High-entropy alloy solid wire for arc cladding and preparation method thereof

A high-entropy alloy and wire technology, which is applied in the coating process and coating of metal materials, can solve the problems of low plasticity, high brittleness and singleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

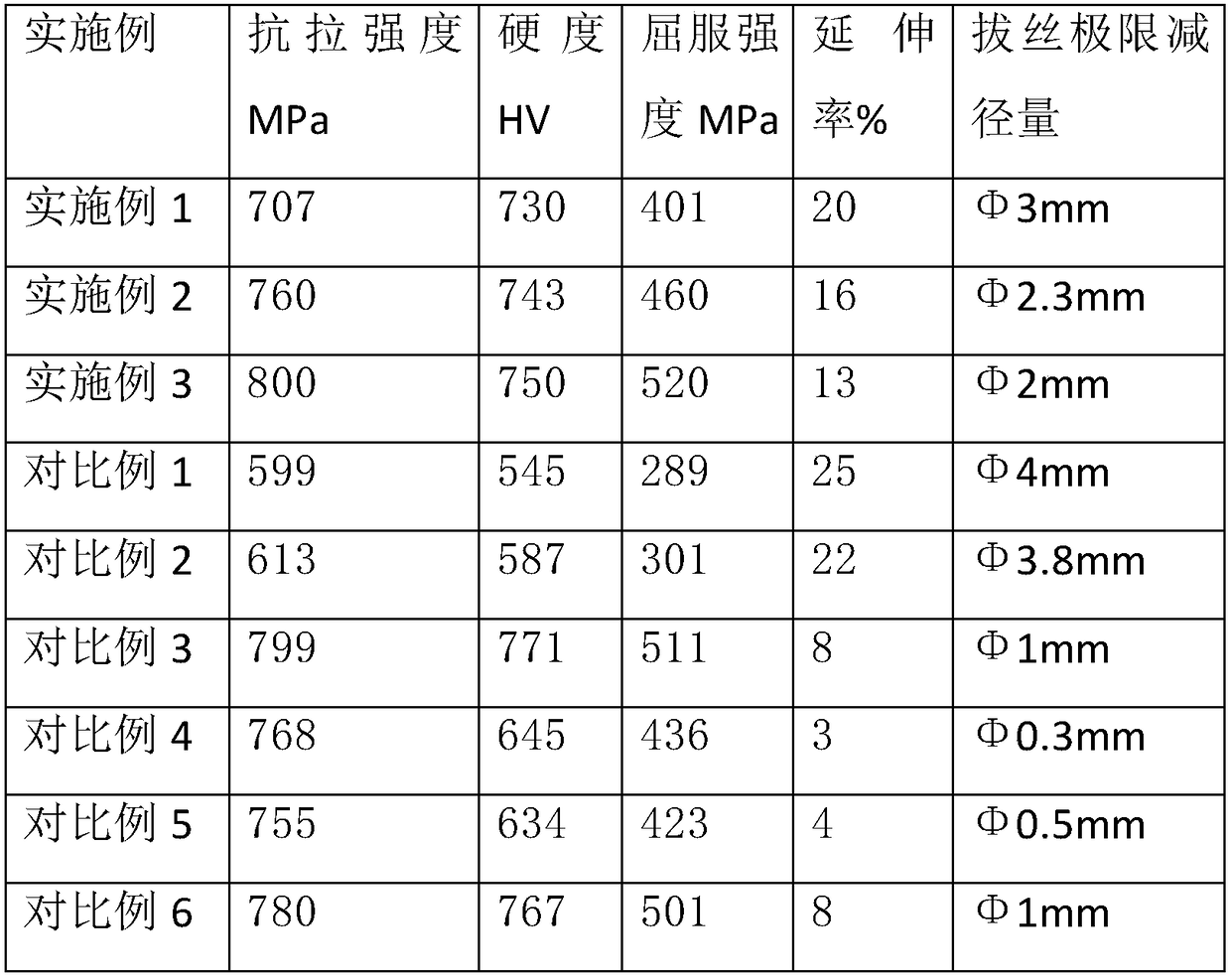

Examples

Embodiment 1

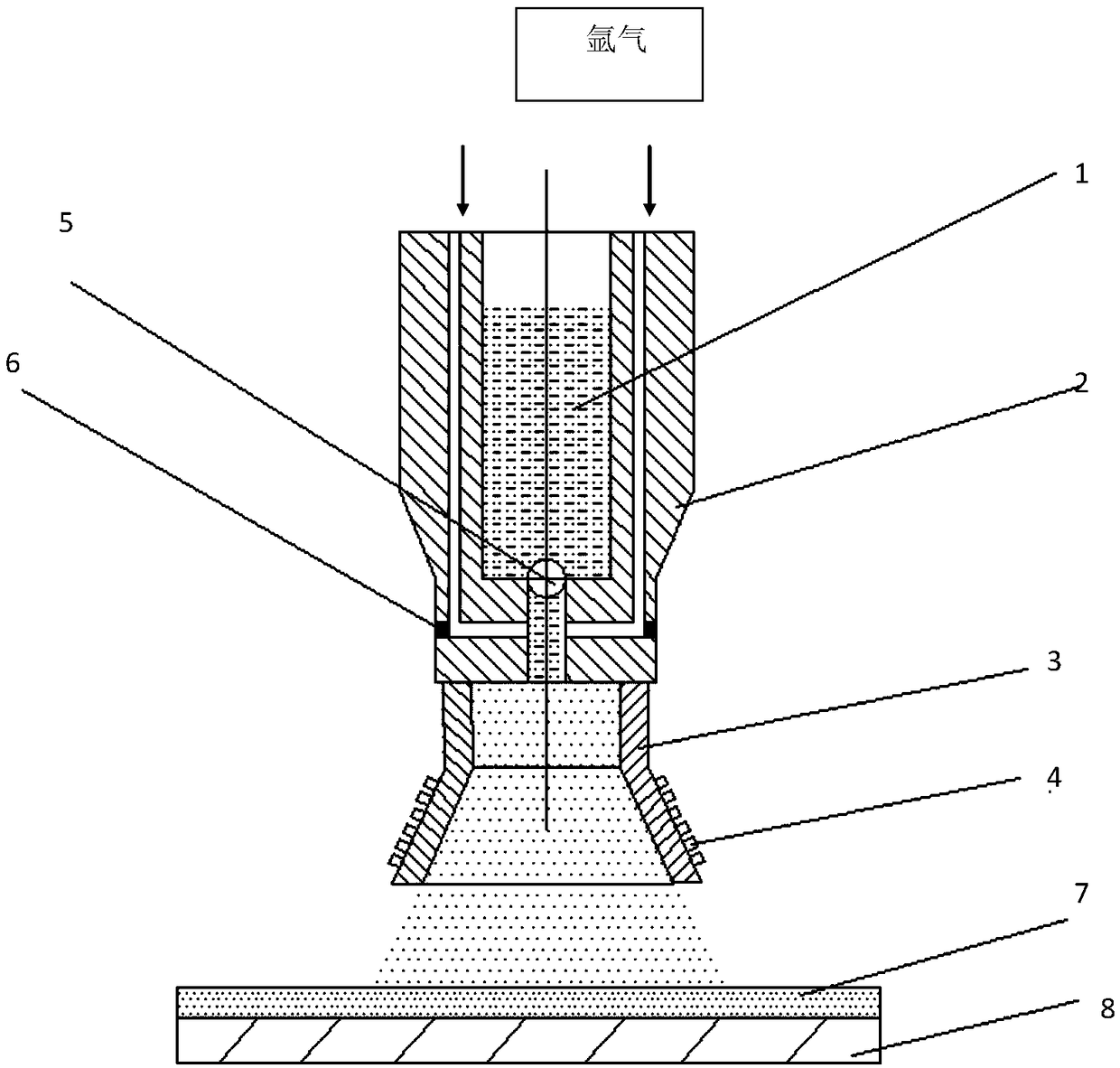

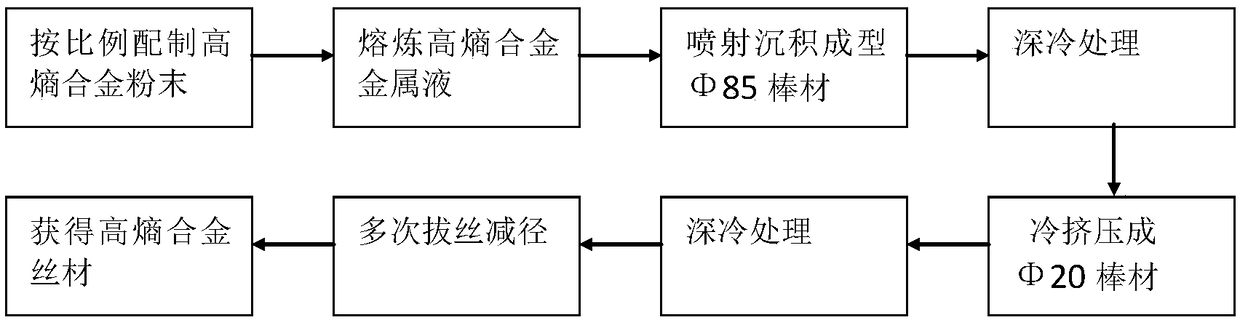

[0027] Embodiment 1: A high-entropy alloy solid wire for arc cladding described in this embodiment and its preparation method, such as figure 1 and figure 2 As shown, the specific steps are as follows:

[0028] (1) Ball milling: weigh Co powder, Cr powder, Fe powder, Ni powder, Mn powder and bait (Er) powder with a purity of 99% to 99.9% in a molar ratio of 19:19:19:19:19:2 Proportioning, uniformly mixed and added to a high-energy ball mill at a rotational speed of 150r / min for 2 hours and then milled to 300-400 mesh to obtain high-entropy alloy powder;

[0029] (2)) Spray deposition molding: the high-entropy alloy powder prepared in step (1) is poured into the crucible melting furnace of the spray deposition equipment for melting, and the melting temperature is 1200°C. Fill the molten metal into the molten metal bag, and pass through the high-pressure argon gas of 0.9-1.2MPa to atomize and deposit the molten metal in a cylindrical mold to obtain a high-entropy alloy rod wi...

Embodiment 2

[0033] Embodiment 2: A high-entropy alloy solid wire for arc cladding described in this embodiment and its preparation method, such as figure 1 and figure 2 As shown, the specific steps are as follows:

[0034] (1) Ball milling: weigh Co powder, Cr powder, Fe powder, Ni powder, Mn powder and bait (Er) powder with a purity of 99% to 99.9% in a molar ratio of 19:19:19:19:19:3 Proportioning, uniformly mixed and added to a high-energy ball mill at a rotational speed of 150r / min for 2 hours and then milled to 300-400 mesh to obtain high-entropy alloy powder;

[0035](2) Spray deposition molding: the high-entropy alloy powder prepared in step 1 is poured into the crucible melting furnace of the spray deposition equipment for melting, and the melting temperature is 1200°C. Fill the molten metal into the molten metal bag, and pass through the high-pressure argon gas of 0.9-1.2MPa to atomize and deposit the molten metal in a cylindrical mold to obtain a high-entropy alloy rod with a...

Embodiment 3

[0039] Embodiment 3: A high-entropy alloy solid wire for arc cladding described in this embodiment and its preparation method, such as figure 1 and figure 2 As shown, the specific steps are as follows:

[0040] (1) Ball milling: weigh Co powder, Cr powder, Fe powder, Ni powder, Mn powder and bait (Er) powder with a purity of 99% to 99.9% in a molar ratio of 19:19:19:19:19:4 Proportioning, uniformly mixed and added to a high-energy ball mill at a rotational speed of 150r / min for 2 hours and then milled to 300-400 mesh to obtain high-entropy alloy powder;

[0041] (2) Spray deposition molding: the high-entropy alloy powder prepared in step (1) is poured into the crucible melting furnace of the spray deposition equipment for melting, and the melting temperature is 1200°C. Fill the molten metal into the molten metal bag, and pass through the high-pressure argon gas of 0.9-1.2MPa to atomize and deposit the molten metal in a cylindrical mold to obtain a high-entropy alloy rod wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com