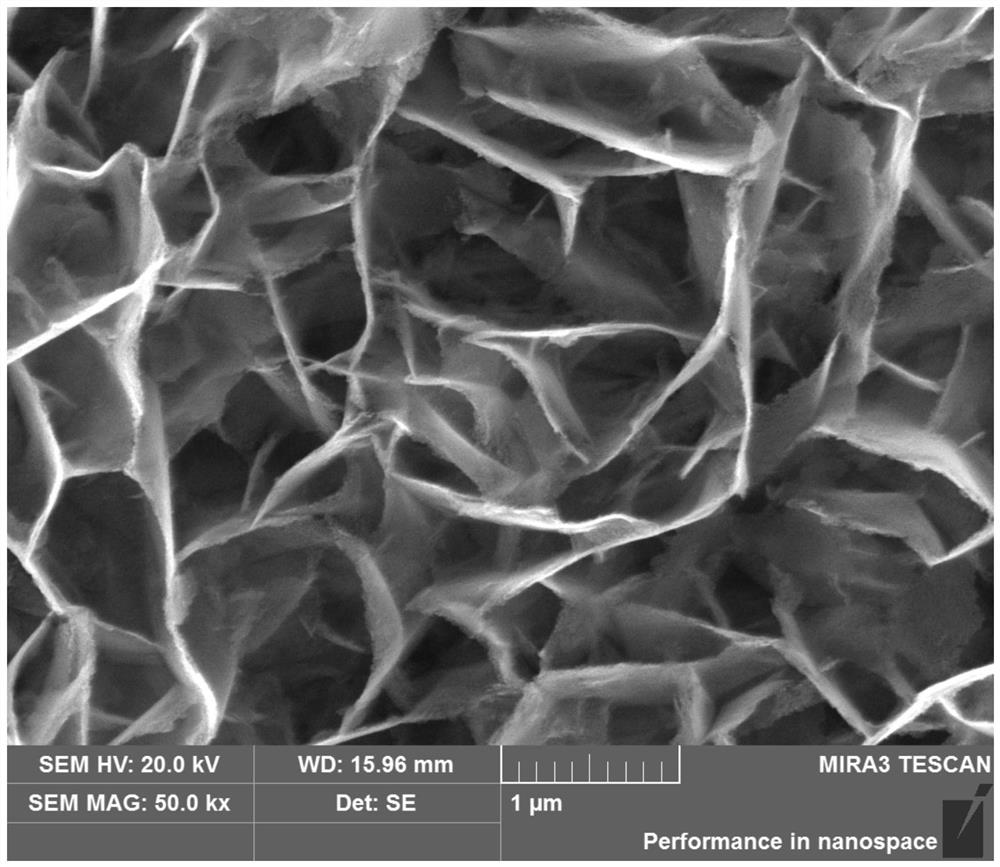

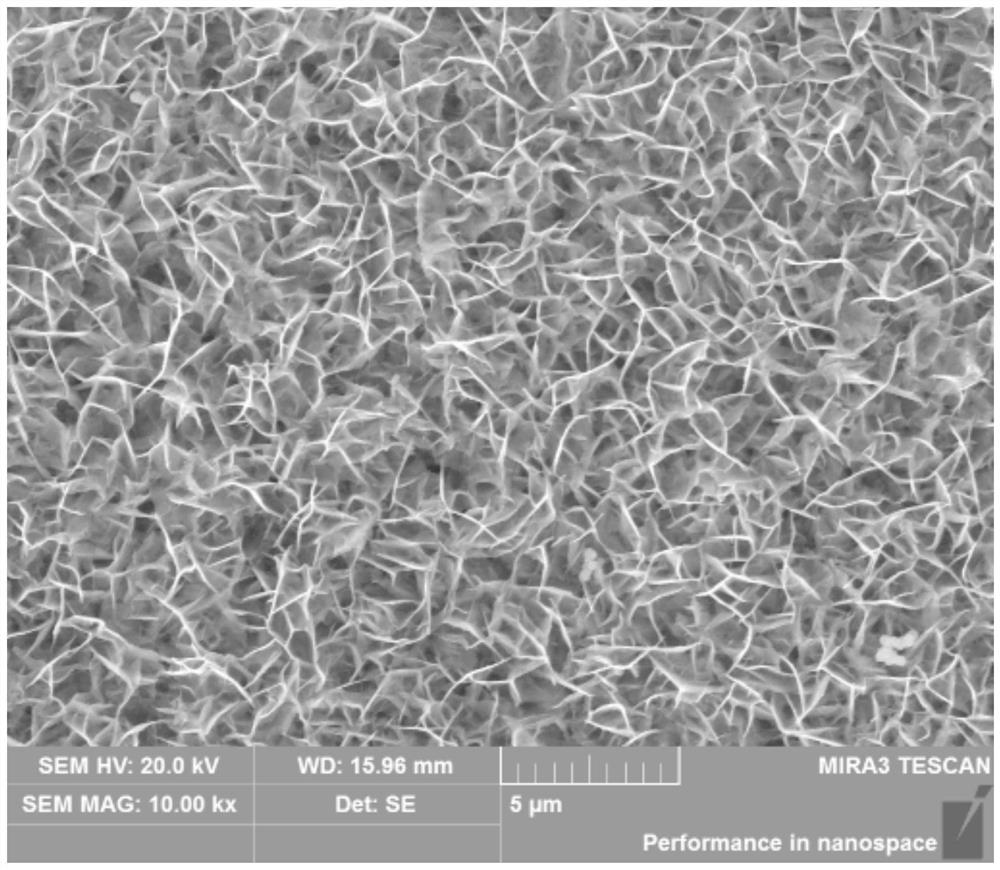

[0025] Morphology was determined by scanning electron microscopy, see figure 2 and image 3 , it can be found that the film is composed of vertical wall-like Sb 2 S 3 The nanosheets are connected to form a network, and the overall shape is like a honeyc...

Embodiment 2

[0028] Using stibnite as the evaporation source, the conductive current collector of titanium foil as the deposition substrate, and the evaporation chamber was evacuated to 0.8×10 - 3 Pa, turn on the evaporation power supply, adjust the current from 0 to 30A at a speed of 0.2A / s, and turn off the evaporation power supply after evaporating for 20 minutes.

[0029] Determining the morphology by scanning electron microscopy, it can be found that the film is composed of vertical wall-like Sb 2 S 3 The nanosheets are connected to form a network, and the overall shape is like a honeycomb, and each piece of Sb 2 S 3 The thickness of the nano wall is 30nm-70nm, and the length is 0.8um-2um.

[0030] The electrochemical performance test of the thin film negative electrode of the present invention adopts lithium sheet as counter electrode and reference electrode, and electrolytic solution is 1M LiPF 6 +EC / DEC / DMC (1:1:1, v / v / v), using Celgard 2032 separator, assembled into CR2032 bu...

Embodiment 3

[0032] with Sb 2 S 3 The recovered product is the evaporation source, the conductive collector of nickel foam is the deposition substrate, and the evaporation chamber is evacuated to 0.8×10 -3 Pa, turn on the evaporation power supply, adjust the current from 0 to 10A at a speed of 0.08A / s, and turn off the evaporation power supply after evaporating for 50s. It should be noted that Sb 2 S 3 Impurities in the recovered product were not evaporated onto the deposition substrate at a current of 10A.

[0033] Determining the morphology by scanning electron microscopy, it can be found that the film is composed of vertical wall-like Sb 2 S 3 The nanosheets are connected to form a network, and the overall shape is like a honeycomb, and each piece of Sb 2 S 3 The thickness of the nano wall is 15nm-30nm, and the length is 1um-2um.

[0034] The electrochemical performance test of the thin film negative electrode of the present invention adopts lithium sheet as counter electrode an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com