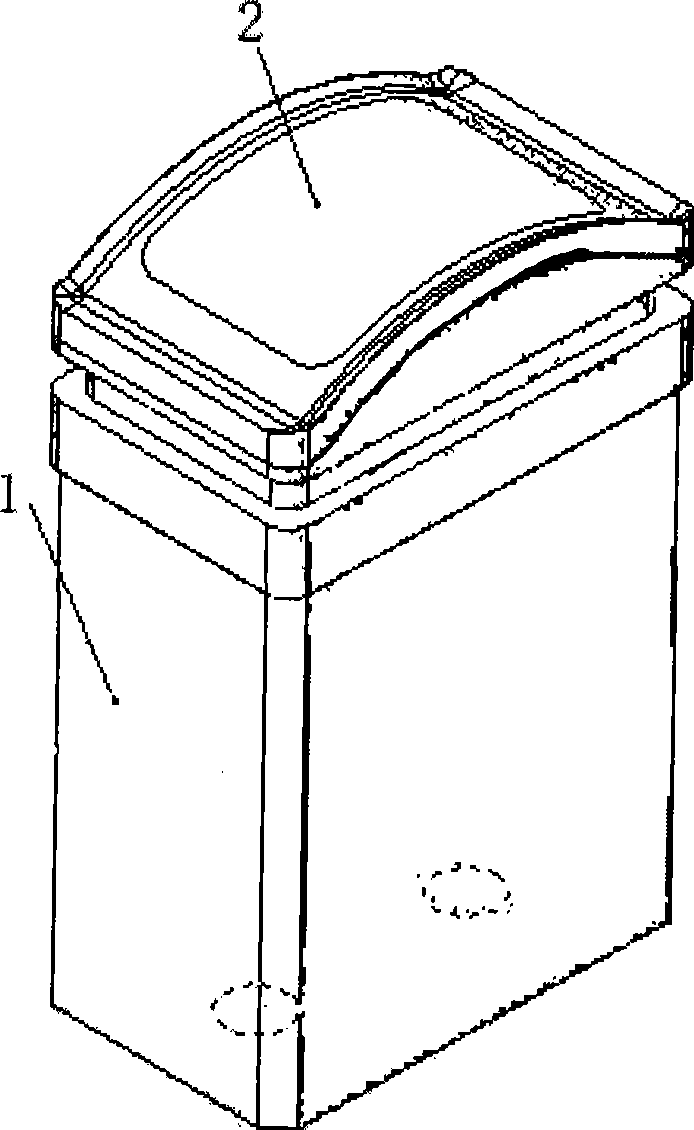

Plunger chip die for processing magnetic material and manufacture method thereof

A magnetic material and mold manufacturing technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding/cutting media/materials, etc., can solve problems such as affecting blanks, easy deformation of punches, and short service life of punches, so as to improve the surface Hardness, reducing punch deformation, and solving the effect of sticking mold problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] Example 1, using 45# steel as the parent material

[0042] Proceed as follows:

[0043] 1) Take 45# steel for tempering and quenching treatment:

[0044] Put 45# steel in a box-type resistance furnace, raise the temperature of the resistance furnace to about 830°C within 2 hours, and keep it warm for about 30 minutes;

[0045] The material is taken out, quenched with brine with a mass percentage concentration of 15%, and the material is naturally cooled in the brine;

[0046] 2) According to the mold drawing and the design of the magnetic force line, the obtained material is made into a matrix of the required shape and size;

[0047] 3) Use a cloth wheel to polish the surface to be welded of the parent body to remove oil and oxide layer, and the surface is required to be as bright as new;

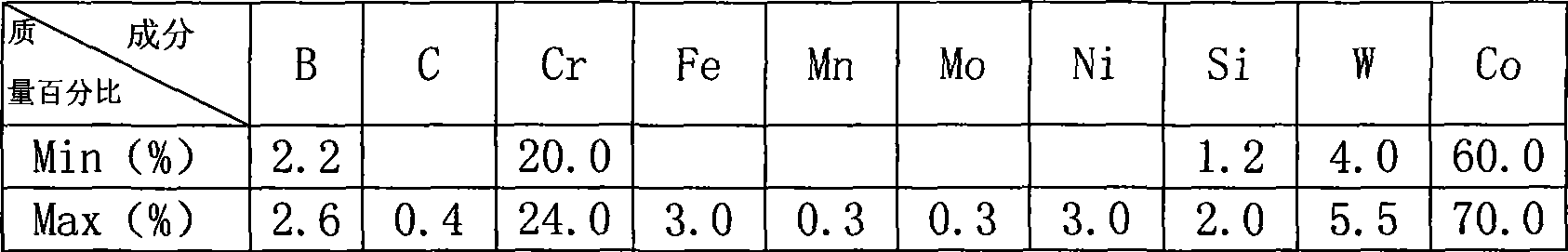

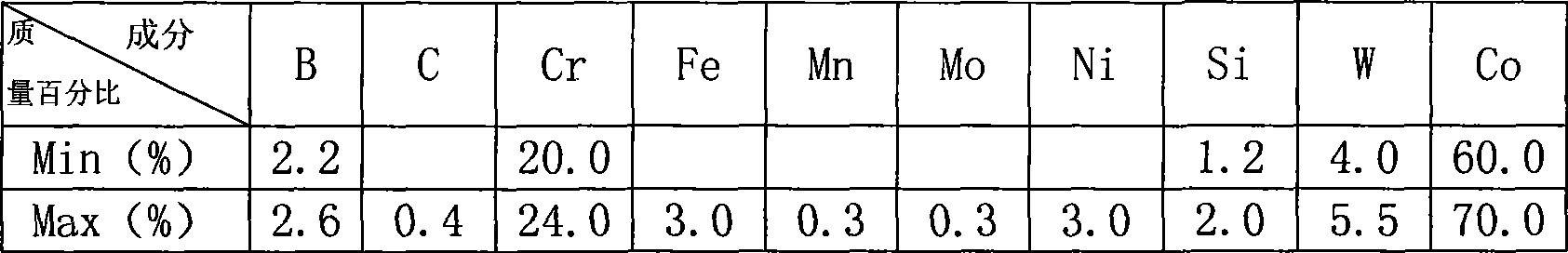

[0048] 4) Adopt spray welding process to process non-magnetic layer:

[0049] First use a welding torch to heat the surface of the parent body to be welded until it turns red, an...

example 2

[0055] Example 2, using T8 steel as the parent material

[0056] Proceed as follows:

[0057] 1) Take T8 steel for tempering and quenching treatment:

[0058] Put T8 steel in a well-type resistance furnace, raise the temperature of the resistance furnace to about 840°C within 2.2 hours, and keep it warm for about 28 minutes;

[0059] The material is taken out, quenched with brine with a mass percentage concentration of 17%, and placed in the brine to cool naturally;

[0060] 2) According to the mold drawing and the design of the magnetic force line, the obtained material is made into a matrix of the required shape and size;

[0061] 3) Use a cloth wheel to polish the surface to be welded of the parent body to remove oil and oxide layer, and the surface is required to be as bright as new;

[0062] 4) Using spray welding process to process non-magnetic layer:

[0063] First use a welding torch to heat the surface of the parent body to be welded until it turns red, and then spr...

example 3

[0069] Example 3, using T10 steel as the parent material

[0070] Proceed as follows:

[0071] 1) Take T10 steel for tempering and quenching treatment:

[0072] Put T10 steel in a box-type resistance furnace, raise the temperature of the resistance furnace to about 820°C within 1.8 hours, and keep it warm for about 33 minutes;

[0073] The material is taken out, quenched with brine with a mass percentage concentration of 14%, and the material is placed in brine to cool naturally;

[0074] 2) According to the mold drawing and the design of the magnetic force line, the obtained material is made into a matrix of the required shape and size;

[0075] 3) Use a cloth wheel to polish the surface to be welded of the parent body to remove oil and oxide layer, and the surface is required to be as bright as new;

[0076] 4) Using spray welding process to process non-magnetic layer:

[0077] First use a welding torch to heat the surface of the parent body to be welded until it turns r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com