Gradient porous titanium mesh and preparation method of super-hydrophobic gradient porous titanium mesh

A gradient porous and super-hydrophobic technology, applied in the field of surface processing, can solve the problems of reducing the bonding force between the substrate and the coating, complicated steps, etc., and achieve the effect of improving the oil-water separation rate, adjustable mechanical strength, and high filtration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

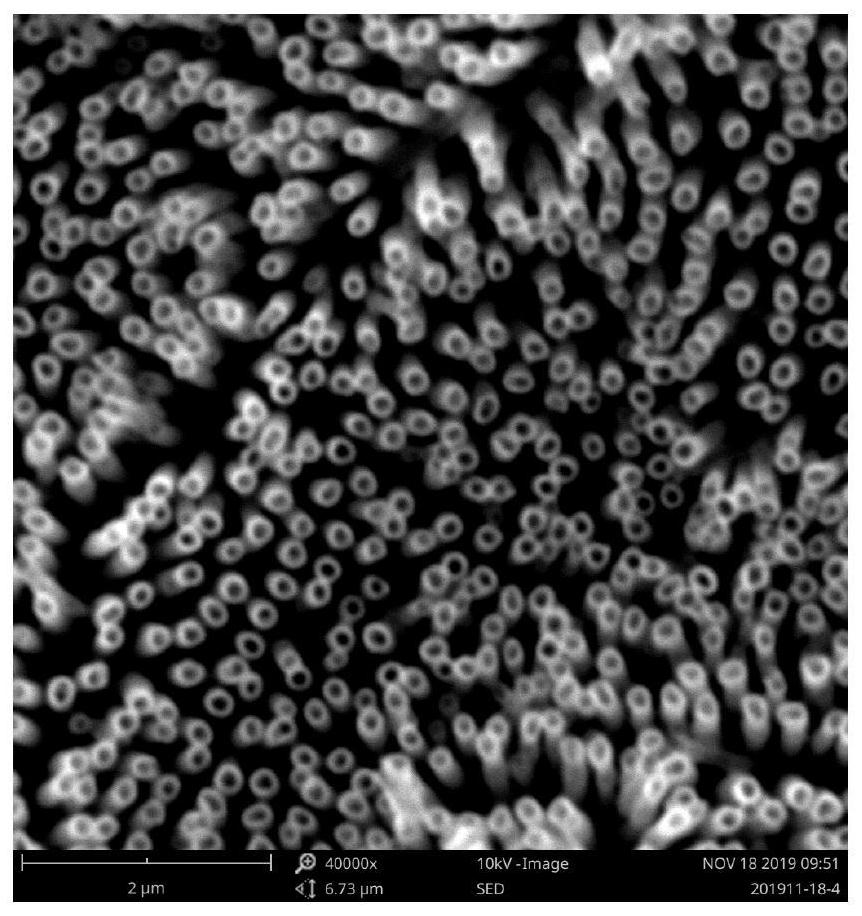

[0063] 1. Porous structure design and laser processing of gradient porous titanium

[0064] Such as Figure 4 As shown, the overall gradient porous titanium mesh is divided into two parts: the upper coarse porous layer and the lower fine porous layer.

[0065] The upper coarse-porous layer structure is a uniform three-dimensional spatially connected porous network structure with a pore diameter of 700 μm and a porosity of 76.8%. This part of the hole network structure consists of a circular arc edge with a thickness of 250 μm in the XZ plane, a chord length of 800 μm, and 130° and a support column with a height of 80 μm in the Z direction; and a circle with a thickness of 250 μm in the YZ plane, a chord length of 800 μm, and 130°. Composed of arc edges and Z-direction support columns with a height of 80 μm and a thickness of 250 μm.

[0066] The lower pore layer structure is a uniform three-dimensional spatially connected porous structure with a pore diameter of 200 μm and a...

Embodiment 2

[0079] 1. Porous structure design and laser processing of gradient porous titanium

[0080] Such as Figure 5 As shown, the overall gradient porous titanium mesh is divided into two parts: the upper coarse porous layer and the lower fine porous layer.

[0081] The upper coarse-porous layer structure is a uniform three-dimensional spatially connected porous network structure with a pore diameter of 750 μm and a porosity of 80.5%. This part of the hole network structure consists of a circular arc edge with a thickness of 275 μm in the XZ plane, a chord length of 900 μm, and 140° and a support column with a height of 90 μm in the Z direction; and a circle with a thickness of 275 μm in the YZ plane, a chord length of 900 μm, and 140°. It is composed of arc ribs and Z-direction support columns with a height of 90 μm and a thickness of 275 μm.

[0082] The lower pore layer structure is a uniform three-dimensional spatially connected porous structure with a pore diameter of 250 μm ...

Embodiment 3

[0096] 1. Porous structure design and laser processing of gradient porous titanium

[0097] The overall gradient porous titanium mesh is divided into two parts: the upper coarse porous layer and the lower fine porous layer.

[0098] The upper coarse-porous layer structure is a uniform three-dimensional spatially connected porous network structure with a pore diameter of 800 μm and a porosity of 88.7%. This part of the hole network structure consists of an arc edge with a thickness of 300 μm in the XZ plane, a chord length of 1000 μm, and 150°, and a support column with a height of 100 μm in the Z direction; and a circle with a thickness of 300 μm in the YZ plane, a chord length of 1000 μm, and 150°. It is composed of arc edges and Z-direction, 100 μm in height and 300 μm in thickness support columns.

[0099] The lower pore layer structure is a uniform three-dimensional spatially connected porous structure with a pore diameter of 300 μm and a porosity of 65%. This part of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com