Preparation method and application of small-pore molecular sieve-loading noble metal material prepared by one-pot reaction

A molecular sieve and noble metal technology, applied in the field of thermal catalysis, can solve the problems of requiring more equipment, not conducive to industrial application, and cumbersome synthesis steps, and achieve the effect of reducing synthesis steps, more NOx adsorption sites, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

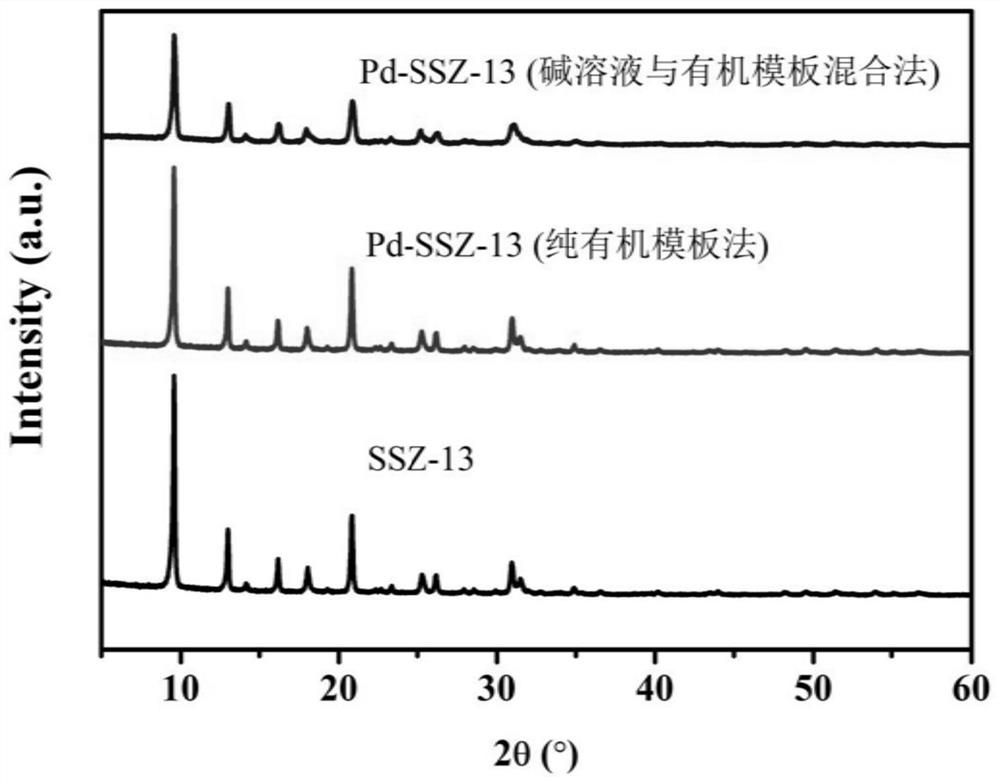

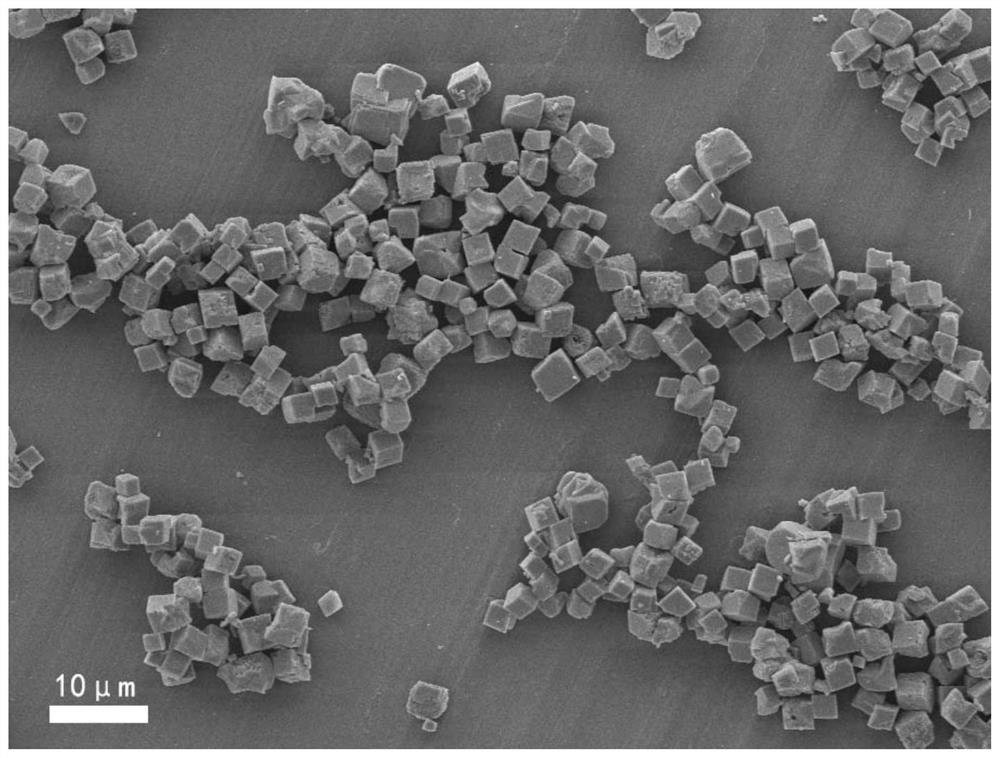

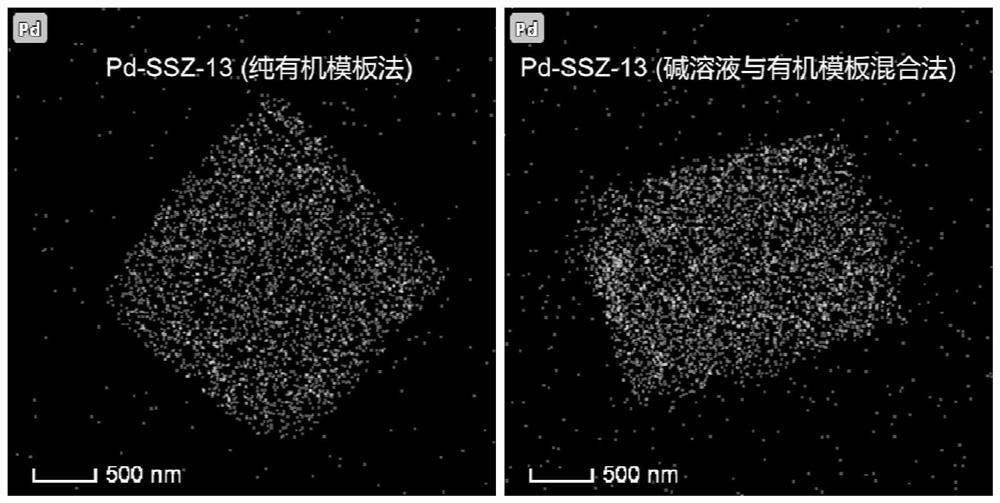

[0029] Example 1: Noble metal-based small-pore molecular sieve material Pd-SSZ-13 (pure organic template method)

[0030] Dissolve 0.7 mL of 0.038 mol / L palladium nitrate dihydrate solution in 28 g of deionized water, then add 30 g of N,N,N-trimethyl-1-adamantyl ammonium hydroxide solution, and stir at room temperature for 15 min . Then weigh 0.3 g of aluminum hydroxide powder into the above solution and stir for 30 min. Finally, 11 g of silica sol (40 wt%) was weighed into the above solution and stirred at room temperature for 2 h to form a homogeneous solution.

[0031] The mixture was transferred to a 100 mL reactor and subjected to static crystallization in an oven at 160 °C for 6 days. After the crystallization reaction, the product was washed several times with deionized water until the pH of the supernatant was neutral, the product was collected by filtration, and then dried in an oven at 100 °C for 24 h. The dried product was further placed in a tube furnace, and ca...

Embodiment 2

[0032] Example 2: Noble metal-based small-pore molecular sieve Pd-SSZ-13 (mixing method of alkali solution and organic template)

[0033] Measure 0.7 mL 0.038 mol / L palladium nitrate dihydrate solution, weigh 15 g N,N,N-trimethyl-1-adamantyl ammonium hydroxide solution and 4 g 5 mol / L sodium hydroxide solution , followed by adding 36 g of deionized water, stirring and mixing at room temperature for 15 min. Then, 0.3 g of aluminum hydroxide powder was weighed and added to the above solution and stirred for 30 min. Finally, 11 g of silica sol (40 wt%) was weighed into the above solution and stirred for 2 h to obtain a homogeneous solution.

[0034] The mixture was transferred to a 100 mL reactor and subjected to static crystallization in an oven at 160 °C for 6 days. After the crystallization reaction, the product was washed several times with deionized water until the pH of the supernatant was neutral, the product was collected by filtration, and then dried in an oven at 100 °C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com