Bi-phase nano particle reinforced titanium alloy protective coating and preparation method of bi-phase nano particle reinforced titanium alloy protective coating

A technology of nano-particles and protective coatings, applied in the direction of metal material coating process, coating, etc., can solve the problem of less research on coatings, achieve strong engineering application value, improve work ability, and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

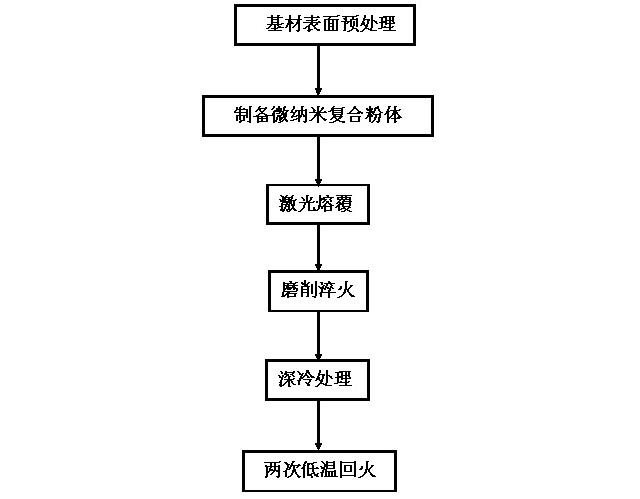

[0030] A method for preparing a dual-phase nanoparticle-reinforced titanium alloy protective coating, the key of which is to pretreat the surface of the titanium alloy first, then prepare micro-nano composite powder, and finally pass laser cladding, grinding quenching, cryogenic treatment and Twice low-temperature tempering to obtain a protective coating with high hardness, high strength and excellent wear resistance, corrosion resistance and heat resistance. Specific steps are as follows:

[0031] 1. For the pretreatment of the titanium alloy surface, first use W28 metallographic sandpaper to polish it, and then use W20, W14, W10 sandpaper to polish it in turn. The purpose is to maintain a certain roughness on the surface of the titanium alloy, which is conducive to enhancing the bonding force of the coating. Finally, clean the polished titanium alloy with alcohol and dry it with cold air for later use.

[0032] 2. Preparation of micro-nano composite powder: first, 4 gra...

Embodiment 2

[0038] A method for preparing a dual-phase nanoparticle-reinforced titanium alloy protective coating, the key of which is to pretreat the surface of the titanium alloy first, then prepare micro-nano composite powder, and finally pass laser cladding, grinding quenching, cryogenic treatment and Twice low-temperature tempering to obtain a protective coating with high hardness, high strength and excellent wear resistance, corrosion resistance and heat resistance. Specific steps are as follows:

[0039] 1. For the pretreatment of the titanium alloy surface, first use W28 metallographic sandpaper to polish it, and then use W20, W14, W10 sandpaper to polish it in turn. The purpose is to maintain a certain roughness on the surface of the titanium alloy, which is conducive to enhancing the bonding force of the coating. Finally, clean the polished titanium alloy with alcohol and dry it with cold air for later use.

[0040] 2. Preparation of micro-nano composite powder: first, 2 gra...

Embodiment 3

[0046] A method for preparing a dual-phase nanoparticle-reinforced titanium alloy protective coating, the key of which is to pretreat the surface of the titanium alloy first, then prepare micro-nano composite powder, and finally pass laser cladding, grinding quenching, cryogenic treatment and Twice low-temperature tempering to obtain a protective coating with high hardness, high strength and excellent wear resistance, corrosion resistance and heat resistance. Specific steps are as follows:

[0047] 1. For the pretreatment of the titanium alloy surface, first use W28 metallographic sandpaper to polish it, and then use W20, W14, W10 sandpaper to polish it in turn. The purpose is to maintain a certain roughness on the surface of the titanium alloy, which is conducive to enhancing the bonding force of the coating. Finally, clean the polished titanium alloy with alcohol and dry it with cold air for later use.

[0048] 2. Preparation of micro-nano composite powder: first, 6 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com