Tablet and preparation method

A tableting and tableting technology, applied in the field of medicine, can solve problems such as sticking and punching, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

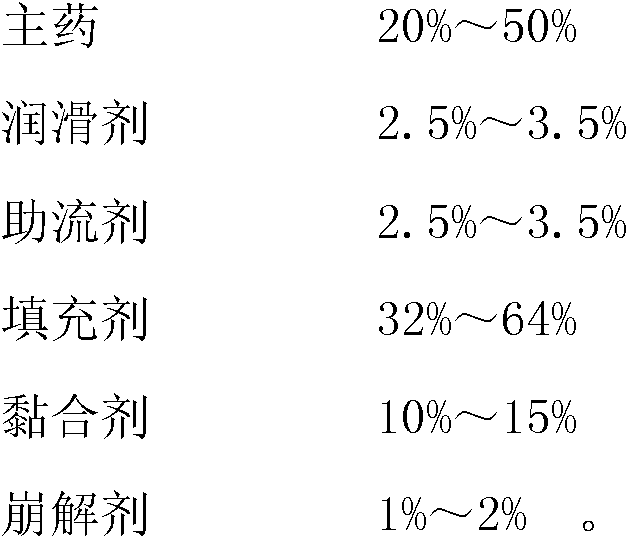

[0037] Tablet preparation method of the present invention comprises the following steps:

[0038] Grinding, mixing, and drying 2.5% to 3.5% of the lubricant and 20% to 50% of the main ingredient to obtain a mixture 1;

[0039] Pulverize and mix 1.5% to 2% of glidants and 32% to 64% of fillers to obtain mixture 2;

[0040] Mix 10% to 15% of binder, 1% to 1.5% of glidant, and 1% to 2% of disintegrant to obtain mixture 3;

[0041] Mix the mixtures 1, 2, and 3, dry, and pass through a 60-100 mesh sieve;

[0042] Tablets are obtained by using a rotary tablet press at a pressure of 8000N to 11000N and a speed of 10 to 15 rpm.

[0043] Another tablet preparation method of the present invention comprises the following steps:

[0044] Grinding, mixing, and drying 2.5% to 3.5% of the lubricant and 20% to 50% of the main ingredient to obtain a mixture 1;

[0045] Pulverize and mix 1.5% to 2% of glidants and 27% to 57% of fillers to obtain mixture 2;

[0046] Mix 10% to 15% of binder...

Embodiment 1

[0058] 1. Components and their weight percentages:

[0059]

[0060] 2. Preparation method:

[0061] To prepare lipoic acid powder, put 60-80 mesh food-grade lipoic acid raw materials into a tank mixer for crushing, so that the fluidity of the main drug lipoic acid is greatly increased, and through a 60-80 mesh sieve, lipoic acid is obtained Powder.

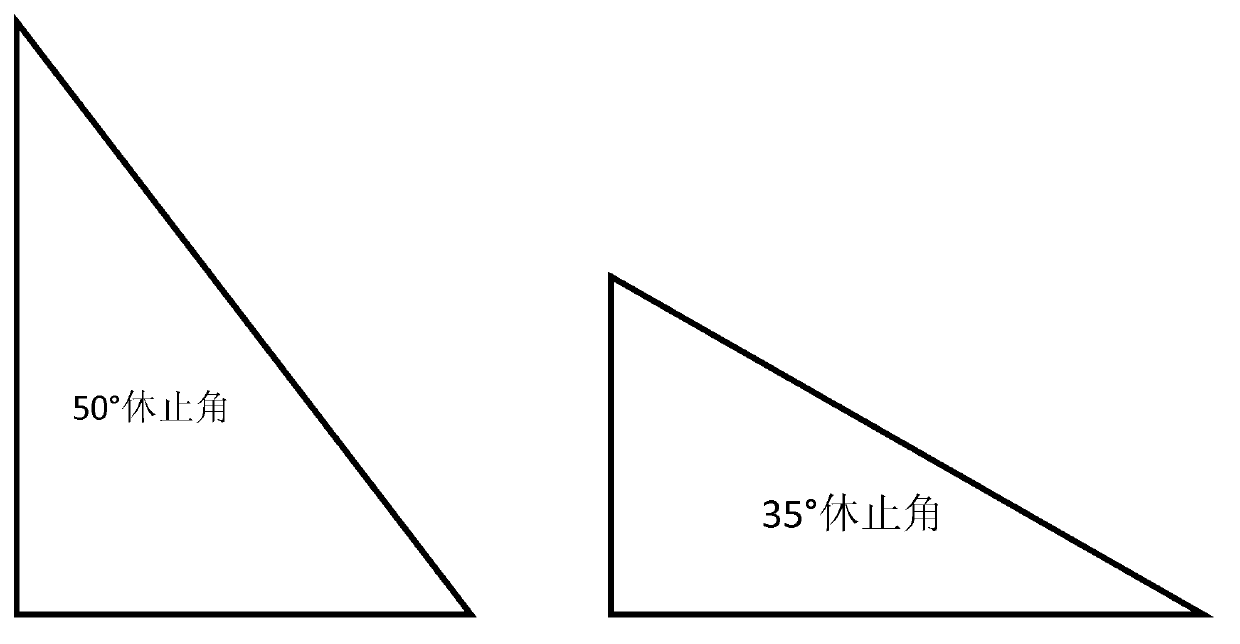

[0062] Weigh 3% lubricant magnesium stearate and food-grade lipoic acid powder and fully mix to obtain mixture 1. Magnesium stearate with fine particle size can effectively improve the fluidity of lipoic acid powder and make its angle of repose In the original 50°~60° tends to 30°~40° (see figure 1 ), providing a good foundation for the subsequent direct compression.

[0063] Weigh 57% of the filler microcrystalline cellulose and 2% of the glidant talcum powder and put them into a tank mixer for sufficient pulverization and mixing to obtain a mixture 2.

[0064] 1% micronized silica gel, 10% hydroxypropyl cellulose with fi...

Embodiment 2

[0067] 1. Components and their weight percentages:

[0068]

[0069]

[0070] Two, preparation method: with the preparation method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com