Quenching/subzero treatment method for heat treatment of low-temperature nickel steel

A cryogenic treatment and low-temperature steel technology, which is applied in the field of heat treatment of low-temperature alloy structural steel, can solve the problems that it is difficult to meet the mechanical properties of 9Ni steel, low strength and toughness, and affect the safety of low-temperature steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing:

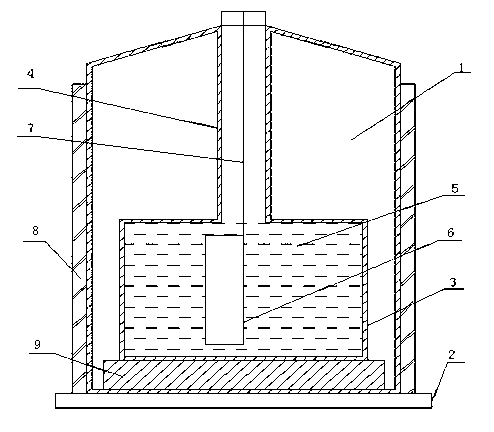

[0054] figure 1 As shown, it is the cryogenic treatment state diagram of low-temperature nickel steel. The position of each part must be correct, and the process parameters must be strictly controlled and operated in sequence.

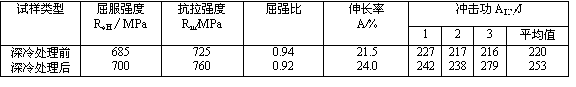

[0055] The amount of chemical substances that have just been cryogenically treated by low-temperature nickel is determined according to a preset range, with millimeters and milliliters as measurement units.

[0056] The cryogenic treatment of low-temperature nickel steel is carried out in a liquid nitrogen cryogenic treatment box, and is completed in a cryogenic state in a liquid nitrogen tank;

[0057] The liquid nitrogen cryogenic treatment box is vertical, and a workbench 9 is arranged at the inner bottom of the liquid nitrogen cryogenic treatment box 1, and a liquid nitrogen tank 3 is placed on the workbench 9, and a feed channel is provided o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com