Preparing method for gray ultraviolet resistant non-woven

An anti-ultraviolet, non-woven fabric technology, applied in non-woven fabrics, textiles and papermaking, feeding solution to spinnerets, etc., can solve the problems of poor anti-ultraviolet performance, poor anti-ultraviolet performance, etc., and achieve anti-ultraviolet effect. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

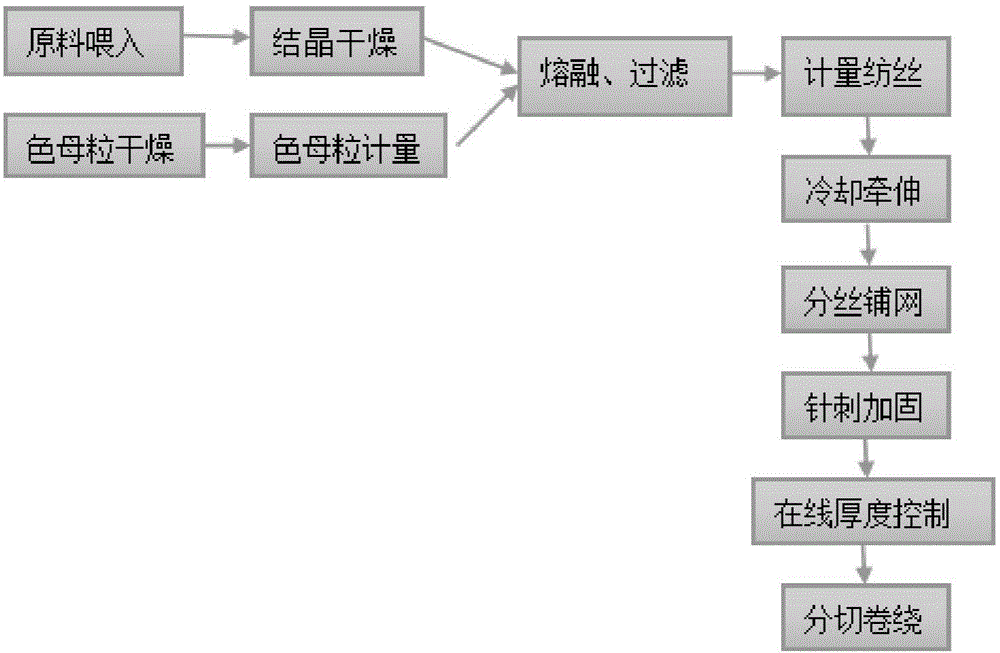

Method used

Image

Examples

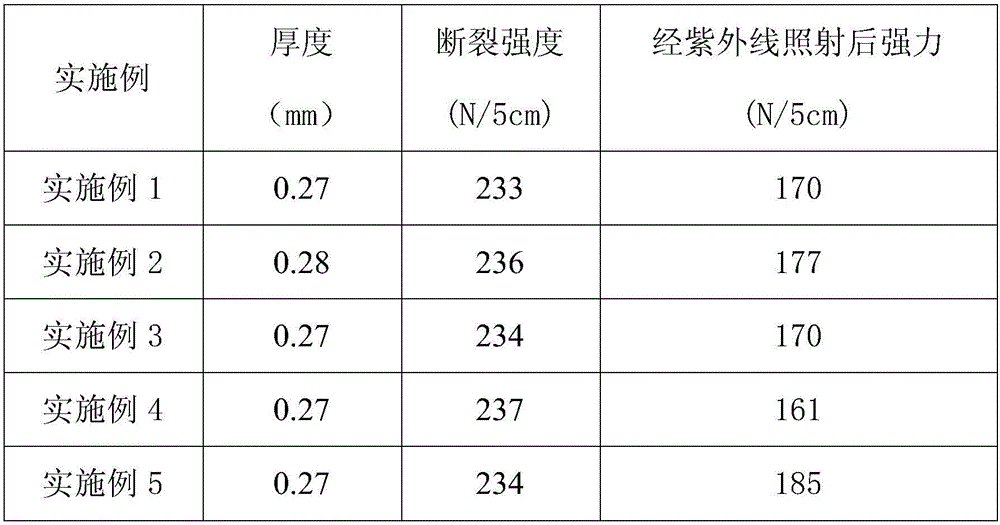

Embodiment 1

[0014] 1. Add polyester chips to the main silo, crystallize and dry at 170°C to remove the moisture in the chips, and then enter the screw for melting; then add black 0.5% of the amount of polyester chips added by the metering device to the small silo Masterbatch, mixed with 2% anti-aging masterbatch, dried at 90°C for 3-5 hours, added to a large screw, mixed and melted.

[0015] 2. After mixing, it is melted and extruded by a screw extruder. The temperature of the first zone of the screw extruder is 275°C, the temperature of the second zone is 280°C, the temperature of the third zone is 285°C, the temperature of the fourth zone is 290°C, and the temperature of the fifth zone is 288°C, the temperature in the sixth zone is 288°C; after the melt is filtered by a filter and metered by a metering pump, it enters the spinning box for spinning, and then is blown sideways. On the pendulum plate, divide the yarn on the pendulum plate and spread it evenly on the net curtain. The produc...

Embodiment 2

[0020] 1. Add polyester chips to the main silo, crystallize, dry at 170°C to remove the moisture in the chips, and then enter the screw for melting; then add black powder that accounts for 1% of the amount of polyester chips added by the metering device to the small silo. Masterbatch, mixed with 2% anti-aging masterbatch, dried at 90°C for 3-5 hours, added to a large screw, mixed and melted.

[0021] 2. After mixing, it is melted and extruded by a screw extruder. The temperature of the first zone of the screw extruder is 275°C, the temperature of the second zone is 280°C, the temperature of the third zone is 285°C, the temperature of the fourth zone is 290°C, and the temperature of the fifth zone is 288°C, the temperature in the sixth zone is 288°C; after the melt is filtered by a filter and metered by a metering pump, it enters the spinning box for spinning, and then is blown sideways. On the pendulum plate, divide the yarn on the pendulum plate and spread it evenly on the ne...

Embodiment 3

[0026] 1. Add polyester chips to the main silo, crystallize, dry at 170°C to remove the moisture in the chips, and then enter the screw to melt; then add black polyester chips that account for 1.5% of the amount of polyester chips added by the metering device to the small silo. Masterbatch, mixed with 2% anti-aging masterbatch, dried at 90°C for 3-5 hours, added to a large screw, mixed and melted.

[0027] 2. After mixing, it is melted and extruded by a screw extruder. The temperature of the first zone of the screw extruder is 275°C, the temperature of the second zone is 280°C, the temperature of the third zone is 285°C, the temperature of the fourth zone is 290°C, and the temperature of the fifth zone is 288°C, the temperature in the sixth zone is 288°C; after the melt is filtered by a filter and metered by a metering pump, it enters the spinning box for spinning, and then is blown sideways. On the pendulum plate, divide the yarn on the pendulum plate and spread it evenly on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com