Biomacromolecule/chitin nanocrystalline composite scaffold material and preparation method thereof

A technology of chitin nanocrystals and biopolymers, which is applied in the field of biomedical materials and tissue engineering, can solve the problems of mechanical properties that need to be improved, lack of biological activity, and cells that cannot adhere, so as to facilitate reconstruction and repair and promote adhesion. and mineralization, enhance the effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

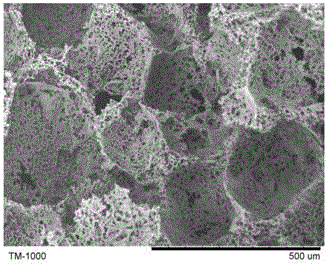

[0027] Step (1). Weigh 2g of PHBV powder with a weight-average molecular weight of 250,000 and a molar content of hydroxyvalerate (HV﹪) of 20%, dissolve it in 10ml of dioxane, and stir magnetically at 90°C for 2 hours to form a PHBV solution . Ultrasonic disperse 0.1g of chitin nanocrystals in 10ml of dioxane, and disperse evenly to obtain a chitin nanocrystal solution; then add the dispersed chitin nanocrystal solution to the PHBV solution, stir magnetically for 30 minutes, and then pour in a cylindrical mold.

[0028] Step (2). Weigh 6 g of sodium chloride particles sieved by a standard sieve with a particle size ranging from 200 to 350 μm, and add to the above mixed solution. Place the mold on a vortex mixer to mix evenly, and freeze in a -20°C refrigerator for 4 hours.

[0029] Step (3). Take the frozen and solidified PHBV / chitin nanocrystal mixture out of the mold, put it into 500ml of ice water, change the distilled water every 4 hours, and stir it magnetically for 2 d...

Embodiment 2

[0034] Step (1). Weigh 1 g of polylactic acid with a weight average molecular weight of 200,000, dissolve it in 10 ml of dioxane, and stir magnetically at 90°C for 2 hours to form a uniform polylactic acid solution. Ultrasonic disperse 0.1g of chitin nanocrystals in 5ml of dioxane, and disperse evenly to obtain a chitin nanocrystal solution; then add the dispersed chitin nanocrystals to the polylactic acid solution, stir magnetically for 30 minutes, and pour into in a cylindrical mold.

[0035] Step (2). Weigh 9 g of sodium potassium tartrate tetrahydrate granules with a particle size ranging from 200 to 400 μm and sieve through a standard sieve, and add them to the above mixed solution. Place the mold on a vortex mixer to mix evenly, and freeze in a -20°C refrigerator for 4 hours.

[0036] Step (3). Take the frozen and solidified polylactic acid / chitin nanocrystalline mixture out of the mold, put it into 500ml ice water, change the distilled water every 4 hours, and stir it ...

Embodiment 3

[0039] Step (1). Weigh 2 g of polycaprolactone with a weight average molecular weight of 100,000 and dissolve it in 20 ml of dichloromethane / dioxane mixed solution (the volume ratio of dichloromethane to dioxane is 2:8) , 40 ° C magnetic stirring for 2 hours to form a homogeneous polycaprolactone solution. Ultrasonic disperse 0.2g of chitin nanocrystals in 10ml of dichloromethane / dioxane mixed solution, and disperse evenly to obtain a chitin nanocrystal solution; then add the dispersed chitin nanocrystals to the polycaprolactone solution , stirred magnetically for 30 minutes and poured into cylindrical molds.

[0040] Step (2). Weigh 6 g of sodium chloride particles sieved with a standard sieve in the particle size range of 200-300 μm, and add to the above mixed solution. Place the mold on a vortex mixer to mix evenly, and put it in a -80°C refrigerator for 4 hours.

[0041] Step (3). Take out the frozen and solidified polycaprolactone / chitin nanocrystalline mixture from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com