Method for preparing heat-resisting magnesium alloy containing silicon, zirconium and beryllium

A magnesium alloy, silicon zirconium beryllium technology, applied in the field of non-ferrous metal preparation and application, can solve the problems of low mechanical properties, poor ingot structure compactness, poor heat resistance of magnesium and magnesium alloys, etc. Good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

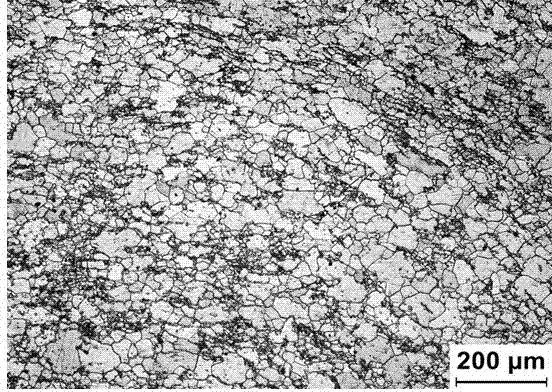

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with accompanying drawing:

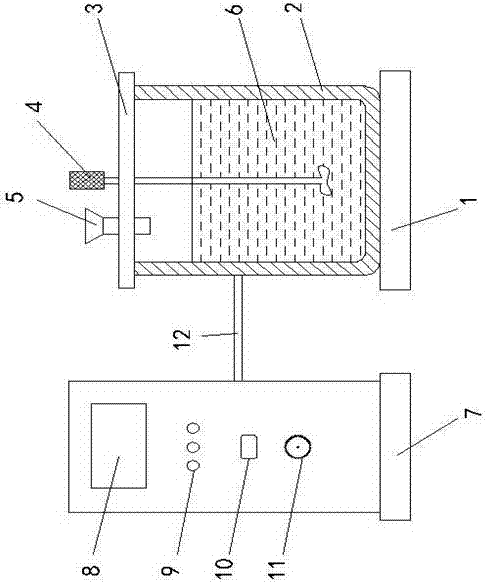

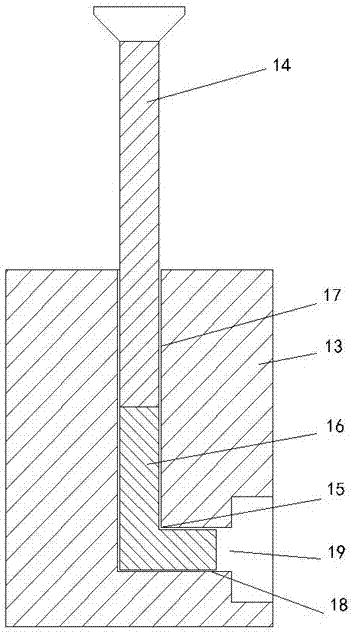

[0084] figure 1 Shown is the smelting state diagram of the heat-resistant magnesium alloy with silicon zirconium beryllium, and the positions of each part

[0085] To be correct, match the ratio according to the amount and operate in sequence.

[0086] Quantities of the chemical substances used in the preparation are determined according to a preset range, with grams and milliliters as measurement units.

[0087] The smelting of the heat-resistant magnesium alloy with silicon, zirconium and beryllium is carried out in the crucible of the smelting furnace, and is completed in the process of heating, stirring, and adding the master alloy;

[0088] The melting furnace is cylindrical. The upper part of the melting furnace 1 is the melting crucible 2. The upper part of the melting crucible 2 is the furnace cover 3. The agitator 4 and the feeder 5 are arranged on the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| fracture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com