Porous composite metal oxide catalytic material, synthesis method and application thereof in purification of volatile organic pollutants

A composite metal and catalytic material technology, applied in the field of air pollution control, can solve the problems of poor stability, intermediate toxic by-products, etc., and achieve the effects of low preparation cost, enhanced porosity and specific surface area, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

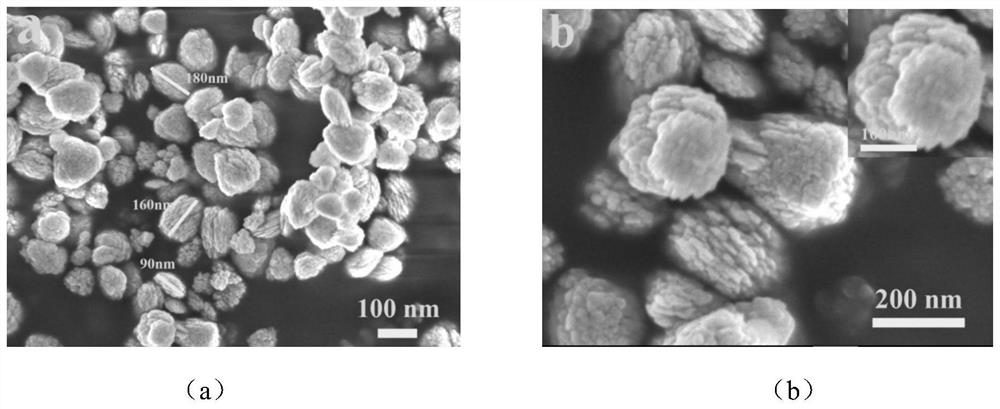

[0041] Example 1 Preparation of Porous Composite Metal Oxide Using Surfactant Induced Soft Template Method

[0042] (1) Dissolve 1.5 g of cetyltrimethylammonium bromide in 160 mL of deionized water, and continue stirring at 900 rpm for 20 min to form a transparent and clear solution.

[0043] (2) Add 0.65 g of Pluronic F127 to the above transparent and clear solution, and fully dissolve it under stirring at 650 rpm. The purpose of adding F127 is to provide a porous template.

[0044] (3) Add 0.30 mol of copper acetate to the solution obtained in step (2), stir at 650 rpm for 10 min to dissolve completely, then add 1.25 mol of cerium nitrate, stir at 500 rpm for 10 min to dissolve completely.

[0045] (4) Next, add 0.50 mol of praseodymium nitrate to the solution obtained in step (3), and stir at 1000 rpm for 30 min to mix the components evenly.

[0046] (5) Subsequently, 4.5 g of hexamethylenetetramine was added to the solution obtained in step (4), and stirred at 1100 rpm fo...

Embodiment 2

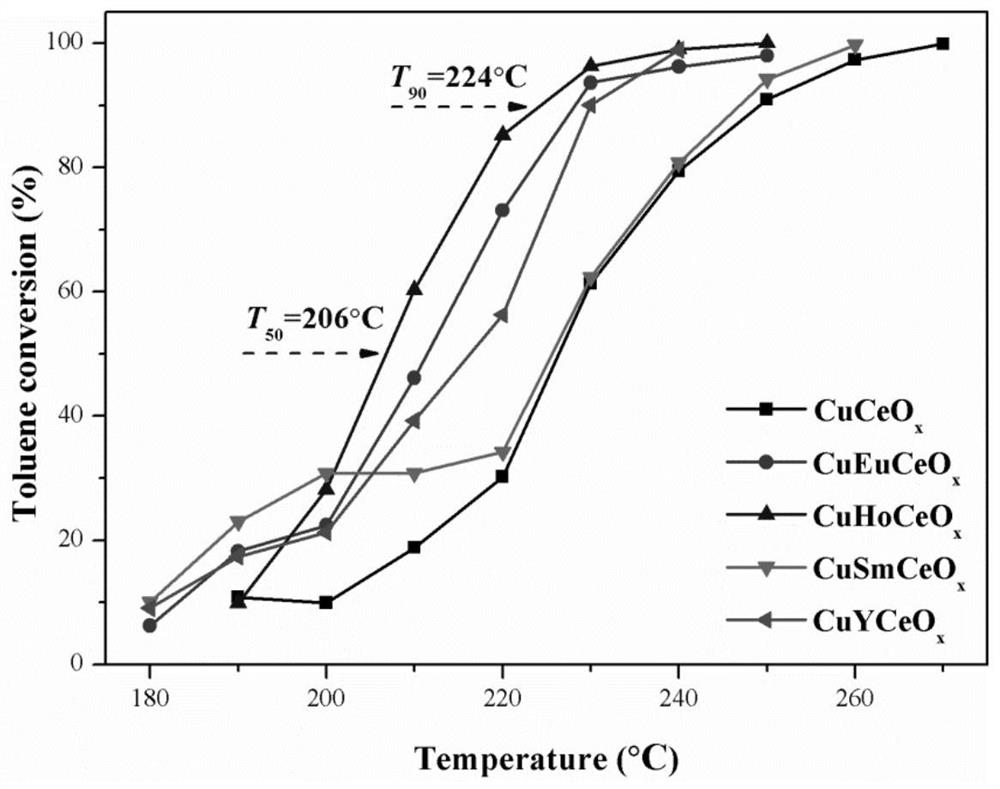

[0049] Example 2 Preparation of various porous composite metal oxides by surfactant-induced soft template method

[0050] By replacing the praseodymium nitrate in Example 1 with holmium nitrate, different porous copper-based-rare earth metal composite oxides (CuHoCeO x ).

Embodiment 3

[0052] By replacing the praseodymium nitrate in Example 1 with europium nitrate, different porous copper-based-rare earth metal composite oxides (CuEuCeO x ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com