Connected metal link heat treatment process method

A process method and metal chain technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of destroying the performance of adjacent links and failing to meet the requirements of link processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

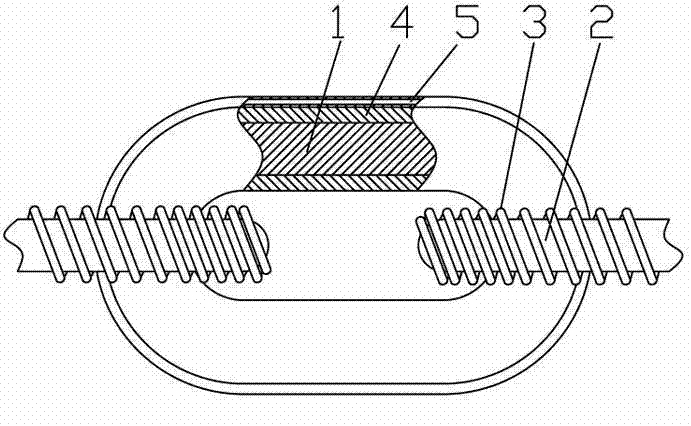

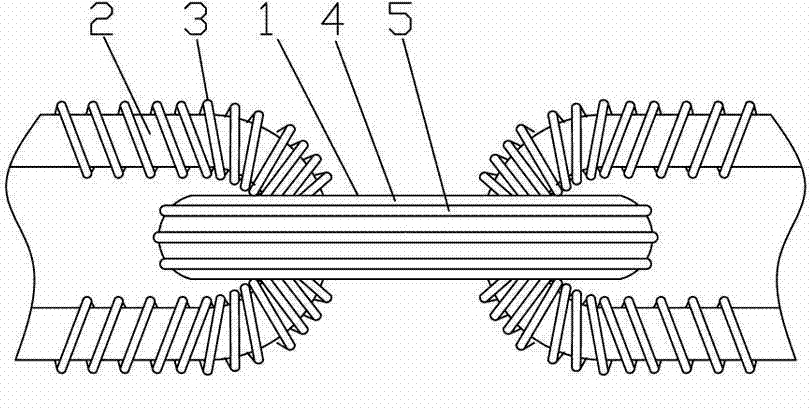

[0021] refer to figure 1 , figure 2 , a kind of heat treatment method provided by the present invention has good heat treatment effect and has no influence on nearby links.

[0022] A. Wrap the cooling pipe 3 on other links 2 adjacent to the connecting link 1. According to the temperature, the winding density of the cooling pipe 3 is also different. The winding density of the cooling pipe 3 increases with the distance from the connecting link. 1 gradually decreases. In order to ensure the speed of heat dissipation, the cooling pipe 3 is hollow, and a cooling liquid flows inside the cooling pipe 3, through which the heat on other chain links 2 can be quickly dissipated, so that it is not affected. As a preferred embodiment, in order to speed up the heat dissipation, multiple groups of cooling pipes 3 may be provided, and each group of cooling pipes 3 is individually connected to a coolant pump to ensure rapid heat dissipation.

[0023] B. Wrap a heat-insulating and insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com