Preparation method of nanometer hollow spherical shell-shaped high-rate-performance LaFeO3 lithium ion battery negative electrode material

A lithium-ion battery and anode material technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve problems such as inability to use on a large scale, and achieve the effects of easy control, easy availability of raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

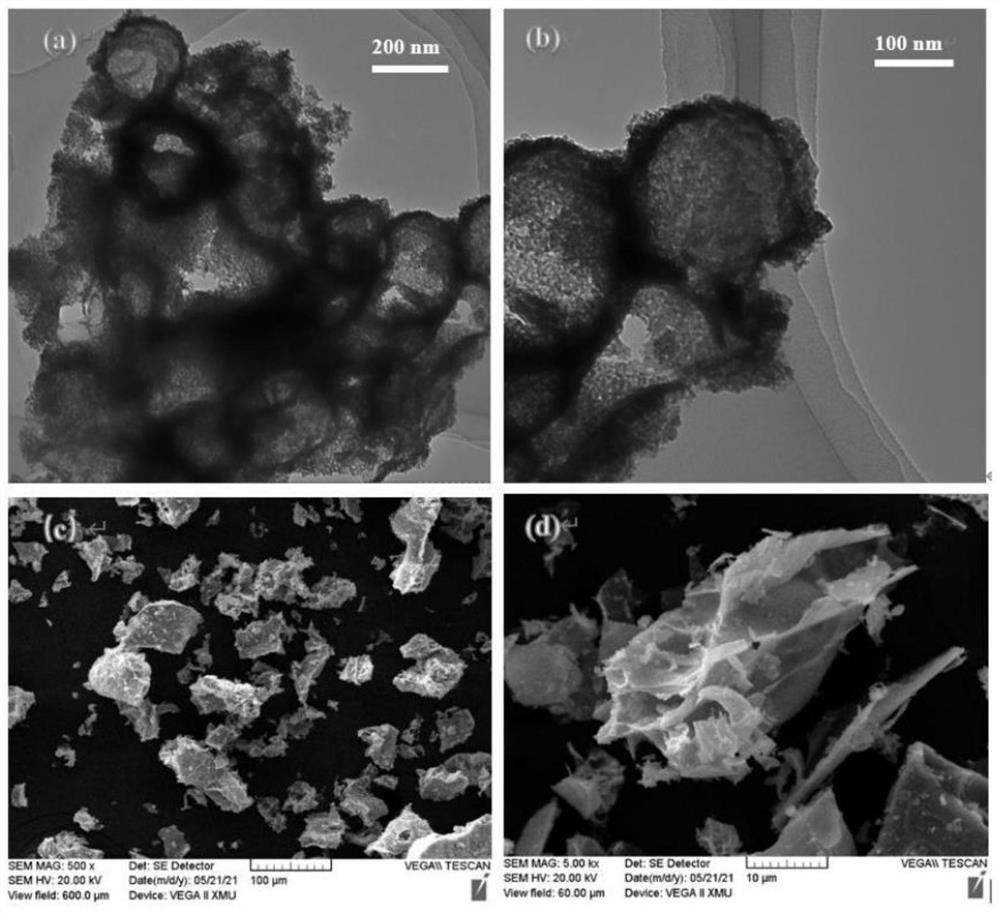

[0048] Embodiment 1 A kind of LaFeO of nano-hollow spherical shell with high rate performance 3 Preparation method of lithium ion battery negative electrode material

[0049] The invention is a nano hollow spherical shell LaFeO with high rate performance 3 The preparation method of the lithium ion battery negative electrode material is prepared according to the following sequence of steps:

[0050] (11) La(NO 3 ) 3 ·6H 2 O and Fe(NO 3 ) 3 Dissolve in distilled water, add carbon spheres and stir to fully dissolve to obtain a yellowish-brown turbid liquid, denoted as A1, La(NO 3 ) 3 ·6H 2 The molar mass ratio of O to carbon spheres is 1:0.003;

[0051] Carbon spheres are carried out in sequence according to the following steps:

[0052] (I) Glucose was dissolved in distilled water to form a glucose solution with a mass concentration of 0.1 g / mL, stirred by magnetic force for 0.5 h, and recorded as solution a;

[0053] (II) Pour solution a into a polytetrafluoroethylen...

Embodiment 2-4

[0061] Example 2-4 LaFeO with nanometer hollow spherical shell and high rate performance 3 Preparation method of lithium ion battery negative electrode material

[0062] Embodiments 2-4 are respectively a kind of LaFeO with nano hollow spherical shell and high rate performance 3 The preparation method of the lithium ion battery negative electrode material, the preparation process is similar to that of Example 1, the only difference is that the corresponding technical parameters in the preparation process are different, see the table below for details.

[0063]

[0064]

Embodiment 5

[0065] Embodiment 5 performance test

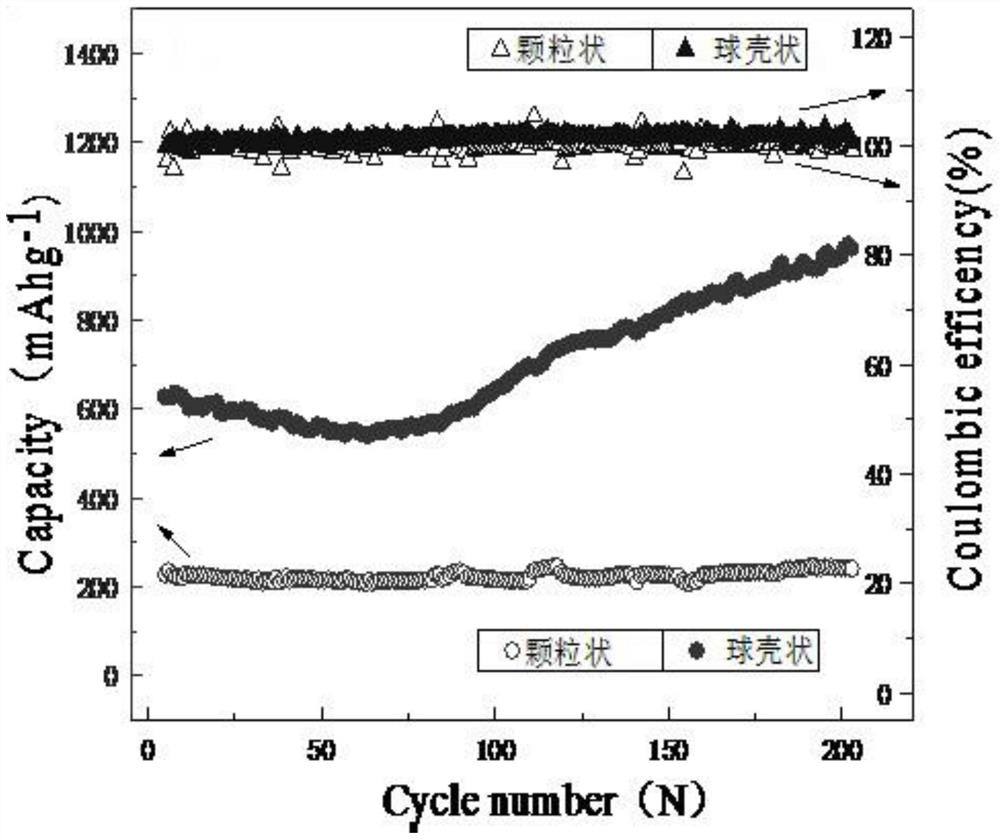

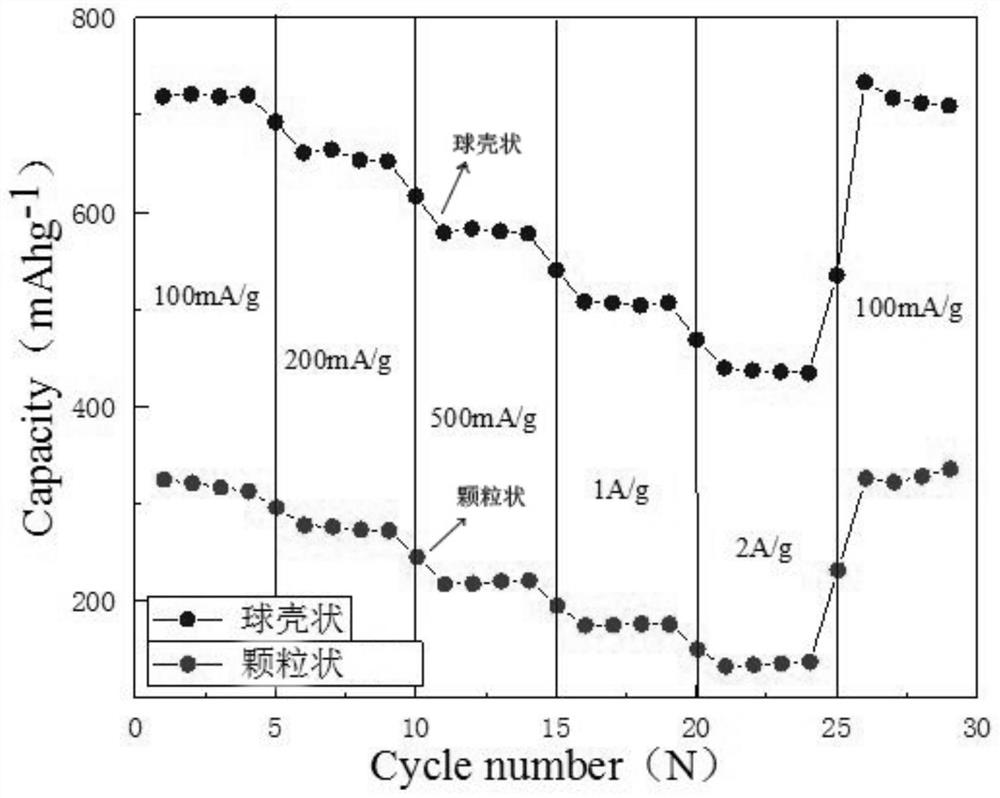

[0066] The LaFeO prepared by embodiment 1 3 Negative electrode material and the granular LaFeO prepared by existing preparation method (embodiment 6) 3 Apply the existing technology to prepare the negative electrode of lithium-ion battery, and assemble the battery for electrochemical performance test. For the specific test results, see figure 2 with image 3 .

[0067] figure 2 is granular LaFeO 3 and nanoshell-like LaFeO 3 Respectively as the life cycle diagram of the lithium-ion battery negative electrode at a current density of 500mA / g, it can be seen from the figure that the spherical shell-shaped LaFeO 3 Under the current density of 500mA / g, the average discharge specific capacity of the material is about 750mAh / g, and the spherical shell LaFeO 3 The discharge specific capacity of the battery is initially 640mAh / g, then decays and then increases, and finally stabilizes at around 850mAh / g. This is because some materials faile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com