Patents

Literature

101results about How to "Informative and accurate data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

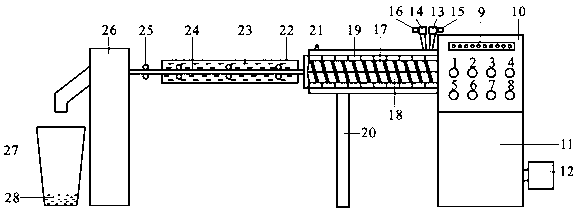

Preparation method for heat-resisting polylactic acid fiber

InactiveCN102839443AImprove heat resistanceEnsuring environmental friendlinessSpinning head liquid feederMelt spinning methodsPolymer scienceTriethoxysilane

The invention relates to a preparation method for a heat-resisting polylactic acid fiber, which comprises the following steps: drying polylactic acid grains in a vacuum drum; modifying the surface of nanometer silicon dioxide by using a silane coupling agent, namely, gamma-aminopropyl triethoxy silane; mixing the dry polylactic acid grains with the modified nanometer silicon dioxide; preparing into polylactic acid plus silicon dioxide master batches by utilizing a double-screw extruding machine; uniformly mixing the master batches and the polylactic acid grains at weight ratio; pouring the mixture into a melt spinning machine for spinning; and drafting through two areas, thereby obtaining polylactic acid plus silicon dioxide fibers. The process of the preparation method is advanced; the data is full and accurate; the preparation method is suitable for mass production; the prepared polylactic acid filament is excellent in heat resistance and mechanical property; the problem of poor heat resistance of the polylactic acid fiber is effectively solved; and the application scope of the polylactic acid fiber is widened.

Owner:TAIYUAN UNIV OF TECH

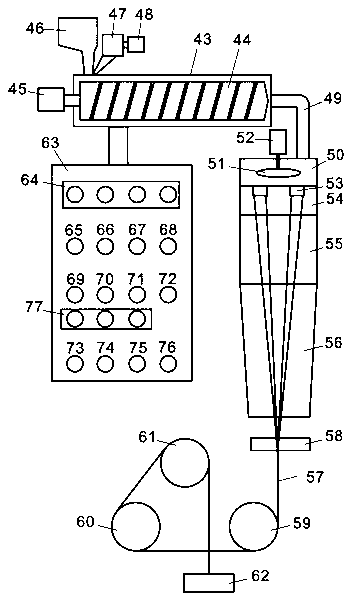

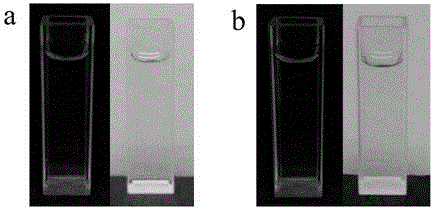

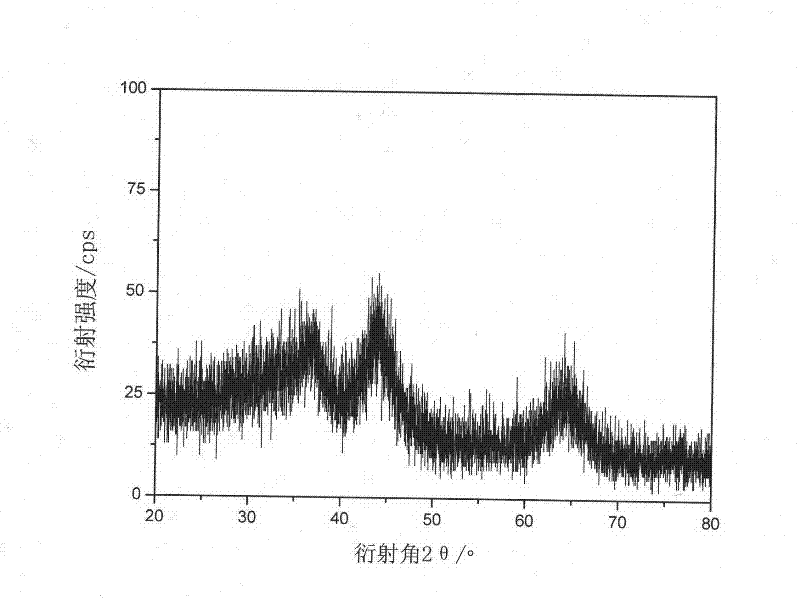

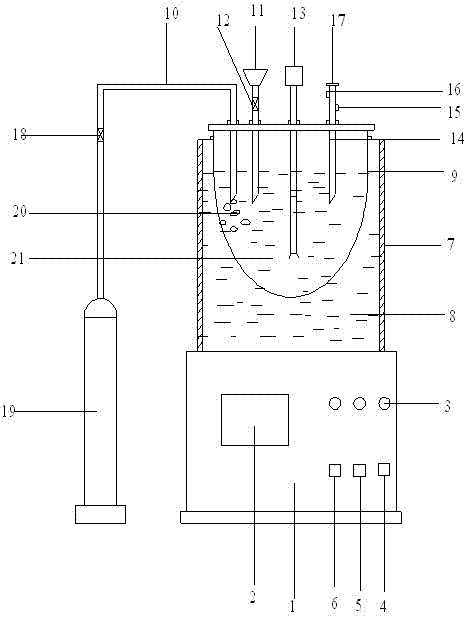

Method for quickly preparing carbon quantum dots emitting blue light and carbon quantum dots emitting green light

ActiveCN104531147AFast purityGood water solubilityMaterial nanotechnologyNanoopticsSolubilityDispersity

The invention relates to a method for quickly preparing carbon quantum dots emitting blue light and carbon quantum dots emitting green light. According to the method, an environmentally-friendly hydrothermal synthesis method is adopted, L-ascorbic acid and ethidene diamine serve as raw materials, deionized water serves as solvent, the carbon quantum dots emitting the blue light and the carbon quantum dots emitting the green light are formed by quick synthesis of the L-ascorbic acid at different temperatures, the purity of products reaches 99%, the water solubility reaches 99.5%, the particle diameter of the carbon quantum dots emitting the blue light is smaller than or equal to 6 nm, the particle diameter of the carbon quantum dots emitting the green light is smaller than or equal to 6.2 nm, and the carbon quantum dots are good in dispersity, good in water solubility, good in fluorescence, capable of being applied to fluorescence probes, biomedical imaging, printing inks and photovoltaic devices; the preparation method is advanced in process, precise and detailed in data, high in preparation speed, good in product purity and stable in light-emitting performance and is a very ideal method for quickly preparing the carbon quantum dots emitting the blue light and the carbon quantum dots emitting the green light.

Owner:TAIYUAN UNIV OF TECH

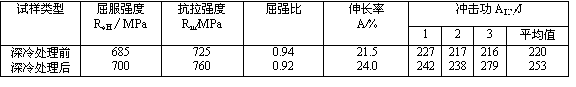

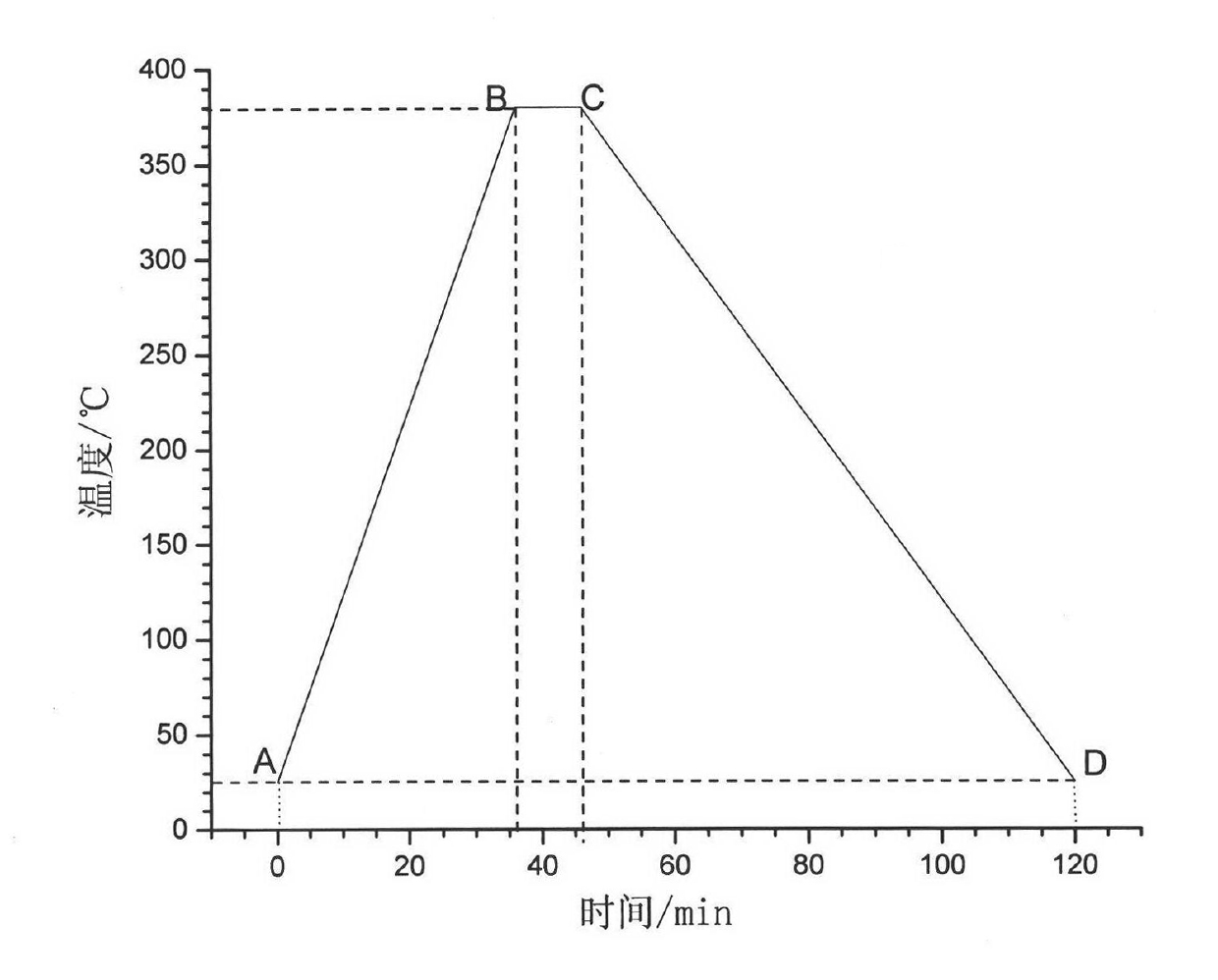

Quenching/subzero treatment method for heat treatment of low-temperature nickel steel

The invention relates to a quenching / subzero treatment method for heat treatment of low-temperature nickel steel, which comprises the following steps: based on characteristics and service conditions of low-temperature nickel steel, performing quenching, rapid cooling and liquid nitrogen subzero treatment on 9Ni low-temperature steel; and performing low-temperature tempering to relieve the internal stress, thus greatly enhancing the strength, toughness and hardness of the 9Ni low-temperature steel. After the treatment, the hardness can be up to HRC31-33, the yield strength is up to 695-705MPa, the tensile strength is up to 750-760MPa, and the low-temperature impact energy of the toughness is up to 250-260J. The technical method is advanced, full and accurate in data, favorable in treatment effect and high in stability, thus being a very ideal low-temperature nickel steel quenching / subzero treatment method. Other types of low-temperature steel can also be treated by using the method.

Owner:TAIYUAN UNIV OF TECH

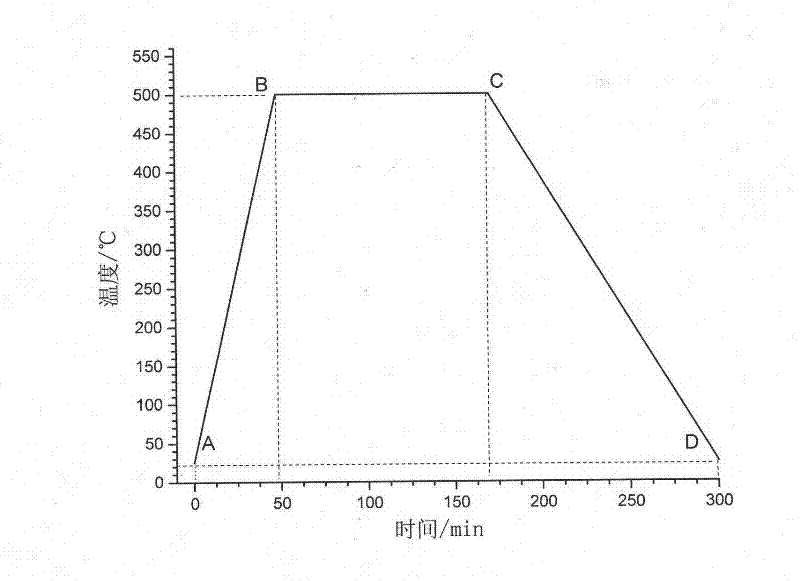

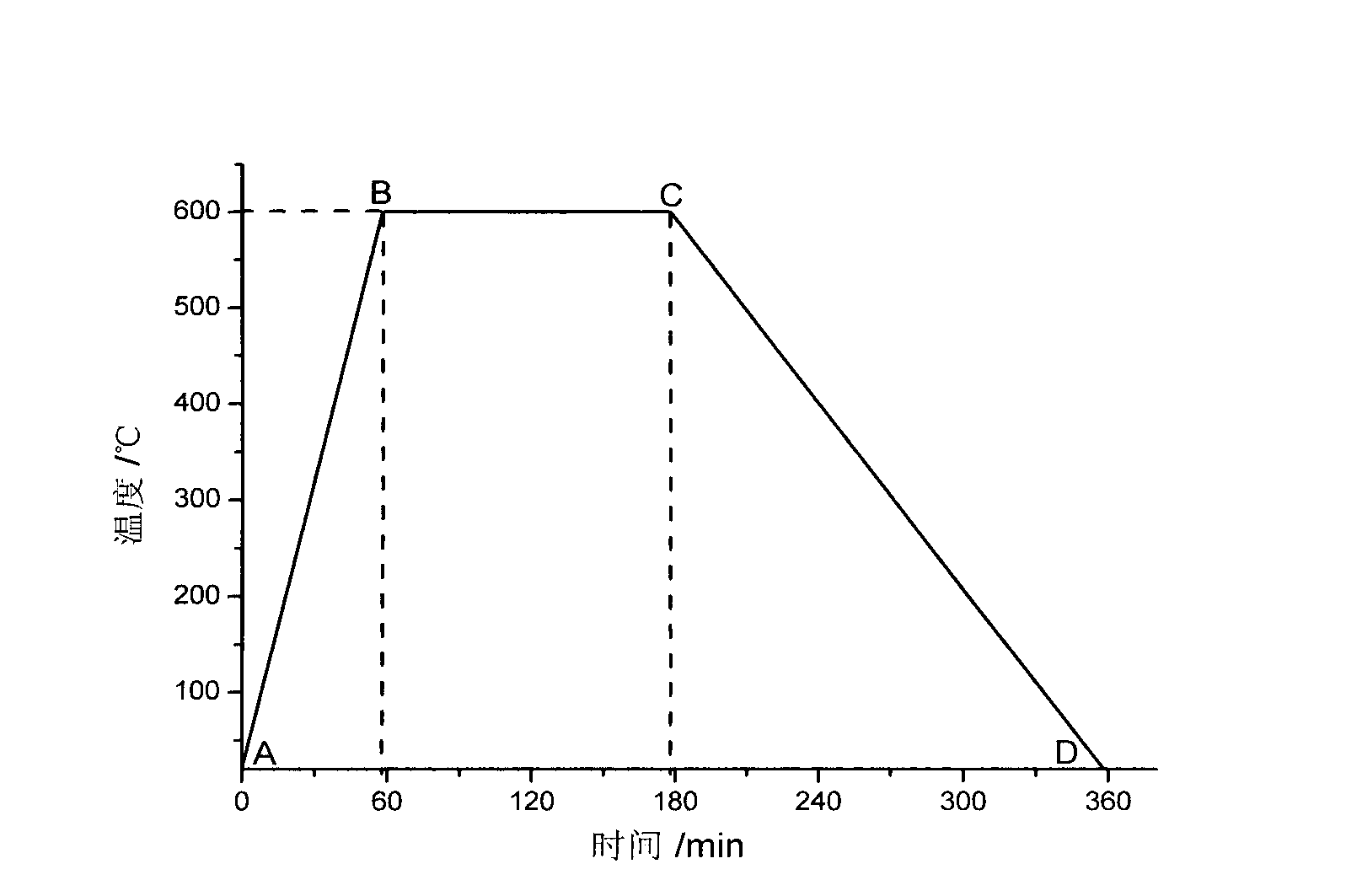

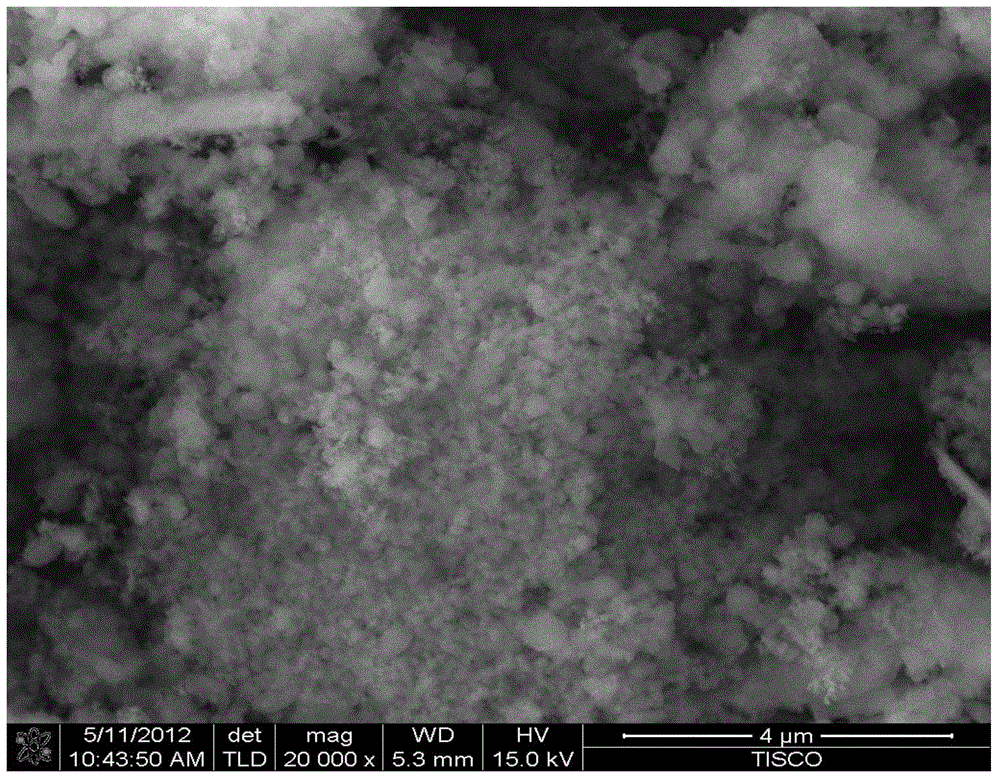

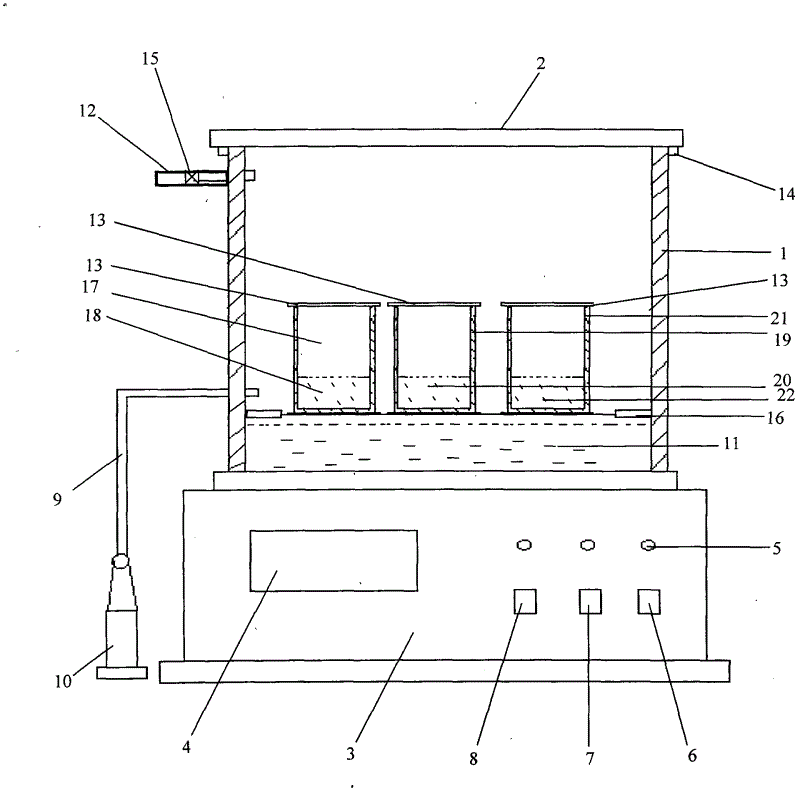

Preparation method of thermometal methanation catalyst with high-temperature resistance

InactiveCN102513116AReasonable ratioImprove stabilityGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsMethanation

The invention relates to a preparation method of a thermometal methanation catalyst with high-temperature resistance, which comprises the following steps of: taking alumina as a vector, taking nickel oxide as a main active component, taking cobalt oxide as a second active component, taking lanthanum oxide as an adjuvant and mixing the above oxides evenly by adopting a double-hydrolyzing homogeneous-phase coprecipitation method of inorganic salt so as to prepare the methanation catalyst by filtering, washing, drying and calcining. The dispersion of each component in the catalyst is uniform, the stability and the coagulating resistance are good, the quick methanation of the catalyst can be realized by mixing with raw gas, and the catalyst can have the function of effectively resisting coagulation and accumulation in a high-temperature environment generated in the quick reaction process and has favorable catalytic capability at the temperature of 500 to 700 DEG C. The preparation method has short technological process, reasonable mixture ratio of materials and full and accurate data, is easy to operate and is a very ideal preparation method of the thermometal methanation catalyst with high-temperature resistance.

Owner:TAIYUAN UNIV OF TECH

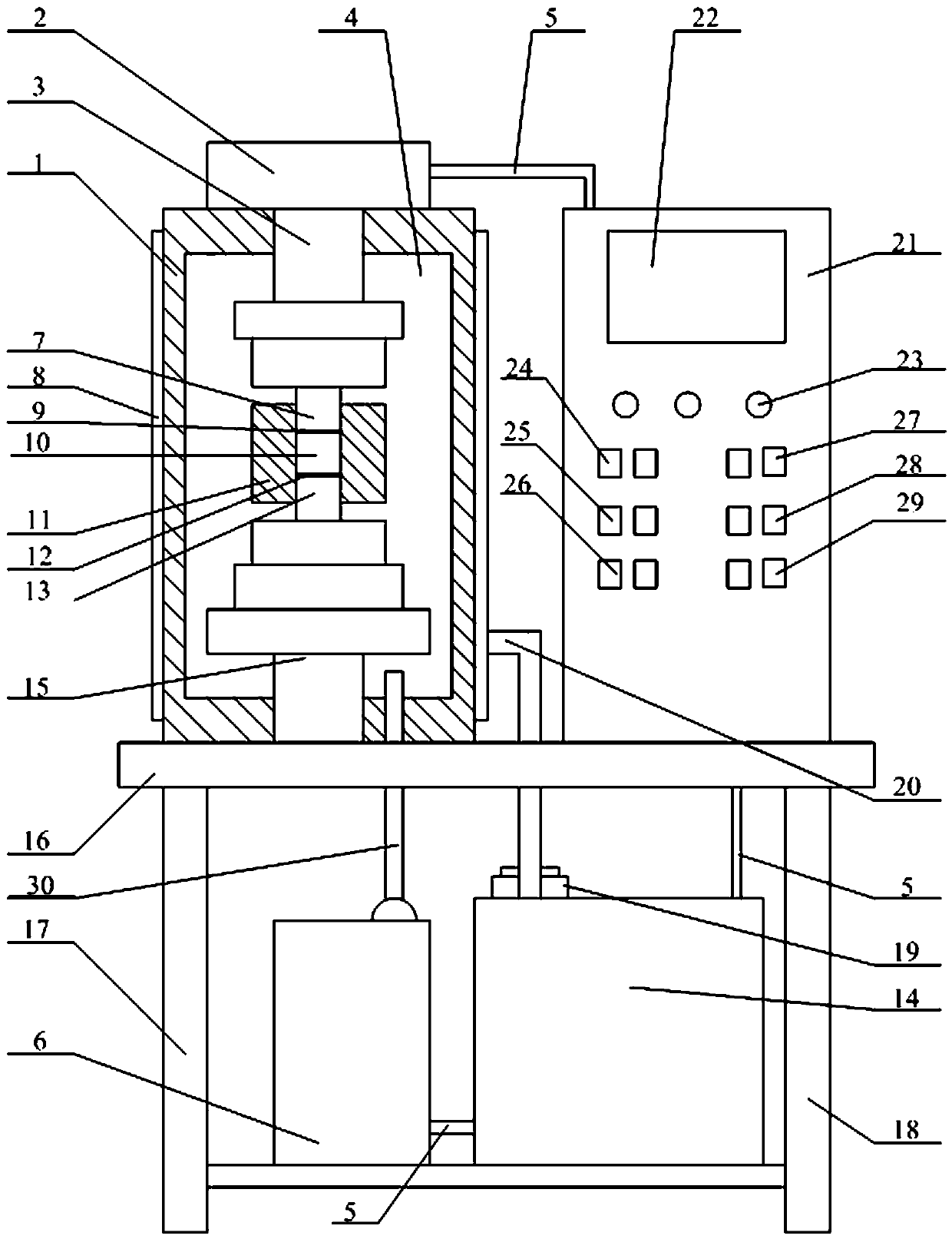

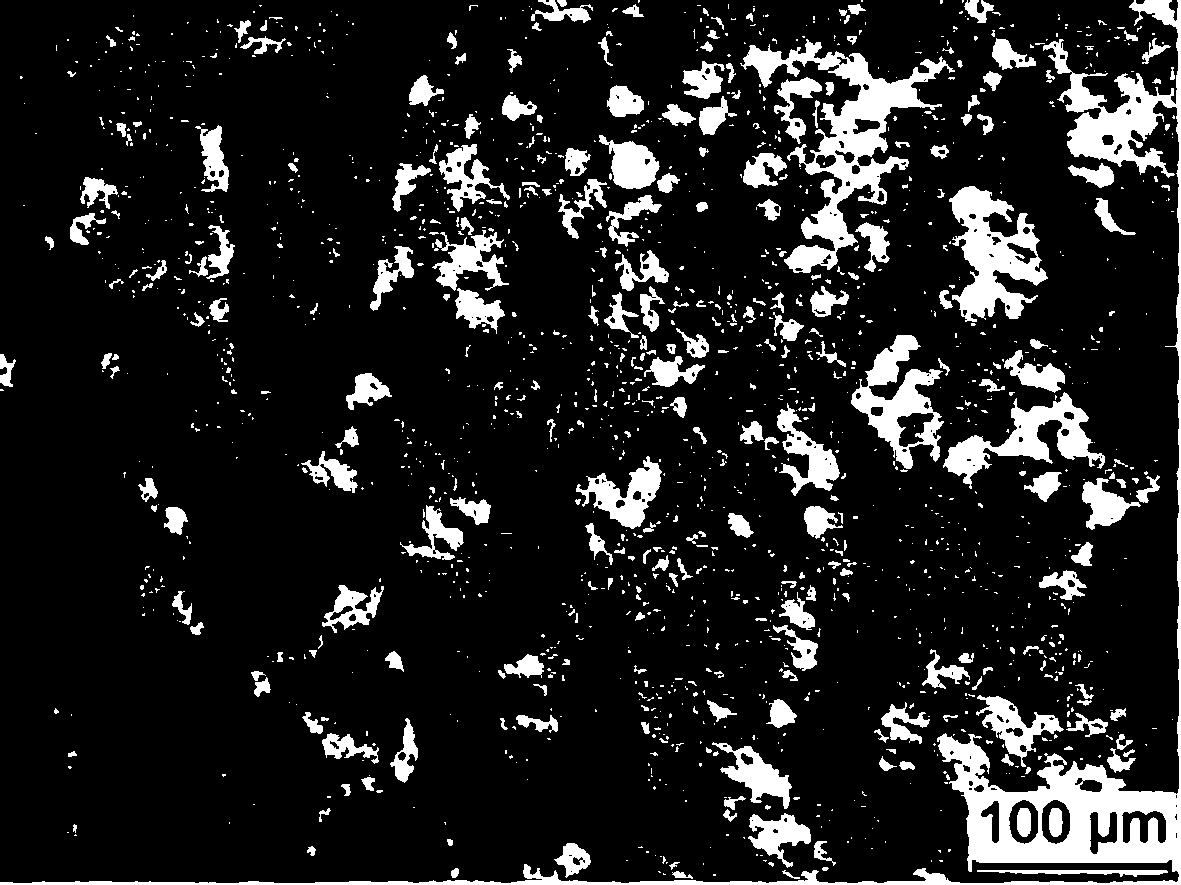

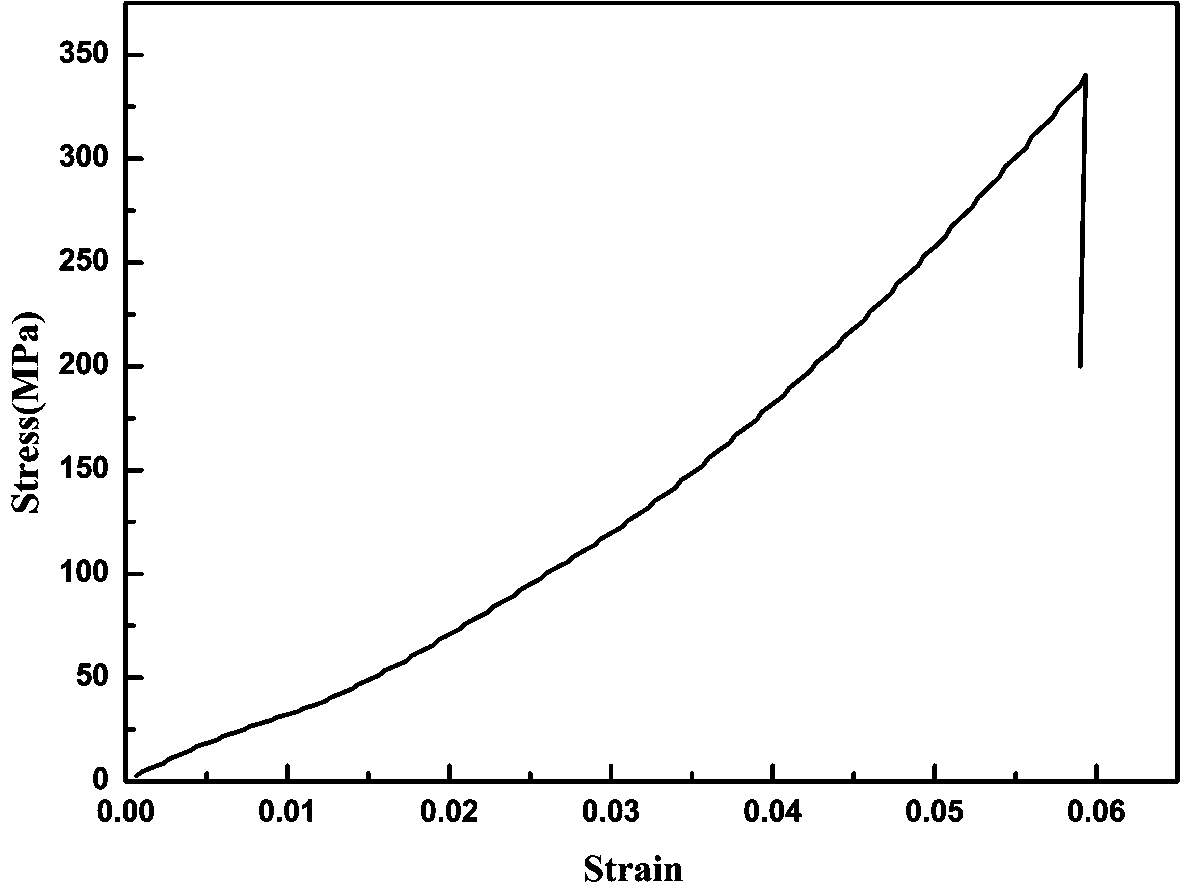

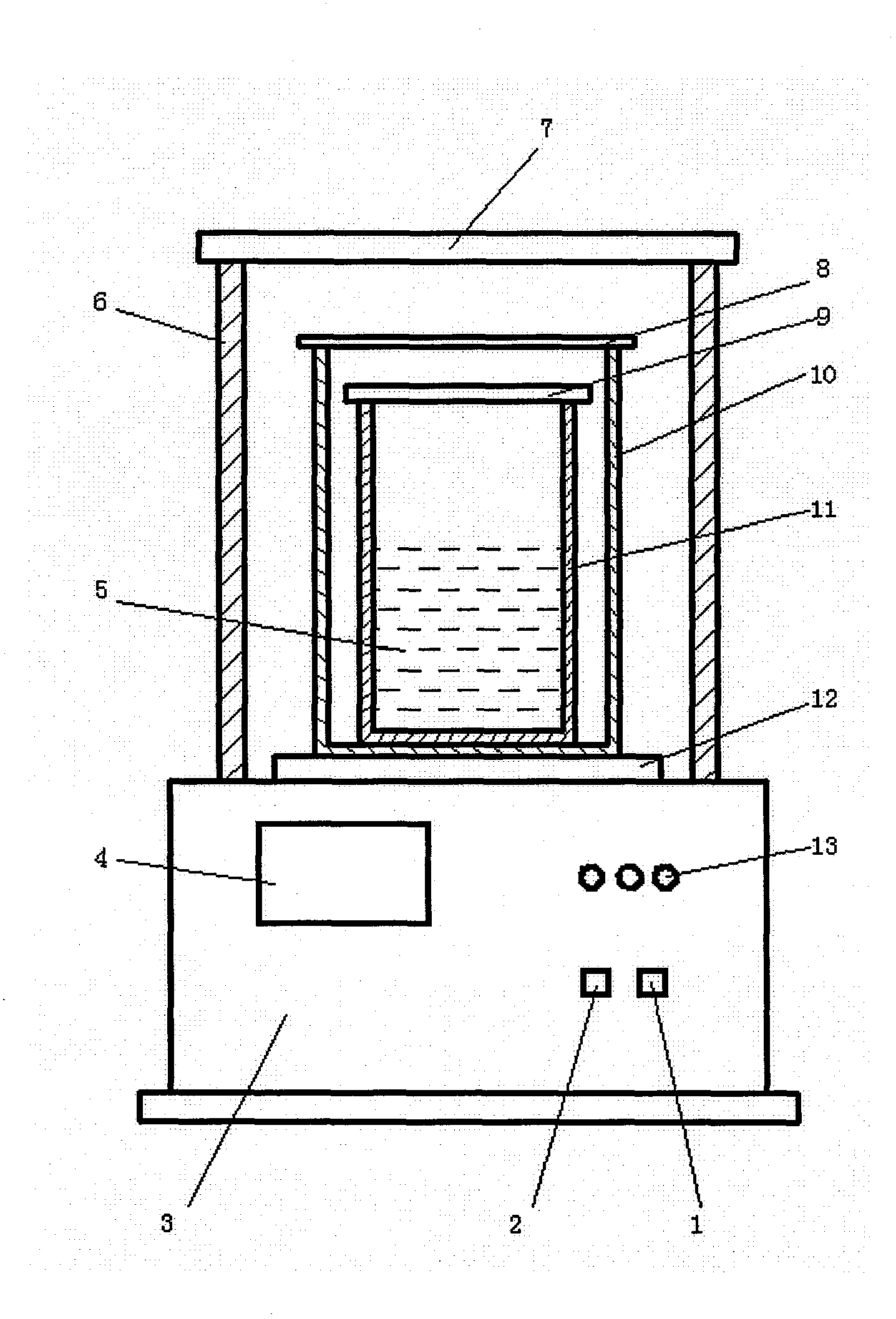

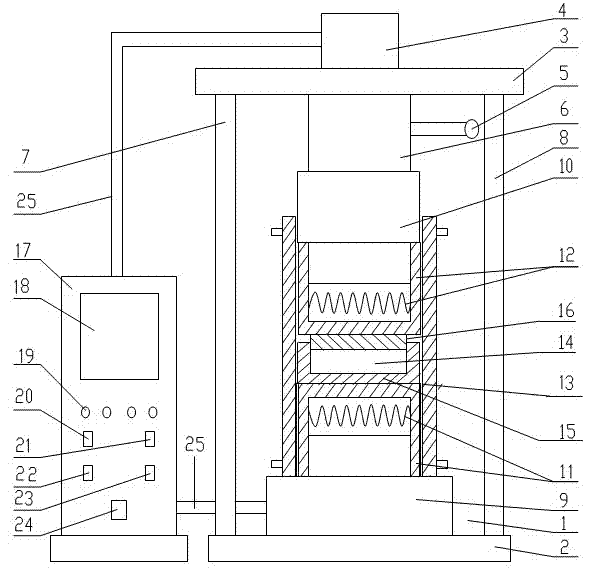

Preparation method of reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material and application

ActiveCN108660352AImprove shape deformation abilityPrevent oxidationShieldingAl powderElectrical resistance and conductance

The invention belongs to the technical field of nonferrous metal alloy preparation, and in particular, relates to a preparation method of a reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material. The preparation method comprises the following steps: the ball milling and the mixing are performed on Al powder, Co powder, Cr powder, Fe powder and Ni powder according to a mole ratioof 1: 1: 1: 1: 2 to prepare AlCoCrFeNi2 high-entropy alloy powder; the ball milling and the mixing are performed on the AlCoCrFeNi2 high-entropy alloy powder, the Al powder and B4C powder according to a volume ratio of 6: 3: 1; a plasma discharge sintering technology is adopted to sinter under the conditions of vacuum, resistance heating and pressurization to prepare the reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material; B4C particles are uniformly distributed in a basal body; through adding of the Al powder, the plastic deformation capacity of the material can be further improved; the oxidation of the material can be effectively prevented in the vacuum environment; through plasma discharge quick sintering, the growth of grains in the material can be prevented; local high temperature is generated by particle tip discharge to improve the interface connecting strength of the material; the preparation method is advanced in process and precise and accurate in data;the compactness of the AlCoCrFeNi2 high-entropy alloy base neutron absorbing material can reach 98%; the hardness can reach HV0.5=563.3; and the tensile strength can reach 340 MPa.

Owner:TAIYUAN UNIV OF TECH

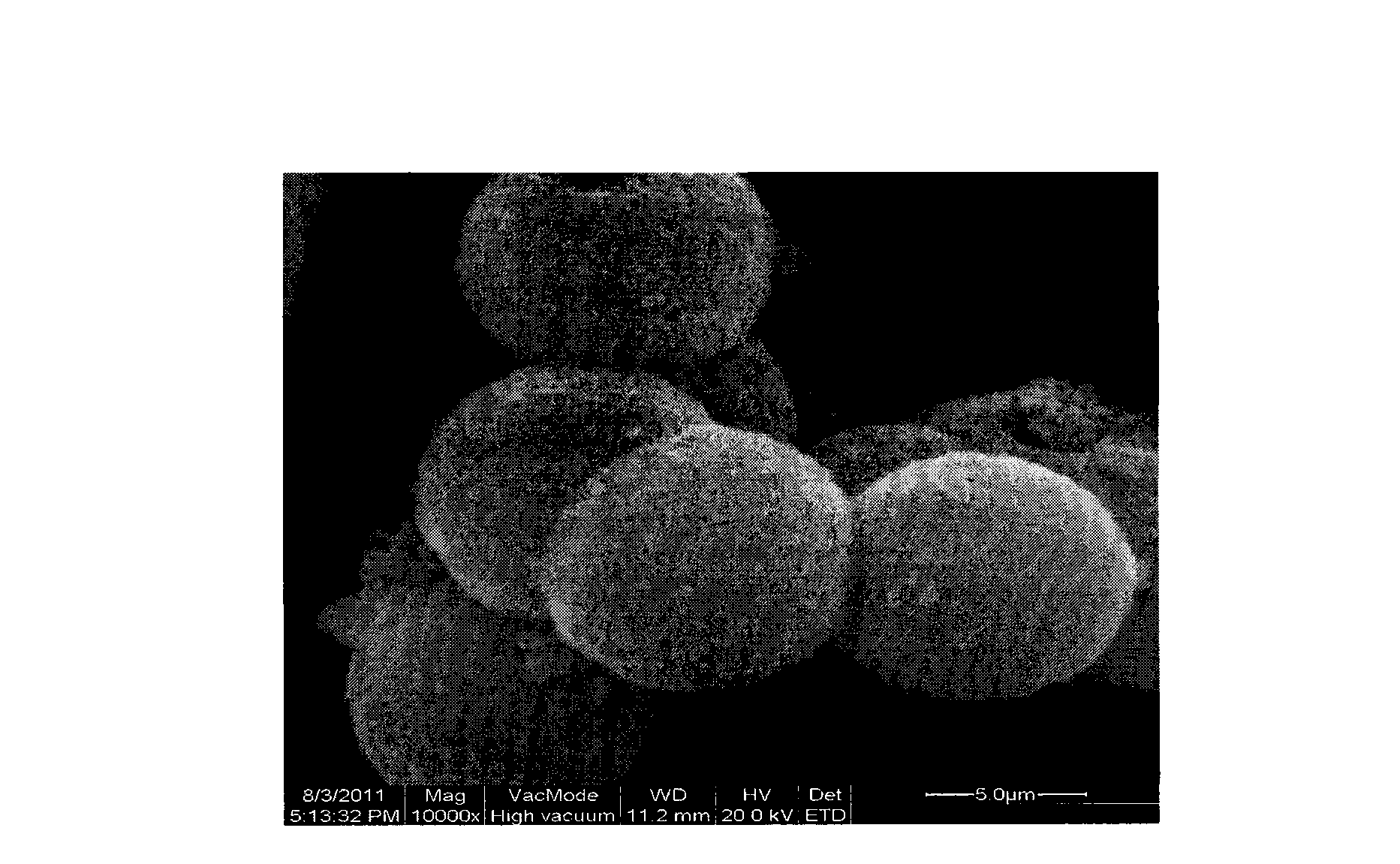

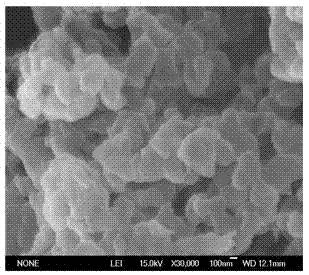

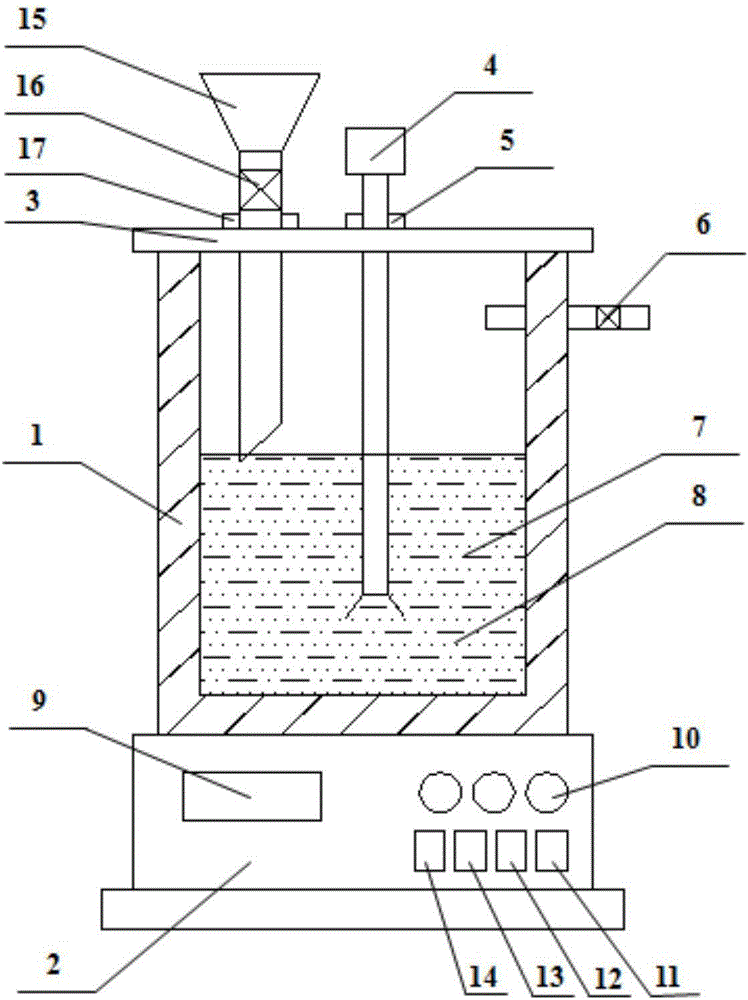

Method for preparing large-specific-surface-area porous nickel oxide microspheres

The invention discloses a method for preparing large-specific-surface-area porous nickel oxide microspheres. The method comprises the following steps of: preparing and synthesizing a mixed solution by taking nickel nitrate and urine as raw materials, taking hexadecyl trimethyl ammonium bromide as a surfactant, taking absolute ethanol and deionized water as washing agents and refining raw materials; heating in a reaction kettle for preparing hydrogen nickel carbonate; and washing, performing suction filtration, drying in vacuum, and baking to obtain large-specific-surface-area porous nickel oxide microspheres. The preparation method has the advantages of advanced process, short process flow, small using amount of raw materials, detailed and accurate data, high product yield which can be up to 95 percent and high product purity, which can be up to 98.5 percent; the specific surface area of the product, i.e., nickel oxide microspheres is 748.25m<2> / g, microsphere particles are less than or equal to 10 mum, irregular hexagonal nano-sheets are distributed on the surfaces of the microspheres and are less than or equal to 40 nanometers in diameter, and the microspheres can be matched with a plurality of chemical substances; and the method is very ideal method for preparing large-specific-surface-area porous nickel oxide microspheres.

Owner:TAIYUAN UNIV OF TECH

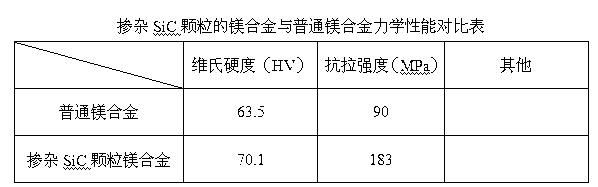

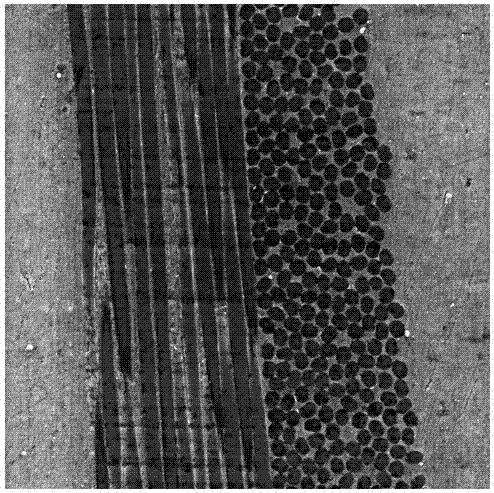

Preparation method of magnesium base composite doped with SiC grains

The invention relates to a preparation method of a magnesium base composite doped with SiC grains. Due to the fact that the mechanical property of a magnesium alloy is poor, the ceramic SiC grains are doped in a smelting process of the magnesium alloy to prepare a reinforced magnesium alloy block material through smelting, doping, gas shielding, casting, and extruding; the strength and the hardness of a magnesium alloy ingot are improved largely; the Vickers hardness of the composite reaches 70.1, and is increased by 30% compared with a common magnesium alloy; the tensile strength reaches 183 MPa, and is increased by 103.3% compared with the common magnesium alloy; the preparation method is advanced in process, detailed and accurate in data, and is an ideal method of preparing the reinforced magnesium base composite.

Owner:ZHONGBEI UNIV

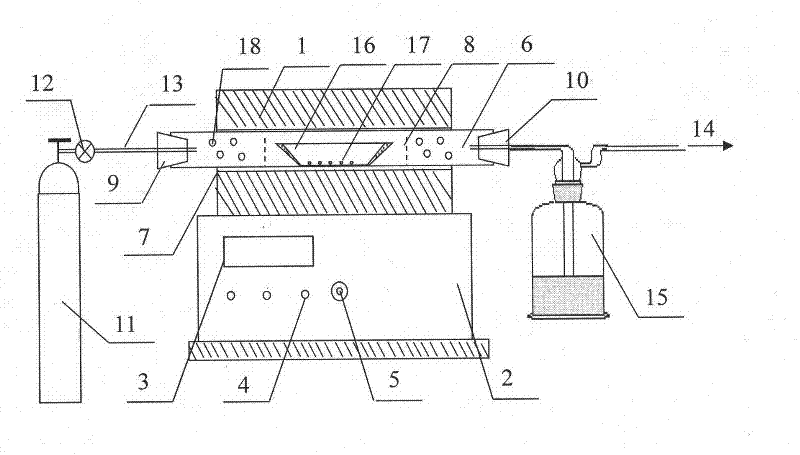

Method for welding ferritic stainless steel with trailing intense cooling

ActiveCN102941401AAdvancedAvoid grain growthArc welding apparatusHeat-affected zoneSS - Stainless steel

The invention relates to a method for welding ferritic stainless steel with trailing intense cooling and aims at the problem that a crystal grain grows and is brittle in the welding process of the ferritic stainless steel. A argon tungsten-arc welding machine is adopted, liquid nitrogen is used in the welding process to conduct welding with trailing intense cooling, and argon is used for protection, so that the problem that the crystal grain grows and is brittle in the welding heat affected zone is effectively prevented, the data are full and accurate, the quality of a welding joint is good, a welding line is good in fusion property and is not easily cracked, the strength of extension of the welding line is up to 481.5MPa, and therefore, the method is a quite ideal method for welding ferritic stainless steel.

Owner:太原理工技术转移有限公司

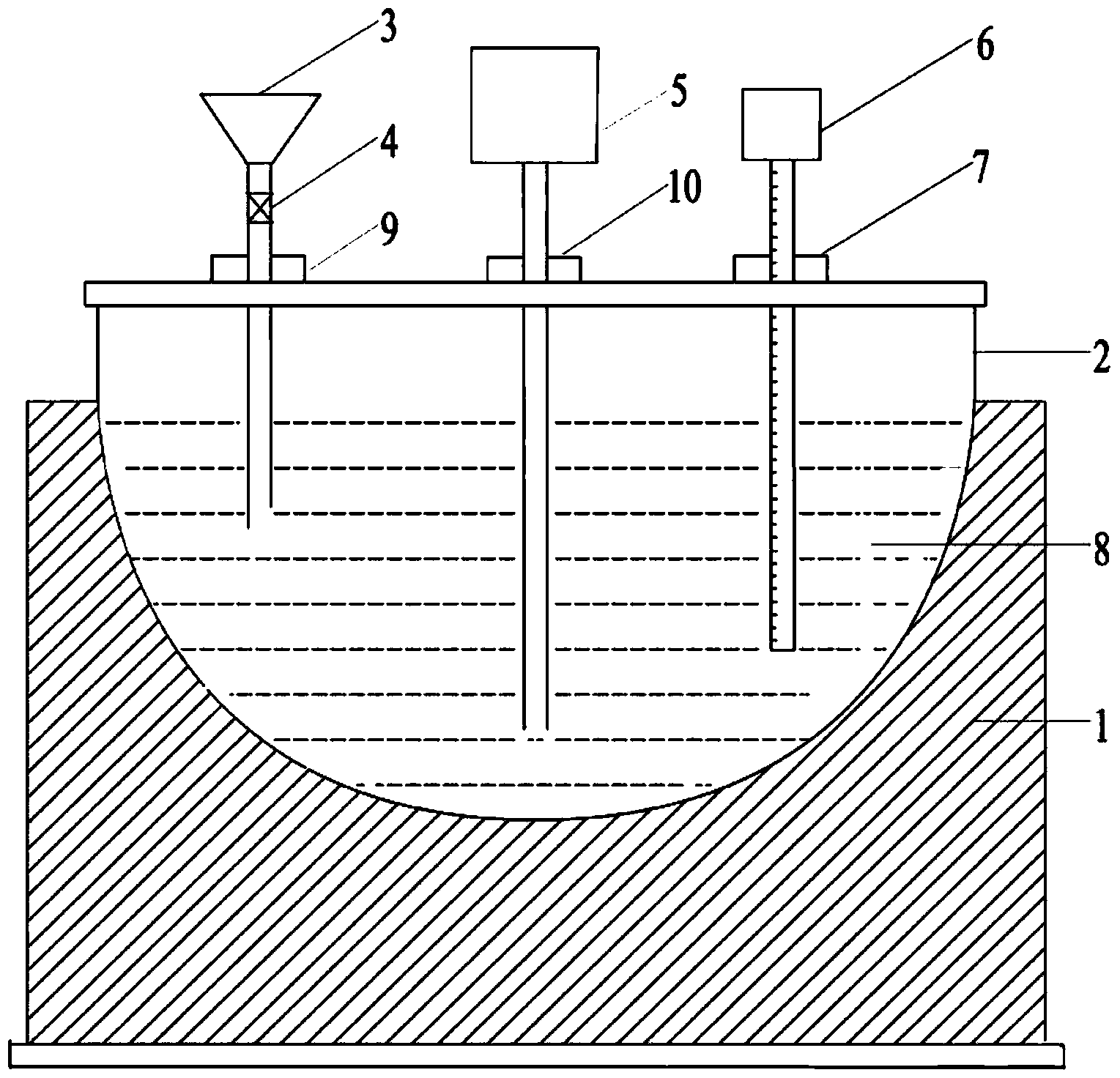

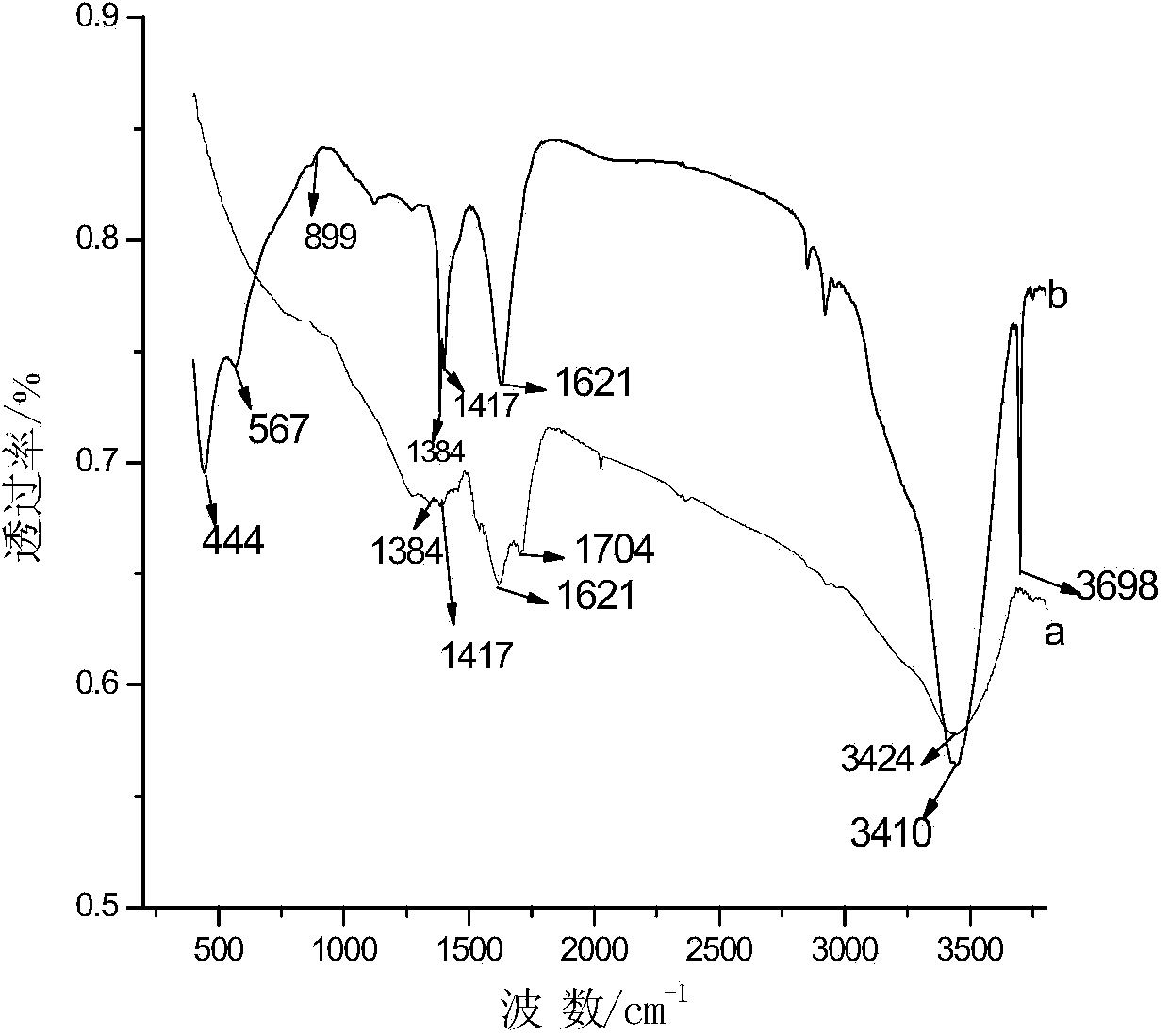

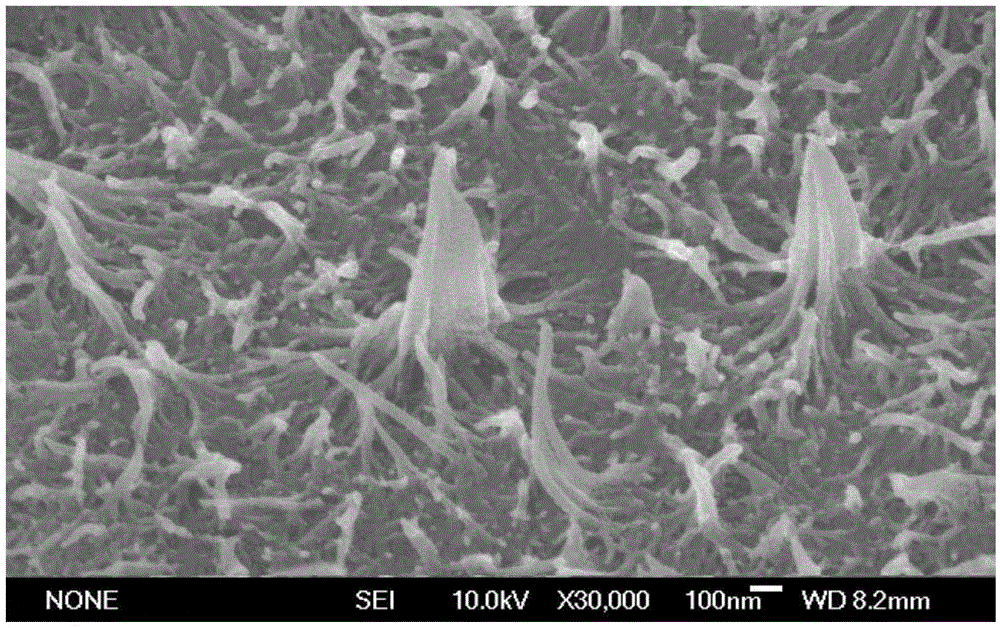

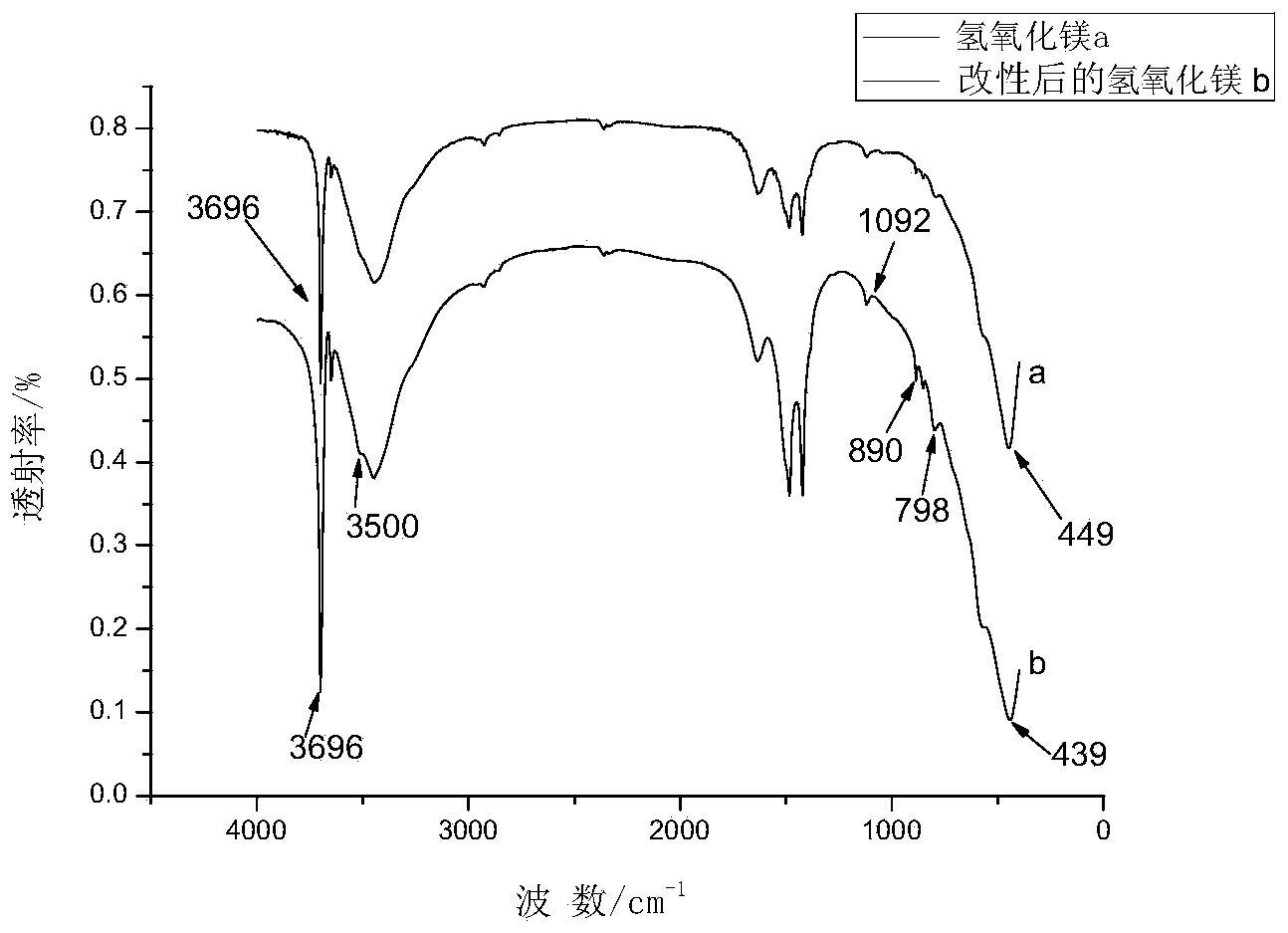

Method for preparing flame retardant through coating carbon microsphere with magnesium hydroxide

The invention relates to a method for preparing a flame retardant through coating carbon microspheres with magnesium hydroxide. Aiming at the disadvantages of magnesium hydroxide in the flame retardant and combining the characteristic of thermal stability of the carbon microspheres, the method is characterized in that the carbon microspheres are coated with magnesium hydroxide so as to produce the flame retardant; the carbon microspheres are made of glucose; magnesium chloride generates magnesium hydroxide in an alkaline environment and conducts coating, and through the treatment of ultrasonic dispersion, pH value regulation, washing, suction filtration, vacuum drying, grinding and screening, the product of magnesium hydroxide coated carbon microsphere flame retardant powder particles can be obtained. The method is advanced in technology and full and accurate in data; the product is black gray powder particles which are 500 to 650 nm in diameter, the thickness of a coating layer is 15 to 50 nm, the purity is as high as 97%, and the flame-retardant effect is good; the method can be applied to textile, dye printing and a plurality of industrial fields and is a very ideal method for preparing the flame retardant through coating the carbon microsphere with magnesium hydroxide.

Owner:TAIYUAN UNIV OF TECH

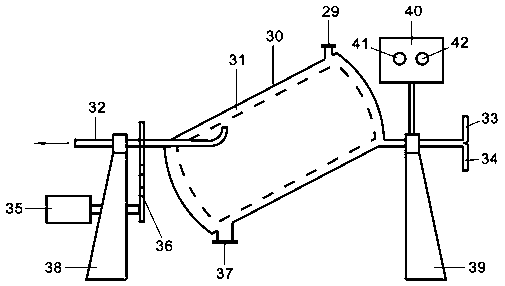

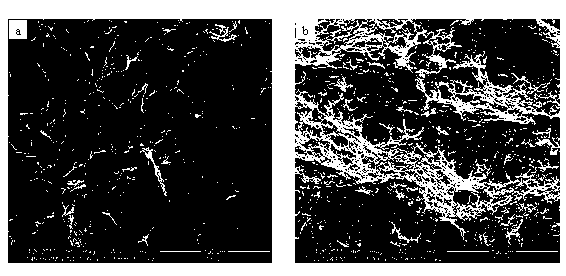

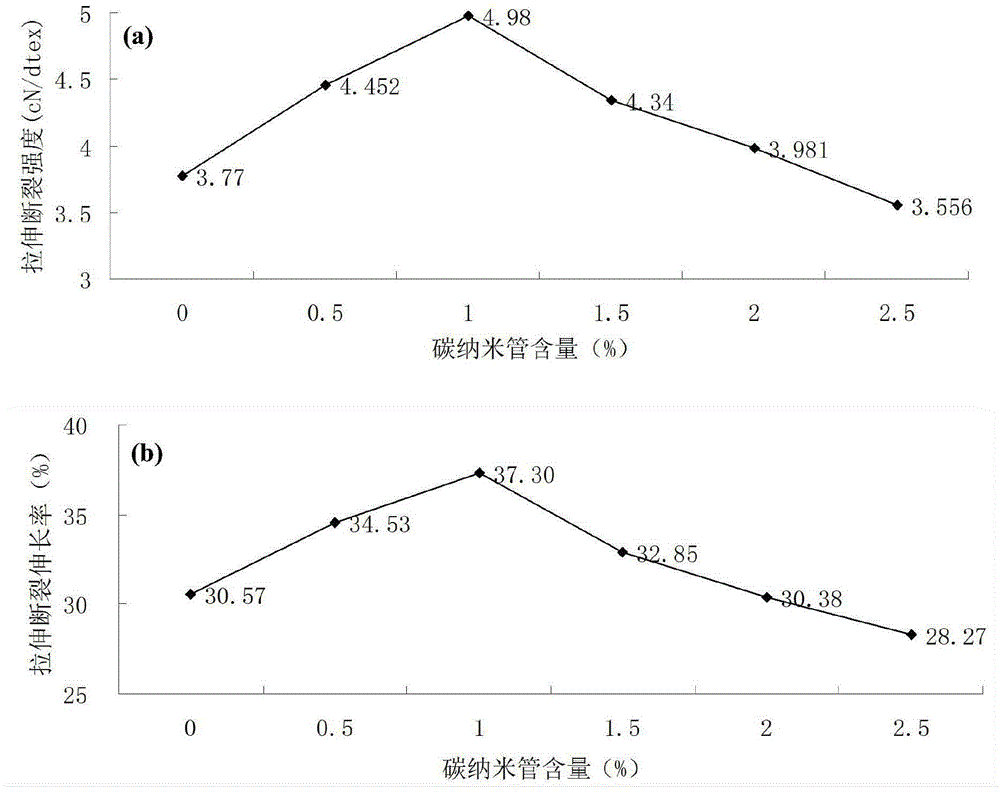

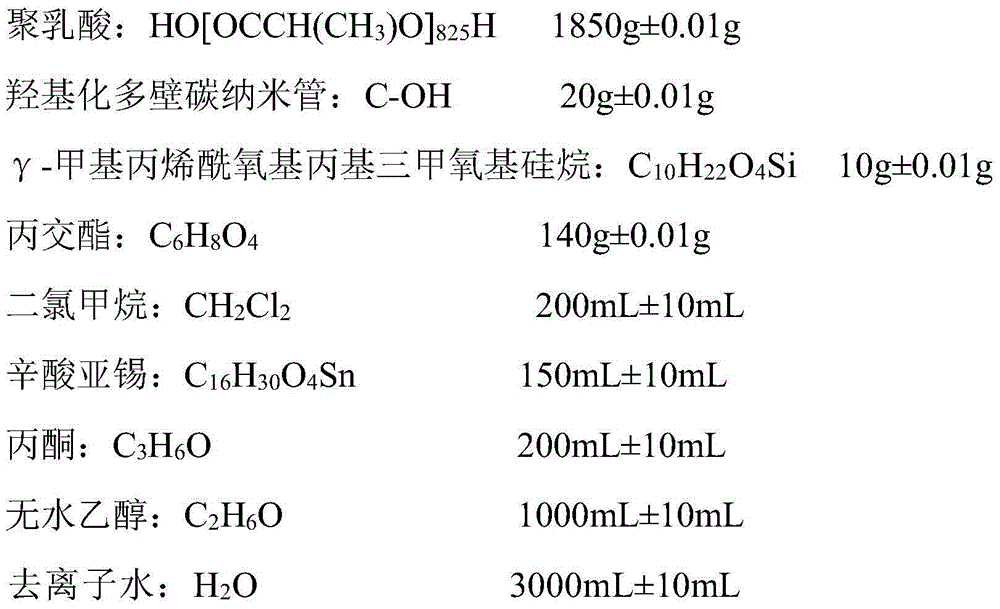

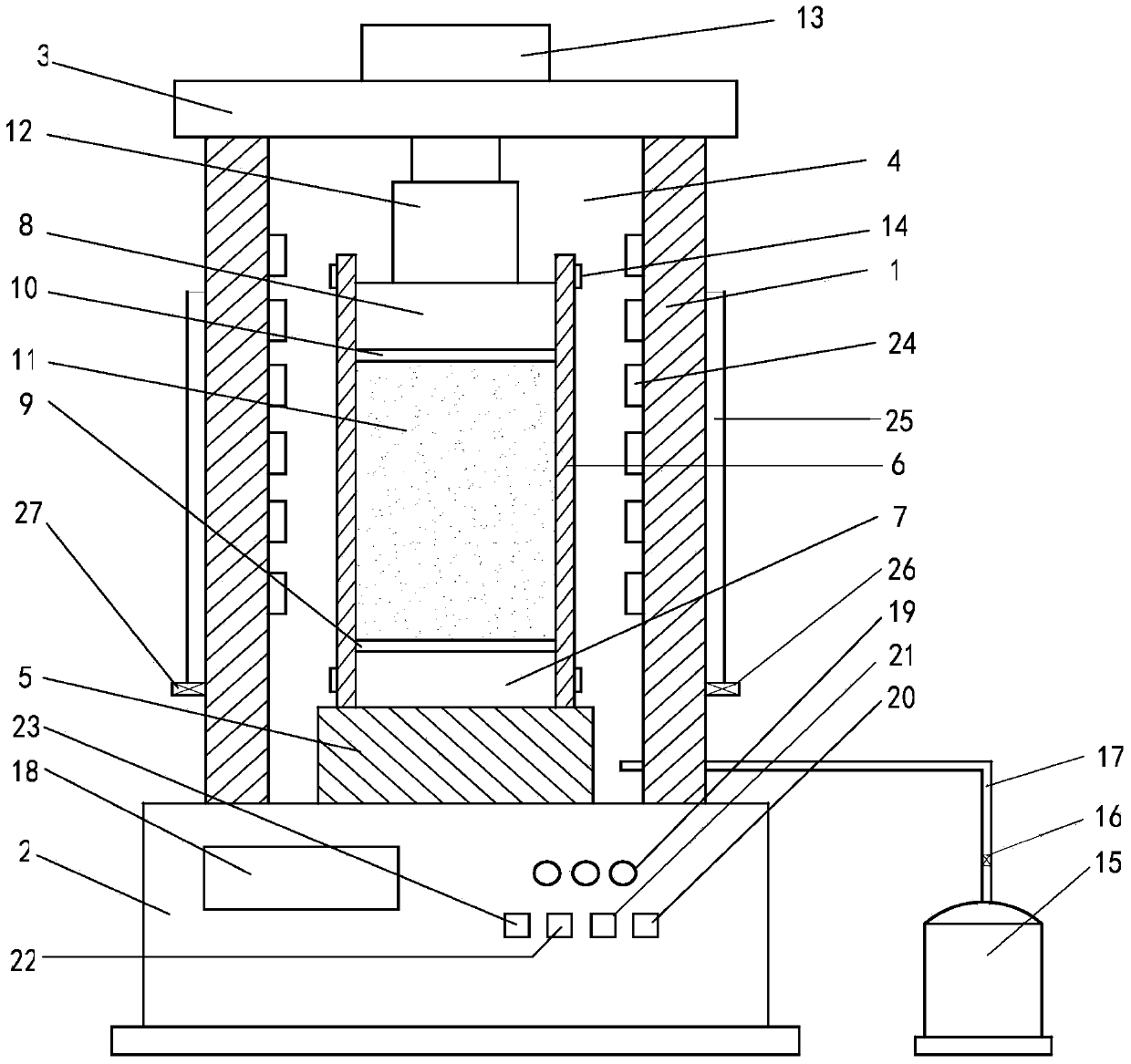

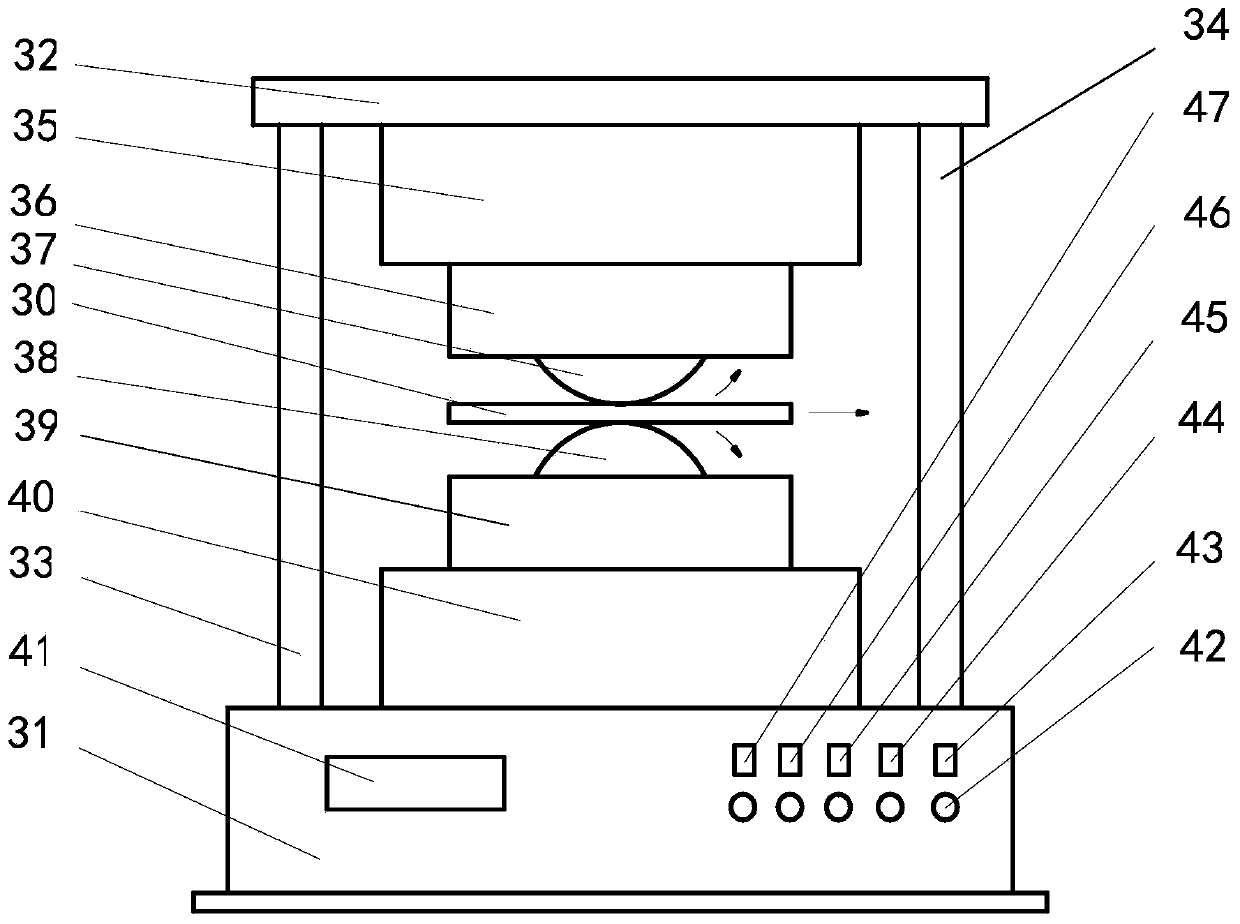

Preparation method of tough polylactic acid composite fiber

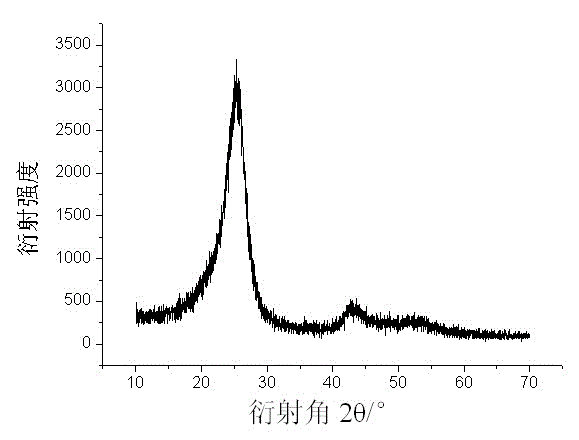

ActiveCN104357953AAdvancedInformative and accurate dataFilament/thread formingConjugated synthetic polymer artificial filamentsMasterbatchBreaking strength

The invention relates to a preparation method of a tough polylactic acid composite fiber. Hydroxylated multiwalled carbon nanotubes are added in polylactic acid fibers and are subjected to surface modification, polymerization grafting, masterbatch preparation and melt spinning, so as to prepare the tough polylactic acid composite fiber for solving the problems of low intensity and poor toughness of the polylactic acid fiber. The preparation method has advanced technology, the data is accurate and detailed, the prepared tough polylactic acid composite fiber can reach 4.98cN / dtex in breaking strength, is 37.3% in elongation at break and has breaking strength improved by 32% and elongation at break improved by 22%, the application range of the polylactic acid composite fiber is expanded, and the method is ideal for preparing the tough polylactic acid composite fiber.

Owner:TAIYUAN UNIV OF TECH

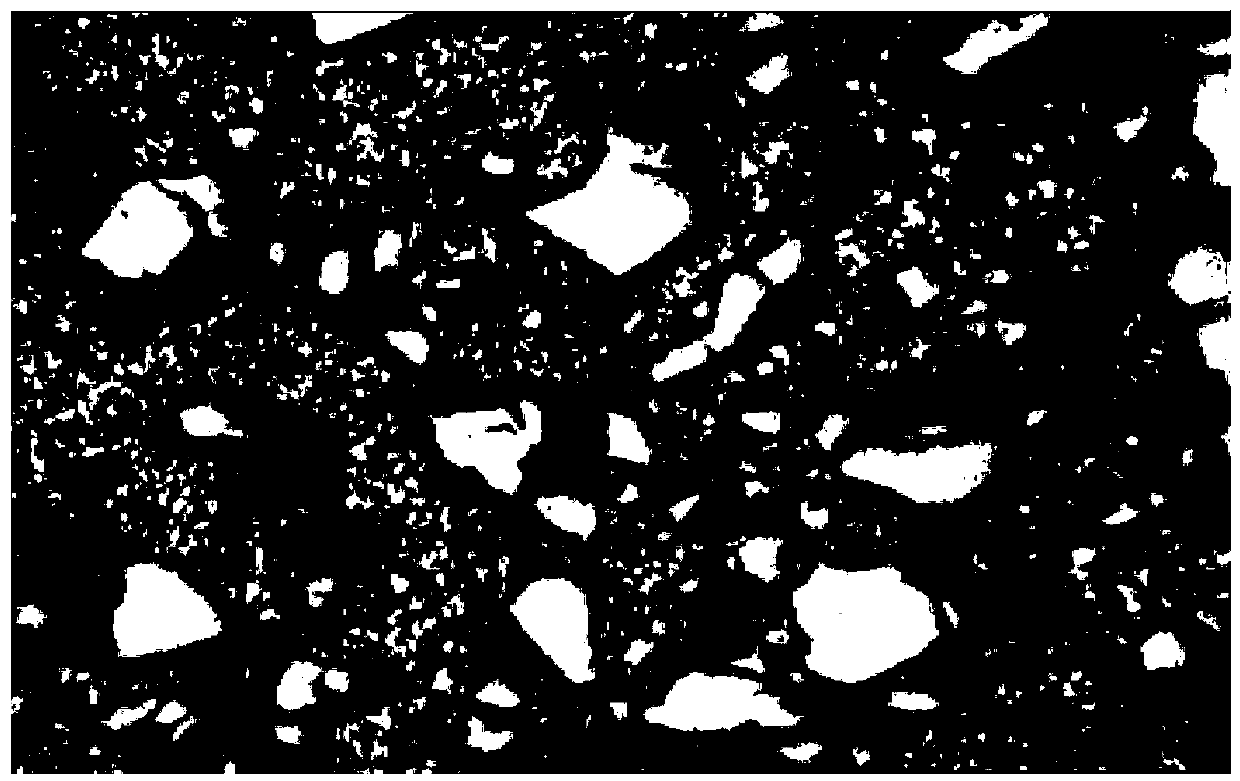

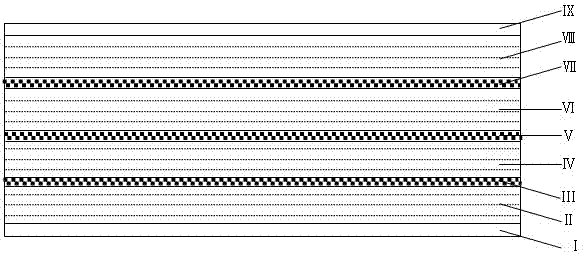

Method for preparing boron, lead and aluminum composite board preventing X rays, gamma rays and neutron irradiation

The invention relates to a method for preparing a boron, lead and aluminum composite board preventing X rays, gamma rays and neutron irradiation to overcome the defect that a nuclear radiation and ray shielding material is single in shielding property. According to the method, aluminum powder, boron carbide powder and lead powder serve as raw materials, ball grinding, powder processing, material mixing, microwave heating, vacuum hot pressing blank stamping, and heating rolling forming are carried out, and then the boron, lead and aluminum composite board is prepared. The preparing method is advanced in technology, data are accurate and detailed, the prepared boron, lead and aluminum composite board has a good ray and neutron irradiation shielding effect, the X-ray shielding rate is larger than or equal to 95 percent, the gamma-ray shielding rate is larger than or equal to 40 percent, the neutron absorptivity is larger than or equal to 90 percent, boron carbide is evenly distributed, particles and a base body are combined tightly, high mechanical strength is achieved, the surface microhardness reaches 186.3 HV, the bending angle is larger than or equal to 15 degrees, the tensile strength is 305 MPa, the elongation after fracture is larger than or equal to 6 percent, the mechanical property and the shielding property of the boron, lead and aluminum composite board are improved, and the boron, lead and aluminum composite board can be used for single irradiation protection and can also be used for various types of radiation protection.

Owner:TAIYUAN UNIV OF TECH

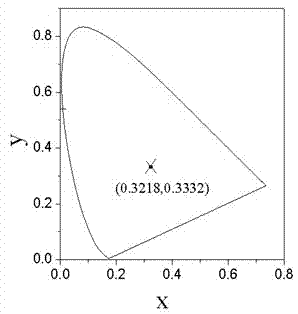

Preparation method of white fluorescent powder containing europium terbium beryllium polymer

ActiveCN102887973AGood luminous purityImprove luminous efficiencyGroup 3/13 element organic compoundsGroup 2/12 element organic compoundsUltraviolet lightsEuropium

The invention relates to a preparation method of white fluorescent powder containing europium terbium beryllium polymer. The method comprises the steps of: firstly, preparing red europium complex, green beryllium complex and blue beryllium complex; and carrying out polymerization reaction in a four-hole boiling flask, and washing, leaching, drying and grinding to prepare the white fluorescent powder containing the europium terbium beryllium polymer. According to the preparation method, the process is advanced, the data is accurate, the light emitting purity of the white fluorescent powder is good, and the luminous efficiency is high; chromaticity coordinates under 365nm of ultraviolet light excitation are that x is 0.3218 and y is 0.3332, and the preparation method is an ideal method for preparing the white fluorescent powder containing the europium terbium beryllium polymer.

Owner:SHANXI FEIHONG MICRO NANO PHOTOELECTRONICS SCI & TECH

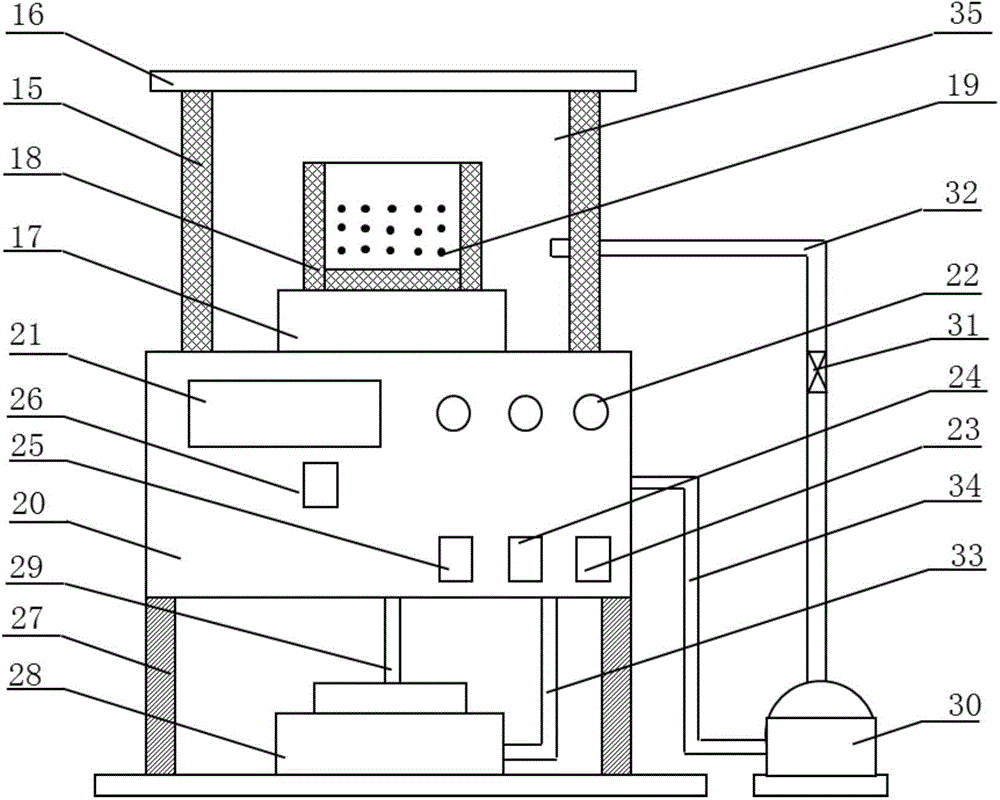

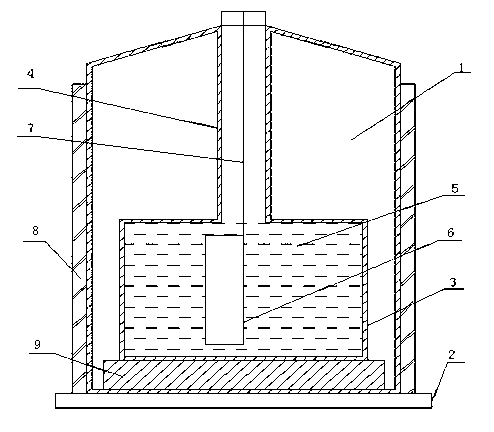

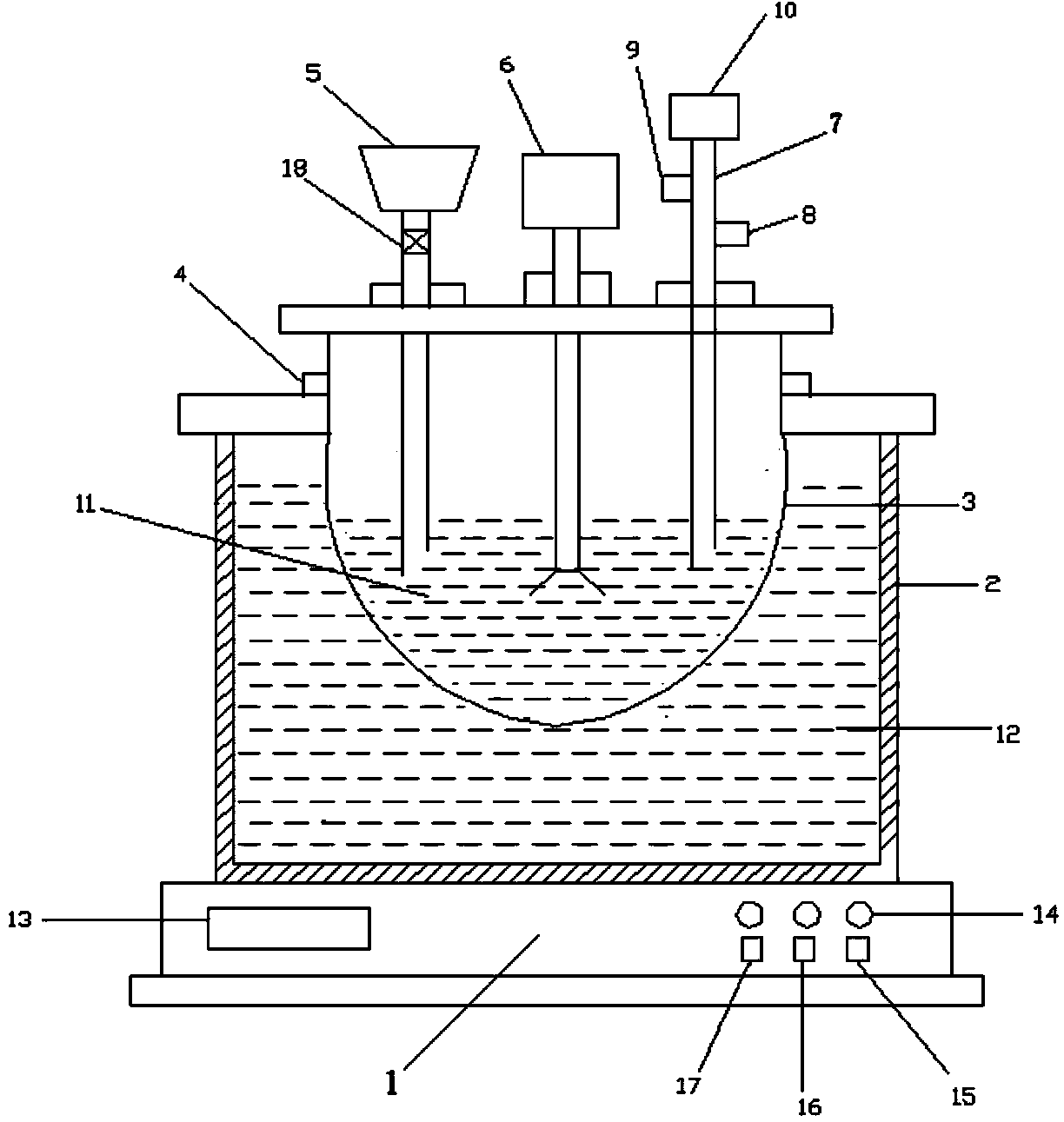

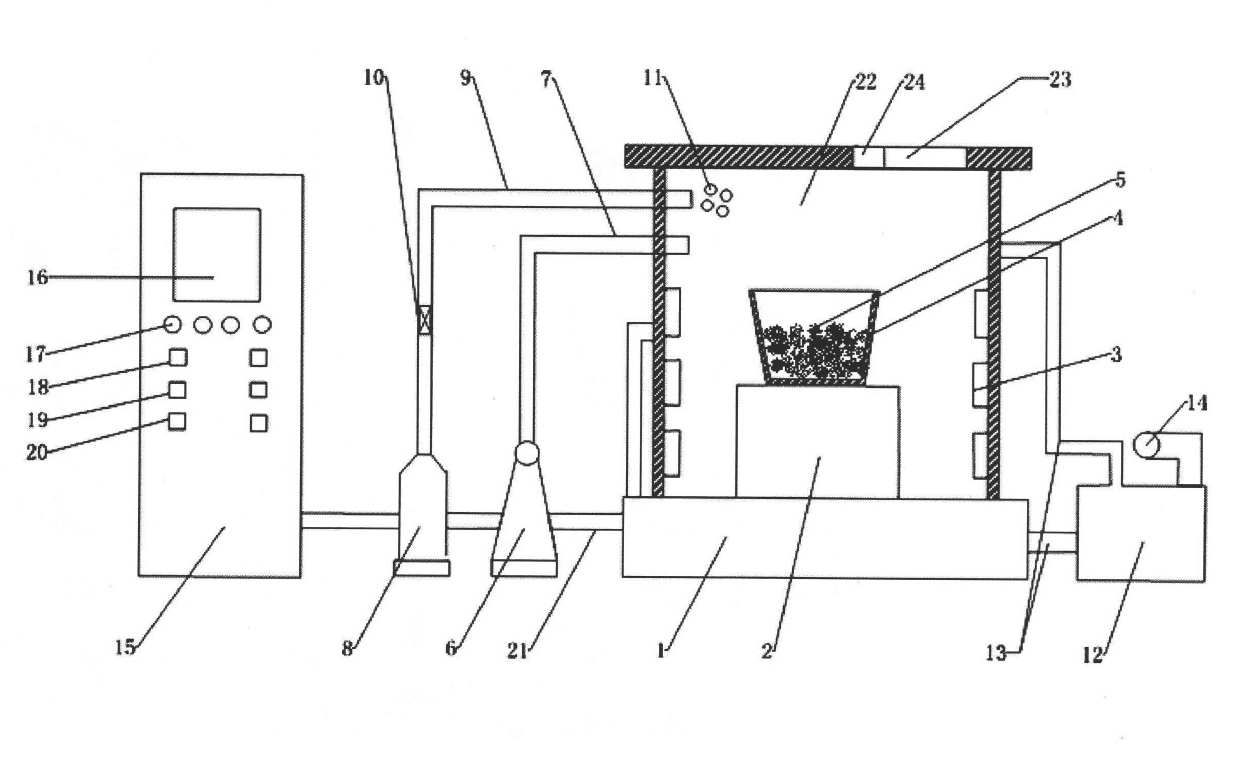

Method for preparing core-shell type flame retardant

ActiveCN103436270AAdvancedHigh purityPigment treatment with organosilicon compoundsWater circulationDyeing

The invention relates to a method for preparing a core-shell type flame retardant. According to the method, the stability of thermal performance of a carbon microsphere is combined aiming at the defects of a flame-retardant property of magnesium hydroxide, and the carbon microsphere is coated by the magnesium hydroxide so as to form a core-shell structure. The method comprises the following steps: preparing a carbon microsphere in a high-pressure heating furnace reaction kettle, preparing an aqueous solution of a silane coupling agent, magnesium hydroxide slurry and a carbon microsphere and ethanol mixed solution, preparing a core-shell type magnesium hydroxide coated carbon microsphere in a water bath heating, stirring and water circulation condensation state in a three-necked flask, washing, filtering, performing vacuum drying and grinding to prepare a nanoscale final product. The preparation method is advanced in process and detailed and accurate in data, the product refers to grey powder particles, the diameter of the particles is less than or equal to 700 nm, the thickness of the coating layer is 15-50 nm, the purity reaches up to 98 percent, and the core-shell type flame retardant is good in flame-retardant effect and high in matching property and can be applied to serving as a flame-retardant material in textile manufacturing, printing and dyeing and high-additional value industries.

Owner:TAIYUAN UNIV OF TECH

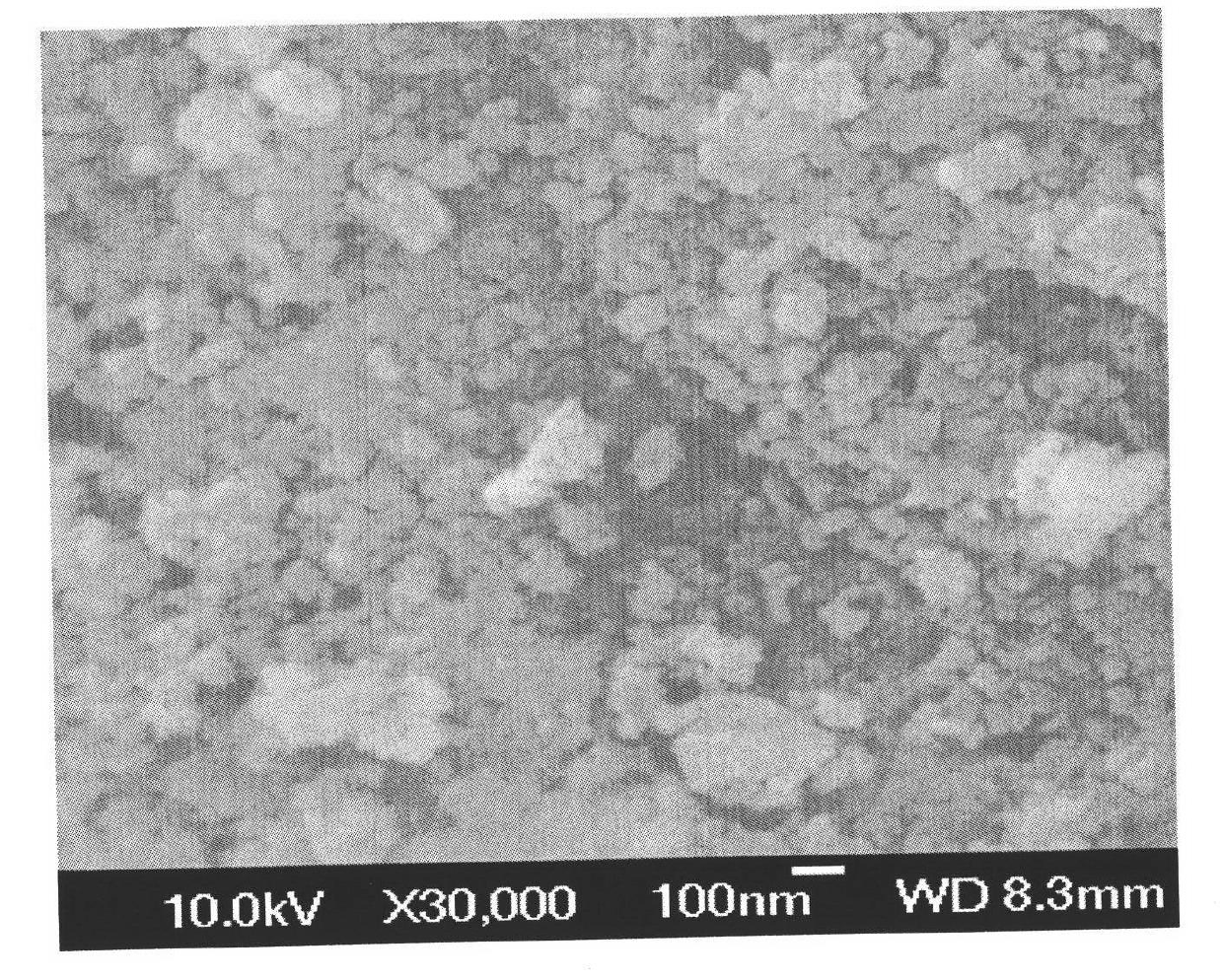

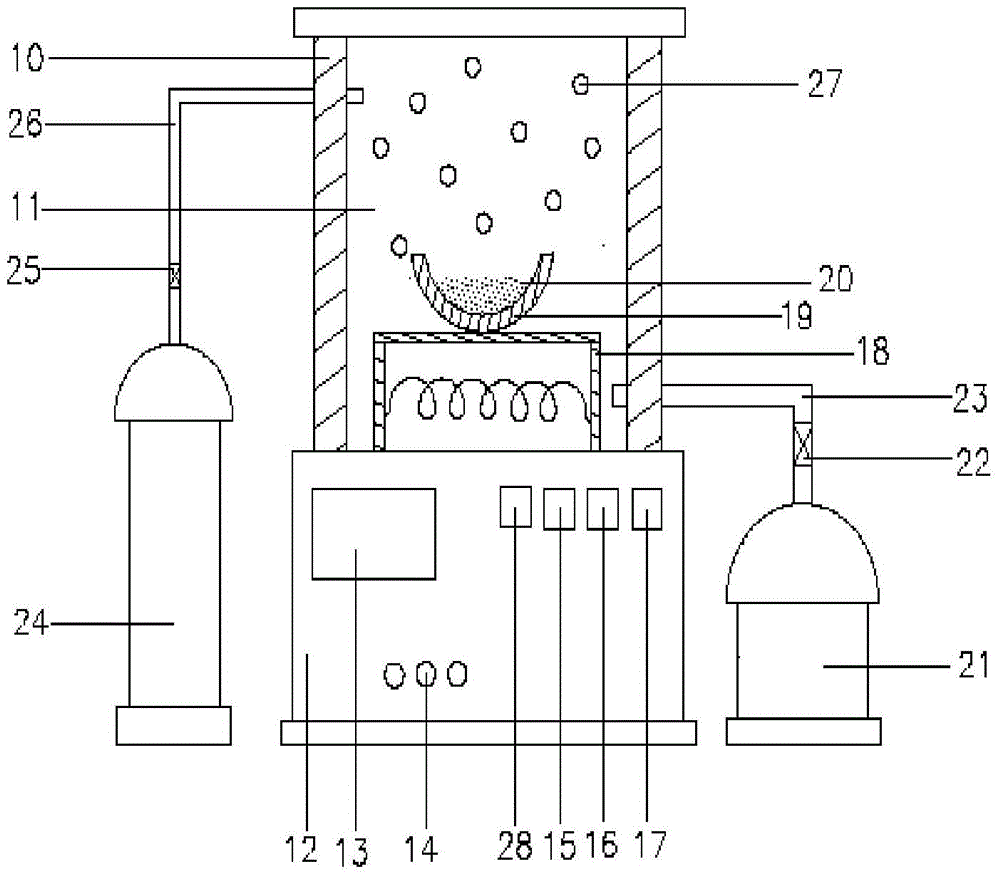

Method for preparing catalyst for coke-oven gas methanation

InactiveCN102389826AImprove stabilityGood anti-knot effectPhysical/chemical process catalystsGaseous fuelsDecompositionMethanation

The invention relates to a method for preparing a catalyst for coke-oven gas methanation, which belongs to preparation aiming at the practical application condition of the coke-oven gas methanation. The catalyst uses Gamma-phase alumina as a carrier, silicon carbide as a wave-absorbing material, nickel oxide as an active ingredient and cerium oxide as an auxiliary agent, the grinding, the sieving, the solid-phase mixing, the microwave heating and the calcining decomposition are adopted, the sage green powder solid catalyst is finally synthesized, the content of the product active component ofthe nickel oxide is 19.67 percent, the crystal grain diameter is smaller than or equal to 100nm, in addition, the dispersion is uniform, and the methanation can be fast completed through the mixing with coke-oven gas, so the coke-oven gas is better applied. The preparation method has the advantages that the process is advanced, the flow process is short, the operation is simple and convenient, the preparation time is short, the energy consumption is low, the material proportion is reasonable, the data is full and accurate, the product stability is good, the methanation of the coke-oven gas under the condition of supplementing the carbon dioxide can be realized, and the method belongs to an ideal method for preparing the catalyst for the coke-oven gas methanation.

Owner:TAIYUAN UNIV OF TECH

Preparation method of carbon fiber strengthened aluminum-base-layer-shaped composite board

The invention relates to a preparation method of a carbon fiber strengthened aluminum-base-layer-shaped composite board, and aims to solve the condition that the intensities of aluminum and aluminum alloy are low and the tenacity is poor. According to the preparation method, aluminum powder and carbon fiber cloth are heated, fused and combined, vibrated and pressurized so as to manufacture an aluminum base-layer-shaped composite board, the carbon fiber strengthened aluminum base-layer-shaped composite board is manufactured on a heating and vibrating press machine in a heating, pressurizing and vibrating process, so that a nine-layer structure is formed, an aluminum solution is utilized for wetting the carbon fibers under low temperature, pressure and vibration actions, and a fragility compound can not be formed, so that the organization structure is compact, the tensile strength achieves 144MPa, the elongation achieves 21.2%, the process is advanced, the data is full and accurate, the process flow path is short, and the preparation method is an ideal method for preparing the carbon fiber strengthened aluminum base-layer-shaped composite board.

Owner:TAIYUAN UNIV OF TECH

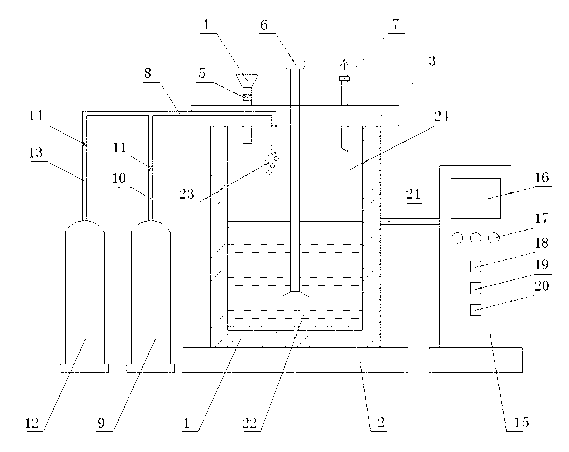

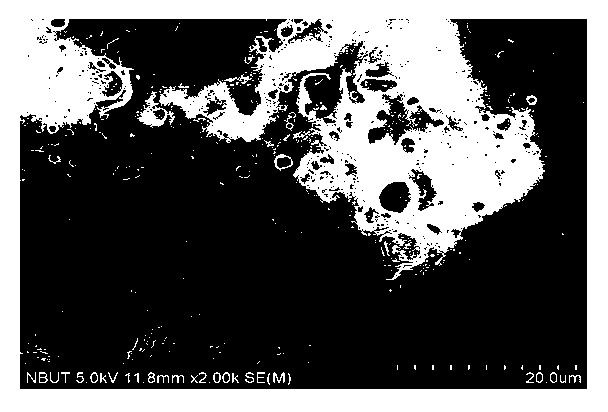

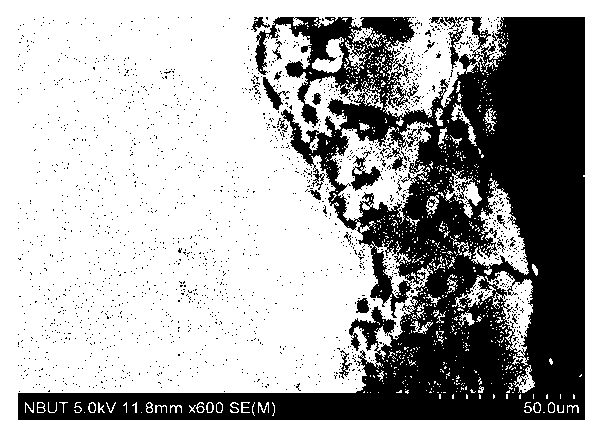

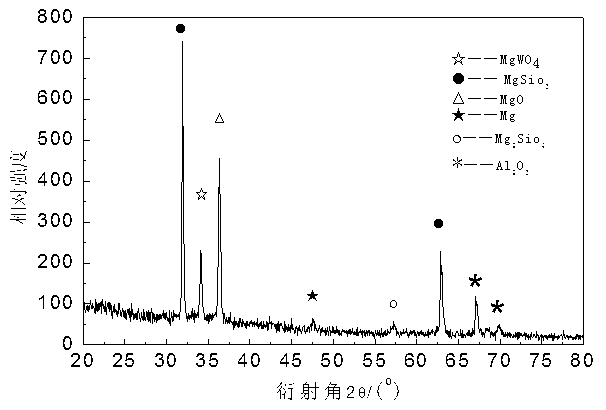

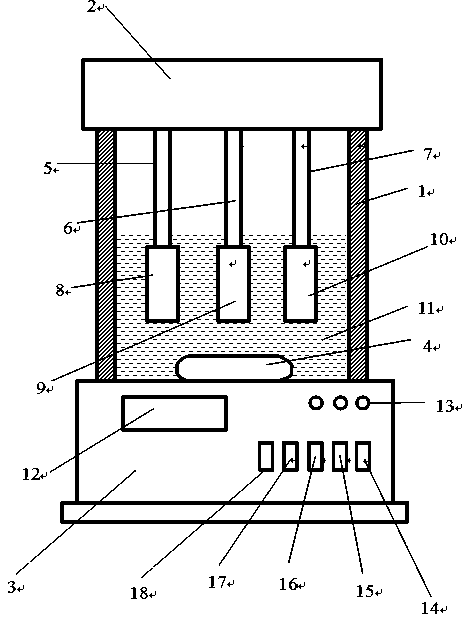

Method for coating film on magnesium alloy plate by microarc oxidation

The invention relates to a method for coating a film on a magnesium alloy plate by microarc oxidation. According to the method, the film is coated on the magnesium alloy plate in electrolyte of sodium silicate, sodium tungstate, glycerol, sodium hydroxide and alumina hydrocolloid; during film coating, the film is coated in the electrolyte of sodium silicate, sodium tungstate, glycerol and sodium hydroxide under the action of pulse direct -current electric field; then alumina hydrocolloid is added to the electrolyte, and a composite film layer is formed on the surface of the magnesium alloy plate; the thickness of the film layer reaches 75 mu m; the composite film layer can be adhered firmly and is high in compactness and corrosion resistance, and few holes are formed on the surface of the composite film layer; the method for coating the film is advanced in process, data is detailed and accurate, the film layer is high in thickness, fixation performance and compactness and does not fall easily; and the invention provides an effective method for coating the film on the surface of the magnesium alloy plate.

Owner:TAIYUAN UNIV OF TECH

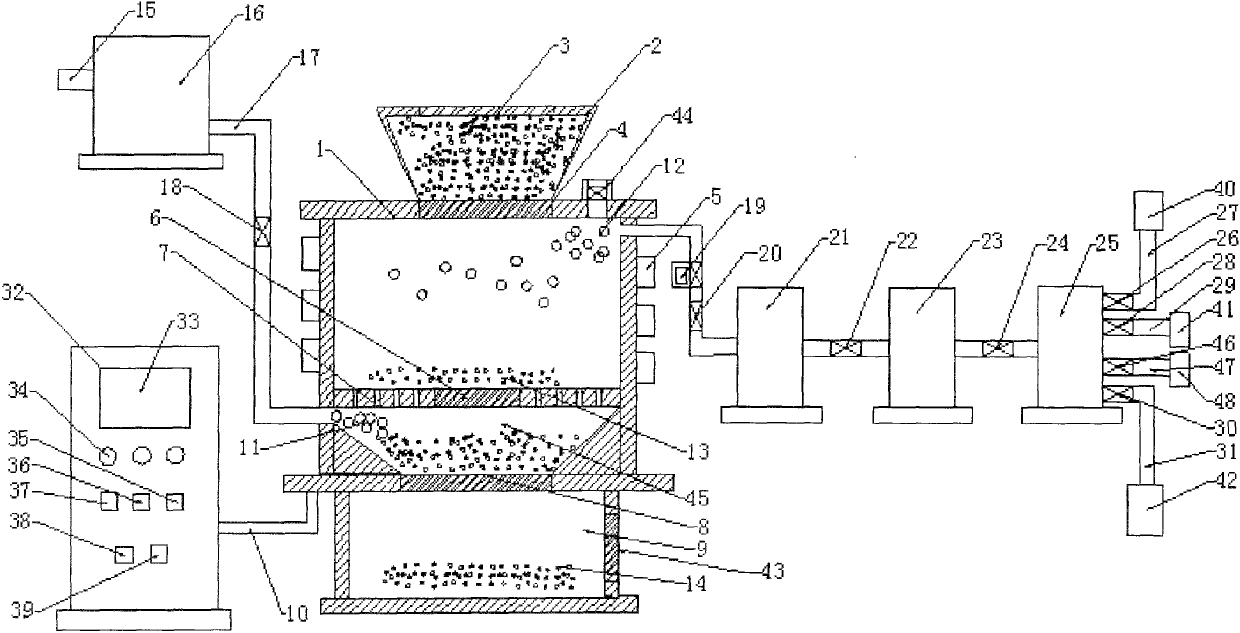

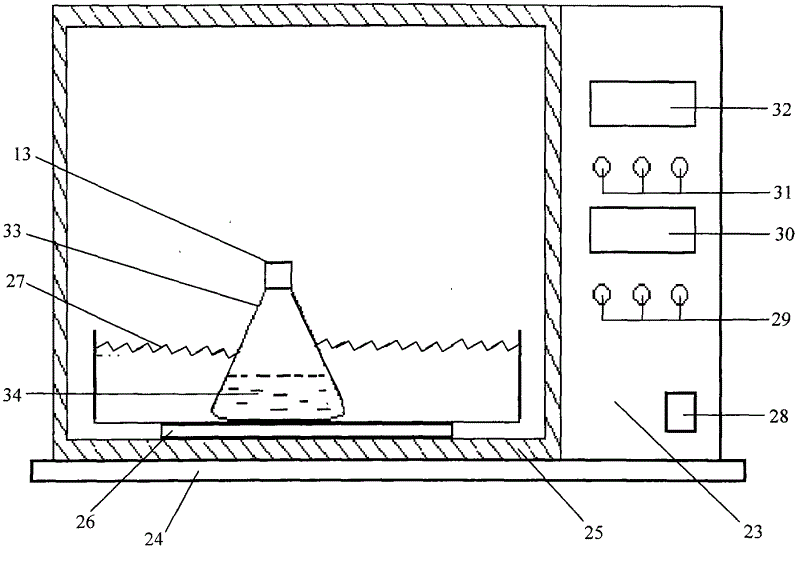

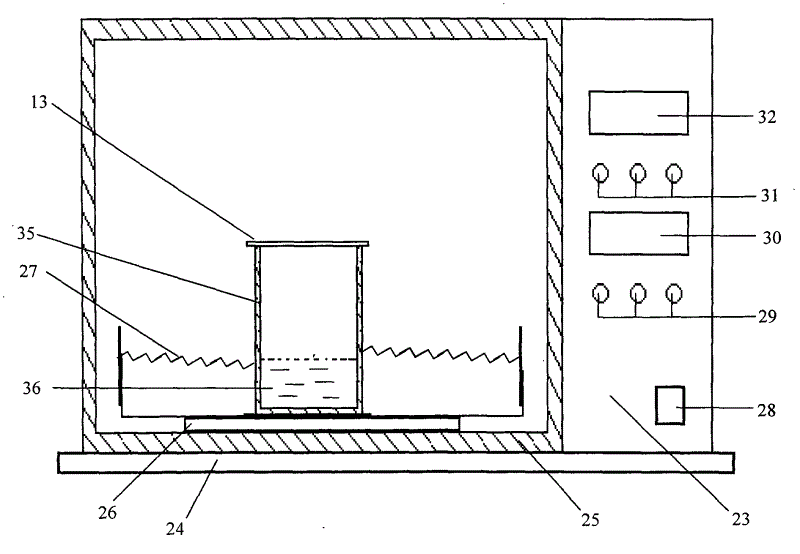

Method for treating oxygen-bearing coalbed methane by using coal gangue

ActiveCN103131491APollution controlAdvanced technologySolid waste disposalGaseous fuelsOxygenLiquid gas

The invention relates to a method for treating oxygen-bearing coalbed methane by using coal gangue. According to the method, the oxygen-bearing coalbed methane is used as raw material, and the coal gangue is used as a catalytic deoxidizing agent, and thermo-chemical treatment is conducted in a microwave oven; deoxidized and desulfurized methane liquefied gas, liquefied carbon dioxide and liquefied nitrogen are prepared through desulfurization purification, pressure swing adsorption separation and compression under the action of the coal gangue and the oxygen-bearing coalbed methane, and meanwhile, an aluminosilicate mixture is obtained through decarburization of the coal gangue; and the liquefied methane and tail gas can be used as burning energy, the liquefied carbon dioxide can be used as chemical material, the liquefied nitrogen is used as inert protective gas, and the aluminosilicate mixture can be used as the chemical material. The treating method has the advantages that process is advanced, data is full and accurate, the waste coal gangue is used, the oxygen-bearing coalbed methane is treated, coal gangue pollution and coalbed methane pollution are treated, new products are obtained, and a double-advantage of the process is achieved.

Owner:TAIYUAN UNIV OF TECH +1

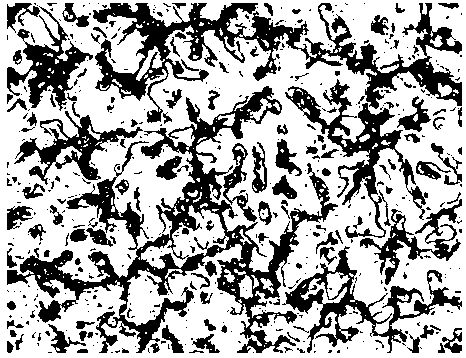

Method for preparing heat-resisting magnesium alloy containing silicon, zirconium and beryllium

The invention relates to a method for preparing heat-resisting magnesium alloy containing silicon, zirconium and beryllium. The method comprises the following steps of: adding magnesium-silicon intermediate alloy, magnesium-zirconium intermediate alloy and aluminum-beryllium intermediate alloy in the process of melting magnesium alloy, smelting to obtain a magnesium-alloy ingot, and carrying out vertical equal-channel pressing on the magnesium-alloy ingot for 8 times to obtain the heat-resisting magnesium alloy. The room-temperature tensile strength of the magnesium-alloy ingot subjected to casting and equal-channel pressing is 225MPa and the high-temperature creep resistance is 68h, while the room-temperature tensile strength of the as-cast magnesium-alloy ingot is 127Mpa and the creep rupture life is 0.86h. The elongation rate of the magnesium-alloy ingot is increased to 22% from 7.6%, and the metallographic structure has good compactness. The advanced process is adopted by the method, the data are full and accurate, the product has good heat resistance, and the method is a very ideal method for preparing the heat-resisting magnesium alloy.

Owner:TAIYUAN UNIV OF TECH

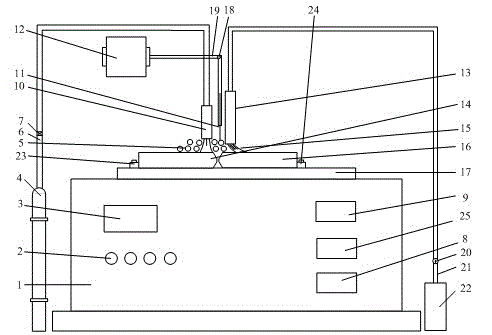

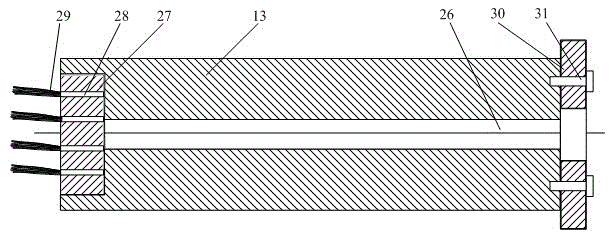

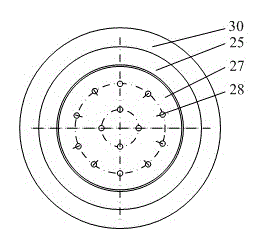

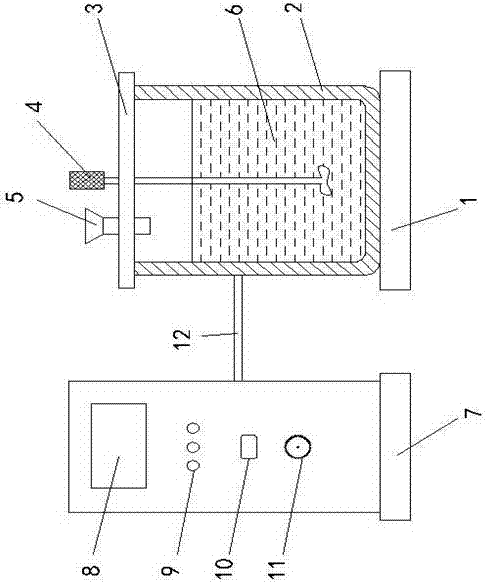

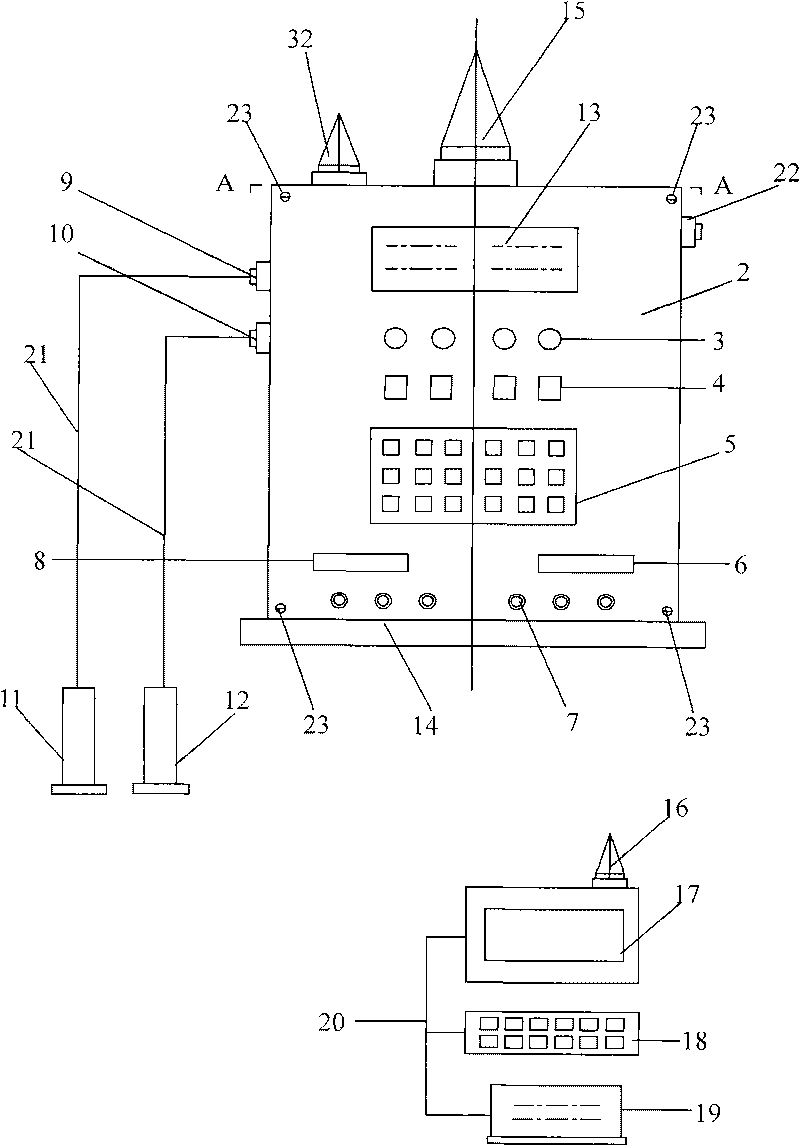

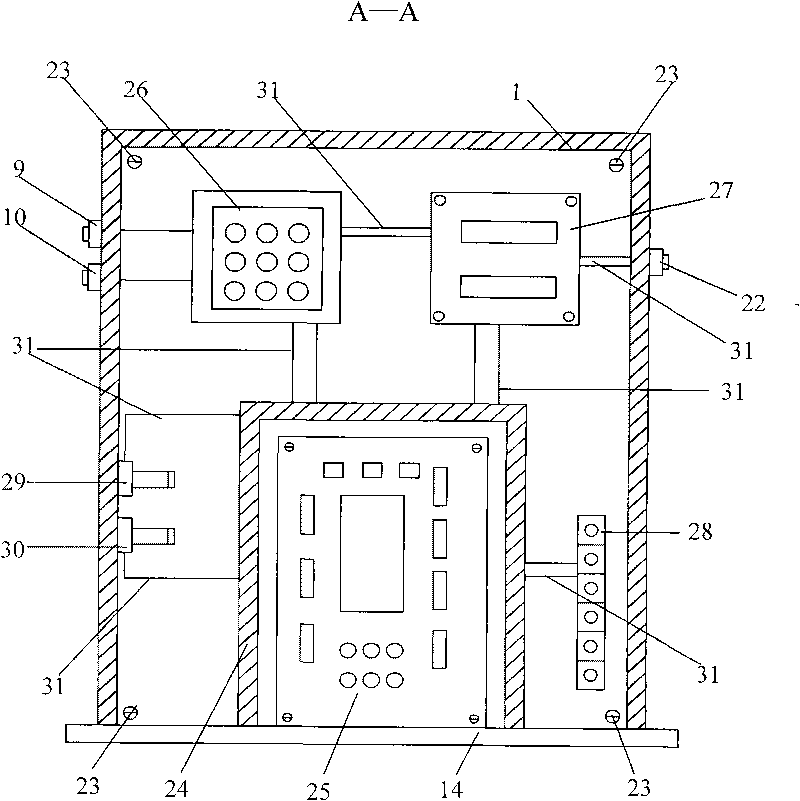

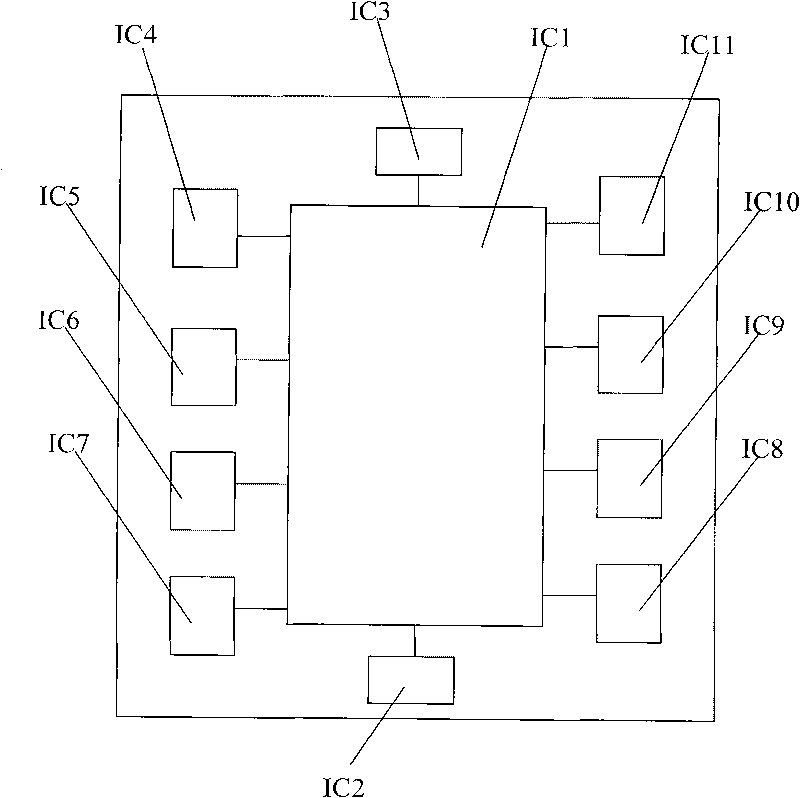

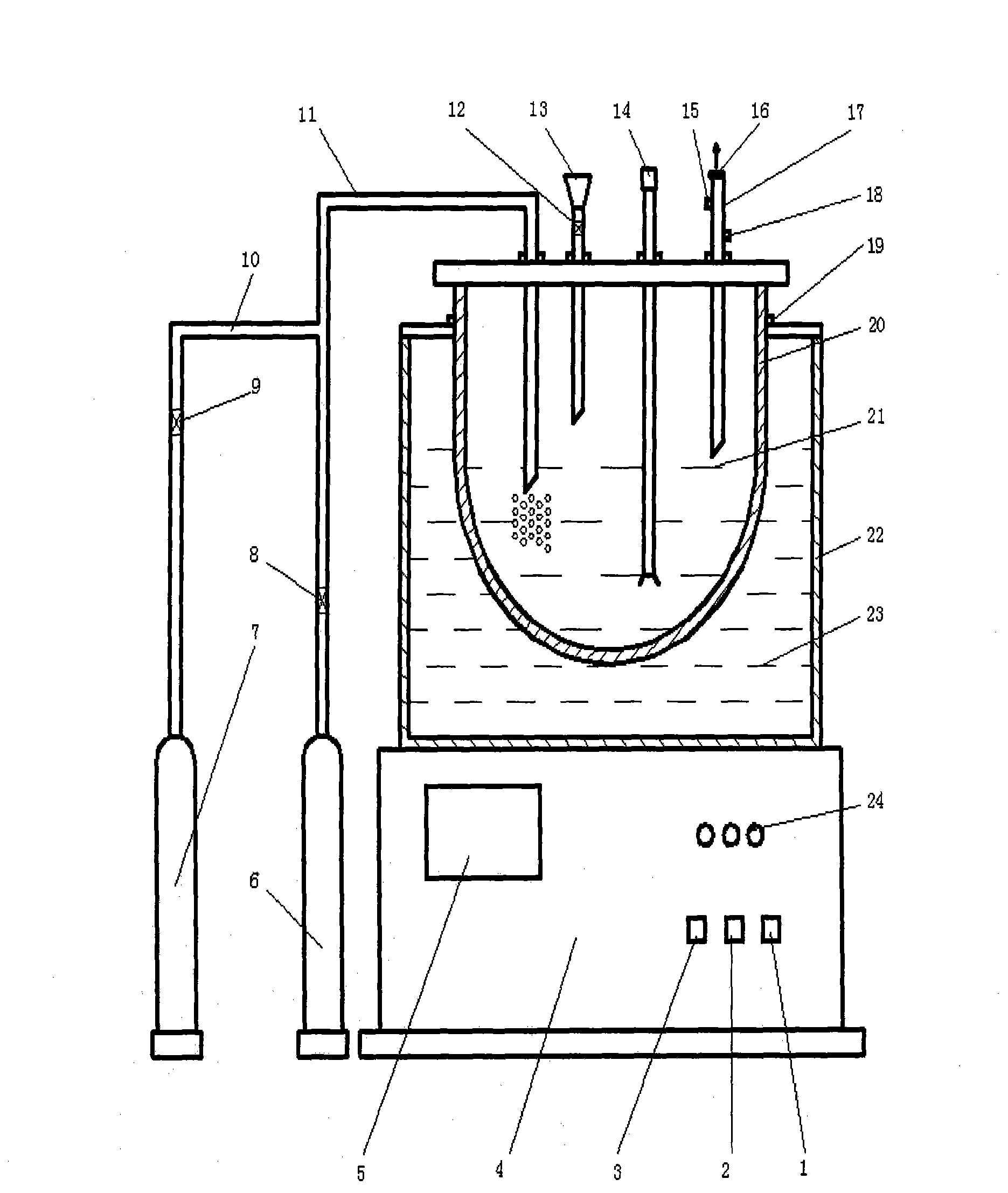

Remote monitoring device for water flow

InactiveCN101726335ARealize remote monitoring and controlAdvancedTransmission systemsVolume/mass flow measurementChemical industryEngineering

The invention relates to a remote monitoring device for water flow, which is mainly controlled by a main control computer. The remote monitoring device is provided with a plurality of terminal cases for sub-control; a GPRS wireless communication transmitter transmits water flow information to realize multi-terminal and long-distance monitoring for the water flow; a dual-shielding control circuit, an ultrasonic flow meter, a water flow sensor, a counting card socket, a sound control alarm, a liquid crystal display, an operating keyboard, an AC / DC transformer and the like are arranged on the terminal case; and the main control computer is controlled by a computer program to calculate and process. The device has the advantages of advanced and reasonable design, compact structure, safety, stability, reliability and accurate and detailed data, realizes remote monitoring and control on the flow of scattered water resources, fills the blank of the technology, is a quite ideal remote monitoring device for the water flow, and also can be used for remote monitoring and control on sites of petroleum, chemical industry, heating, food and the like.

Owner:TAIYUAN UNIV OF TECH

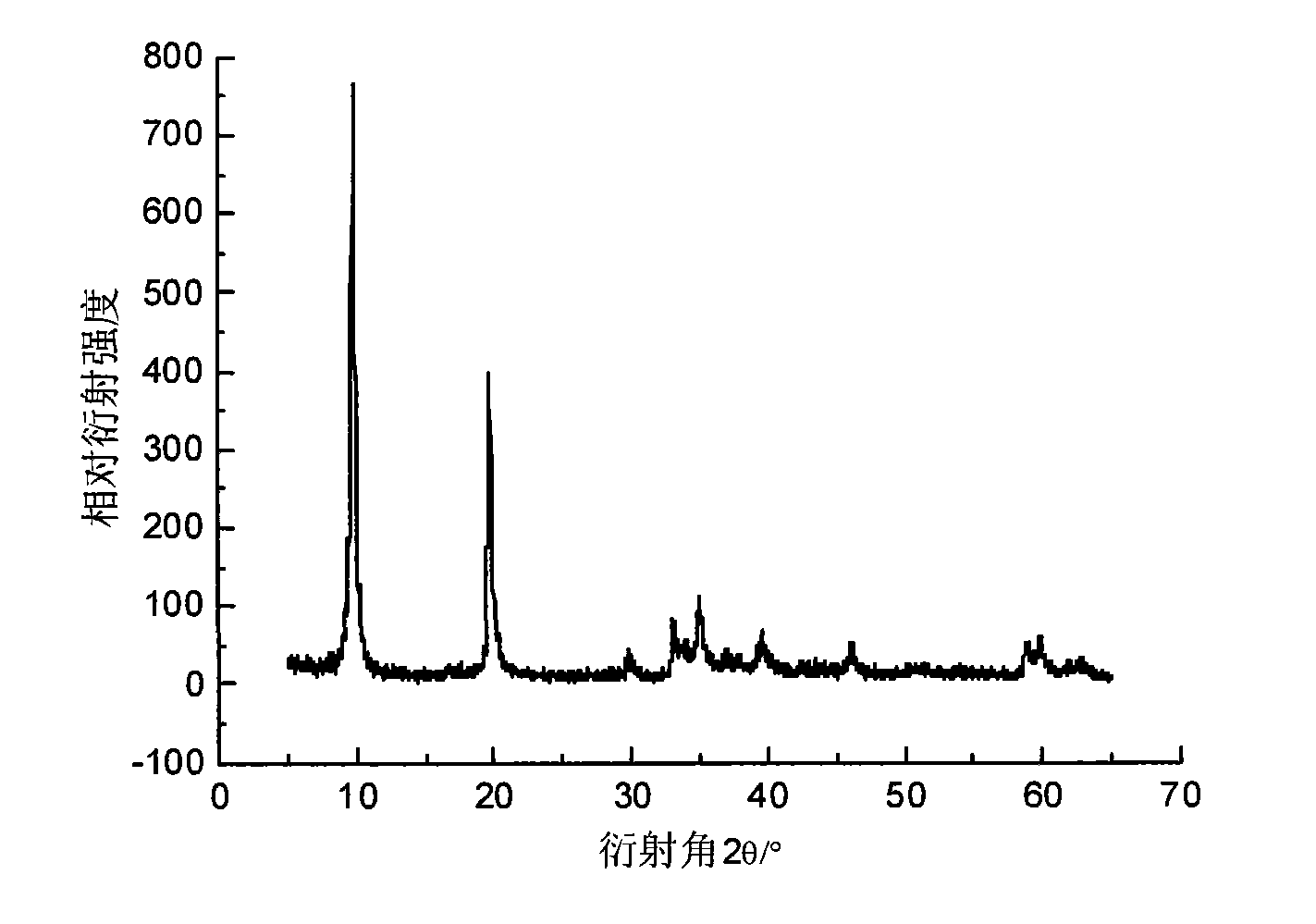

Method for rapidly preparing nanocrystalline zinc-iron hydrotalcite

The invention relates to a method for rapidly preparing nanocrystalline zinc-iron hydrotalcite. The method comprises the following steps of: performing solution preparation, heating, stirring, water circulation condensing, nitrogen protection and a combination reaction under oxygen oxidation with a uniform precipitation method by taking zinc sulfate and ferrous sulfate as raw materials, taking hexamethylene tetramine as a precipitating agent, taking deionized water as a solvent and a washing agent, taking absolute ethanol as a washing agent, taking nitrogen as protection gas and taking oxygen as an oxidant; and washing, performing suction filtration, drying in vacuum, grinding and screening to obtain nanocrystalline zinc-iron hydrotalcite. The preparation method has the advantages of advanced and precise process, high preparation speed, detailed and accurate data and high product purity, which can be up to 99 percent; the product zinc-iron hydrotalcite is an irregular hexagonal flaky crystal which is less than or equal to 80 nanometers in diameter, and can be matched with a plurality of chemical substances; and the method is very ideal method for rapidly preparing nanocrystalline zinc-iron hydrotalcite.

Owner:TAIYUAN UNIV OF TECH

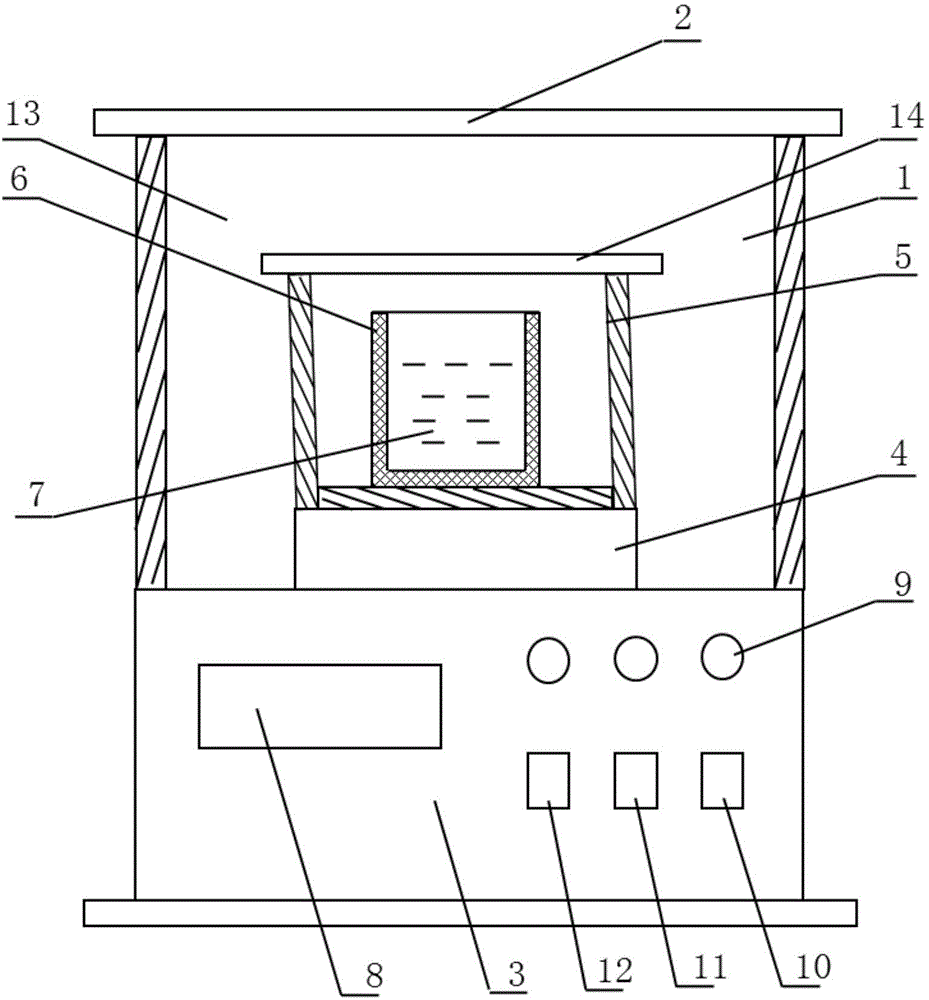

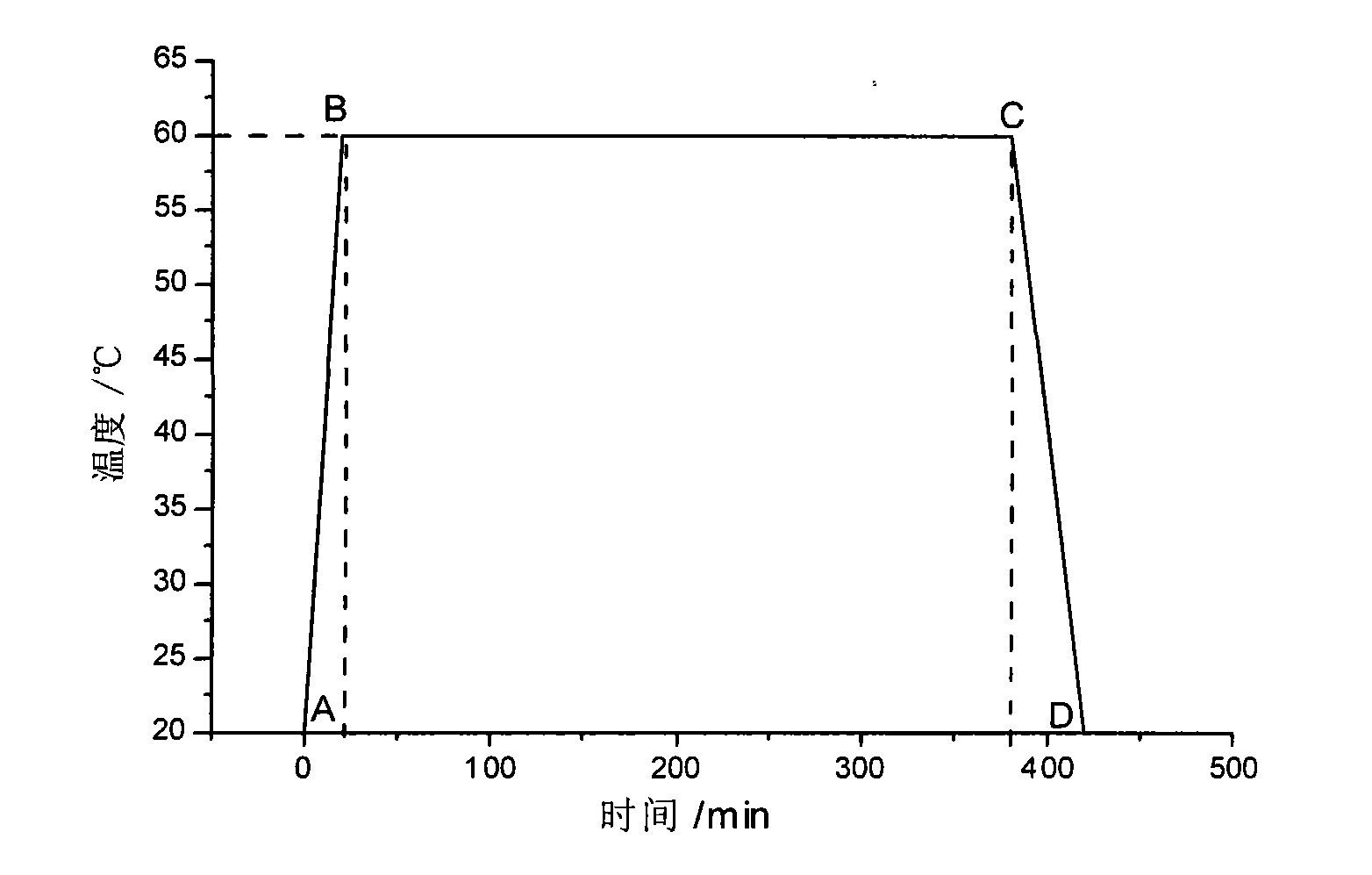

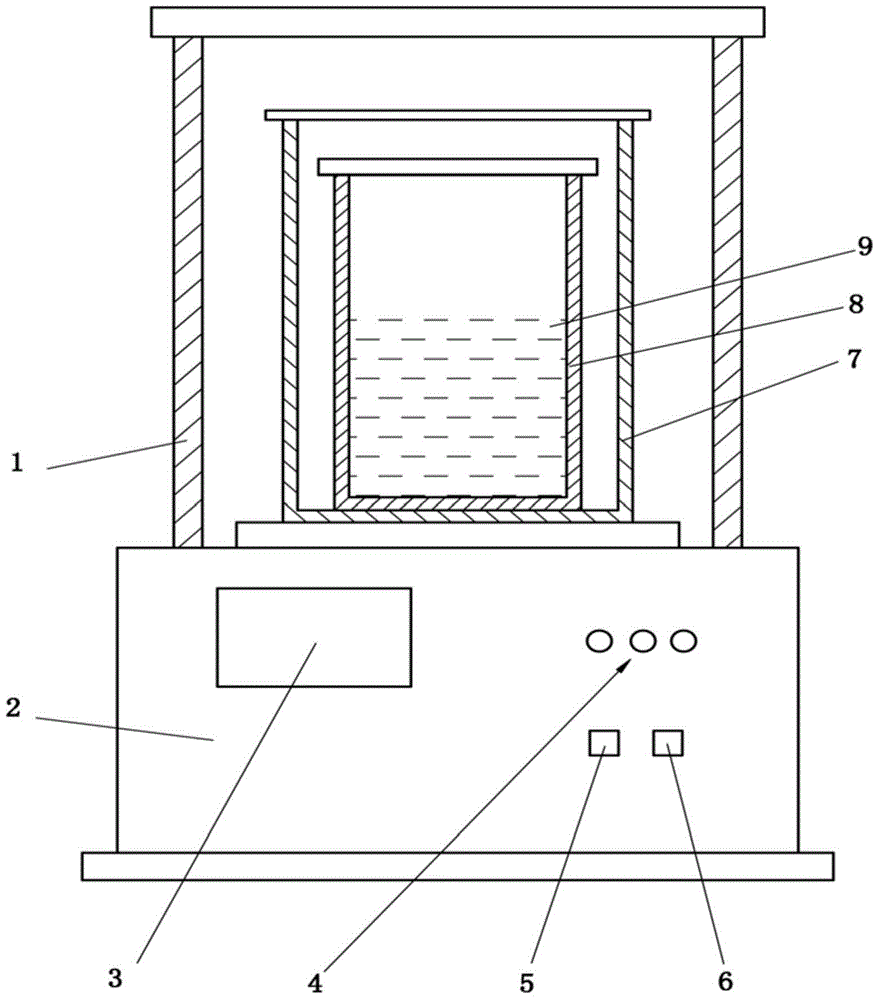

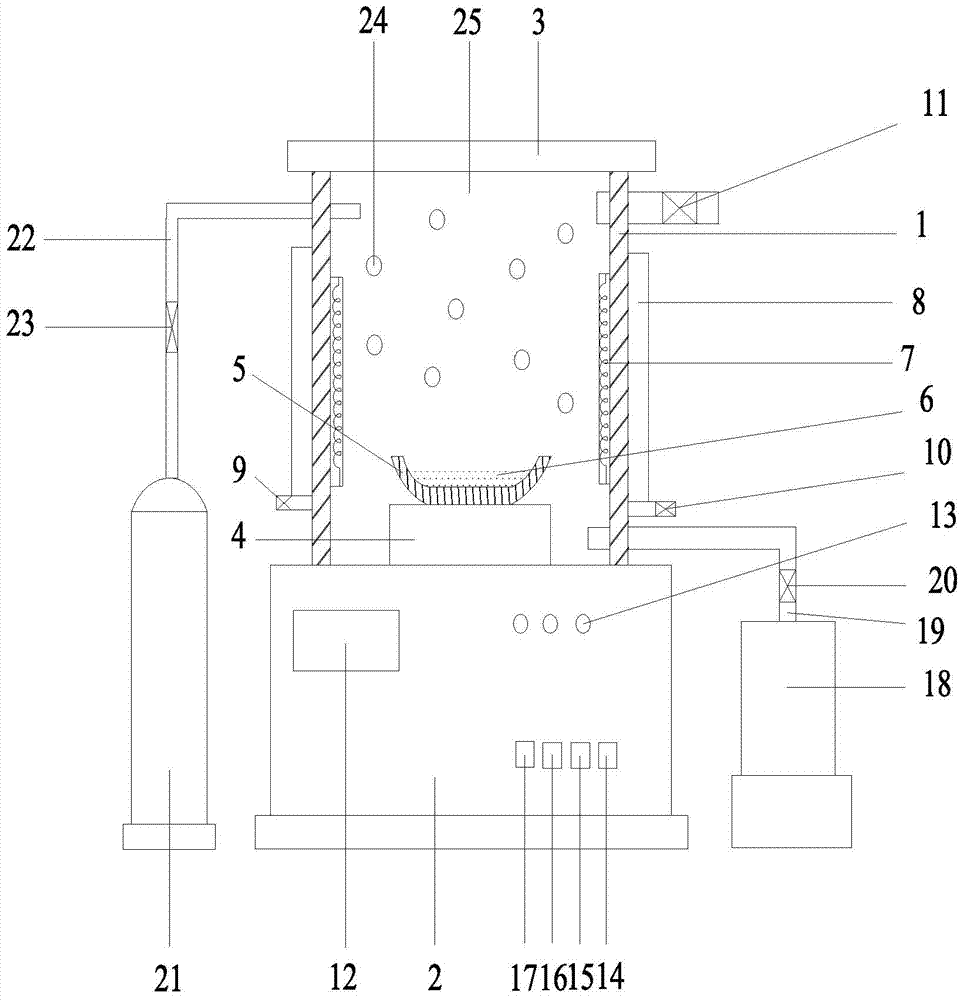

Preparation method of multistage pore passage composite molecular sieve adsorbent

InactiveCN103949204AAdvancedInformative and accurate dataOther chemical processesAluminium silicatesSorbentThermostat

The invention relates to a preparation method of a multistage pore passage composite molecular sieve adsorbent for overcoming a phenomenon that volatile organic compounds pollute environment. Silicon sol, tetraethoxysilane, aluminum sulfate, sodium hydroxide, hydrochloric acid, hexamethonium bromide, hexadecyl trimethyl ammonium bromide and deionized water are used as raw materials, and the preparation method comprises the steps of synthesizing a ten-ring microporous molecular sieve firstly, then synthesizing a micropore-mesoporous molecular sieve, and finally performing procedures of heating in a thermostat, crystallization reaction in a reaction kettle, quenching, vacuum drying, and high-temperature roasting, thereby obtaining the multistage pore passage composite molecular sieve adsorbent. The preparation method has advanced process and accurate and full data, and the prepared multistage pore passage composite molecular sieve adsorbent has the grain diameter of less than or equal to 1.5 microns, the pore passage diameter of less than and equal to 2.83nm and the purity up to 96%; the multistage pore passage composite molecular sieve adsorbent can be directly used as a volatile organic compound adsorbent, or can be matched with multiple chemical substances to serve as an adsorbing material; the preparation method of the multistage pore passage composite molecular sieve adsorbents is ideal.

Owner:TAIYUAN UNIV OF TECH

Preparation method of titanium dioxide/cuprous oxide coaxial heterostructure

InactiveCN103710737APromote absorptionAdvancedElectrolytic inorganic material coatingSurface reaction electrolytic coatingUltraviolet lightsSolar power

The invention relates to a preparation method of a titanium dioxide / cuprous oxide coaxial heterostructure. On the basis of photocatalytic efficiency of titanium dioxide and conductivity of cuprous oxide, an electrochemical electrolytic oxidation process is utilized to firstly prepare a titanium dioxide nanotube array substrate and then prepare the titanium dioxide / cuprous oxide coaxial heterostructure product. The preparation method has the advantages of advanced technique and accurate and complete data. The product is yellow and flaky, the cross section is rectangular, and the titanium dioxide and cuprous oxide are combined through chemical bond. The product has obvious absorption action on ultraviolet light and visible light, and the current density under the irradiation of visible light is 1.0-1.6 mA / cm<2>. The titanium dioxide / cuprous oxide coaxial heterostructure can be used in solar power generation and photovoltaic products; and the preparation method is a very ideal method for preparing the titanium dioxide / cuprous oxide coaxial heterostructure.

Owner:TAIYUAN UNIV OF TECH

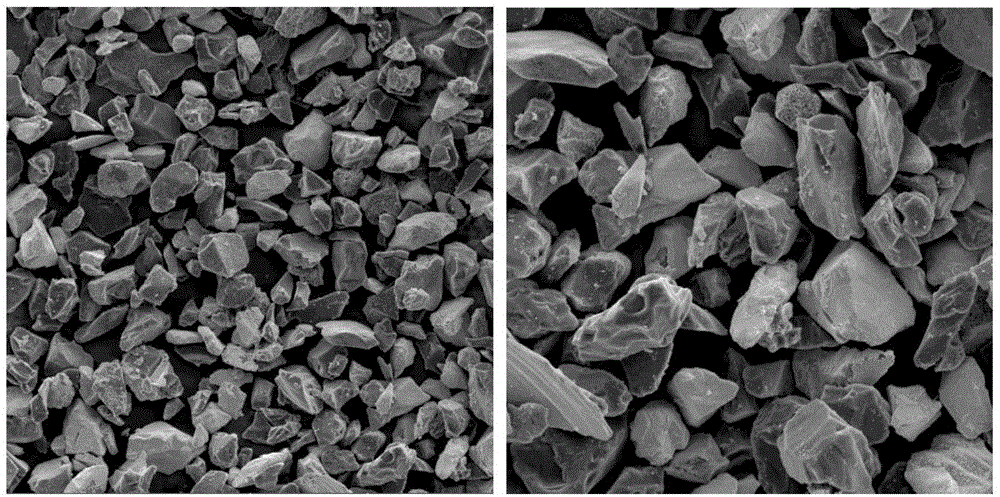

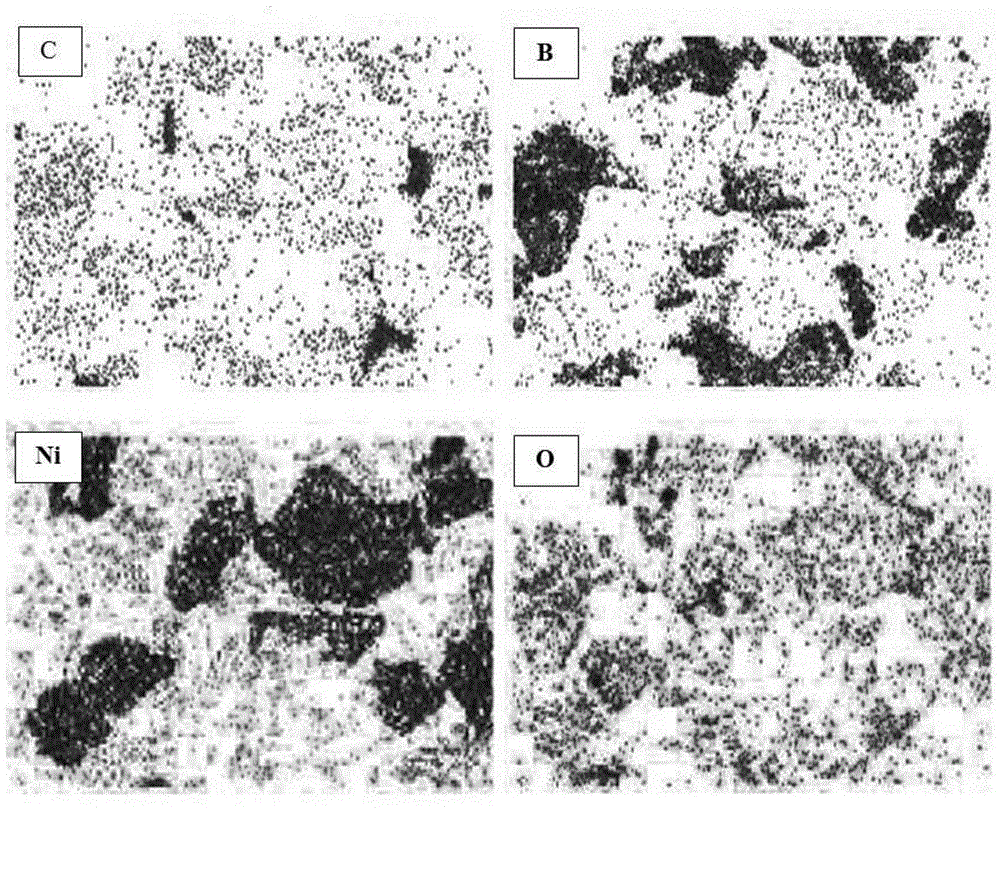

Boron carbide particle surface nickel plating method

InactiveCN104630751AImprove wettabilityGood compatibilityLiquid/solution decomposition chemical coatingBoron carbideHardness

The invention relates to a boron carbide particle surface nickel plating method. The surface nickel plating method is used for solving the cases of low fracture toughness, high sintering hardness, poor oxidation resistance and poor composite wettability to the interface between the boron carbide particles and metal of the boron carbide particles. By carrying out alkali washing, pickling, roughening, sensitizing, activating and surface nickel-plating on boron carbide particles, the surfaces of the boron carbide particles are uniformly plated with a nickel coating, the diameters of the nickel-plated boron carbide particles are less than or equal to 50mu m and the thickness of the nickel coating on the surfaces of the boron carbide particles is less than or equal to 30nm. After the nickel plating, the wettability and matching performance of the surfaces of the boron carbide particles are improved, the nickel plating method is an advanced boron carbide particle nickel plating method, the data are accurate and informative and the boron carbide particle surface coating is uniform in thickness and firm.

Owner:SHANXI ZHONGTONG HIGH TECH +1

Purification treatment method for nickel plating wastewater

InactiveCN102616940AImprove purification rateNo pollutionWaste water treatment from metallurgical processBiological water/sewage treatmentStenotrophomonas maltophiliaReclaimed water

The present invention relates to a purification treatment method for nickel plating wastewater. According to the method, a microbiological method is adopted, nickel plating wastewater is simulated and prepared, microbial bacteria stenotrophomonas maltophilia is cultured, treatments of enrichment and purification are performed, then the bacteria is mixed with the nickel plating wastewater, an oscillation purification treatment is performed on heavy metals in the nickel plating wastewater, wherein the treatment purification efficiency is 98.5%, the reclaimed water standard in the national standard is reached, and the purified water can be used for washing and irrigation farmlands. The purification treatment method of the present invention has the following advantages that: the process is advanced and quick; the process is short; the data is abundant and accurate; the environmental pollution is not generated; the treatment purification efficiency on the nickel plating wastewater is high;the method is suitable for the industrial treatment, and is an ideal nickel plating wastewater purification treatment method; other wastewater containing heavy metals can further be treated and purified by the method of the present invention.

Owner:TAIYUAN UNIV OF TECH

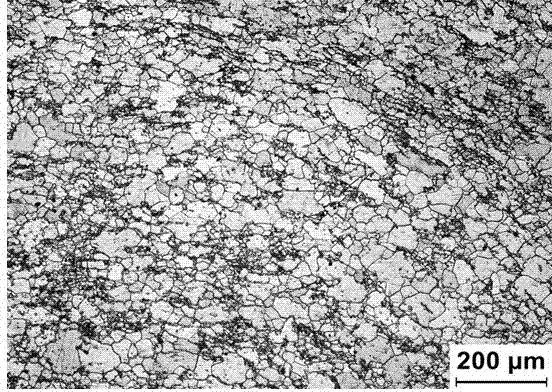

Preparation method of particle-reinforced magnesium-lithium-aluminum-calcium-silicon alloy plate

The invention relates to a preparation method of a particle-reinforced magnesium-lithium-aluminum-calcium-silicon alloy plate, and the preparation method is designed for aiming at a situation that a magnesium-lithium alloy is low in strength, poor in heat resistance and unstable in mechanical properties. The method comprises the following steps: preparing an aluminum-silicon eutectic alloy and a magnesium-aluminum-calcium eutectic alloy firstly; carrying out high-frequency induced heating and melting as well as suction casting on the alloys so as to obtain a magnesium-lithium-aluminum-calcium-silicon alloy ingot; and rolling the alloy ingot by using a roller mill, so that the magnesium-lithium-aluminum-calcium-silicon alloy plate is prepared. The preparation method is advanced in process and detailed and accurate in data, the size of reinforced particles is less than and equal to 200 nm, the reinforced particles are uniformly distributed in an alloy beta-Li matrix, alpha-Mg crystal particles are refined until the granularity of 10 mu m, the yield strength of alloys is 298 Mpa, the tensile strength is 320 Mpa, the elongation reaches 7%, and the mechanical properties of the magnesium-lithium-aluminum-calcium-silicon alloy plate are improved, and the application range of the magnesium-lithium-aluminum-calcium-silicon alloy plate is enlarged, so that the method disclosed by the invention is an extremely ideal reinforced preparation method of a magnesium-lithium-aluminum-calcium-silicon alloy plate.

Owner:TAIYUAN UNIV OF TECH

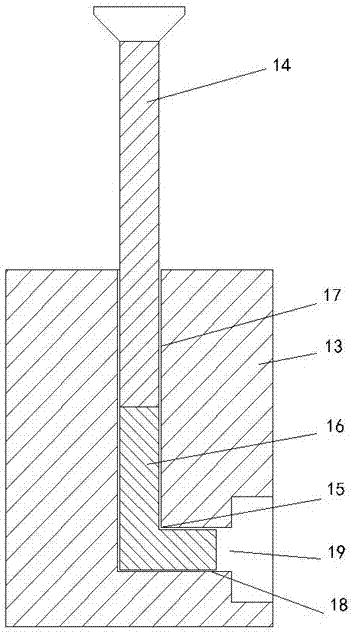

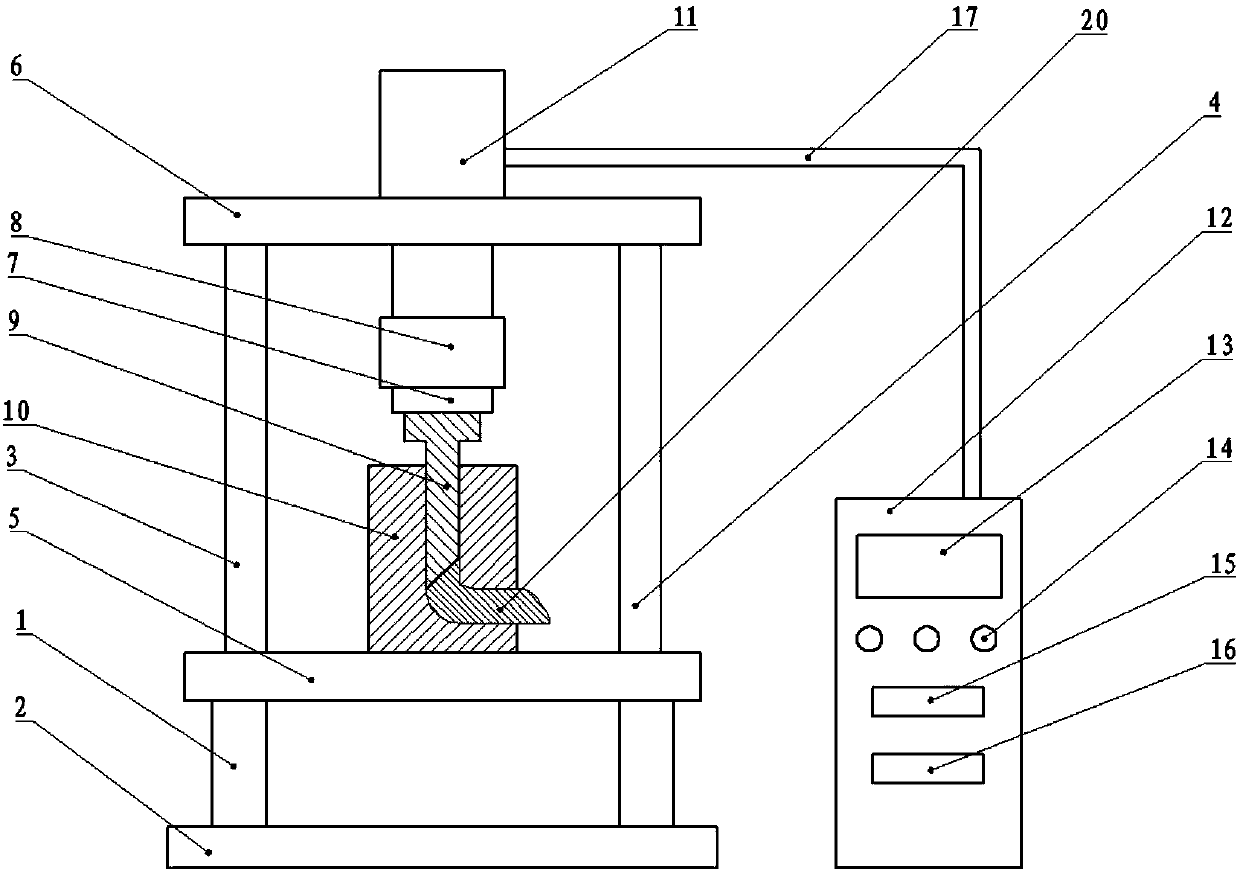

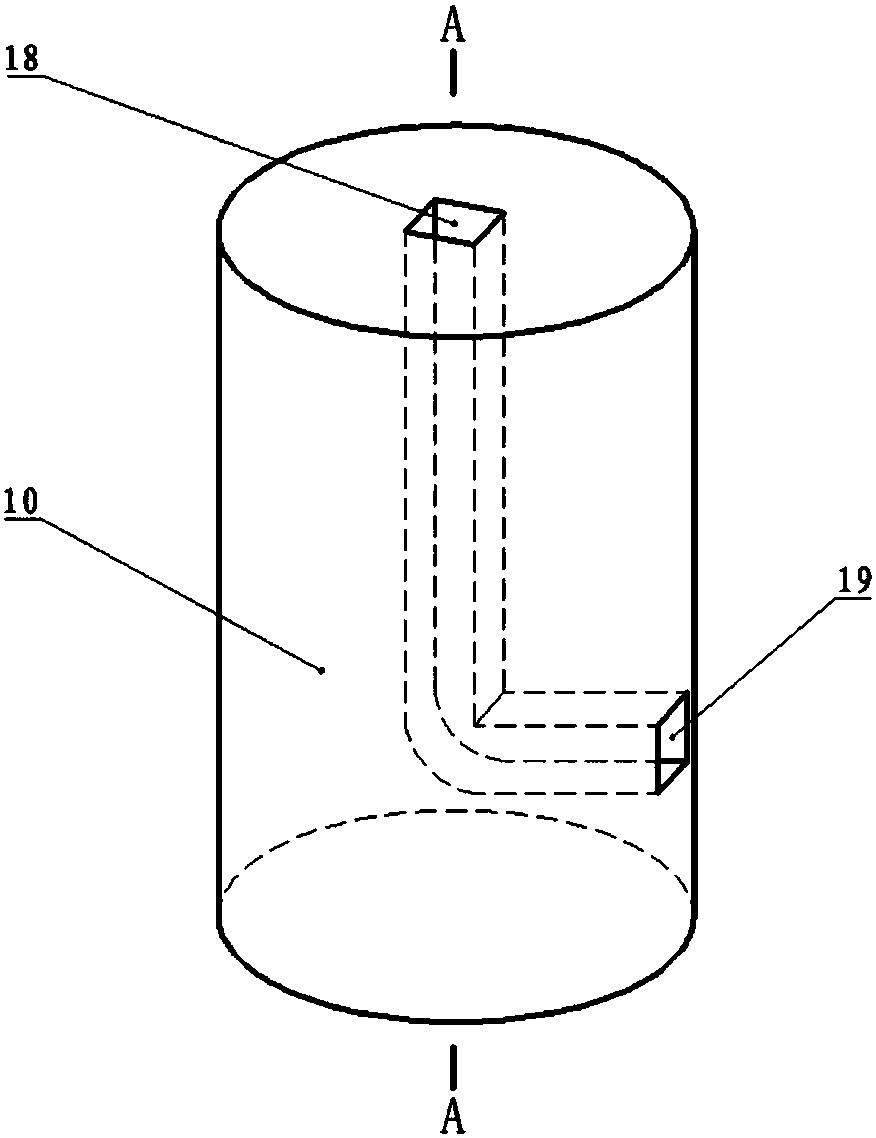

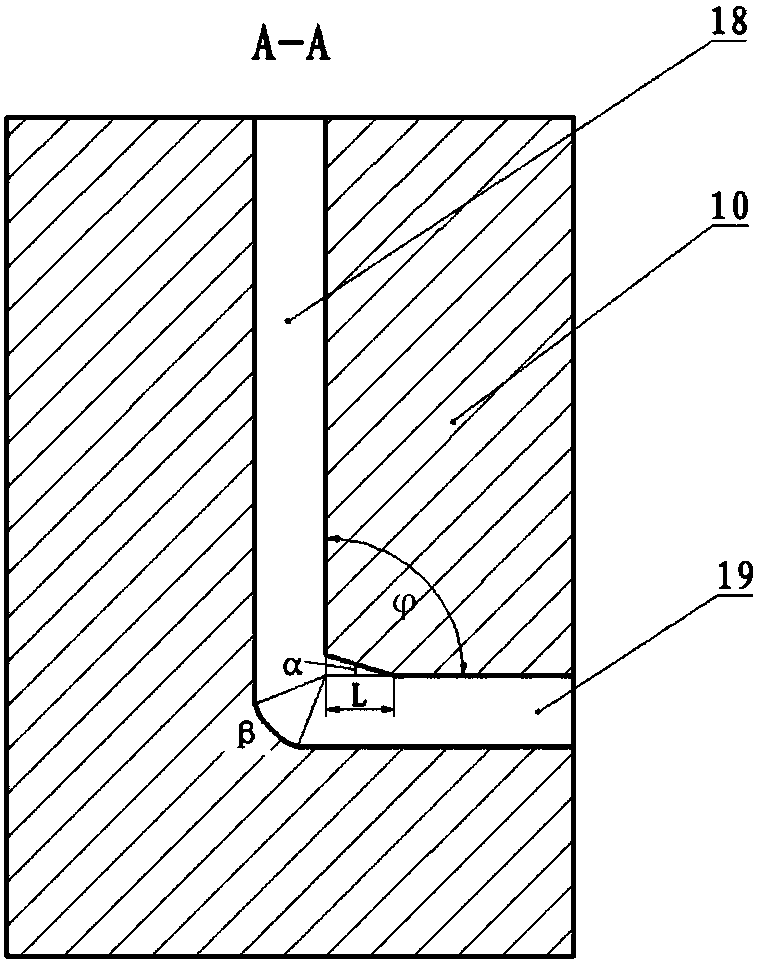

Equal-channel angular pressing method of iron-covered magnesium

ActiveCN103624238AIdeal Room Temperature Large Plastic Deformation MethodAdvancedRoom temperatureGrain structure

The invention relates to an equal-channel angular pressing method of iron-covered magnesium. The method aims to solve the problems that magnesium is low in strength and poor in plastic forming performance. An iron-covered magnesium combination is manufactured by the adoption of a copper mould suction casting method. Equal-channel angular pressing is carried out at the room temperature of 25 DEG C, annealing is carried out at a moderate temperature, and magnesium grain structures are refined. The manufacturing process is advanced in method, data are detailed and accurate, the iron-covered magnesium combination is organically combined, magnesium grains are refined to 200nm, compactness is good, the application range of magnesium is widened, and the method is an ideal method for room-temperature severe plastic deformation of the magnesium.

Owner:TAIYUAN UNIV OF TECH

Preparation method of cigarette filter additive for removing NO

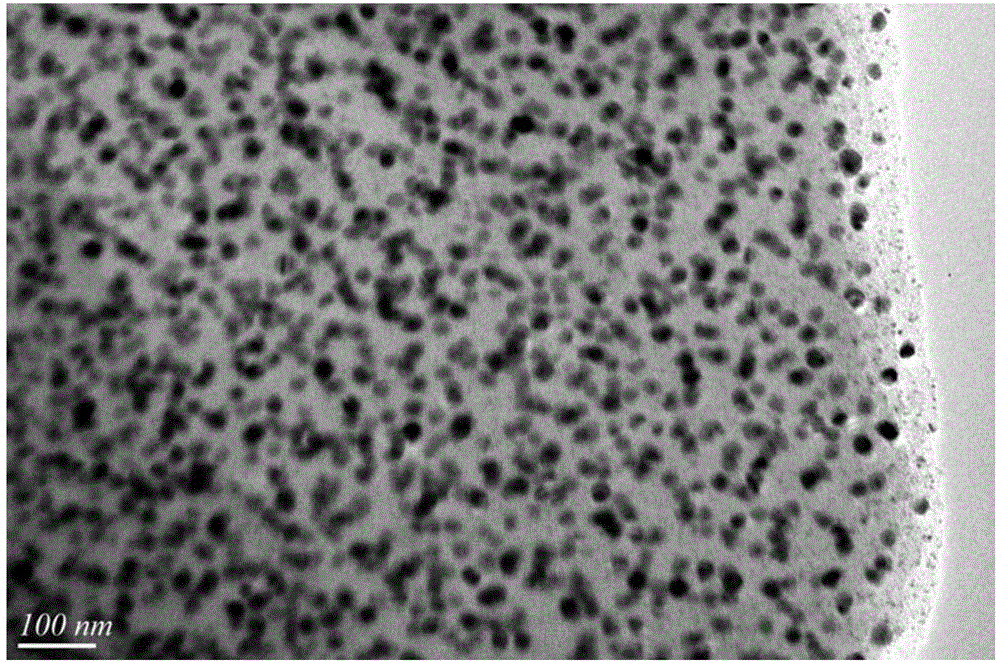

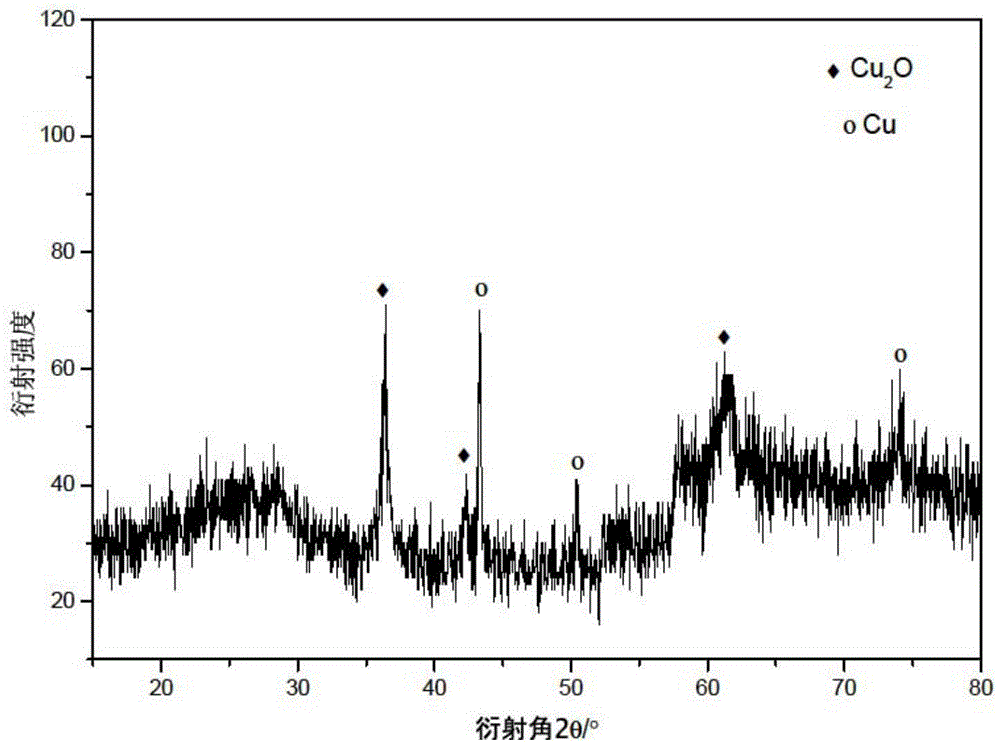

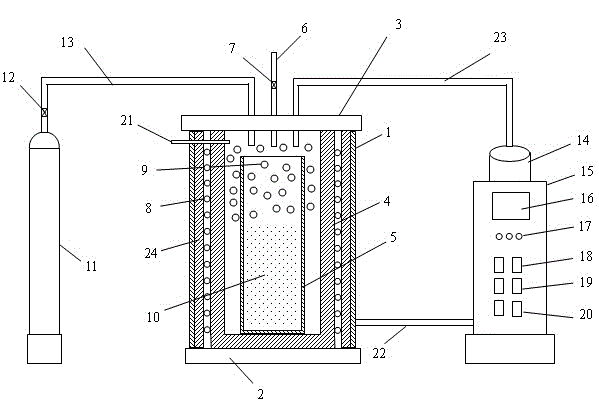

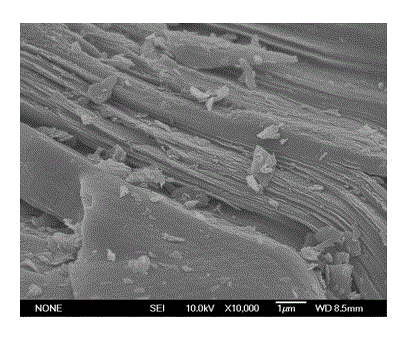

The invention relates to a preparation method of a cigarette filter additive for removing NO. The additive aims at the containing of harmful substances comprising sulfur dioxide, formaldehyde, nitrogen monoxide in cigarette smoke. The cigarette filter additive is prepared by adopting active carbon fiber felts as a raw material and copper nitrate and cerium nitrate as active component precursors, adopting ultrasonic immersion and carrying out microwave roasting under the protection of nitrogen. The preparation method has the advantages of advanced process and accurate and complete data, the above product obtained in the invention is a black slice, the thickness of the slice is not greater than 1mm, each of the length and the width of the slice is not greater than 10mm, the surface of the active carbon fiber felts has -C=C, -OH and -C-O organic functional groups, and the active components are uniformly dispersed as nanoparticles, wherein the copper element exists as crystal Cu2O, metallic element Cu and amorphous CuO, a relative atom percentage ratio of Cu<2+> to low valence copper component is 42.1:57.9, cerium exists as Ce<3+> and Ce<4+>, and a relative atomic content ratio of Ce<3+> / Ce<4+> is 55.5 / 44.5.The cigarette filter additive has a good cigarette smoke filtering effect, and makes the NO removal rate reach 71.9% and the SO2 removal rate reach 60%.

Owner:TAIYUAN UNIV OF TECH

Method for preparing ordered needle coke through using coal tar pitch

InactiveCN103333706AHigh purityQuality improvementWorking-up pitch/asphalt/bitumenCoking carbonaceous materialsMicrosphereDistillation

The invention relates to a method for preparing ordered needle coke through using coal tar pitch. The method which aims at the disadvantages of the chemical and physical characteristics and the mechanical performances of coal tar pitch comprises the steps of removal of quinoline insoluble substances from coal tar pitch, distillation, coal tar pitch microsphere extraction, reduced pressure distillation, high temperature charring and high temperature calcining to prepare the ordered needle coke having a purity of 99%. The method has the advantages of advanced technology, full and accurate data, high product purity and good product quality, can be used in a plurality of industrial fields, and is a very ideal method for preparing ordered needle coke through using the coal tar pitch.

Owner:TAIYUAN UNIV OF TECH

Preparation method of high-strength and high-conductivity aluminum-magnesium-silicon-calcium alloy

The invention relates to a preparation method of a high-strength and high-conductivity aluminum-magnesium-silicon-calcium alloy. Aiming at the disadvantages that an aluminum-magnesium-silicon alloy has low strength, poor conductivity and unstable mechanical properties, a calcium element is doped in the aluminum-magnesium-silicon alloy, and vacuum melting, argon gas bottom blowing protection and pouring and ingot formation are adopted to prepare an alloy with high-strength and high-conductivity characteristics through equal-channel corner extrusion and ageing treatment; a preparation technologyprovided by the invention has an advanced method and detailed and accurate data; the prepared alloy has the yield strength of 370MPa, the tensile strength of 370MPa, the elongation percentage of 12 percent and the electric conductivity of 57.2 percent IACS; compared with the prior art, the tensile strength is improved by 17.5 percent and the electric conductivity is improved by 8.9 percent; the mechanical properties and the conductivity of the aluminum-magnesium-silicon alloy are remarkably improved and an application range is expanded; the preparation method is an advanced preparation methodfor preparing the high-strength and high-conductivity aluminum-magnesium-silicon-calcium alloy.

Owner:山西中工重型锻压有限公司

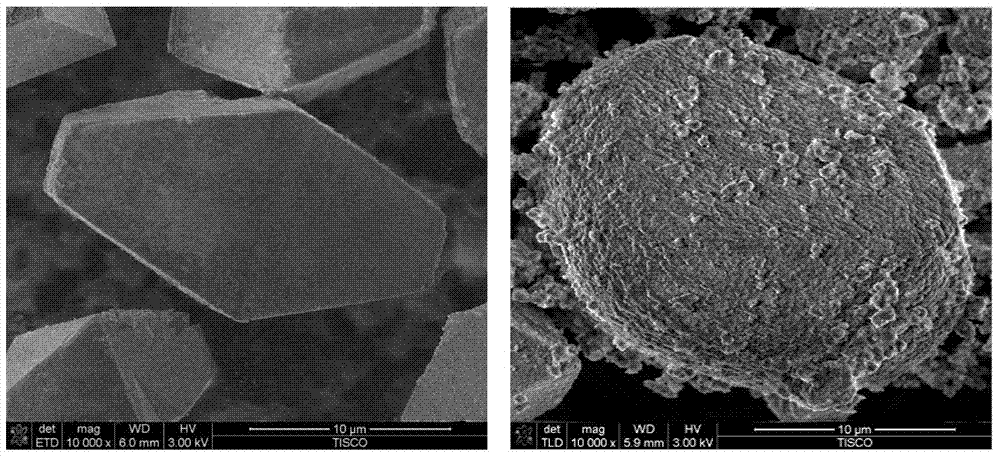

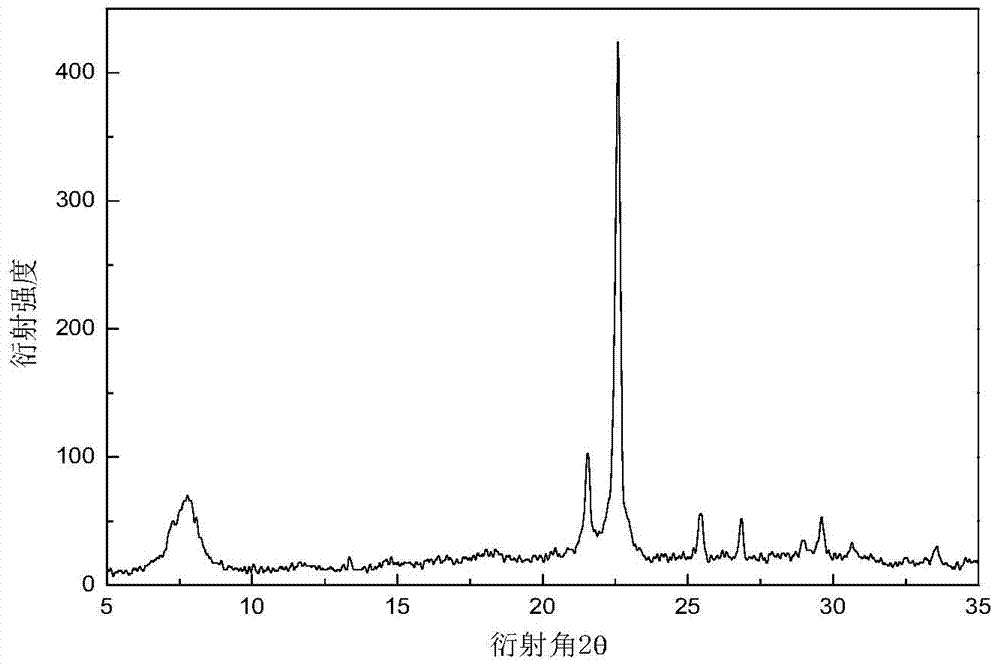

Preparation method of isomorphous-phase core-shell structured beta-molecular sieve

InactiveCN104760972AAdvancedInformative and accurate dataCrystalline aluminosilicate zeolitesQuenchingVacuum drying

The invention relates to a preparation method of an isomorphous-phase core-shell structured beta-molecular sieve, which is implemented by taking white carbon black, tetraethylortho silicate, sodium metaaluminate, tetraethylammonium hydroxide, and ammonium fluoride as raw materials and taking a tetraethylammonium hydroxide aqueous solution as a treating agent through the steps of synthesizing a nuclear-phase beta-molecular sieve firstly; carrying out mixed liquid preparation, and crystallizing the obtained object in a reaction kettle; and sequentially carrying out constant-temperature heating, quenching, cleaning and dispersing, centrifugal separation, vacuum drying, and high-temperature vacuum calcination on the obtained product, so that the isomorphous-phase core-shell structured beta-molecular sieve is obtained. The preparation method is advanced in process and detailed and accurate in data, the crystal diameter of the prepared isomorphous-phase core-shell structured molecular sieve is 15-20 mu m, the outside of each crystal is tightly wrapped with a nanocrystal, the wrapping degree of product reaches 97%, and the product purity reaches 99.9%, so that the molecular sieve can be matched with various chemical substances and then the obtained objects are used as catalysts, therefore, the method disclosed by the invention is an extremely ideal preparation method of an isomorphous-phase core-shell structured beta-molecular sieve.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com