Preparation method of reinforced AlCoCrFeNi2 high-entropy alloy base neutron absorbing material and application

A high-entropy alloy and absorbing material technology, which is applied in the field of preparation of enhanced AlCoCrFeNi2 high-entropy alloy-based neutron absorbing materials, can solve the problems of low secondary ray energy and difficulty in meeting nuclear radiation protection requirements, and achieve good interface bonding strength , Guarantee the interface binding strength and the effect of accurate and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

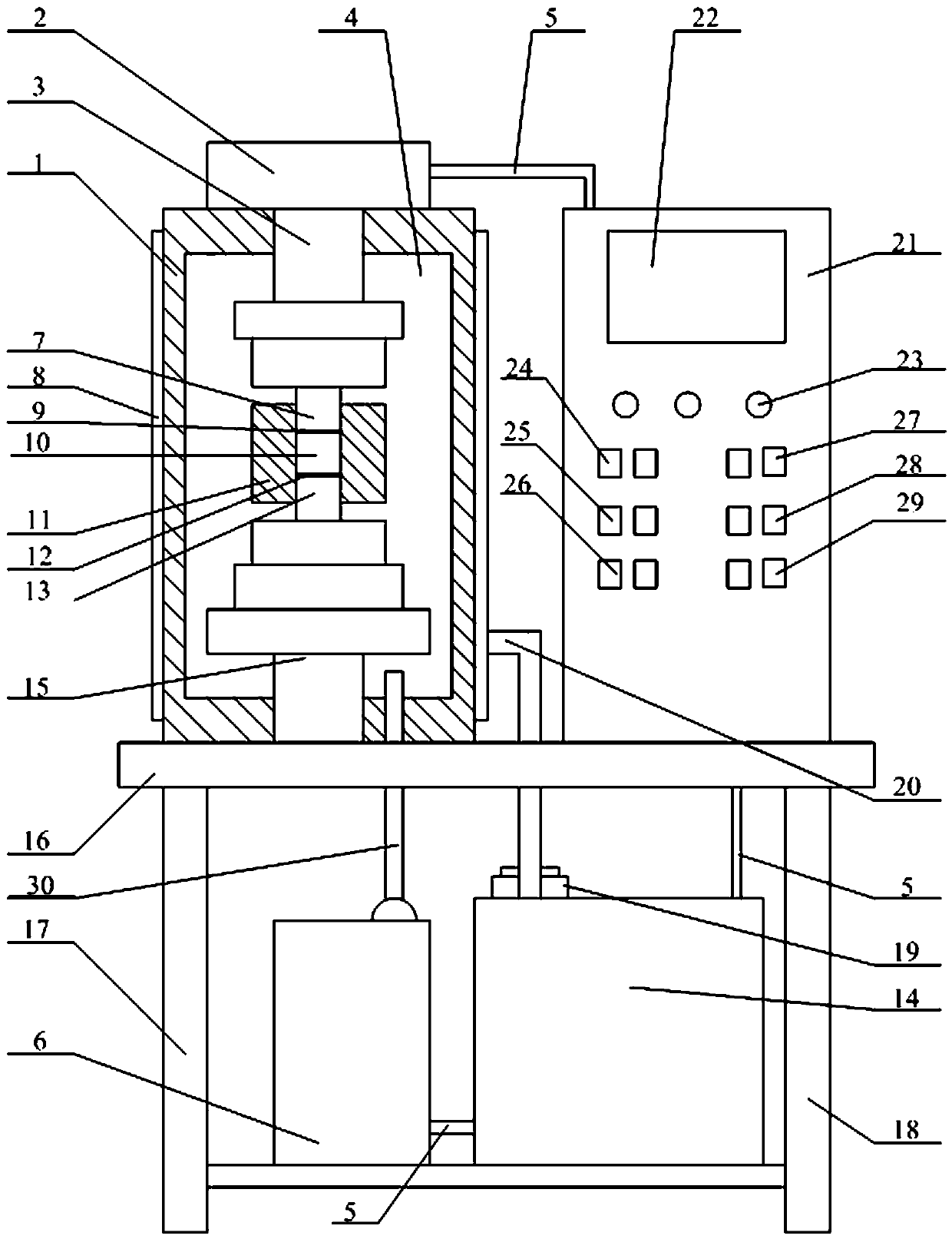

[0046] An enhanced AlCoCrFeNi 2 A method for preparing a high-entropy alloy-based neutron-absorbing material, comprising the following steps:

[0047] (1) Preparation of cylindrical mold

[0048] The cylindrical high-strength mold is made of graphite material, ensuring that the inner wall roughness of the mold is Ra 0.06-0.15 μm, and the mold cavity size is Ф30 mm×70 mm;

[0049] (2) Accurate ratio of Al powder, Co powder, Cr powder, Fe powder and Ni powder

[0050] Weigh 1.30 g ± 0.01 g of Al powder, 2.70 g ± 0.01 g of Co powder, 2.40 g ± 0.01 g of Cr powder, 2.60 g ± 0.01 g of Fe powder, and 5.60 g ± 0.01 g of Ni powder in a vacuum glove box, and place them in a ball mill inside the tank;

[0051] (3) Preparation of AlCoCrFeNi by ball milling method 2 High Entropy Alloy Powder

[0052] Put the stainless steel balls in the ball mill tank according to the ball-to-material ratio of 8:1, and close the ball mill tank;

[0053] Carry out argon gas protection to the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com