Preparation method of thermometal methanation catalyst with high-temperature resistance

A methanation catalyst and bimetal technology, which is applied in the field of preparation of high temperature resistant bimetal methanation catalysts to achieve the effects of improving stability, good catalytic ability, and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

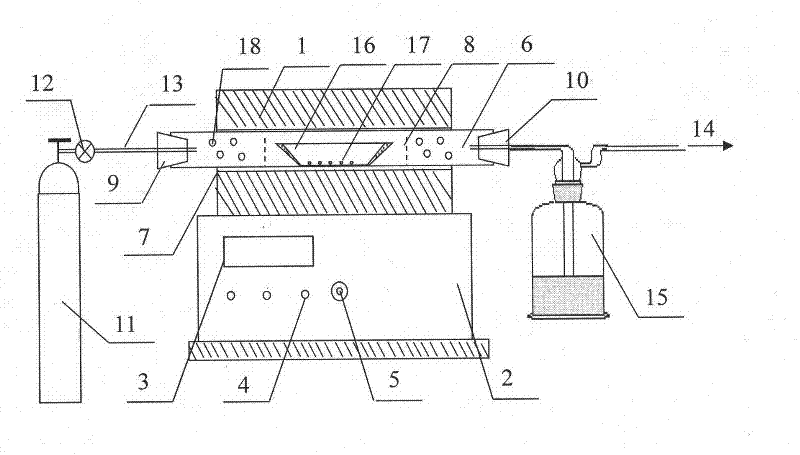

Method used

Image

Examples

Embodiment 1

[0090] To prepare a high-temperature-resistant bimetallic methanation catalyst, the proportion of its chemical substances can also be as follows:

[0091] Sodium aluminate: NaAlO 2 8.12g±0.01g

[0092] Nickel nitrate: Ni(NO 3 ) 2 ·6H 2 O 17.96g±0.01g

[0093] Cobalt nitrate: Co(NO 3 ) 2 ·6H 2 O 4.31g±0.01g

[0094] Lanthanum nitrate: La(NO 3 ) 3 ·6H 2 O 1.97g±0.01g

[0095] Deionized water: H 2 O 3000ml±50ml

[0096] Nitrogen: N 2 10000cm 3 ±100cm 3

[0097] The preparation method is the same as the technical scheme.

Embodiment 2

[0099] Prepare the performance measurement of high-temperature-resistant bimetallic methanation catalyst, the method is as follows:

[0100] Analyzer: Shanghai Haixin Chromatography Co., Ltd. GC-950 gas chromatograph, thermal conductivity cell detector, chromatographic column is carbon molecular sieve TDX-01, carrier gas Ar, mainly analyzes H in reformed gas 2 , CO, CO 2 and CH 4 ; Capillary column is Agilent PLOT Al 2 o 3 , the inner diameter of the column is 0.35mm, and the column length is 50m. 2 and above higher hydrocarbons;

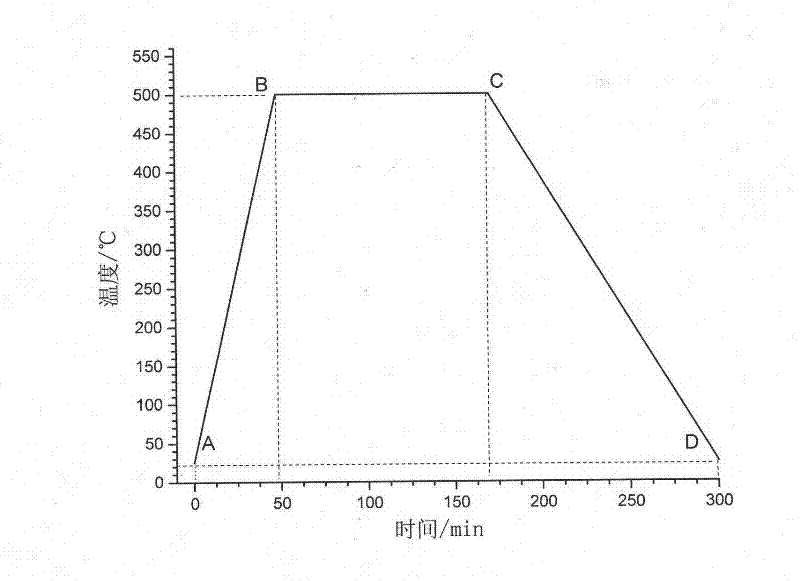

[0101] At a temperature of 430°C, the catalyst was reduced for 4 hours by raising the pressure to 0.5 MPa with hydrogen, and the reduction space velocity was 2000 hours. -1 ; After the reduction is completed, disconnect the hydrogen and feed the reaction gas, the total space velocity of the reaction gas is 16000h -1 , carry out methanation catalytic conversion reaction at 500°C, the catalyst load is 2.00g, the inner diameter of the reactor is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com