Continuous double-helix asynchronous rubber powder plasticization device

A double-helix, rubber powder technology, applied in the field of double-helix asynchronous rubber powder continuous plasticizing device, can solve the problems of troublesome maintenance, aging and explosion of the tank, high labor intensity, etc., achieving simple structure, solving the problem of sticking and blocking, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

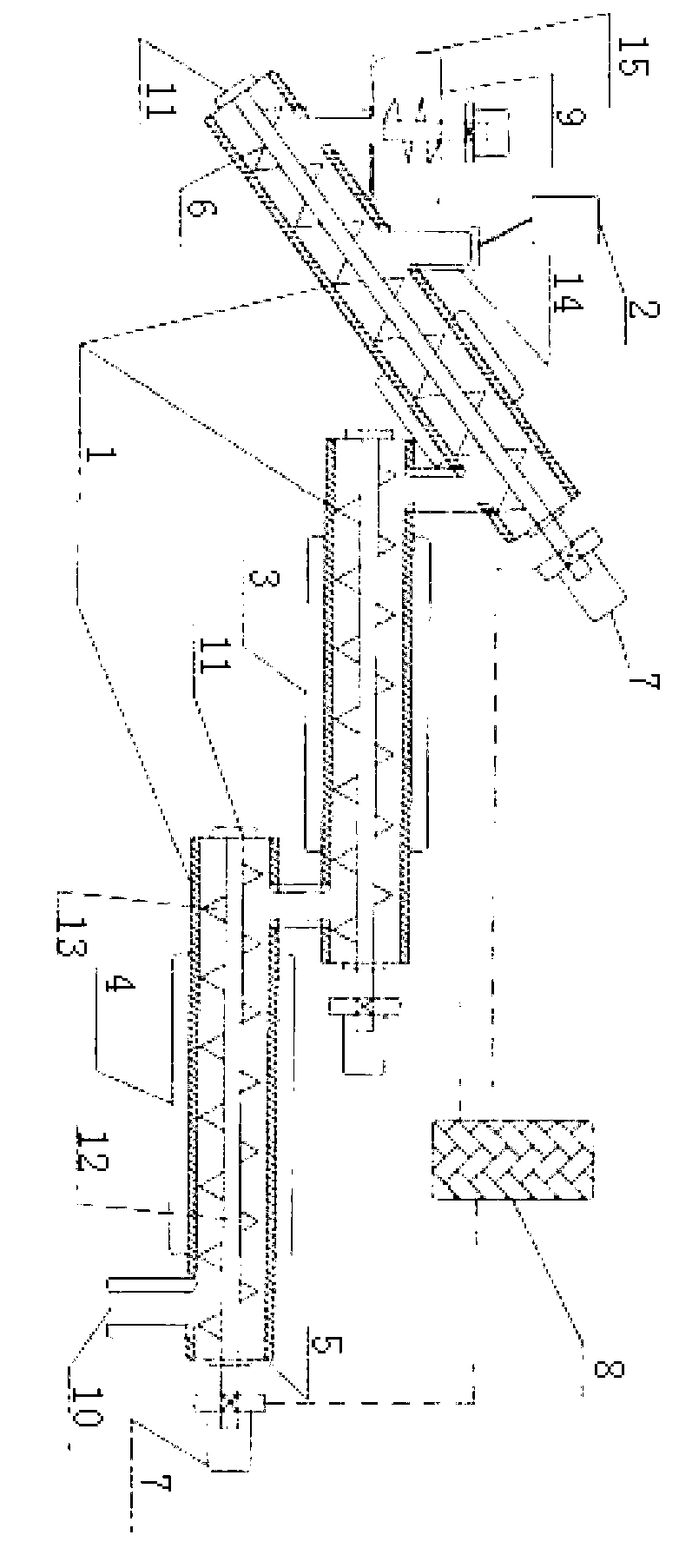

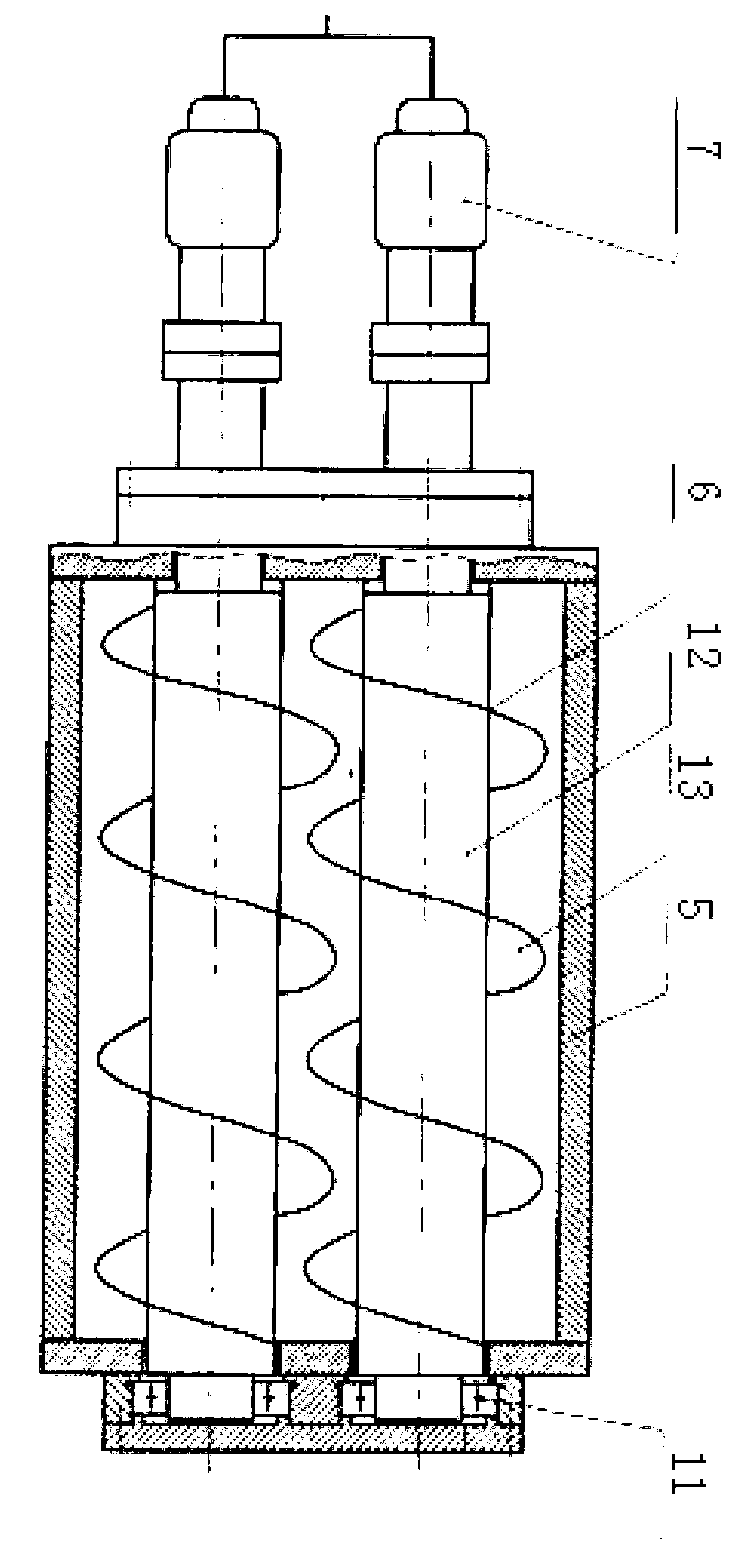

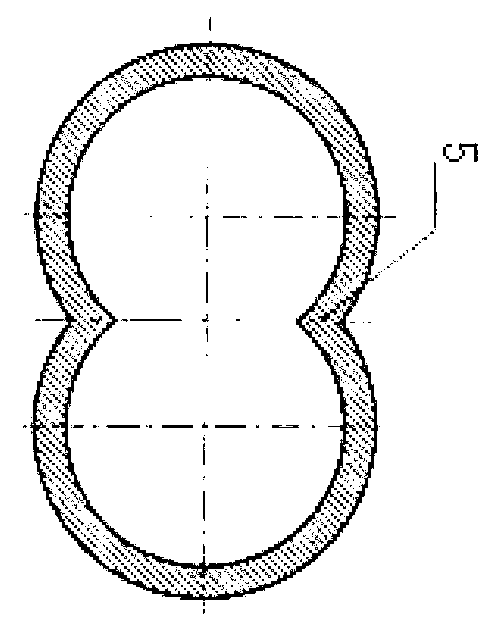

[0012] The main structure of this embodiment includes a double-helix asynchronous conveying system 1, an oil injection system 2, a heating system 3 and a cooling system 4; wherein, the double-helix asynchronous conveying system 1 includes a screw barrel 5, a helical blade 6, a driving motor 7, and a control system 8. Feed port 9, discharge port 10, bearing 11, screw rod 12 and screw wing 13; the cross-section of the screw barrel 5 with a double-circle-segment combination structure forms an 8-shaped cross section, and the screw barrel 5 is composed of two identical structures. The cylinders are cut and connected along the outer wall to form a paired 8-shaped double-cylinder structure. The upper side of one end of the screw barrel 5 is fixed with a feed inlet 9, and the lower side of the other end of the screw barrel 5 is fixed with a discharge port 10. 5. Bearings 11 are respectively fixed on the outer sides of both ends of the seal to support the screw 12; the helical structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com