Method for preparing boron, lead and aluminum composite board preventing X rays, gamma rays and neutron irradiation

An aluminum composite board and γ-ray technology, which is applied in the field of preparation of boron-lead-aluminum composite boards, can solve the problems of limited use and difficulty in taking into account the protection effects of multiple rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

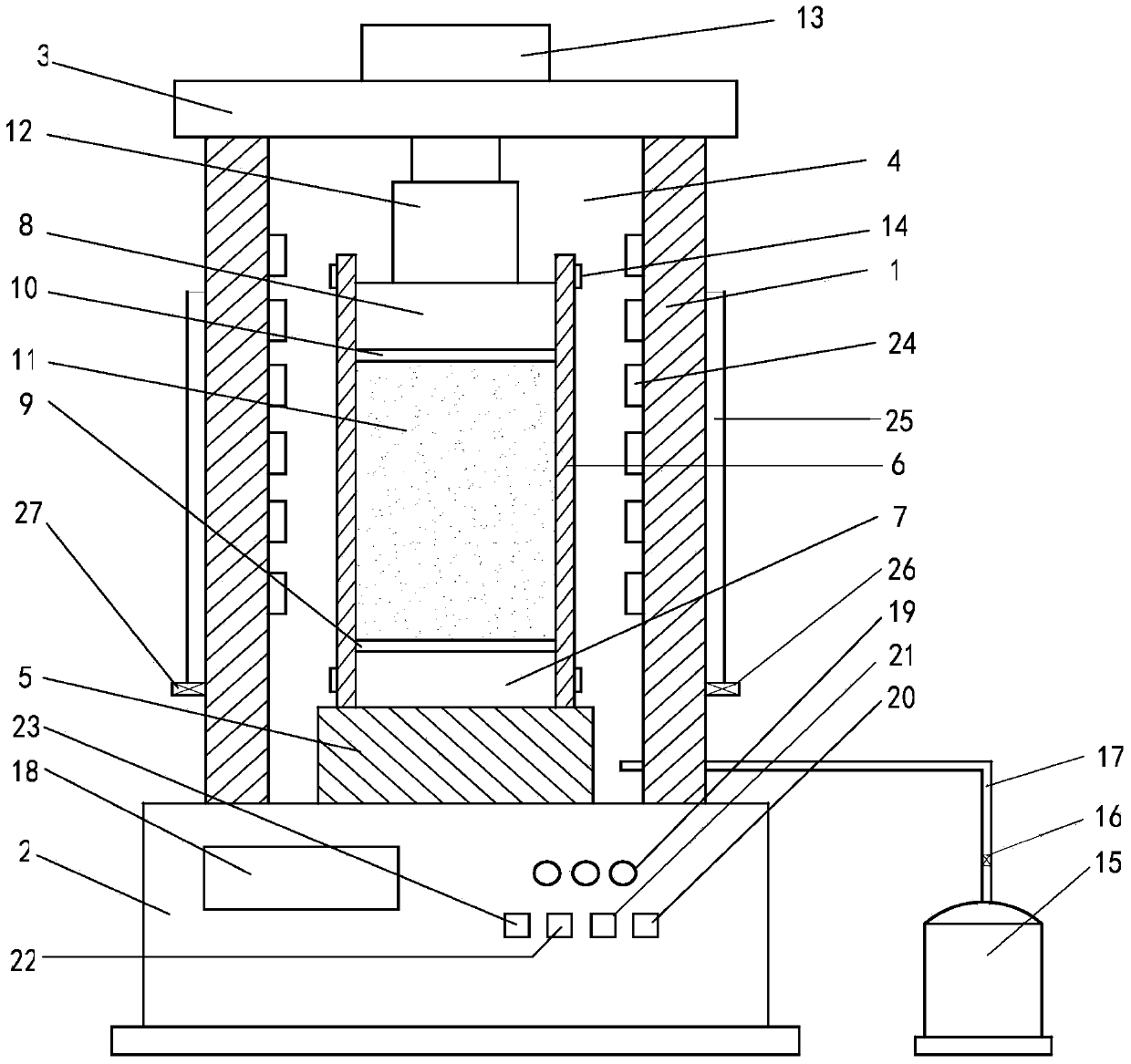

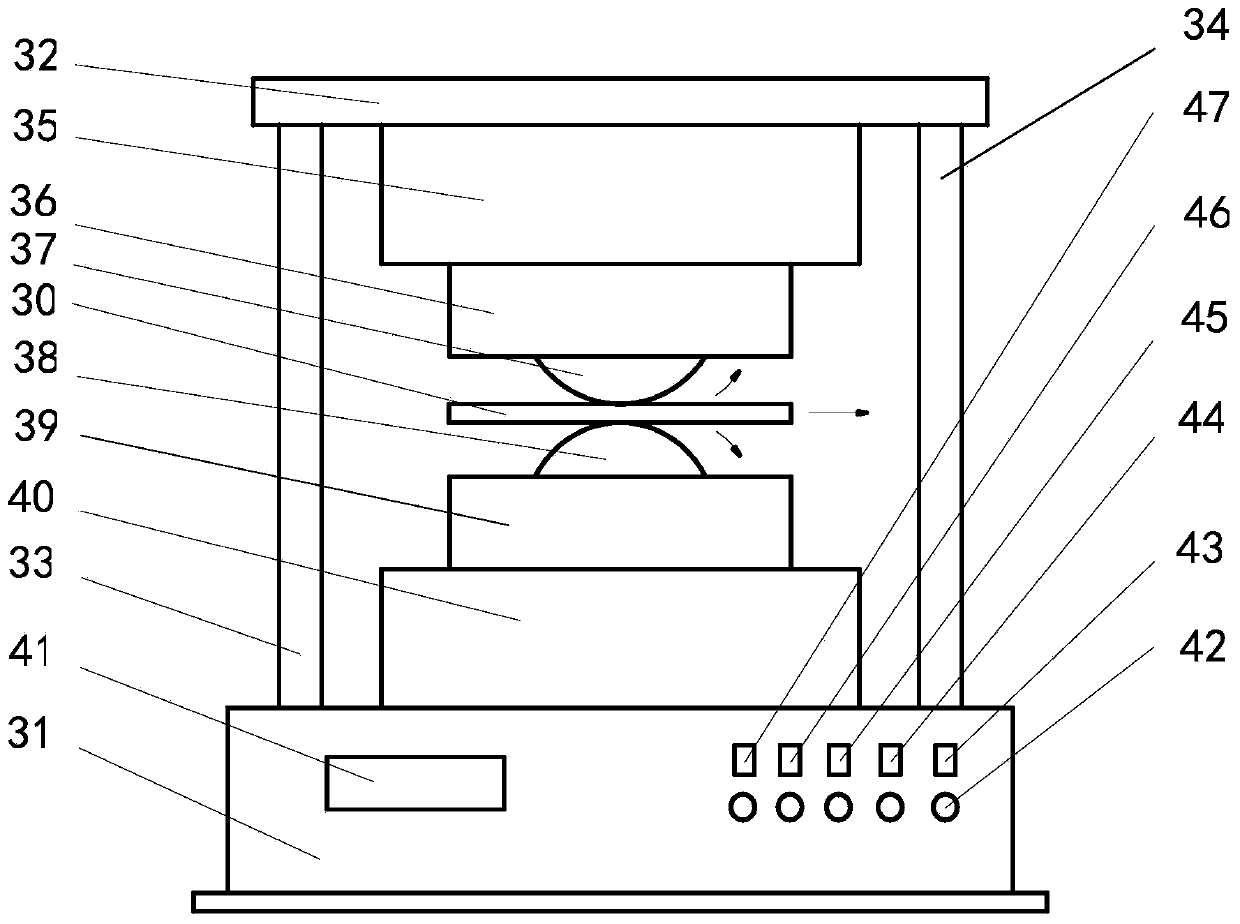

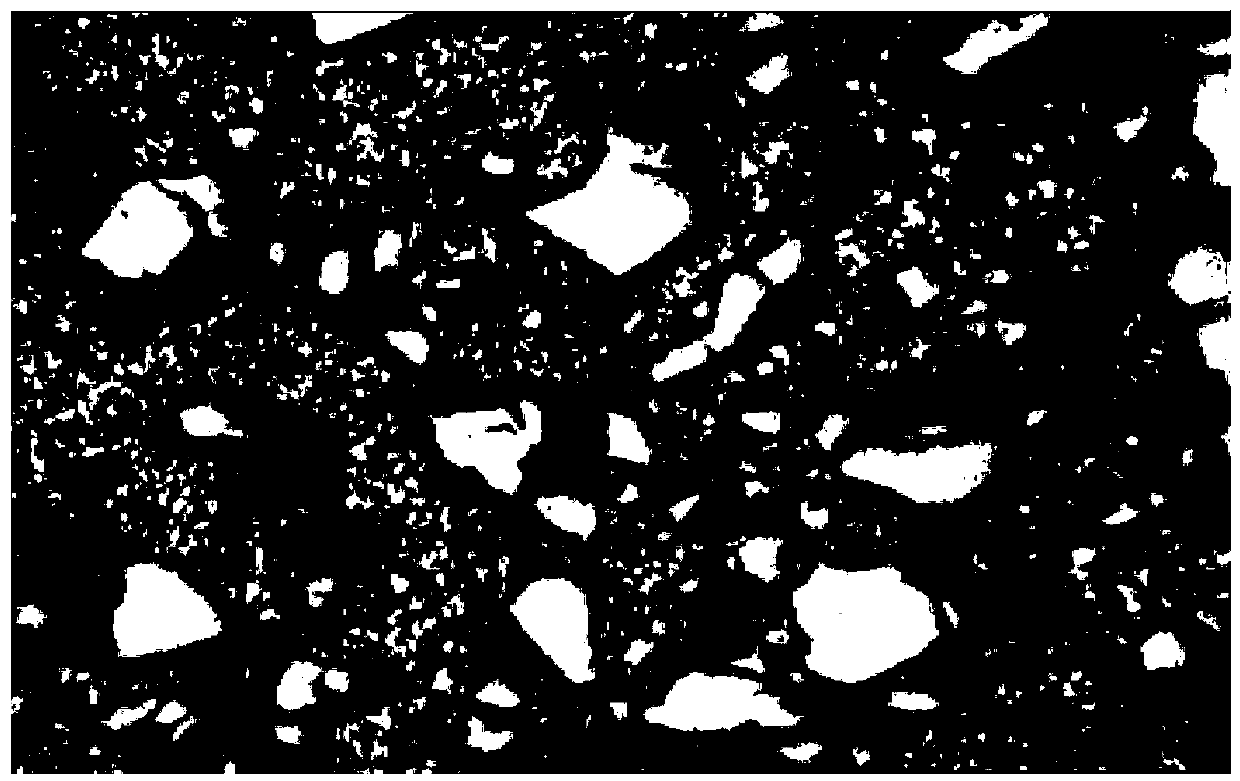

[0068] The present invention will be further described below in conjunction with accompanying drawing:

[0069] figure 1 As shown in the figure, it is a state diagram for the preparation of boron-lead-aluminum billet. The position and connection relationship of each part must be correct, and the operation should be done in sequence.

[0070] Quantities of the chemical substances used in the preparation are determined according to a preset range, with grams, milliliters, and millimeters as measurement units.

[0071] The preparation of the boron-lead-aluminum billet is carried out on a vacuum hot-press forming machine, which is completed in the process of microwave heating, vacuum state, and pressure application;

[0072] The vacuum thermoforming machine is vertical, the bottom of the vacuum thermoforming machine 1 is the molding machine console 2, the upper part is the top seat 3, and the inside is the machine cavity 4; Place open-close type graphite mold 6 vertically on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com