Method for modification of glass fiber composite material by ultralow temperature treatment

An ultra-low temperature treatment, glass fiber technology, applied in the field of high-performance fiber composite material modification, to achieve the effect of improving physical bonding ability, improving bending performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Ultra-low temperature treatment of modified glass fiber short fiber reinforced epoxy resin composites

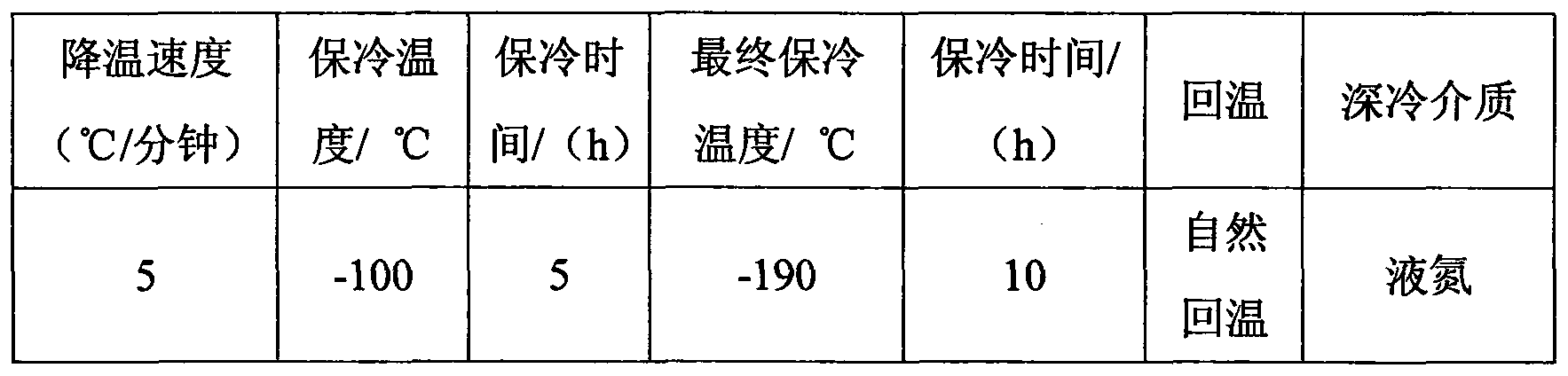

[0027] A method for modifying glass fiber composite material by ultra-low temperature treatment, the glass fiber composite material is short glass fiber reinforced epoxy composite material, which includes a matrix resin and glass fibers used as reinforcements in the matrix resin ; The matrix resin is epoxy resin, and the glass fiber is E-glass fiber, which is set in the matrix resin in the form of chopped strand mat. The glass composite material is self-prepared, the glass fiber length is 3 cm-5 cm, and the fiber monofilament diameter is 13 microns; fabric type: alkali-free E glass fiber non-woven mat; epoxy resin grade: JL-235. The preparation method adopts the vacuum-assisted resin transfer molding method. The specific steps are: put 3 layers of glass fiber felt into the mold. The catheter is connected to the vacuum pump to evacuate, and the auxiliary res...

Embodiment 2

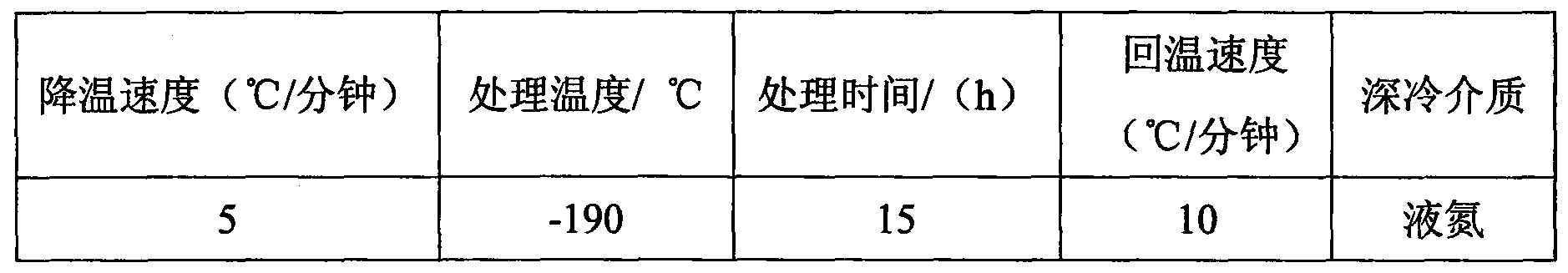

[0032] Example 2 Ultra-low temperature treatment modified two-dimensional plain weave glass fiber reinforced epoxy composite material

[0033]A modification method of glass fiber composite material by ultra-low temperature treatment, the glass fiber composite material is a two-dimensional plain weave glass fiber reinforced epoxy composite material, which includes a matrix resin and glass used as a reinforcement in the matrix resin Fiber, the matrix resin is epoxy resin, and the glass fiber is alkali-free E glass fiber, which is set in the matrix resin in the form of glass two-dimensional fabric. The glass composite material is self-prepared, glass fabric parameters: alkali-free E glass fiber with warp and weft yarn thickness of 1200D, warp and weft density of 5 threads / cm, fabric structure: two-dimensional plain weave fabric; epoxy resin grade: JL-235 . The preparation method adopts the vacuum-assisted resin transfer molding method, and the specific steps are the same as in E...

Embodiment 3

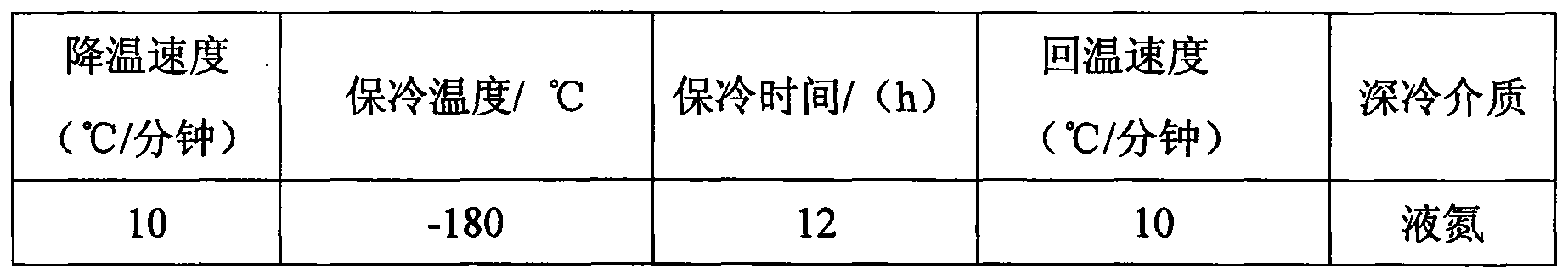

[0038] Example 3 Ultra-low temperature treatment of modified glass fiber short fiber reinforced unsaturated polyester composite material

[0039] A modification method of glass fiber composite material by ultra-low temperature treatment, the glass fiber composite material is a glass fiber short fiber reinforced unsaturated polyester composite material, which includes a matrix resin and glass used as a reinforcement in the matrix resin Fiber; the matrix resin is unsaturated polyester, and the glass fiber is E-glass fiber, which is set in the matrix resin in the form of chopped strand mat. The glass composite material is self-prepared, the glass fiber length is 3 cm-5 cm, and the fiber monofilament diameter is 13 microns; fabric type: alkali-free E glass fiber non-woven mat; unsaturated polyester resin grade: 901-VP. The preparation method adopts the vacuum-assisted resin transfer molding method, and the specific steps are the same as in Example 1. The glass fiber volume conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com