Monodisperse platinum-based two-dimensional metal hydroxide, and in situ synthesis method and application thereof in purification of volatile oxygen-containing hydrocarbons

A hydroxide and in-situ synthesis technology, applied in the field of air pollution control, can solve the problems of easy agglomeration and deactivation of active centers, high price, and limitations, and achieve shortened synthesis time and energy consumption, low surface polarizability, Effect of low atomic coordination number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

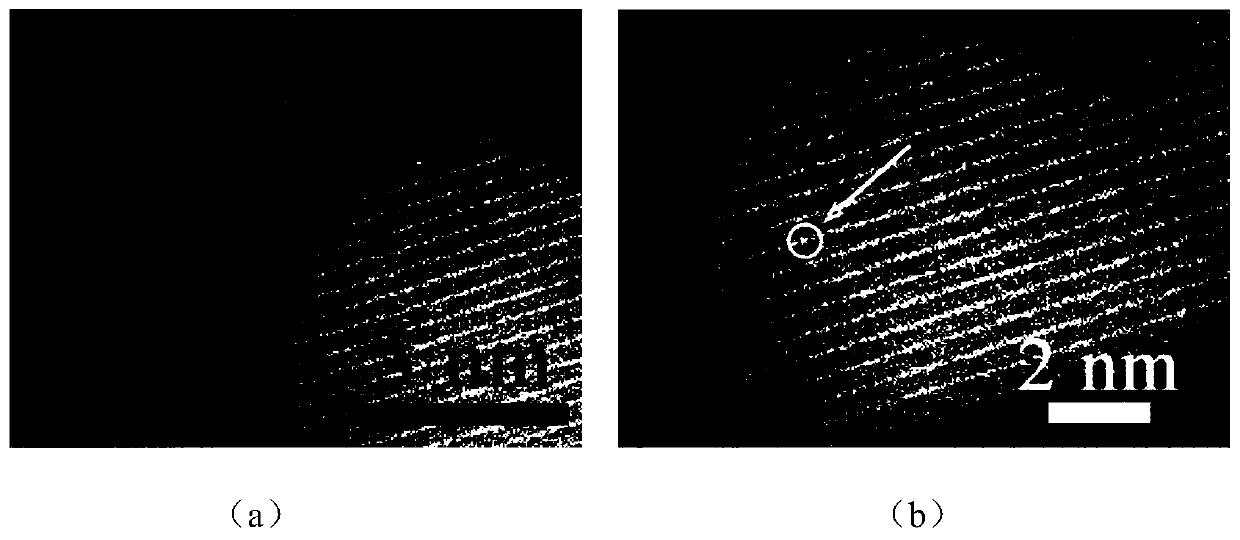

[0039] Example 1 In situ synthesis of monodisperse platinum-based two-dimensional metal hydroxide catalytic materials by microwave-assisted method

[0040] Dissolve 0.27g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) in 30-45mL of deionized water, and continue stirring at 500-800rpm for 15min to form a transparent and clear solution . Add 4.0-5.3 g of hexamethylenetetramine to the above solution, and fully dissolve it under stirring at 500-800 rpm. Subsequently, 5-35 mmoL of cerium chloride heptahydrate (CeCl 3 ·7H 2 O), stir vigorously to fully dissolve. Slowly add 180-220 mL of ethylene glycol solution to the solution obtained above, and continue stirring for 15 min. Immediately after that, 3 mL of chloroplatinic acid hexahydrate-ethylene glycol solution (1.5 mg Pt / mL), and continue stirring at 800-1000rpm for 30min. The solution was placed in a three-necked flask of a microwave generator, and the power was set to 900W. The mix...

Embodiment 2

[0043] With the cerium chloride heptahydrate (CeCl) in embodiment 1 3 ·7H 2 O) was replaced by cobalt chloride hexahydrate (CoCl 2 ·6H 2 O), to obtain monodisperse platinum-based two-dimensional metal hydroxides, namely monodisperse Pt 1 -Co(OH) x Two-dimensional catalytic materials. Others are the same as in Example 1.

[0044] Monodisperse Pt 1 -Ce(OH) x Catalytic Degradation Activity of Methanol by Two-Dimensional Catalytic Materials

[0045] The catalytic reaction is carried out in a fixed bed. The catalyst obtained in Example 1 is pressed into tablets and sieved (40-60 mesh), and 0.3 mL of the sieved catalytic material is accurately weighed, activated at 200° C. for 1.5 h, and methanol (methanol ) as a probe gas, the concentration of reactants is controlled at 800ppm, and the reaction space velocity is 36000h -1 , the volume concentration of oxygen is 20%, respectively test the catalyst at 40°C, 60°C, 80°C, 90°C, 100°C, 110°C, 120°C, 130°C, 140°C, 150°C, 160°C, 1...

Embodiment 3

[0061] Dissolve 0.27 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) in 30 mL of deionized water, and continue stirring at 800 rpm for 15 min to form a transparent and clear solution. 4.0 g of hexamethylenetetramine was added to the above solution, and fully dissolved under stirring at 800 rpm. Subsequently, 35 mmoL of cerium chloride heptahydrate (CeCl 3 ·7H 2O), stir vigorously to fully dissolve. Slowly add 180 mL of ethylene glycol solution to the solution obtained above, and continue stirring for 15 min. Immediately after that, 3 mL of chloroplatinic acid hexahydrate-ethylene glycol solution (1.5 mg Pt / mL), and continue stirring at 800-1000rpm for 30min. The solution was placed in a three-necked flask of a microwave generator, and the power was set to 900W. The mixed solution was heated to 150° C. and condensed and refluxed for 20 minutes under this condition.

[0062] After the liquid was cooled to room temperature, it was ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com