Main shaft performance testing platform

A test platform and spindle technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as inability to evaluate the performance of the spindle, single, and no assessment of the rationality of the spindle assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

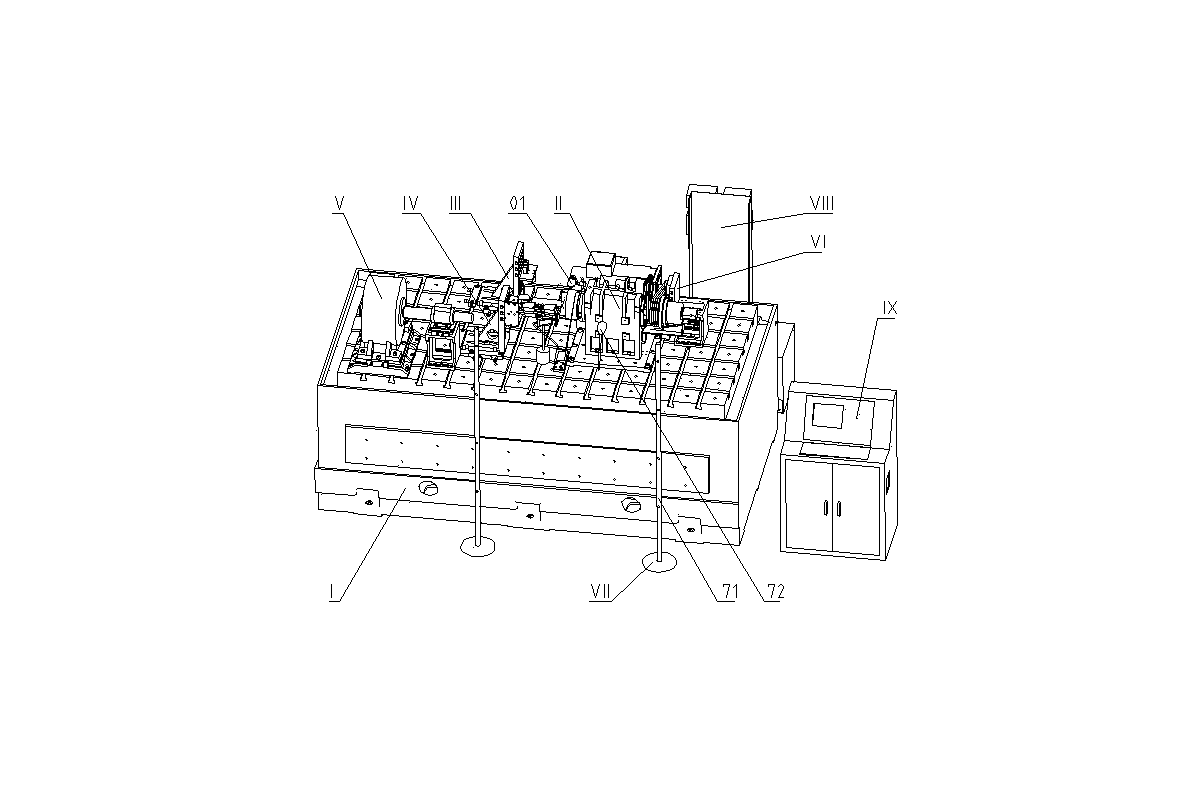

[0029] A performance test platform for ETC series spindles, its overall structure and layout can be found in figure 1 . In view of the fact that the content of the domestic CNC lathe spindle performance testing is relatively single, and many performance indicators that can affect the use of the spindle have not been tested, the present invention integrates the platform base I, the tested spindle box II, and the spindle rigidity measurement module. Ⅲ. Spindle temperature rise thermal deformation measurement module Ⅳ, output torque measurement module Ⅴ, belt tension measurement module Ⅵ, noise measurement module Ⅶ, hydraulic station Ⅷ, and components of the control system Ⅸ. Among them, the platform base I is used as the carrier of the mechanical structure, and a T-shaped slot for fixing is designed on it, the spindle rigidity measurement module III, the spindle temperature rise thermal deformation measurement module IV, the output torque measurement module V, and the belt tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com