Preparation method of gentamicin sulphate-loading porous hydroxyapatite/PLGA (poly(DL-lactide-co-glycolide) microspheres

A technology of gentamicin sulfate and hydroxyapatite, which is applied in the field of preparation of biomedical materials, can solve the problems of large drug release burst and poor drug loading performance, and achieve small burst release effect, long release time, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

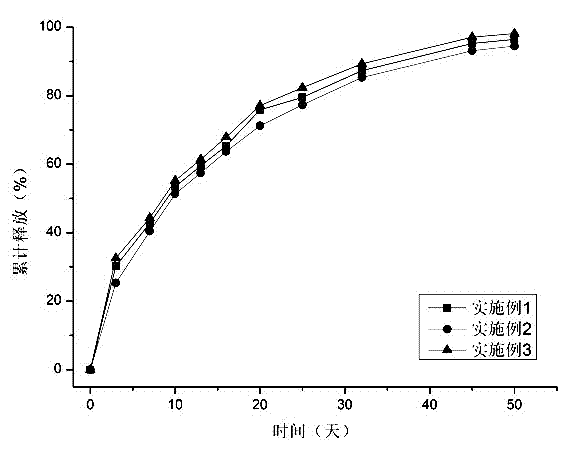

Examples

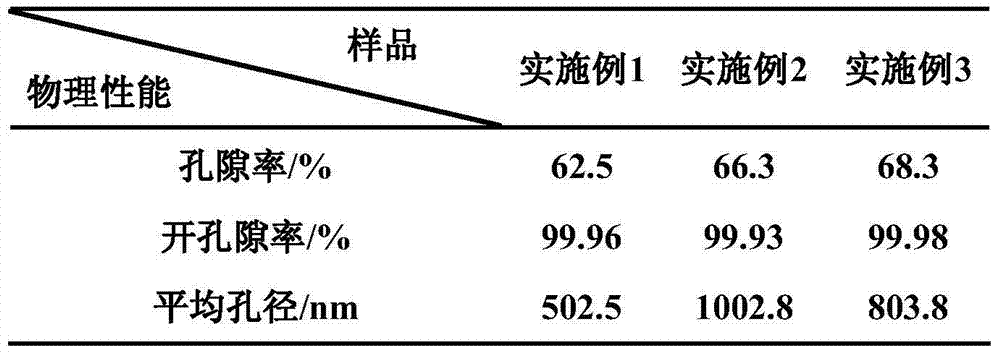

Embodiment 1

[0026] (1) Pour 1.5g of 100-200nm PLGA balls into a beaker, add 15ml of 5% acetone / ethanol blend, and place in the air for 72 hours to completely evaporate the solvent;

[0027] (2) Add 0.16mol L -1 Add 100ml of diammonium hydrogen phosphate solution into the beaker in (1), pour 0.36mol·L -1 100ml of calcium nitrate solution, adjust the pH value to 10 with ammonia water, and after aging the reactant for 5 days, wash the product 5 times with distilled water, dry it at 30°C, and then calcinate at 450°C for 4 hours to remove PLGA, and obtain porous hydroxyapatite ;

[0028](3) After grinding the porous hydroxyapatite, soak it in an aqueous solution containing 0.5 mg / ml gentamicin sulfate and 0.1% PEG, freeze-dry for 60 hours to obtain porous hydroxyapatite loaded with gentamicin sulfate, Store sealed at 4°C for later use.

[0029] (4) Mix 10ml of 10% PLGA acetone solution with 0.3g of gentamicin sulfate-loaded porous hydroxyapatite obtained in (3) to obtain a gentamicin sulfat...

Embodiment 2

[0032] (1) Pour 1.5g of 500-600nm PLGA balls into a beaker, add 30ml of 15% acetone / ethanol blend, and place in the air for 48 hours to completely evaporate the solvent;

[0033] (2) Add 0.11mol·L -1 Add 150ml of diammonium hydrogen phosphate solution into the beaker in (1), pour 0.24mol·L -1 150ml of calcium nitrate solution, adjust the pH value to 9 with ammonia water, and after aging the reactant for 6 days, wash the product 3 times with distilled water, dry it at 35°C, and then calcinate at 900°C for 2 hours to remove PLGA, and obtain porous hydroxyapatite ;

[0034] (3) After grinding the porous hydroxyapatite, soak it in an aqueous solution containing 0.8 mg / ml gentamicin sulfate and 0.5% PEG, freeze-dry for 60 hours to obtain porous hydroxyapatite loaded with gentamicin sulfate, Store sealed at 4°C for later use.

[0035] (4) Mix 10ml of 15% PLGA acetone solution with 0.4g of gentamicin sulfate-loaded porous hydroxyapatite obtained in (3) to obtain a gentamicin sulfa...

Embodiment 3

[0038] (1) Pour 3.75g of 300-400nm PLGA balls into a beaker, add 25ml of 10% acetone / ethanol blend, and place in the air for 60h to completely evaporate the solvent;

[0039] (2) Add 0.08mol·L -1 Add 200ml of diammonium hydrogen phosphate solution into the beaker in (1), pour 0.18mol·L -1 200ml of calcium nitrate solution, adjust the pH value to 8 with ammonia water, and after aging the reactant for 7 days, wash the product 4 times with distilled water, dry it at 40°C, and then calcinate at 600°C for 3 hours to remove PLGA, and obtain porous hydroxyapatite ;

[0040] (3) Grind the porous hydroxyapatite and soak it in an aqueous solution containing 1 mg / ml gentamicin sulfate and 1% PEG, and freeze-dry for 40 hours to obtain porous hydroxyapatite loaded with gentamicin sulfate. Store in a sealed container at 4°C for later use.

[0041] (4) Mix 10ml of 20% PLGA acetone solution with 0.5g of gentamicin sulfate-loaded porous hydroxyapatite obtained in (3) to obtain a gentamicin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com