Biomass fuel boiler

A biomass fuel and biomass energy technology, applied in steam generation, steam generation devices, fluid heaters, etc., can solve the problems of reduced boiler use function, high heat, gelling, etc., and achieve the improvement of flame temperature and thermal efficiency. The effect of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

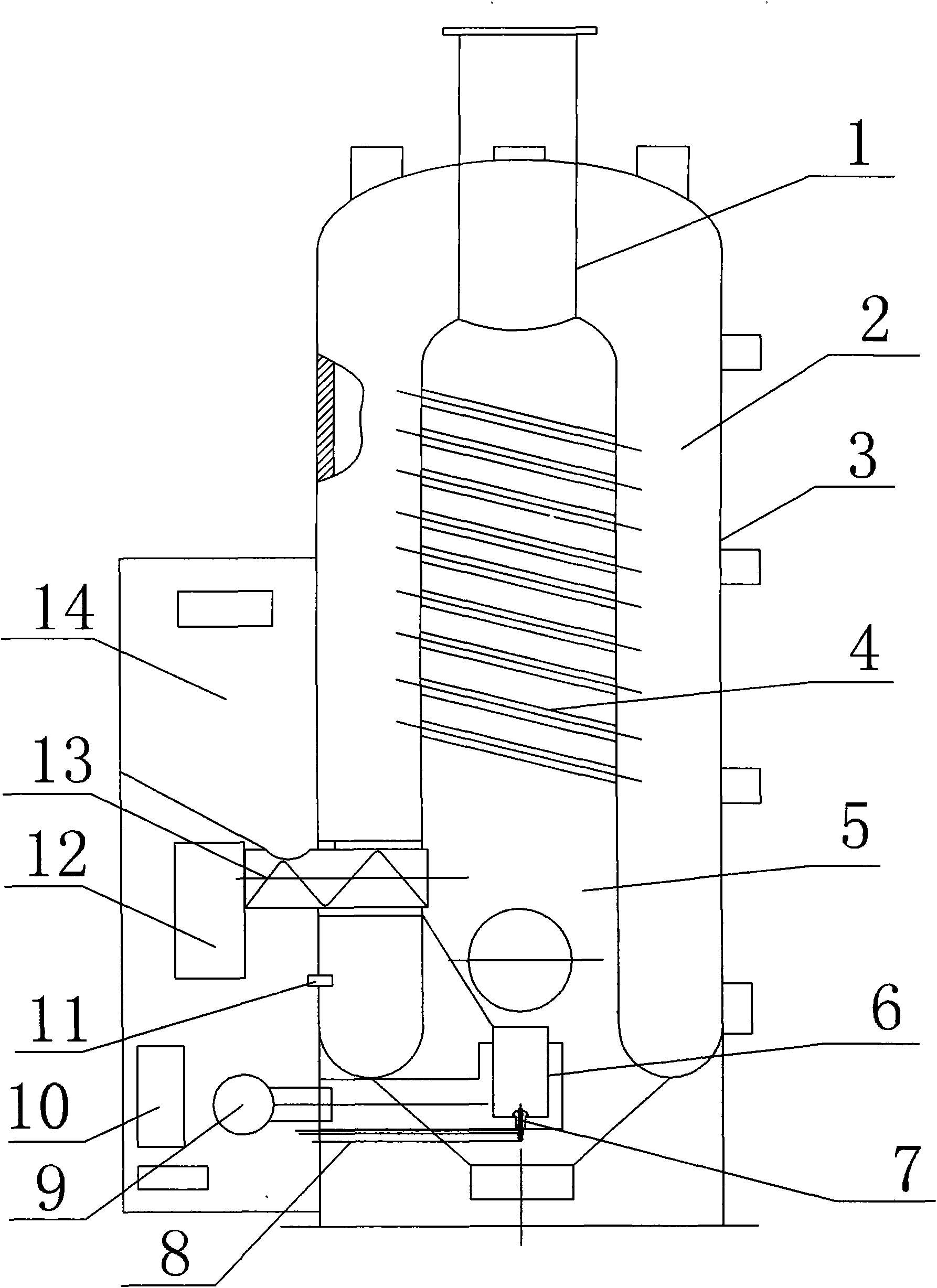

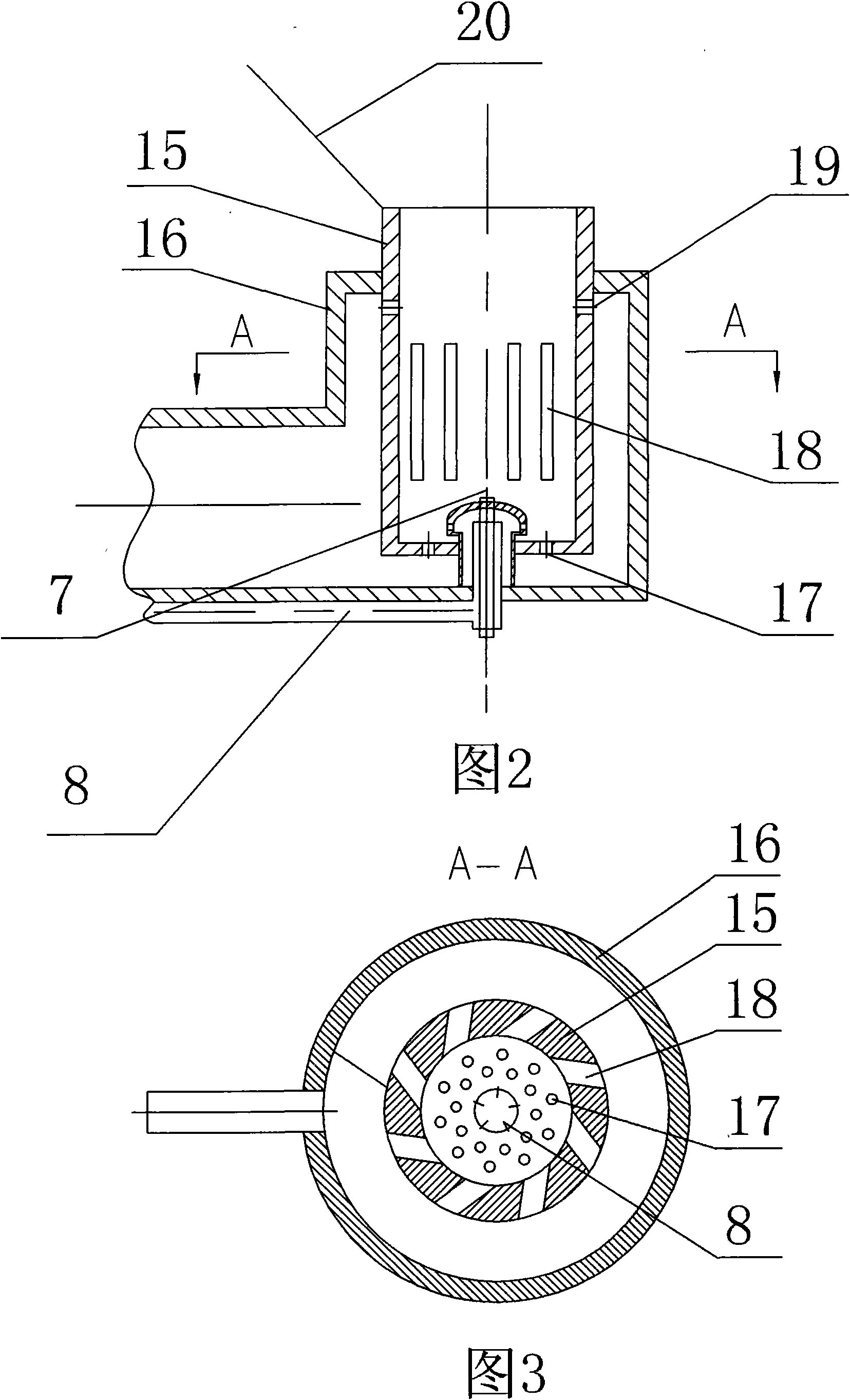

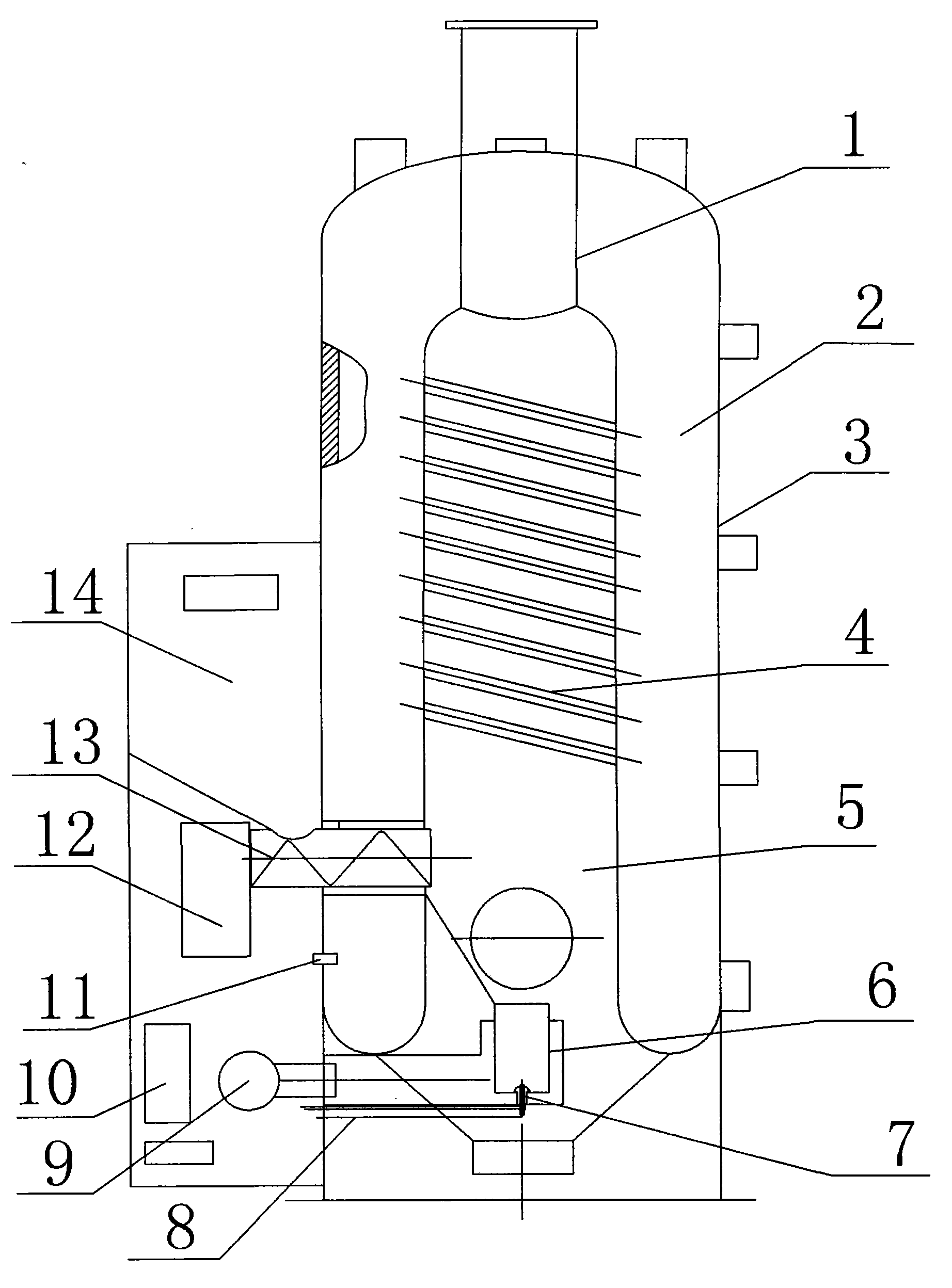

[0011] The present invention is mainly composed of an outer shell 3, a water storage chamber 2 and a combustion chamber 5. The top of the shell 3 is provided with a flue 1, and on the upper part of the combustion chamber 5 is a multi-drainage pipe 4 connected with the water storage chamber 2 at both ends. The water pipe 4 is inclined Installed in the combustion chamber 5. The burner 6 at the lower part of the combustion chamber 5 includes an inner cylindrical body 15 and an outer enclosed body 16. There is an ignition device 7 in the middle of the bottom of the inner cylindrical body 15, and the outer enclosed body 16 communicates with the fan 9; The bottom and sides of the cylinder 15 have air inlets in the middle and upper part. The air inlets 17 on the bottom of the inner layer of the burner 6 are a plurality of evenly distributed circular hole-shaped air inlets; the air inlet 18 in the middle of the inner side of the burner is a circle The upper and lower narrow and long ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com