Silica gel protected LED chip and manufacturing method thereof

A technology of light-emitting diodes and chips, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as silicone damage, affecting the efficiency of sorting, and affecting the appearance of chips, and achieve the effect of reducing viscosity and solving adhesion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

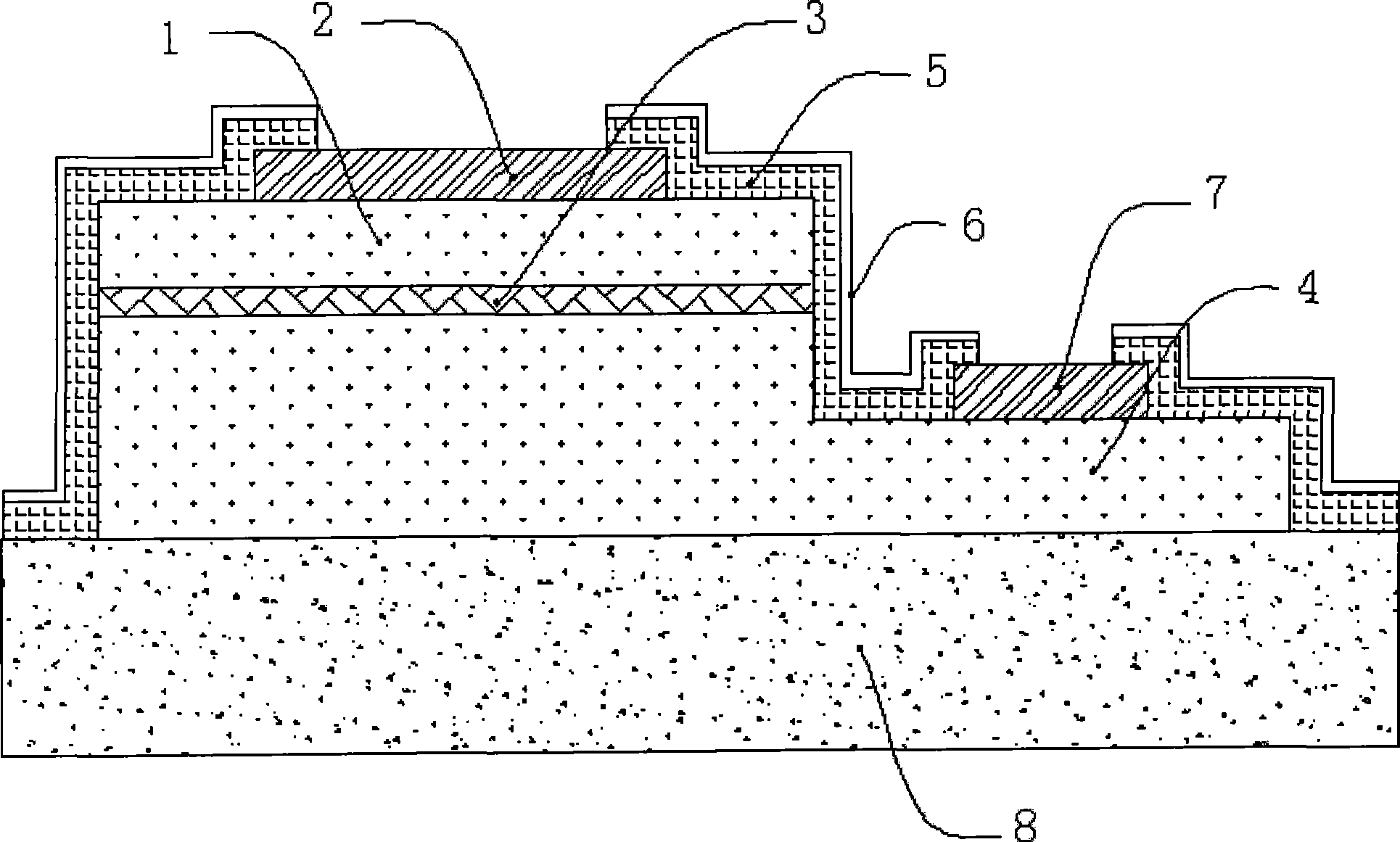

[0021] see figure 1 As shown, the chip structure is a horizontal structure. Substrate 8 is a growth substrate. The multilayer semiconductor structure on the substrate 8 is N-type layer 4, light-emitting layer 3 and P-type layer 2 from bottom to top, N-electrode 7 is arranged on N-type layer 4, and P-type electrode 2 is arranged on P-type layer , a silica gel layer 5 is formed on the surface of the multilayer semiconductor structure. The P electrode 4 and the N electrode 2 are exposed outside the silica gel layer for welding electrode leads. A film 6 for preventing the silicone layer from adhering to other workpieces is formed on the surface of the silicone layer 5 .

[0022] The production process of this embodiment is as follows:

[0023] First, a multi-layer semiconductor structure is formed on a growth substrate by MOCVD growth and chip technology, and a primary chip for further processing is made. Then apply glue on the chip at a speed of 500r / min for 10 seconds, bake...

Embodiment 2

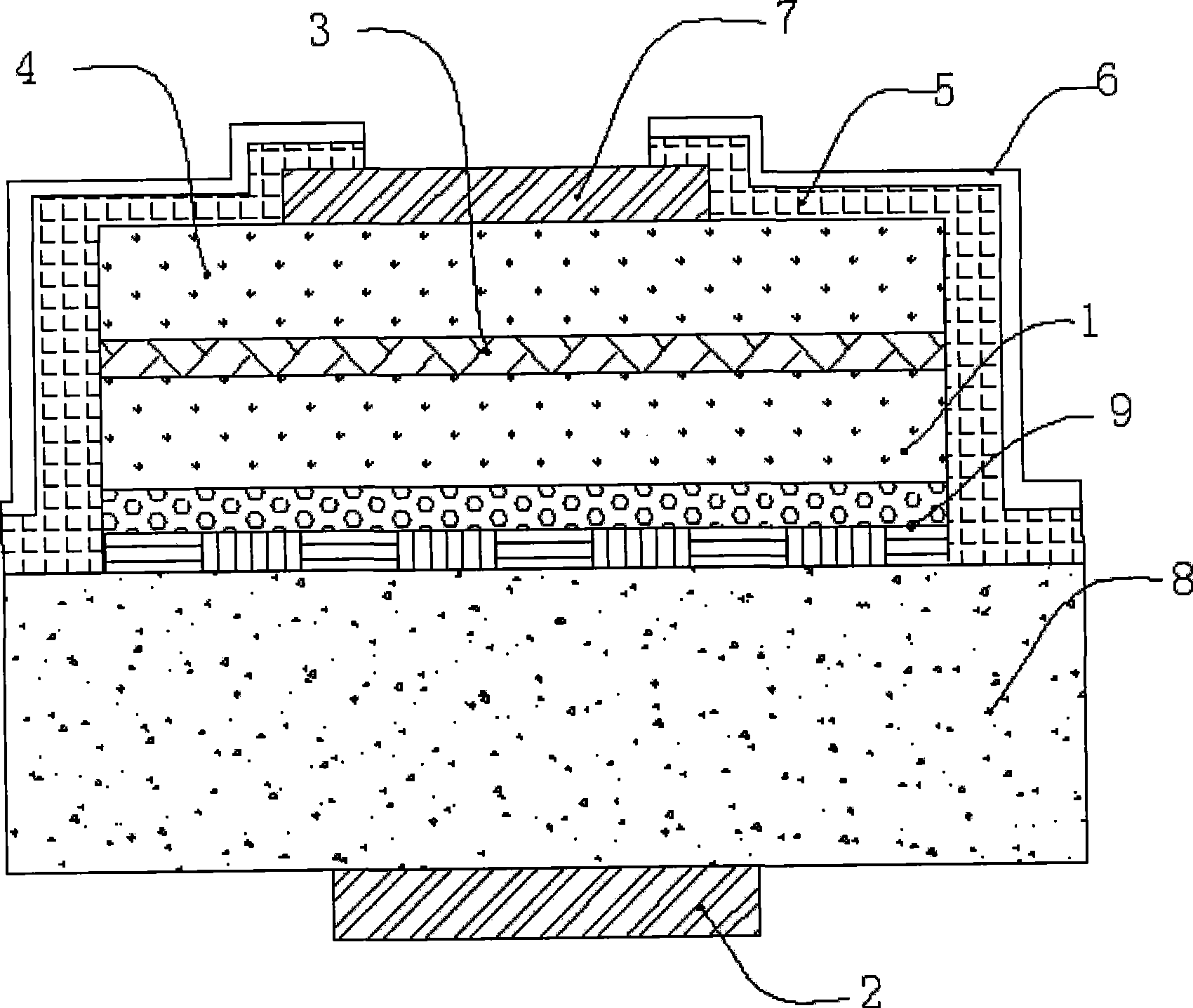

[0026] see figure 2 As shown, the chip structure is a vertical structure. The substrate 8 is a transfer substrate, and the structure is a flip-chip structure. Its structure from bottom to top is P electrode 2 , substrate 8 , transition layer 9 , P type layer 1 , light emitting layer 3 , N type layer 4 and N electrode 7 . A silica gel layer 5 is formed on the surface of the multilayer semiconductor structure. The N electrode 2 is exposed outside the silica gel layer for welding electrode leads. A film 6 for preventing the silicone layer from adhering to other workpieces is formed on the surface of the silicone layer 5 .

[0027] The production process of this embodiment is as follows:

[0028] First, through MOCVD growth and chip processing, such as figure 2 The primary chip shown is then glued on the primary chip at a speed of 3000r / min for 30 seconds, baked with a hot plate at 110°C for 120s, and masked with a photolithography plate at a rate of 1000mJ / cm 2 Expose to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com