Polycarboxylate superplasticizer catalyzing production technology without high temperature

A production process, polycarboxylic acid technology, applied in the field of building materials, can solve the problems of long production cycle, high risk, high purchase price, etc., and achieve the effects of improving production efficiency, reducing pollution, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

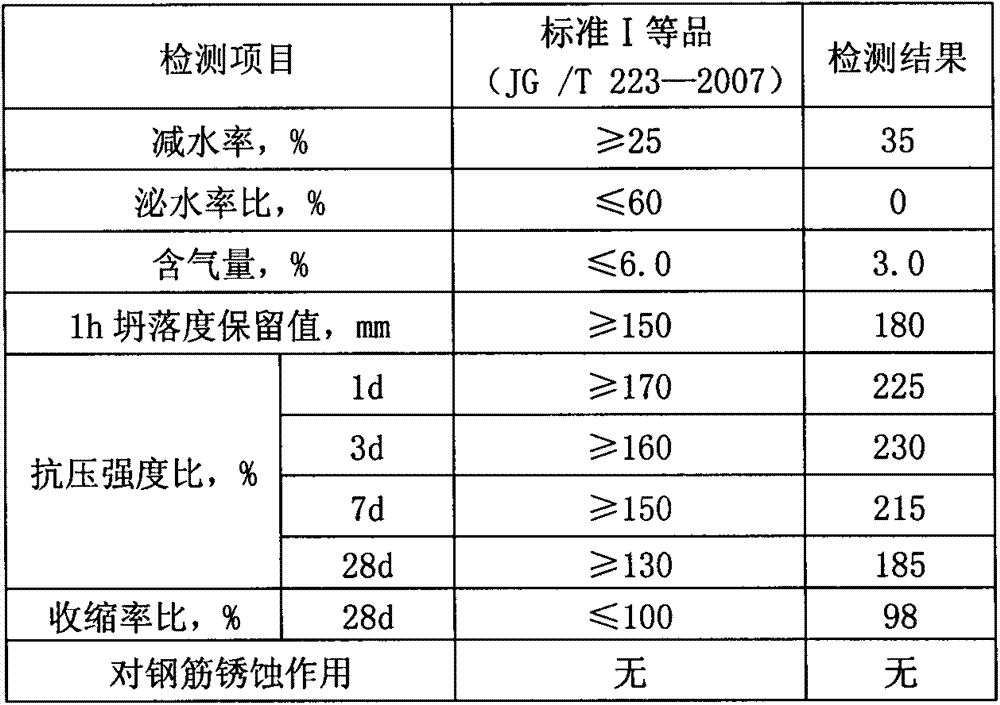

Image

Examples

Embodiment 1

[0013] The production process of the catalyst-free high-temperature polycarboxylate water reducer adopts the following steps:

[0014] (1) After adding 1t of tap water, 1t of methyl alkenyl polyoxyethylene ether, 80kg of sodium persulfate, and 7kg of azodiisopropylimidazoline hydrochloride in sequence in a 5000L stirring tank, turn on the agitator and stir evenly;

[0015] (2) add 35kg sodium bisulfite and 150kg tap water in 250kg metering bucket, fully stir until dissolving completely, obtain sodium bisulfite aqueous solution;

[0016] (3) Add 420kg water, 140kg acrylic acid and the aqueous sodium bisulfite solution obtained in the step (2) successively in the 1000L head tank, stir to obtain a mixed solution;

[0017] (4) Open the valve of the head tank, add the mixed solution prepared in step (3) dropwise into the stirring tank of step (1), stir while adding dropwise, after 1 hour, the catalyzed high-temperature free polycarboxylate is obtained when the material is discharge...

Embodiment 2

[0020] The production process of the catalyst-free high-temperature polycarboxylate water reducer adopts the following steps:

[0021] (1) After adding 1t of tap water, 1t of methyl alkenyl polyoxyethylene ether, 70kg of sodium persulfate, and 5kg of azodiisopropylimidazoline hydrochloride in sequence in a 5000L stirring tank, start the agitator and stir evenly;

[0022] (2) add 30kg sodium bisulfite and 150kg tap water in 250kg metering barrel, fully stir until completely dissolving, obtain sodium bisulfite aqueous solution;

[0023] (3) Add 420kg water, 140kg acrylic acid and the aqueous sodium bisulfite solution obtained in the step (2) successively in the 1000L head tank, stir to obtain a mixed solution;

[0024] (4) Open the valve of the head tank, add the mixed solution prepared in step (3) dropwise into the stirring tank of step (1), stir while adding dropwise, after 1 hour, the catalyzed high-temperature free polycarboxylate is obtained when the material is discharged....

Embodiment 3

[0026] The production process of the catalyst-free high-temperature polycarboxylate water reducer adopts the following steps:

[0027] (1) After adding 1t of tap water, 1t of methyl alkenyl polyoxyethylene ether, 90kg of sodium persulfate, and 10kg of azodiisopropylimidazoline hydrochloride in sequence in a 5000L stirring tank, turn on the agitator and stir evenly;

[0028] (2) add 40kg sodium bisulfite and 150kg tap water in 250kg metering bucket, fully stir until dissolving completely, obtain sodium bisulfite aqueous solution;

[0029] (3) Add 420kg water, 140kg acrylic acid and the aqueous sodium bisulfite solution obtained in the step (2) successively in the 1000L head tank, stir to obtain a mixed solution;

[0030] (4) Open the valve of the head tank, add the mixed solution prepared in step (3) dropwise into the stirring tank of step (1), stir while adding dropwise, after 1 hour, the catalyzed high-temperature free polycarboxylate is obtained when the material is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com