Method for preparing buffer layer material of thin-film solar cell

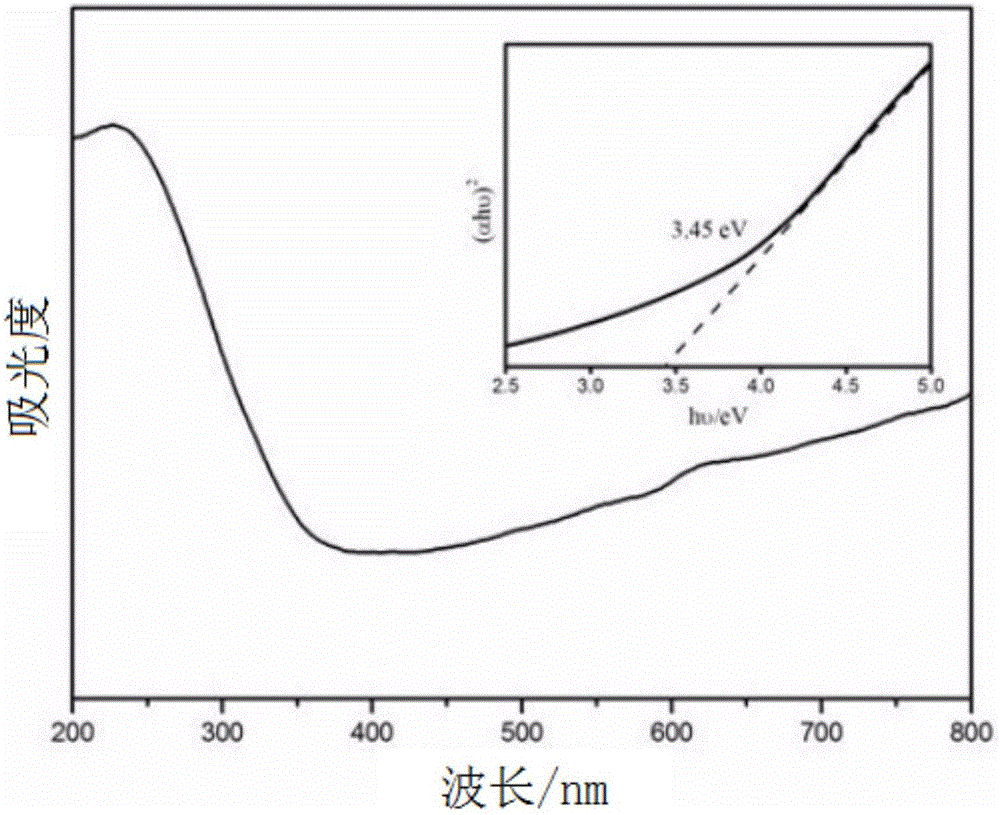

A technology for solar cells and buffer layers, applied in the field of solar cells, can solve the problems of hindering the conversion efficiency of thin-film solar cells, difficult to achieve industrialized large-scale production, difficult to implement large-scale production, etc., and achieves solutions to cadmium metal pollution and good pore connectivity. , the effect of good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of thin-film solar cell buffer layer material, the steps are as follows:

[0038] Step 1, put the organic zinc salt and thioorganic compound into the reaction kettle, and stir at 1000r / min for 2h;

[0039] Step 2, adding the initiator, catalyst and solvent into the reactor, passing through the ammonia gas to circulate the aeration reaction for 3h, wherein, the flow rate of the ammonia gas is 15mL / min, the temperature of the aeration reaction is 60°C, and the amount of the substance of the ammonia gas The amount is 3 times the amount of the organozinc salt substance;

[0040] Step 3, subjecting the reaction solution in the reactor to micro-boiling and stirring reaction for 0.5h, wherein the micro-boiling temperature is 105°C, and the micro-boiling stirring rate is 900r / min;

[0041] Step 4, followed by low-temperature sedimentation at 2°C for 18 hours;

[0042] Step 5, performing rapid ultrasonication on the sedimentation liquid in step 4 for 10 minu...

Embodiment 2

[0049] A preparation method of thin film solar cell buffer layer material, the method specifically comprises the following steps:

[0050] (1) Prepare materials according to the following components and parts by weight: 20 parts of organic zinc salt, 29 parts of thioorganic compound, 2 parts of initiator, 1.3 parts of catalyst, 35 parts of solvent, 13 parts of graphene, 1 part of auxiliary agent, 4 doses;

[0051] (2) After mixing the organozinc salt and the thioorganic compound, stir at 1200r / min for 3h;

[0052] (3) add initiator, catalyzer and solvent respectively, and pass into ammonia gas circulation aeration 8h at 60 ℃, obtain reaction liquid, wherein, the amount of the substance of ammonia is 3 times of the amount of organic zinc salt substance, ammonia The circulation flow rate of gas is 15mL / min;

[0053] (4) After heating the reaction solution to 107°C, stir it at 1100r / min for 0.9h, then settle it at 5°C for 21h, and obtain the settling liquid after ultrasonic tre...

Embodiment 3

[0058] A preparation method of thin film solar cell buffer layer material, the method specifically comprises the following steps:

[0059] (1) Prepare materials according to the following components and parts by weight: 25 parts of organic zinc salts, 23 parts of thioorganic compounds, 5 parts of initiators, 0.5 parts of catalysts, 50 parts of solvents, 9 parts of graphene, 3 parts of additives, dispersing 1 dose;

[0060] (2) After mixing the organozinc salt and the thioorganic compound, stir at 1500r / min for 2h;

[0061] (3) add initiator, catalyzer and solvent respectively, and pass into ammonia circulation aeration 3h at 75 DEG C, obtain reaction solution, wherein, the amount of the substance of ammonia is 7 times of the amount of organic zinc salt substance, ammonia The circulation flow of gas is 30mL / min;

[0062] (4) After heating the reaction solution to 110°C, stir it at 900r / min for 1.5h, then settle it at 2°C for 24h, and obtain the sedimentation liquid after ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com