Patents

Literature

42 results about "Heat inactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

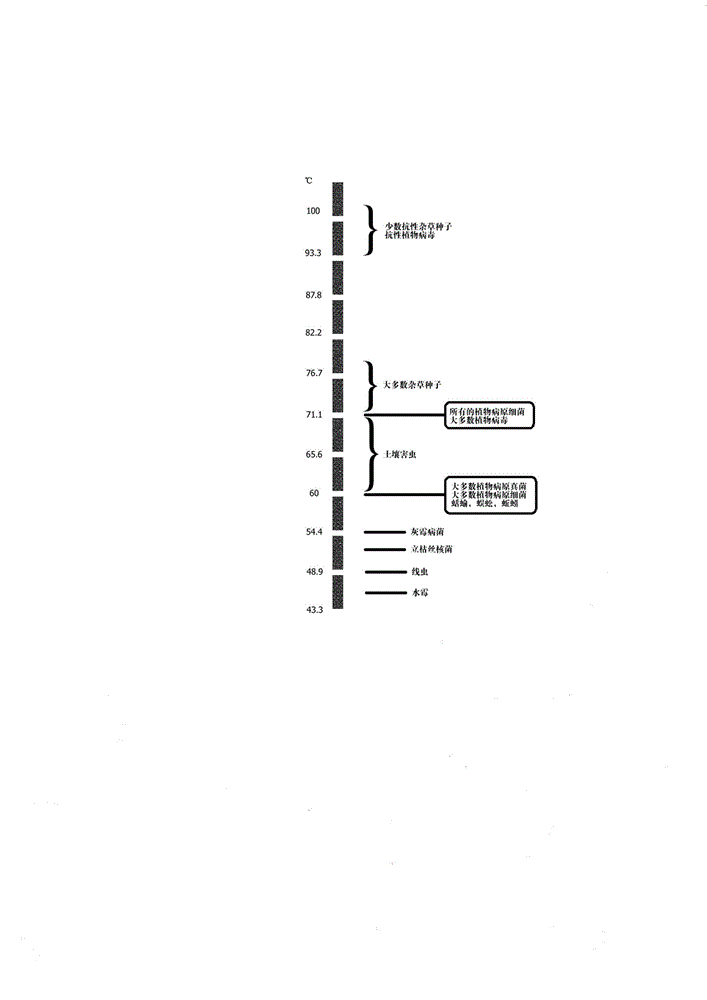

Heat Inactivation. Heat inactivation is a convenient method for stopping a restriction endonuclease reaction. Incubation at 65°C for 20 minutes inactivates the majority of restriction endonucleases that have an optimal incubation temperature of 37°C.

Activated carbon coating/foam silicon carbide structural catalyst and preparation method thereof

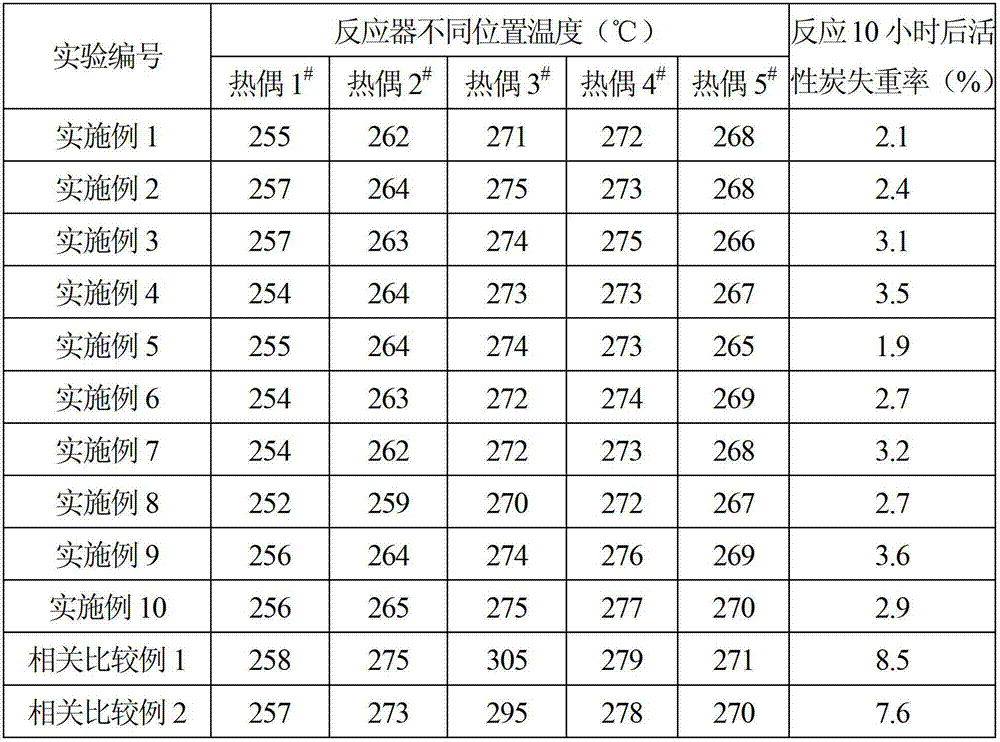

ActiveCN102814188AUniform temperature distributionSufficiently chemically inertCatalyst activation/preparationChemical reactionHeat inactivation

The invention relates to the field of structural catalysts, in particular to an activated carbon coating / foam silicon carbide catalyst with a three-dimensional communicated structure and a preparation method for the catalyst. The invention aims to solve the problems that hole opening is discontinuous, the catalyst and reaction products are separated, a heat transfer and mass transfer effect is poor and the like in the prior art. By taking foam silicon carbide as a catalyst carrier, an activated carbon coating covers on the surface of the foam silicon carbide, wherein the activated carbon coating is between 0.1 micron and 500 microns thick, and a metal catalysis active component is loaded on the activated carbon coating. The activated carbon coating is prepared on the surface of the foam silicon carbide with the three-dimensional communicated structure, then, the metal catalysis active component is loaded, and activating treatment is performed on the metal catalysis active component to obtain the catalyst. According to the activated carbon coating / foam silicon carbide catalyst, holes in the catalyst carrier are totally communicated, thus, an enclosure space does not exist, and a heat transfer and mass transfer process of the chemical reaction can be strengthened. The activated carbon coating / foam silicon carbide catalyst has the characteristics that the temperature field distribution of the catalytic reaction is uniform, the heat inactivation rate is low, the pressure drop is low and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Bioprotein sponge and preparation method thereof

InactiveCN102357259AStrong ability to absorb wound exudateReduce volumeSurgical adhesivesPeptide/protein ingredientsSide effectFreeze-drying

The invention discloses bioprotein sponge and a preparation method thereof. According to the characteristics that internal cells of a human body and an animal body adapt to cell growth environments, the bioprotein is freezed into a dry sponge shape through freeze drying technology by utilizing intercellular substances as controlled-release carrieres of growth factors and acts on the trauma of the human body or the animal body in controlled-release medicament feeding mode. The preparation method of the bioprotein sponge changes the traditional preparation process, adopts S / D virus inactivation, and adds protective agent to reduce probability of virus cross infection of people and livestock simultaneously. The CM cation chromatographic purification process improves purity of bioprotein, promotes stanching and tissue union effect of the bioprotein sponge and reduces clinical side effect. An ultrafiltration process is adopted to replace a dialysis process, so that preparation period is shortened, activity of the bioprotein is protected, and production cost is reduced. A method of heating inactivation virus replaces the method of cobalt60 radiation sterilization, so that the fact that radiation rays bring damage to products is avoided, the activity of the bioprotein is protected, and safe and reliable use of products in clinical application is achieved.

Owner:王珊珊

Inactivated lactobacillus effervescent tablets and preparation method thereof

ActiveCN103211143AFix existing technical deficienciesAvoid defectsFood shapingFood preparationEffervescent tabletDigestion

The invention discloses effervescent tablets with inactivated lactobacillus cells as an effective component, and a preparation method thereof. The inactivated lactobacillus effervescent tablets are prepared from the raw materials of, by weight, 5-15% of inactivated lactobacillus powder, 20-30% of oligosaccharide, 23-33% of an acid source, 25-35% of an alkali source, 2-5% of a disintegrant, and 2-5% of a lubricant. According to the invention, the lactobacillus cells are inactivated through a heat inactivation method. The effervescent tablets comprise lactobacillus cells, and have the functions of digestion promoting, intestinal micro-ecological balance maintaining, and human immunity improving. Also, the tablets comprise oligosaccharide bifidus factors, and can promote probiotic growth in bodies, such that a dual health-care effect is achieved. The effervescent tablets are convenient to carry and to eat. When the effervescent tablet is dissolved in proper amount of drinking water, an instant beverage can be obtained. The tablets are solid health-care beverages for various populations. The effervescent tablet preparation method provided by the invention is simple and feasible, and has important actual application and popularization values.

Owner:胡文锋

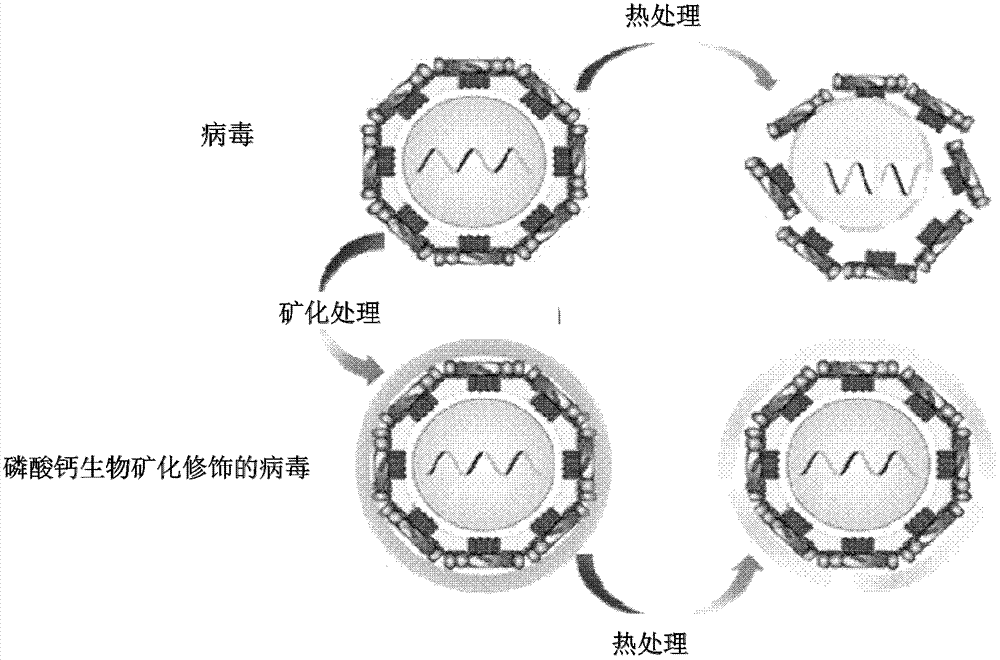

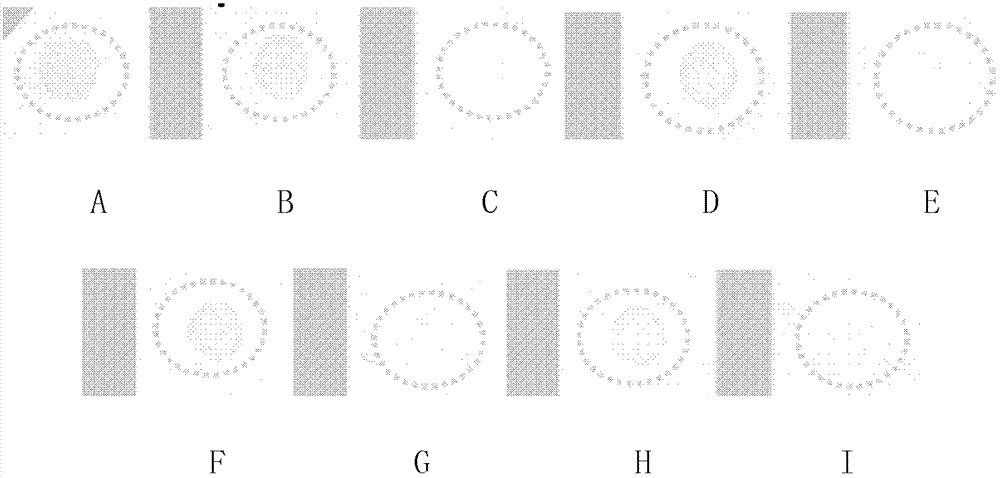

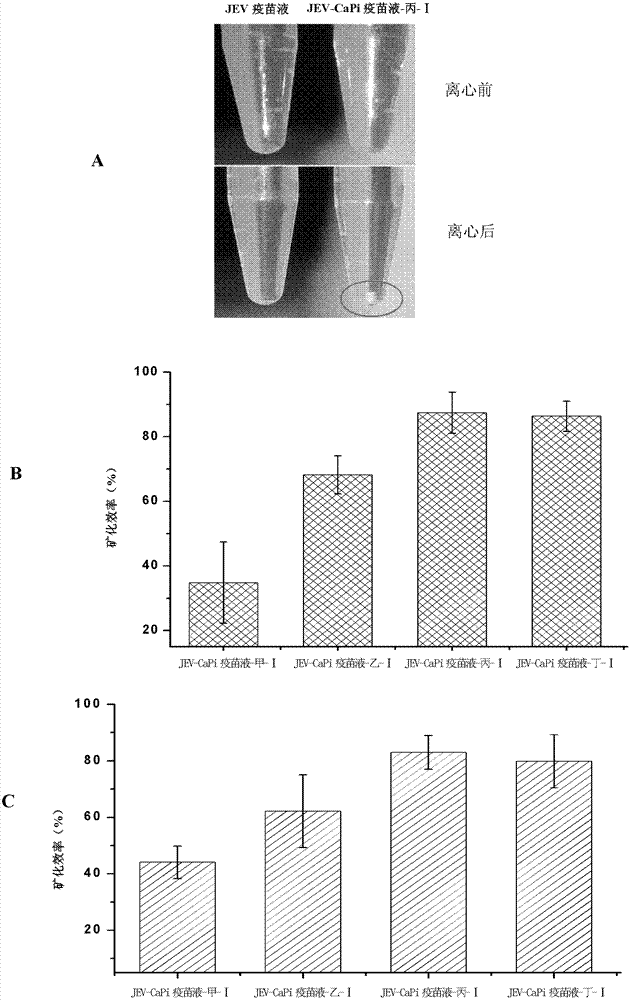

Method for preparing thermal-stability vaccine

ActiveCN102784390AImprove securityImprove effectivenessViral antigen ingredientsInorganic non-active ingredientsCalcium biphosphateVaccine Production

The invention discloses a method for preparing thermal-stability vaccine and particularly relates to a method for preparing thermal-stability vaccine based on calcium phosphate mineralization. The invention provides a method for preparing calcium phosphate coated viruses. The method comprises the following steps that (1) compounds with Ca<2+> ions are added into virus liquid, an initial system is obtained, and PO4<3-> ions are contained in the virus liquid; (3) the initial system is subjected to incubation; and (3) precipitation is centrifugally collected, and the calcium phosphate coated viruses are obtained. The method has the advantages that through virus surface mineralization modification, the problem of heat inactivation phenomenon in the vaccine transportation and storage process can be effectively solved, and the financial expenditure of the attenuated live vaccine is obviously reduced. The method can be widely applied to thermal-stability vaccine production and preparation.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI

Cuprous modified zeolite diesel engine emission pollutant oxidation and purification catalyst

ActiveCN106669843AReduce manufacturing costImprove sulfur resistanceGas treatmentExhaust apparatusSlurryCordierites

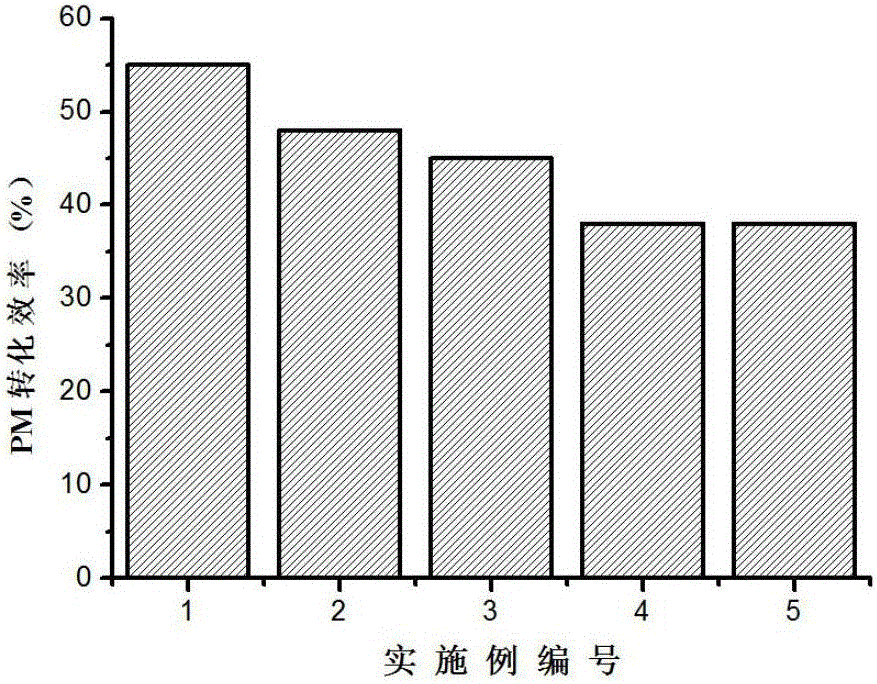

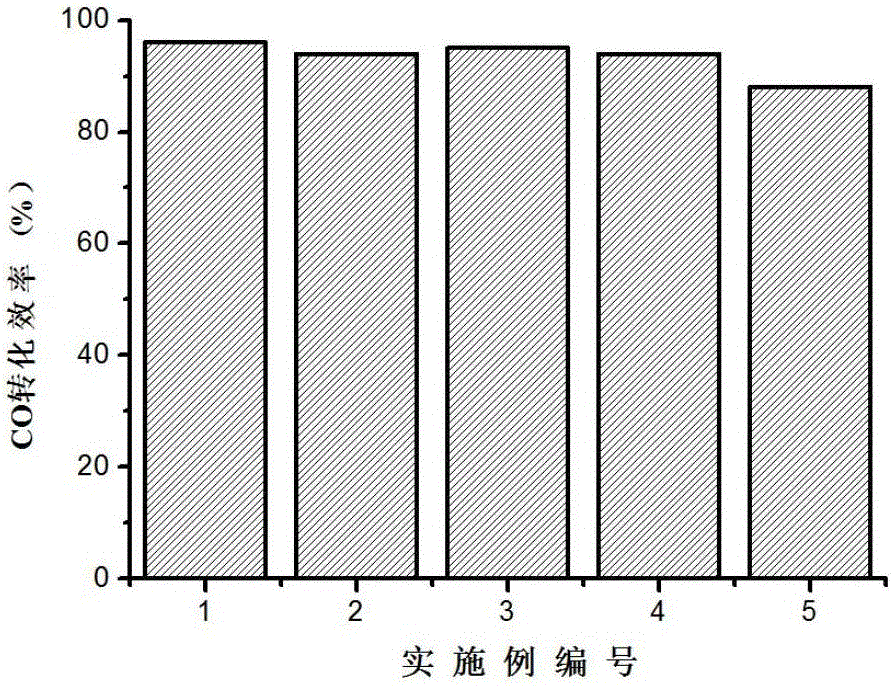

The invention discloses a cuprous modified zeolite diesel engine emission pollutant oxidation and purification catalyst. According to the catalyst, a cuprous modified ZSM-5 molecular sieve and La2O3 form a main catalyst, a CeO2-ZrO2 solid solution is taken as a cocatalyst, SiO2, TiO2 and gamma-Al2O3 form a coating base material and 400-mesh cordierite honeycomb ceramic is taken as a catalyst carrier. The preparation technology comprises the steps of preparation and determination of the raw material amount of a load catalyst, preparation of the cuprous modified ZSM-5 molecular sieve and preparation and coating of coating slurry. The catalyst is used for purifying HC, CO and PM pollutants in diesel engine exhaust by being packaged in a diesel engine oxidation catalyst. a noble metal main catalyst in a traditional diesel engine oxidation catalyst is replaced with the catalyst, so that the production cost is significantly reduced, the sulfur resistance and the heat inactivation resistance of the catalyst are improved, and the catalytic activity of the catalyst in low-temperature oxidation reaction is effectively improved.

Owner:TIANJIN UNIV

Method for removing low-concentration heavy metal by embedding heat-inactivation activated sludge with sodium acetylide

InactiveCN1702044AStrong ability to adsorb mixed heavy metalsWell buriedWater/sewage treatment by sorptionActivated sludgeVolumetric Mass Density

The low concentration heavy metal removal method by sodium alginate embedding heat-activated activated sludge, which pertains to heavy metal waste water disposal method, comprises the following steppes: treating the activated sludge from municipal sewage plant with scouring, centrifugal separation and drying under pressurization to deactivate it; embedding it with sodium alginate(CaCl2) to get immobilization calcium alginate ball(CA); filling fixed reactor with CA in certain density; continuously treating low concentration waste water containing mixing heavy metal such as Cd2+, Pb2+, Cu2+ and Zn2+; and selectively washing CA ball by hydrochloric acid to get mixing heavy metal adsorbed on CA ball. Heavy metal is retained while sorbent material revived to reuse. The invention has the advantages of high efficiency and economical and practical property.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

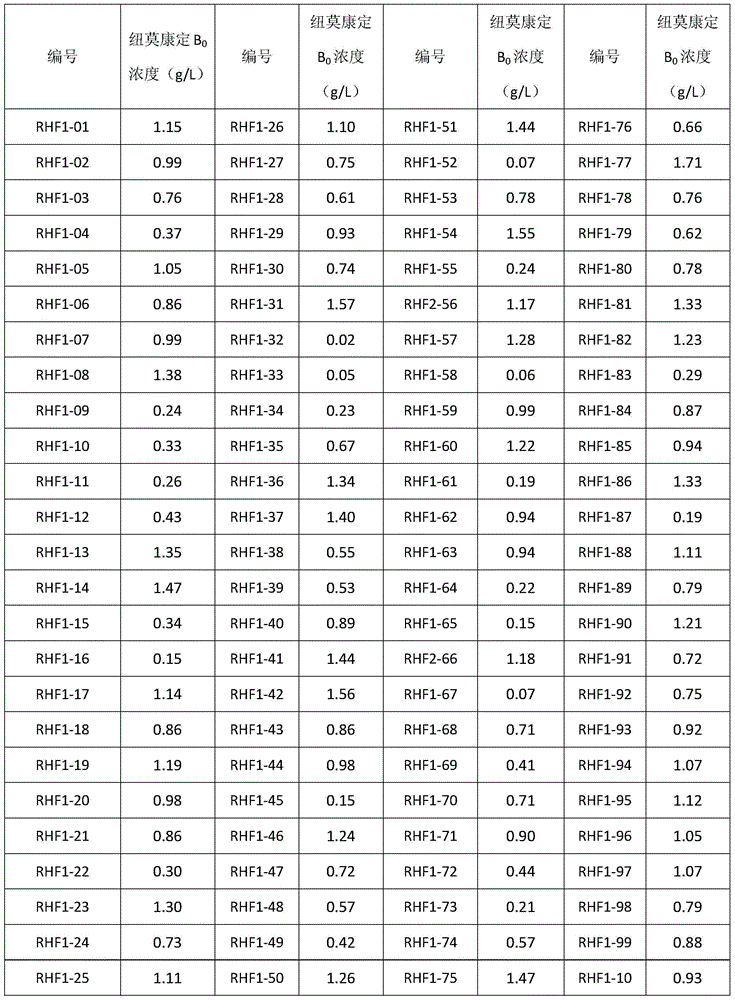

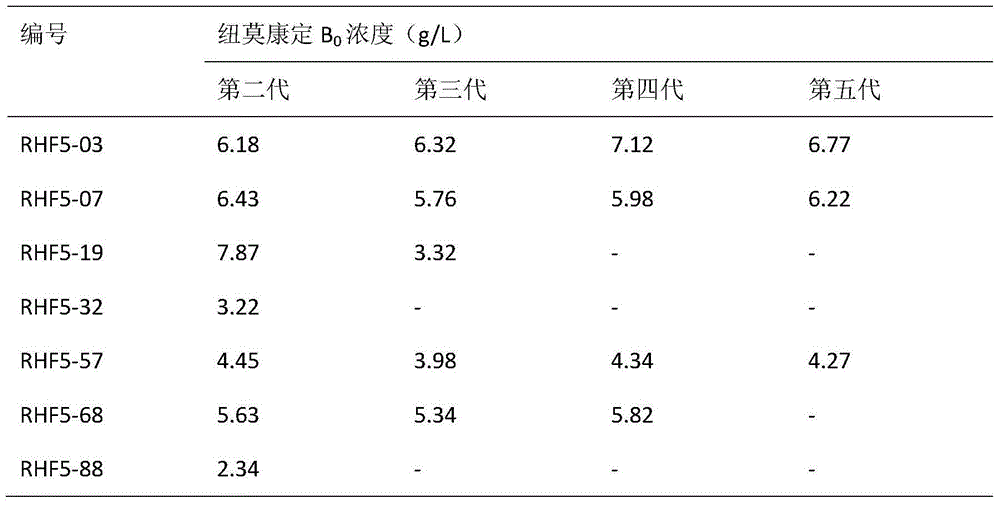

Genetic recombination strain for producing pneumocandins B0, breeding method and application

ActiveCN104531535AShort fermentation cycleEasy to separate and extractFungiMicroorganism based processesLithium chlorideGlarea lozoyensis

The invention discloses a genetic recombination strain for producing pneumocandins B0, a breeding method and applications. The bacterial strain classification name of the genetic recombination strain is Glarea lozoyensis Q45; the preservation registration number is CCTCC NO: M2014416; and the preservation date is September 14, 2014. The method for breeding the strain includes the steps that an original strain is manufactured into a protoplast; a mutation library composed of a plurality of mutant strains is obtained through ion implantation and lithium chloride processing; the mutation library is manufactured into a protoplast again; random fusion is carried out on the protoplasts after ion implantation inactivation and heat inactivation are carried out; fermentation screening is carried out on high-yield genetic recombinant bacteria; and protoplast preparation and fusion and fusant screening are carried out on the screened genetic recombinant bacteria, and therefore the genetic recombination strain is obtained. The genetic recombination strain is excellent in performance and stable in production capacity; the yield of the pneumocandins B0 obtained through fermentation is 6 g / L; in addition, by-products are few; the post-extraction difficulty of the pneumocandins B0 is reduced; the application to high-quality caspofungin preparation is facilitated; and the genetic recombination strain has the important industrial value.

Owner:NANJING UNIV OF TECH

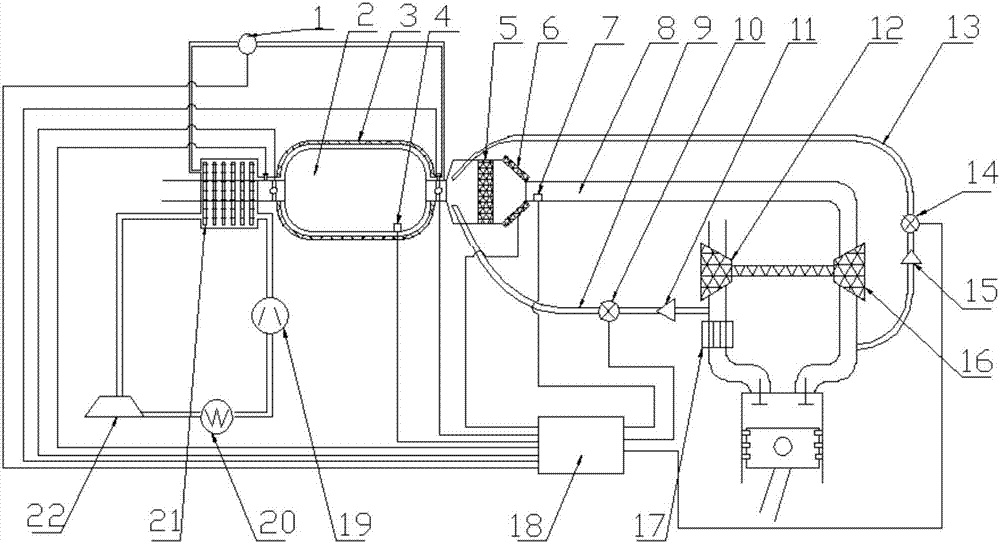

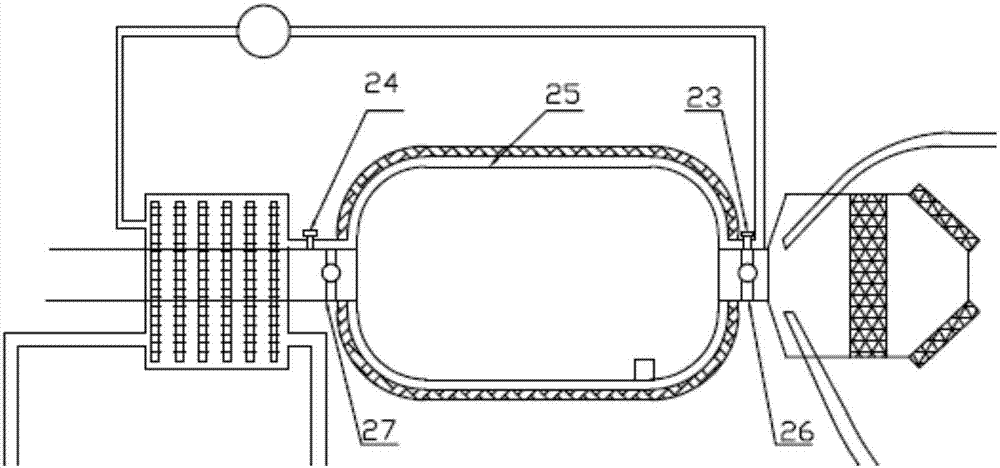

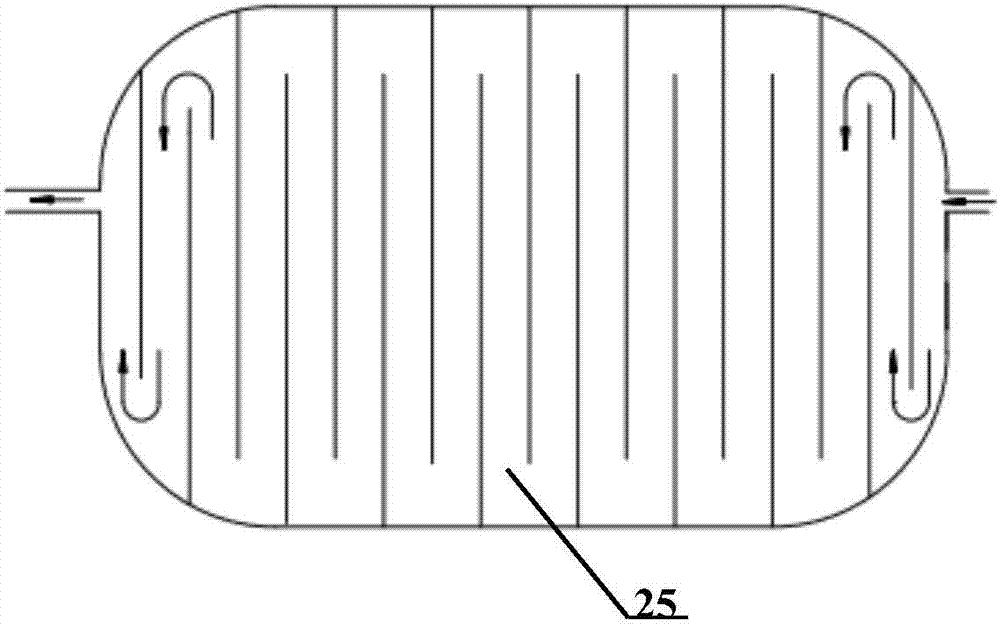

Device for reducing emission during cold start of automobile engine and control method

ActiveCN107035472AShorten light-off timeImprove Radiation AbilityExhaust apparatusSilencing apparatusCatalytic oxidationEngineering

The invention discloses a device for reducing emission during cold start of an automobile engine. During cold start of the engine, an intake bypass, an exhaust bypass and a heating device are used together to effectively shorten the rise time of a three-way catalytic converter, and high-temperature compressed air is pumped in to solve the problems of rich mixture during start of the engine and low conversion efficiency caused by oxygen deficiency during CO and HC catalytic oxidation. When the temperature of the three-way catalytic converter is higher than 850 DEG C, heat in the three-way catalytic converter is carried away by a cooling liquid via a cooling pipeline, so that sharp temperature rise of a catalyst due to sudden braking, abnormal combustion, continuous operation under high-load working condition and the like are prevented, and the conversion efficiency cannot be impacted by heat inactivation of the three-way catalytic converter. A Rankine cycle system is also provided to recover waste gas in an exhaust pipe and energy of the high-temperature cooling liquid flowing out of the three-way catalytic converter, so that air conditioners and other accessories are driven to act for use.

Owner:TIANJIN UNIV

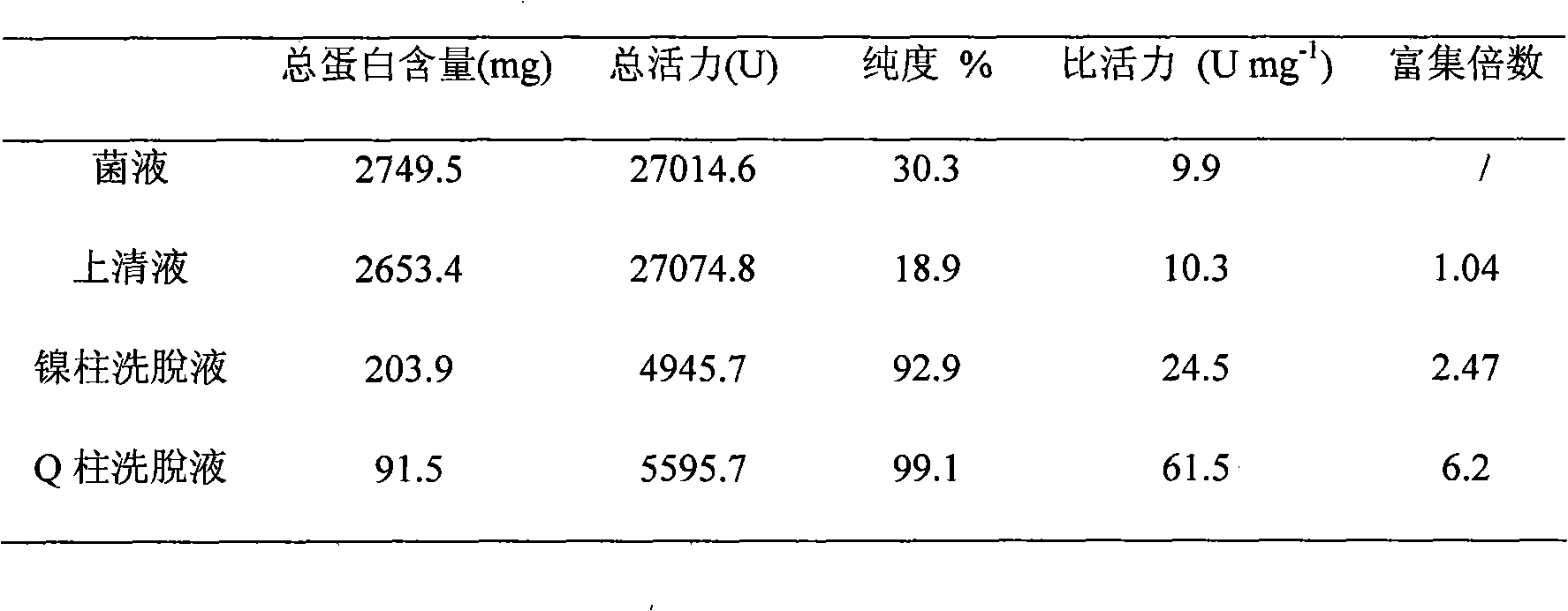

Low temperature alkaline phosphatase and preparation method thereof

InactiveCN102140444AGood inactivation propertiesSimple and fast operationHydrolasesFermentationEscherichia coliIon exchange

The invention belongs to the field of gene engineering, and relates to novel alkaline phosphatase and a preparation method thereof. The cDNA sequence of low temperature alkaline phosphatase shown as SEQ ID NO 1 in a sequence table is cloned to a vector for genetic engineering, and expressed to obtain the low temperature alkaline phosphatase. According to codon bias of Escherichia coli, the DNA sequence of the TAB5 low temperature alkaline phosphatase is transformed, so that the DNA sequence is highly expressed in the Escherichia coli; the alkaline phosphatase is purified by nickel affinity chromatography and ion exchange chromatography; and more than 90mg of TAB5 alkaline phosphatase with the purity of over 99 percent is obtained from each liter of Escherichia coli liquid finally. The invention can be applied to research in the field of molecular biology of the field of life science, particularly multi-step reaction for heat inactivation of alkaline phosphatase, such as sample treatment before DNA sequencing and the like.

Owner:FUDAN UNIV

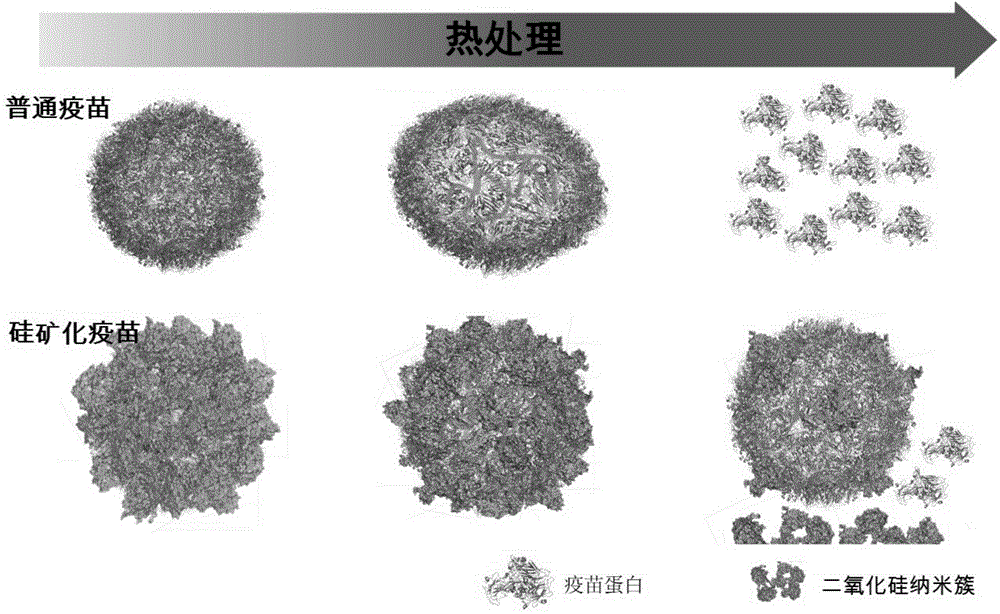

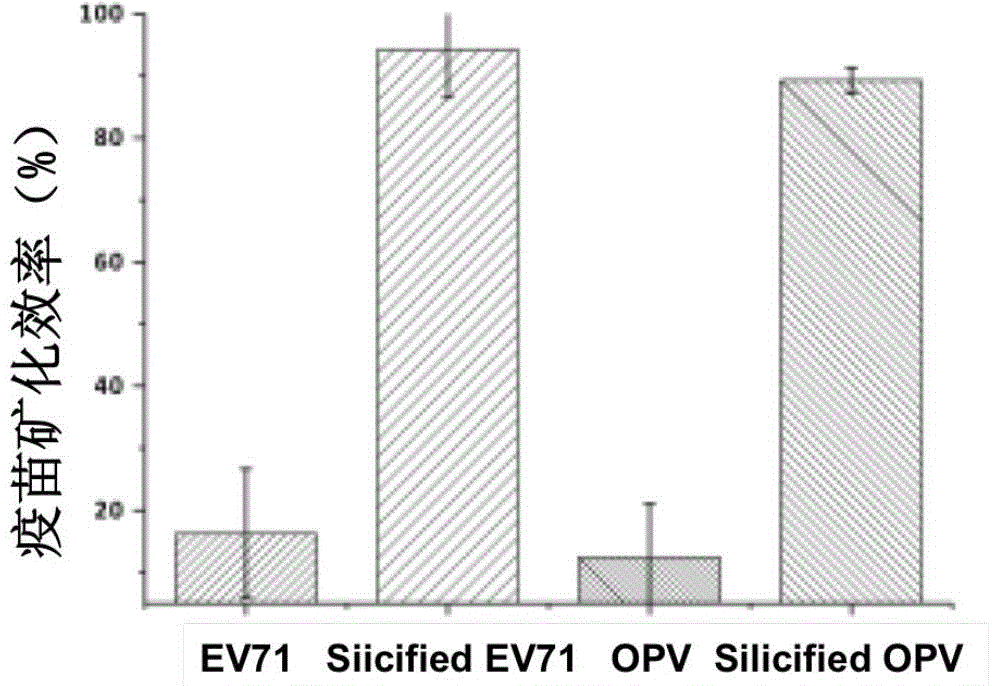

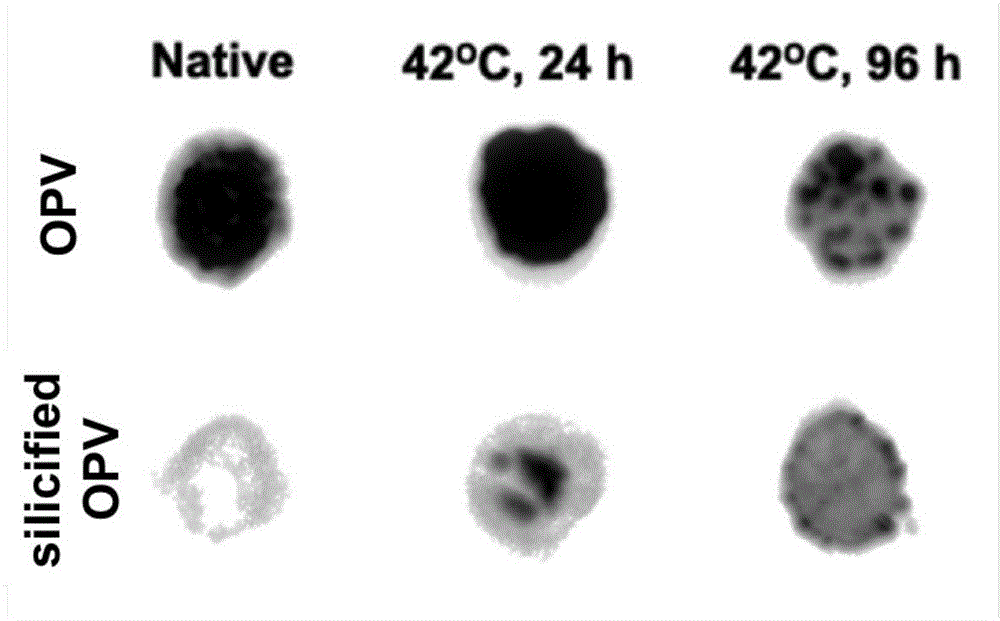

Thermostable vaccine with silica on surface and preparation method therefor

InactiveCN105267970AImprove thermal stabilityImproving immunogenicityAntiviralsMacromolecular non-active ingredientsHydrogenMedicine

The invention discloses a thermostable vaccine with silica on a surface, a preparation method and applications, and especially relates to introduction of a series of uncontinuous amorphous silica with a nanostructure on a surface of a vaccine in a specific manner based on in-situ bionic silicon mineralization. The provided thermostable vaccine is characterized in that uncontinuous amorphous hydrated state silica with a nanostructure exists on the surface of the vaccine. Because amorphous silica can exist stably, a lot of surrounding water molecules can be tied on the surface of the surface through hydrogen bonds to form a protective hydration layer, and therefore a relatively stable microenvironment is provided for the vaccine inside. Experiments show that the silica mineral is effective at the aspect of vaccine protection, the room temperature storage time is prolonged by nearly 10 times, financial expense for vaccine refrigeration is lowered greatly. The preparation method has wide application prospects in development and preparation of a novel thermostable vaccine, and heat inactivation phenomena of vaccines can be solved efficiently in transportation and storage.

Owner:ZHEJIANG UNIV +1

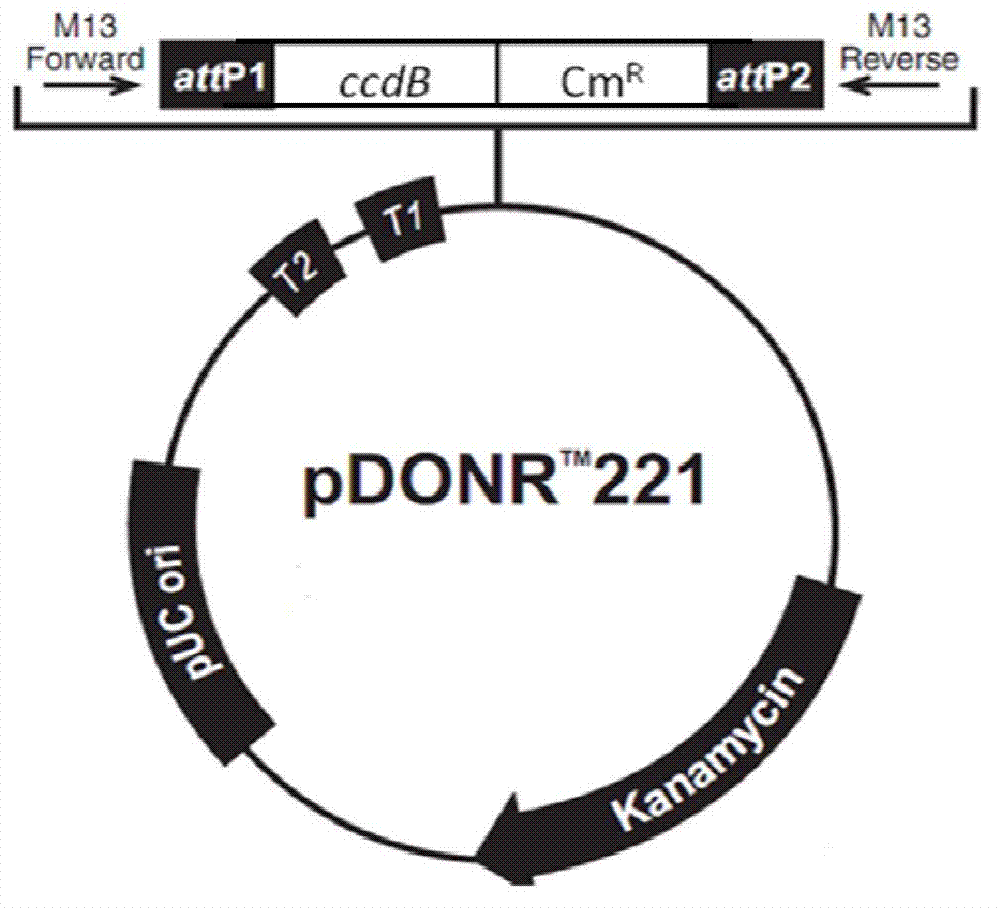

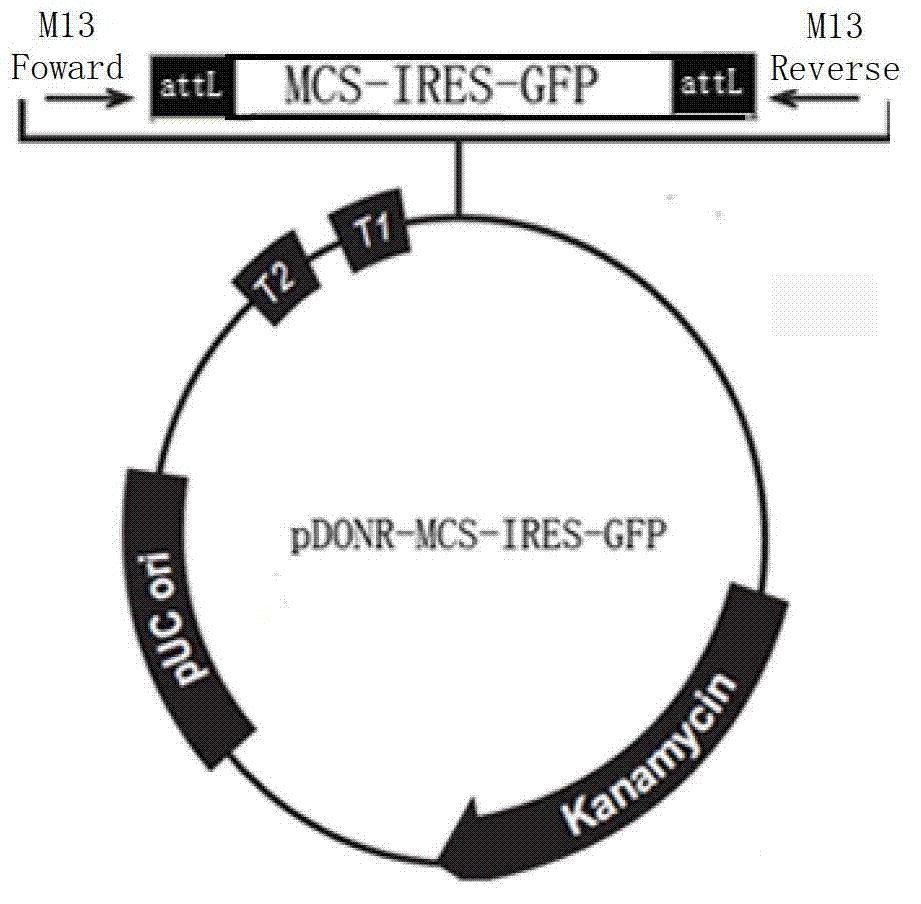

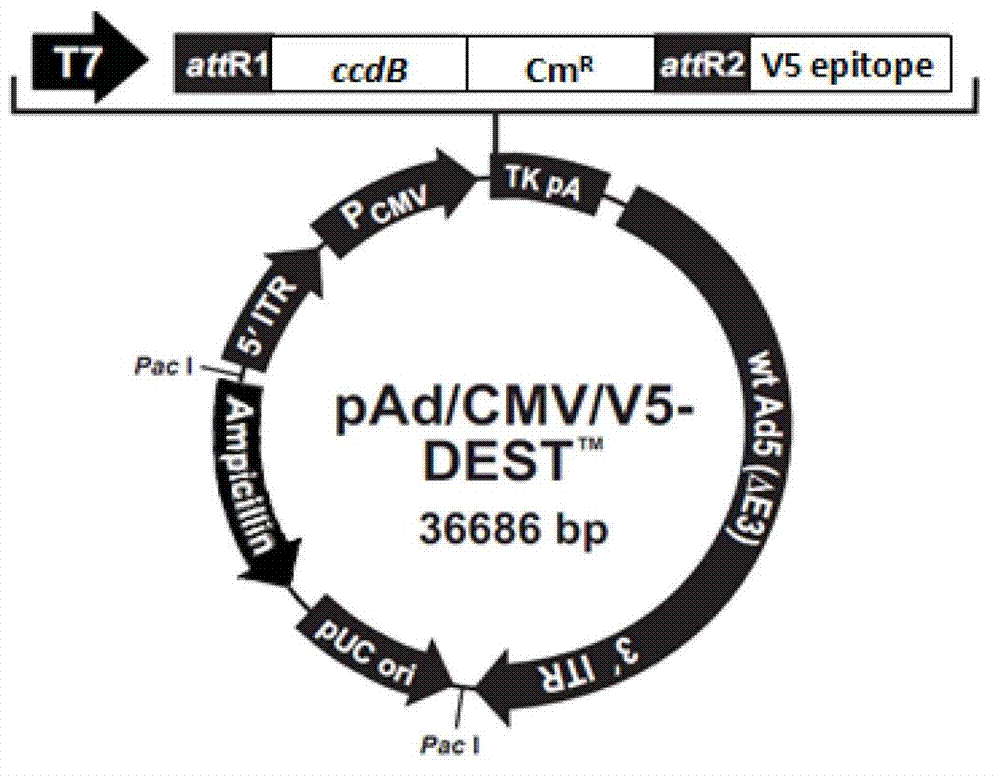

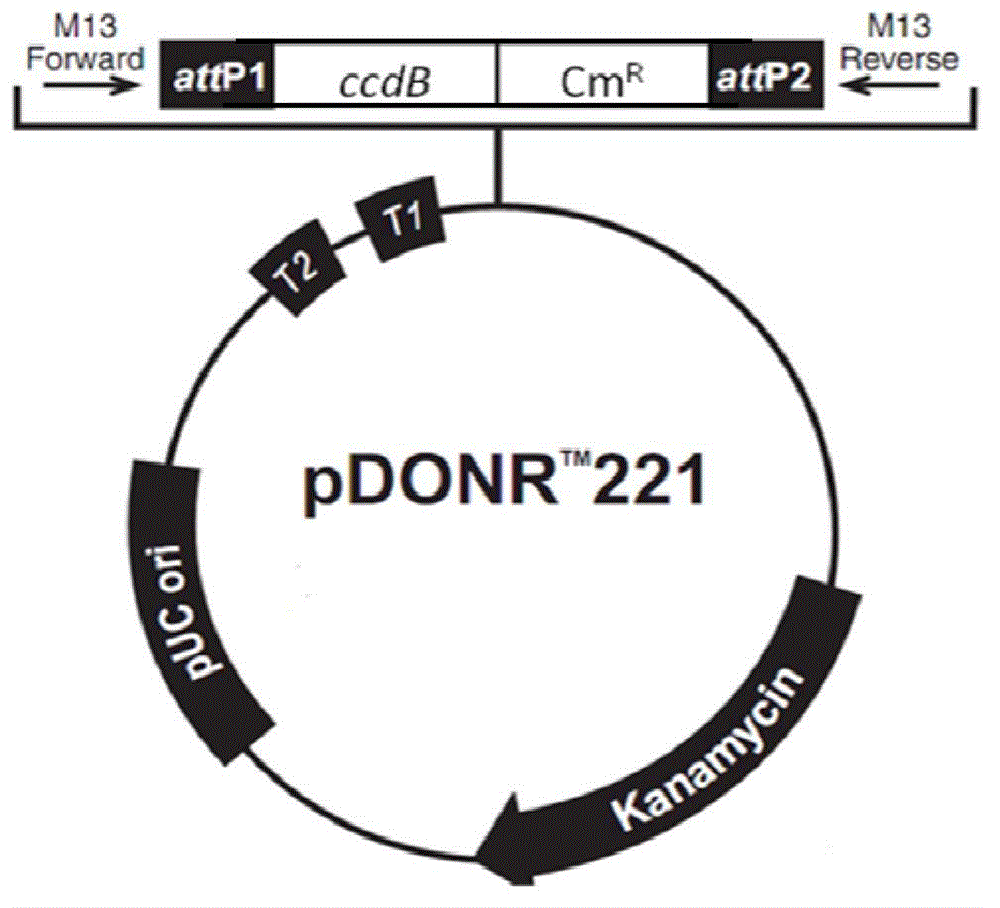

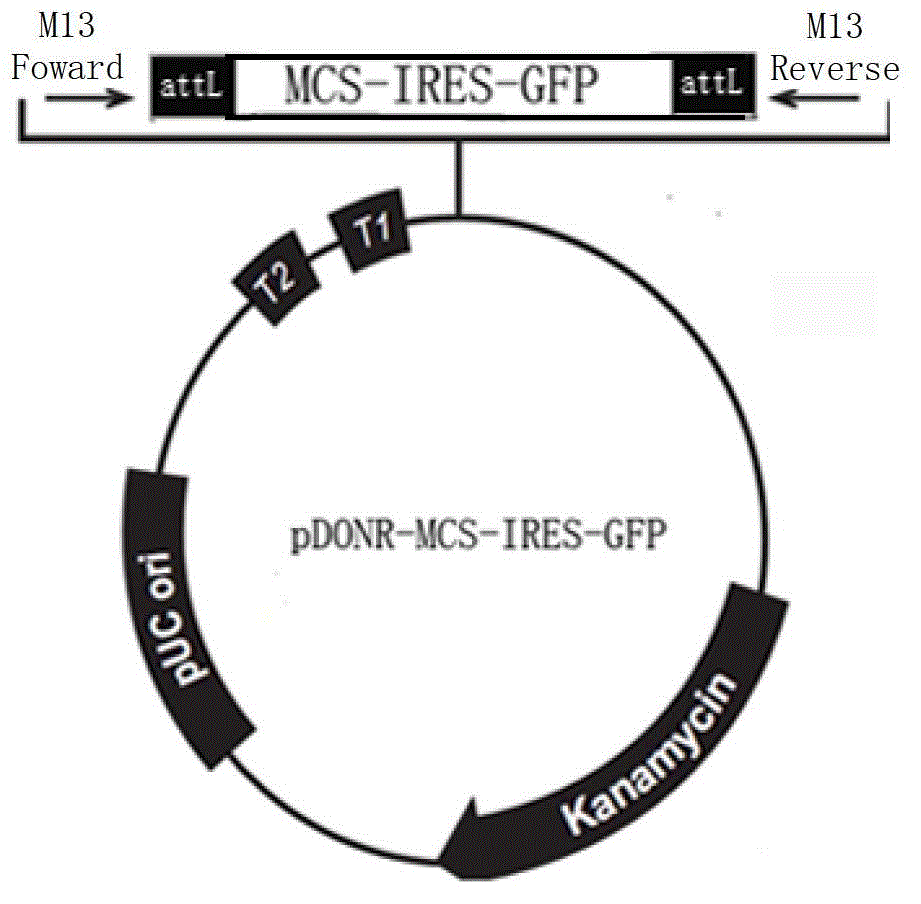

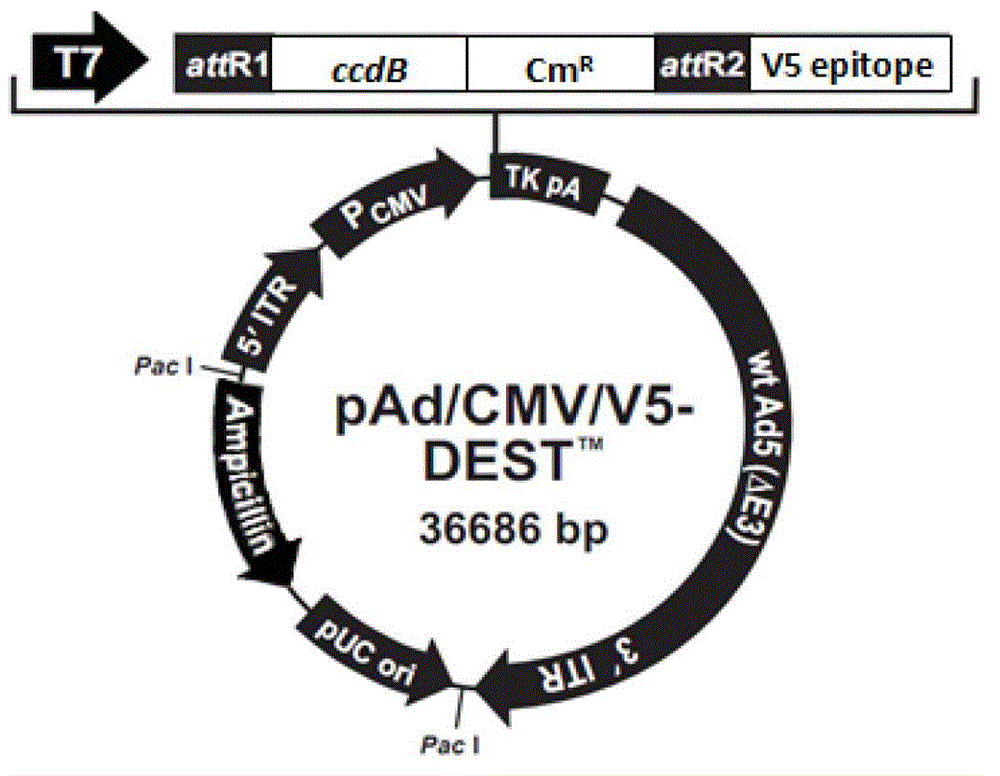

Improved adenovirus vector system, preparation and application of its virus particle

ActiveCN103290052AEffective infectionEasy to operateViruses/bacteriophagesGenetic engineeringInfected cellPurification methods

The invention discloses an improved adenovirus vector system and a virus preparation method. The system takes a pDONR221 vector as an initial vector to make improvement, and multiple cloning sites and an IRES-GFP fragment are inserted. The system combines enzyme digestion connection and recombination reaction technologies, can efficiently construct a vector, and also reduces the reagent cost. The invention also discloses an improved method of purification following after enzyme digestion of the virus vector. The method abandons traditional purification methods adopting phenol, chloroform and isoamyl alcohol, and uses a conventional DNA recovery column or direct heat inactivation method. The method is simple and feasible, shortens the operation time, reduces the material cost, and has no need for toxic phenol and chloroform reagents. The adenovirus system combining the two aspects has improved preparation efficiency and reduced cost, and still maintains high efficiency in infected cells.

Owner:上海诺百生物科技有限公司

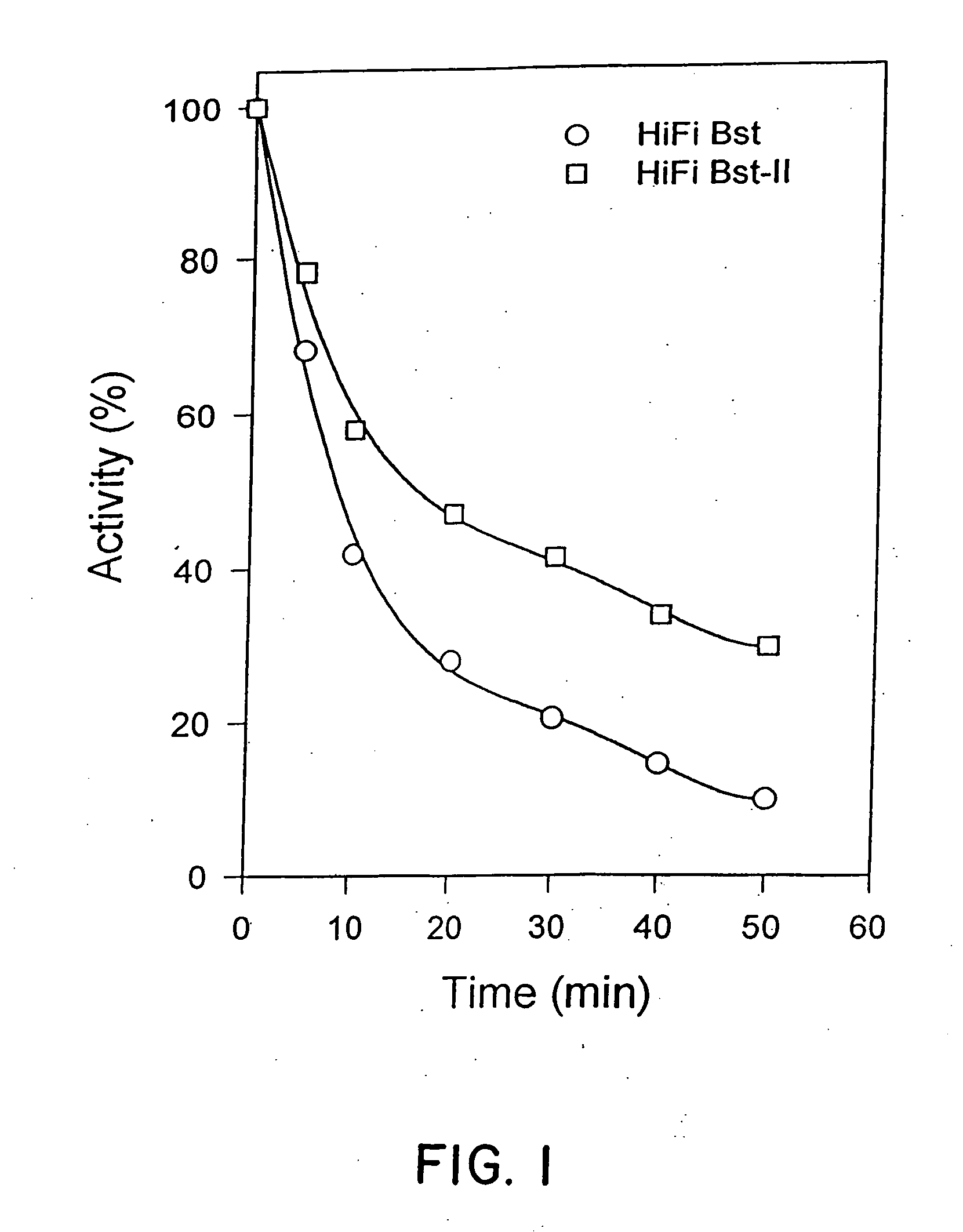

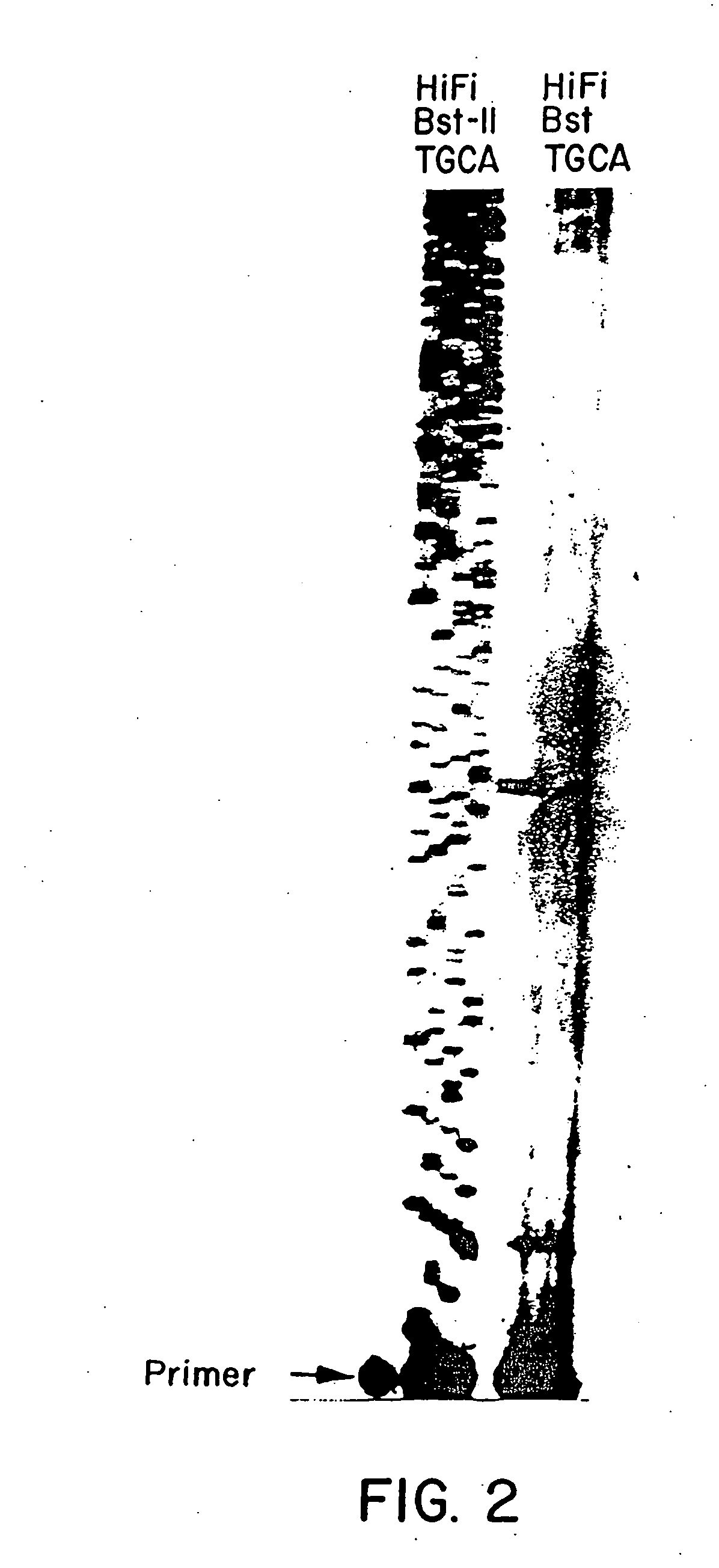

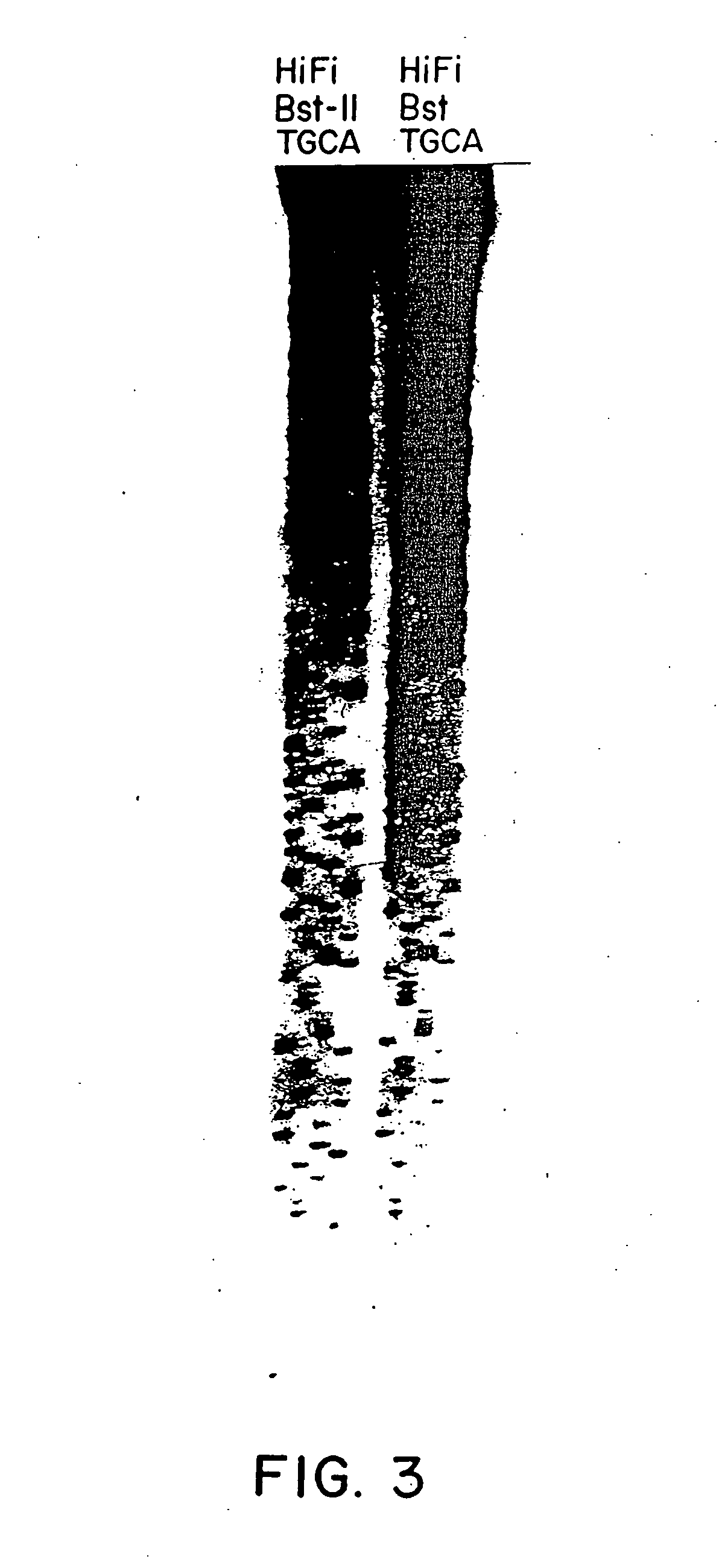

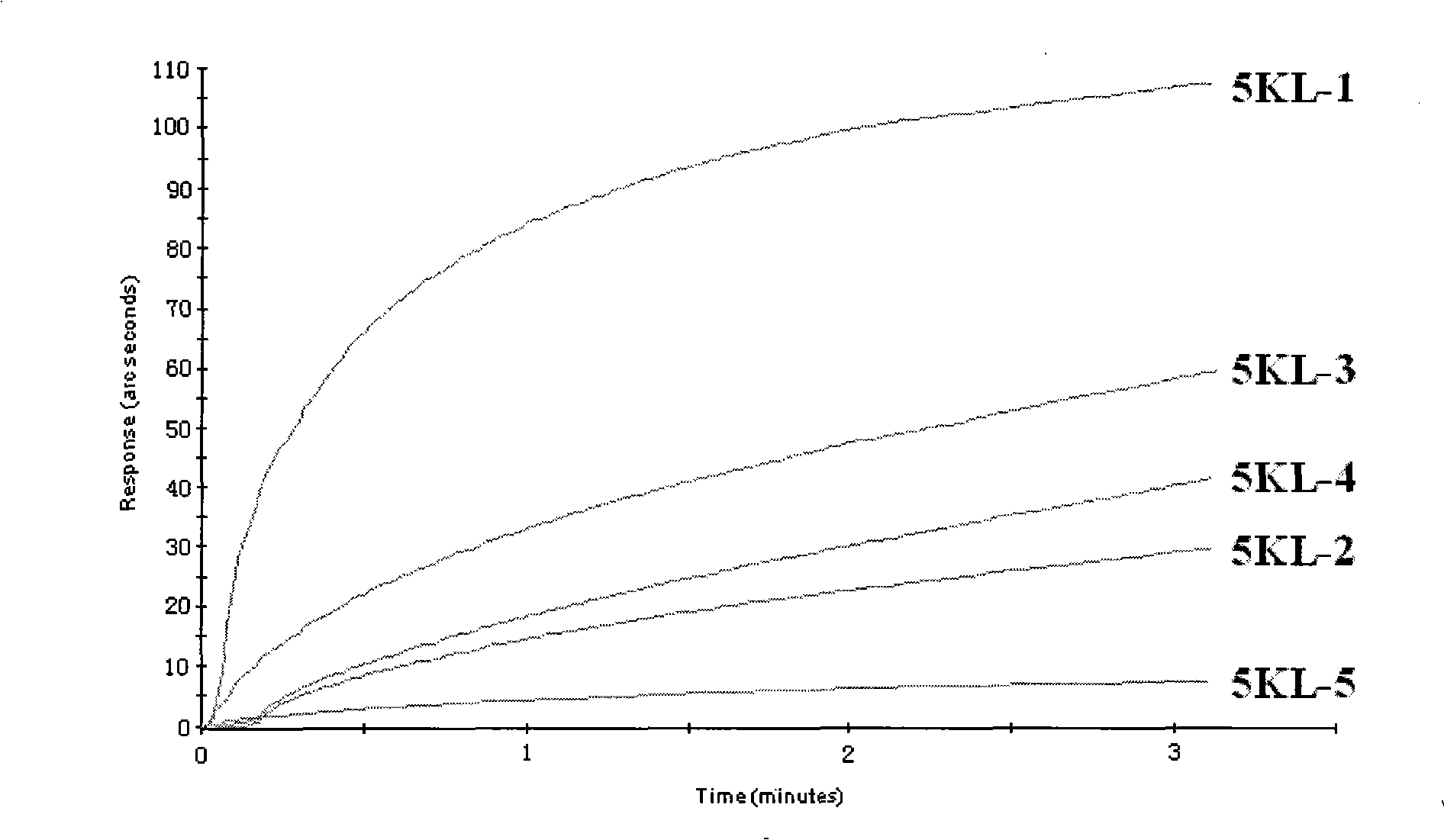

DNA polymerase having ability to reduce innate selective discrimination against fluorescent dye-labeled dideoxynucleotides

InactiveUS20050089910A1Reduced discriminationIncrease ratingsSugar derivativesBacteriaModified dnaFluorescence

The invention relates to genetical modification of DNA polymerase to reduce its innate selective sequence-related discrimination against incorporation of fluorescent dye-labeled ddCTP and ddATP in the enzymatic reaction for preparation of samples for automated florescent dye-labeled terminator DNA sequencing. The modified DNA polymerases are more resistant to heat inactivation and are more effective in dideoxynucleotide incorporation than current DNA polymerases.

Owner:HONG GUOFAN +1

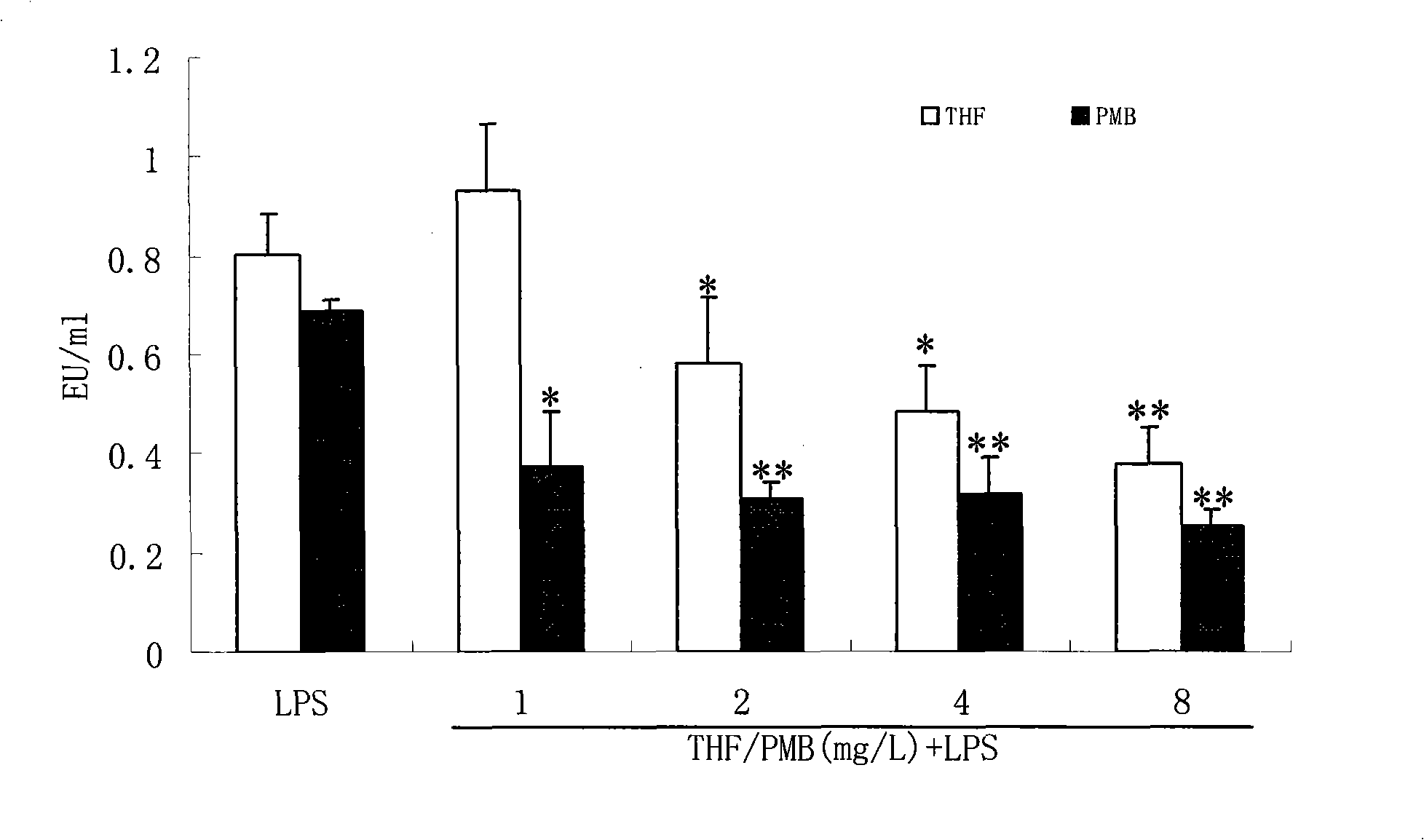

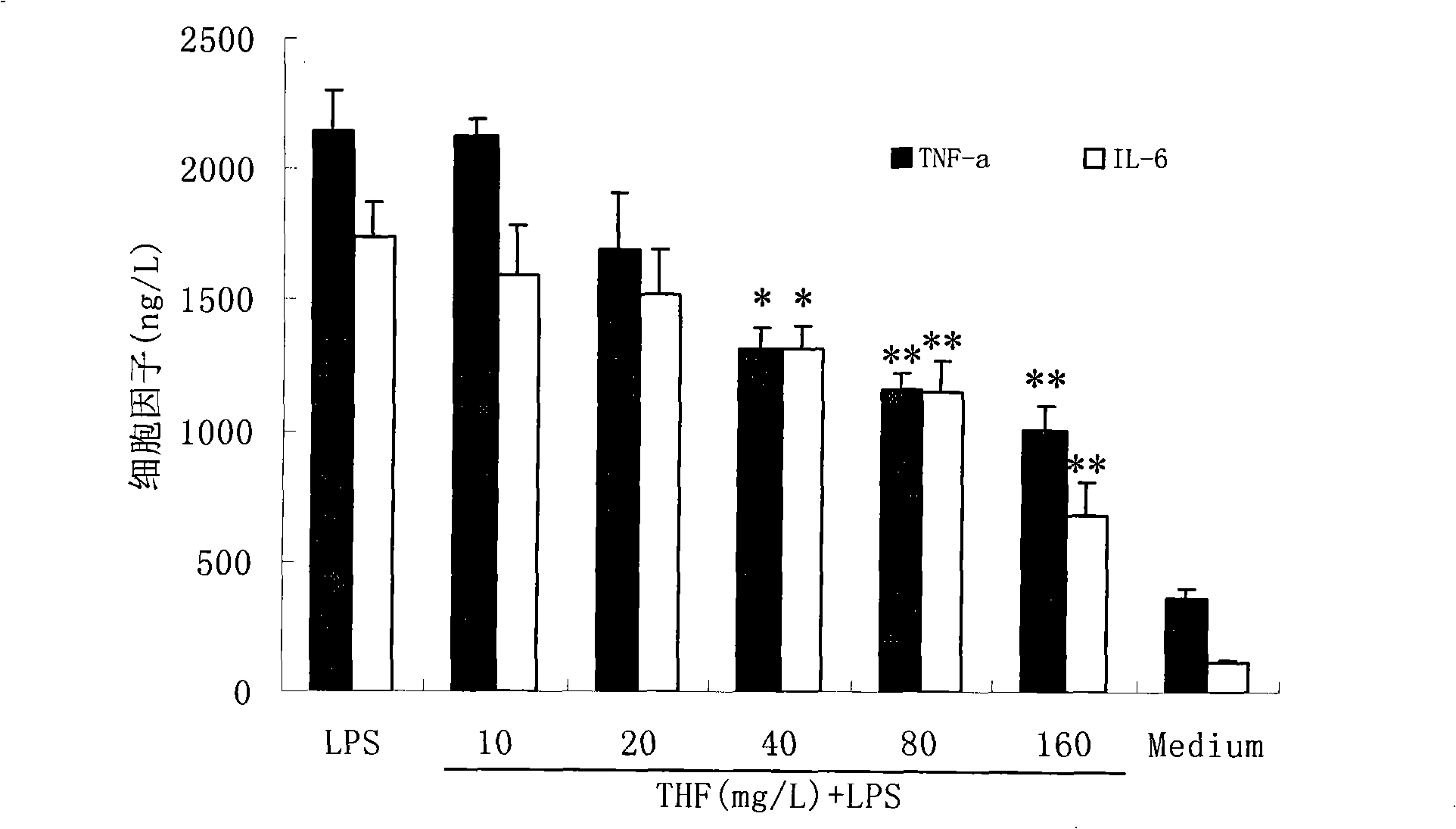

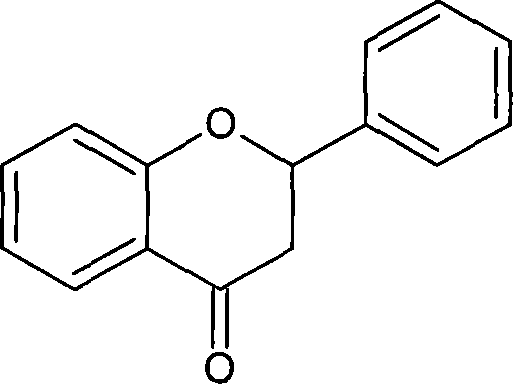

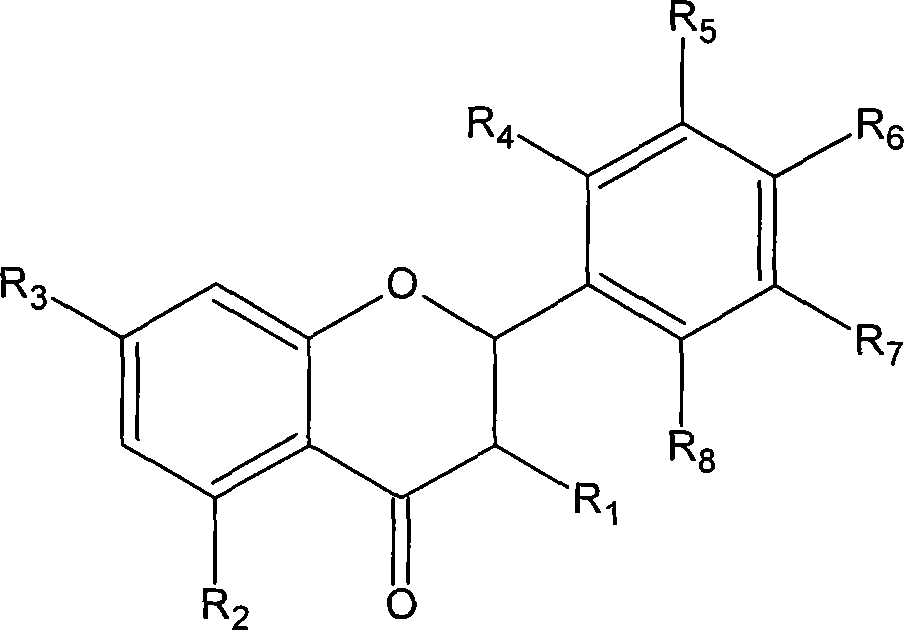

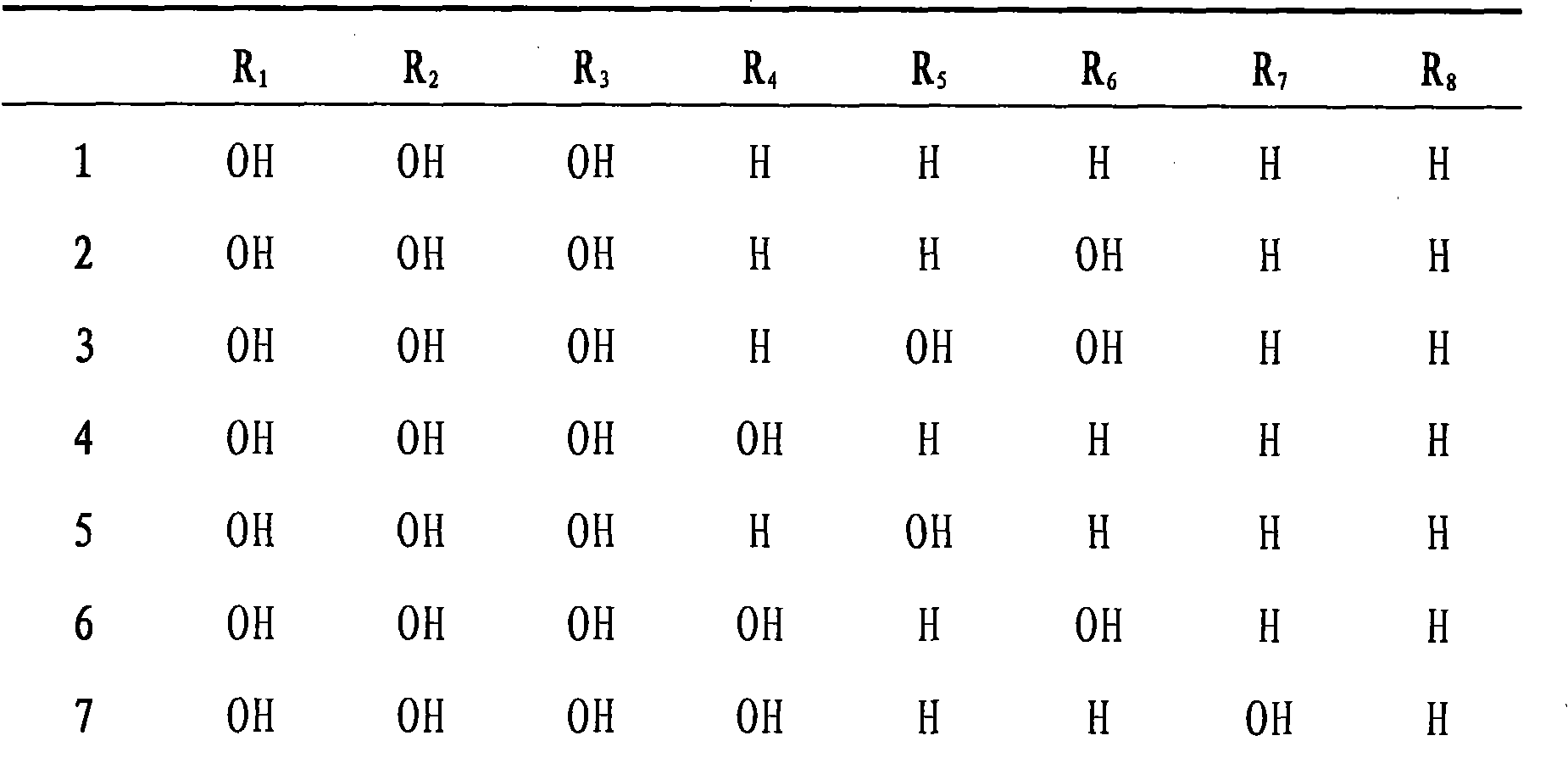

Application of 2í», 5, 6í», 7-tetrahydroxy dihydroflavonol and its derivative for treating sepsis

InactiveCN101264075ALower LPS levelsLower levelOrganic active ingredientsAntipyreticEscherichia coliCell activation

The invention relates to the usage of a 2',5',6',7'-tetrahydroxyflavanonol and the derivative in treating pyohemia, belonging to flavanonol compound THF, which is extracted and separated from baikal skullcap root of Chinese herbal medicine. Through experiment showing, the THF has the advantages that: the THF has direct neutralization effect and reveals better dose effect relationship; the THF also reveals better dose effect relationship upon inhibition of RAW 264.7 cells activation LPS stimulation; the THF can lower LPS level in blood of LPS blood symptom model animal in vivo; the THF also has obvious protection effect upon bacterial sepsis model mouse caused by heat-inactivation escherichia coli with lethal dose; the THF has good application prospect under the condition of lacking effective means treating pyohemia in prior study.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Black tea concentrated solution and preparation method thereof

ActiveCN105230849AStable interfacial tensionPrevent Mutual AggregationPre-extraction tea treatmentTea extractionUltrafiltrationBlack tea

The invention provides a black tea concentrated solution and a preparation method thereof. Specially, the preparation method of the black tea concentrated solution comprises the following steps: (1) leaching: taking a black tea and leaching the taken black tea with water which is 20-40 times as much as the black tea so as to obtain a leaching solution, wherein the water temperature is 60-90 DEG C; (2), performing enzymatic hydrolysis: sequentially adopting esterases for performing enzymatic hydrolysis on the leaching solution obtained in the step (1), adopting tannase for performing enzymatic hydrolysis on the leaching solution on which enzymatic hydrolysis is performed with the esterases, and adopting protease for performing enzymatic hydrolysis on the leaching solution on which enzymatic hydrolysis is performed with the tannase; (3) adding a compounded emulsifying stabilizing agent: performing heat inactivation on the leaching solution on which enzymatic hydrolysis is performed, cooling the leaching solution on which heat inactivation is performed, and adding the compounded emulsifying stabilizing agent which is 0.1-0.5% as many as the weight of the black tea obtained in the step (1), and uniformly stirring the leaching solution and the compounded emulsifying stabilizing agent, wherein the compounded emulsifying stabilizing agent consists of cane sugar fatty acid ester, glyceryl monostearate and sodium hexametaphosphate; (4) homogenizing: sequentially homogenizing the leaching solution at the temperature of 40-50 DEG C and the first-class pressure of 190-210MPa, and then homogenizing the homogenized leaching solution at the temperature of 40-50 DEG C and the second-class pressure of 20-30MPa; and (5) post-treating: centrifuging the homogenized leaching solution, performing ultrafiltration and concentrating the ultra-filtered leaching solution so as to obtain the concentrated solution, regulating the pH value to be 6-6.5, performing sterilization, and filling so as to obtain the black tea concentrated solution.

Owner:SHENZHEN SHENBAO HUACHENG TECH

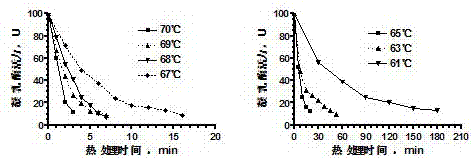

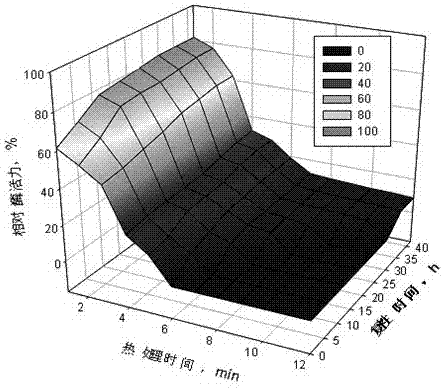

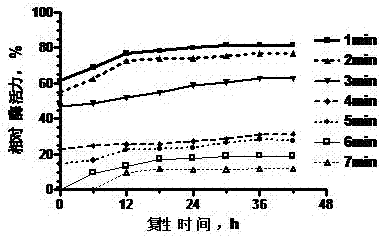

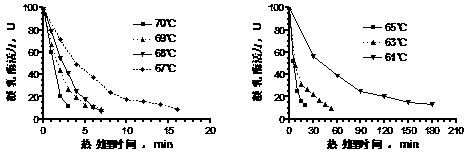

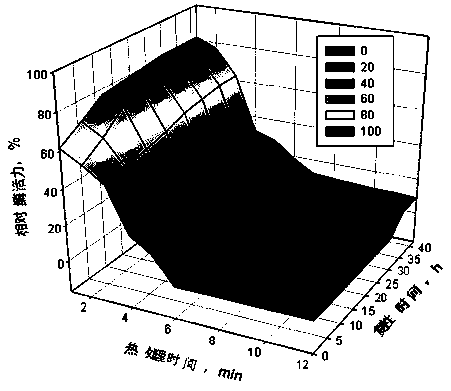

Preparation method for partially inactivated chymosin

The invention belongs to the technical field of protein renaturation and especially relates to a preparation method for partially inactivated chymosin. The preparation method comprises the following steps: (1) placing a chymosin solution containing ectoine under the temperature at 61-70 DEG C and treating for 1-20min, thereby acquiring the partially inactivated chymosin, and (2) quickly cooling the partially inactivated chymosin prepared in the step (1) to 4 DEG C, standing by and refrigerating for 0-42h, thereby acquiring the chymosin after renaturation. The method is different from the treating method for high concentration urea, and the like; a heat inactivation method is adopted for preparing the partially inactivated chymosin; the operation is simple and easy, the repeatability is high and the state of the partially inactivated chymosin is more approximate to the heat inactivation state of enzyme; the inactivated chymosin prepared according to the method has the characteristics of obvious renaturation effect, high enzyme activity after renaturation, and the like.

Owner:SHANDONG POLYTECHNIC

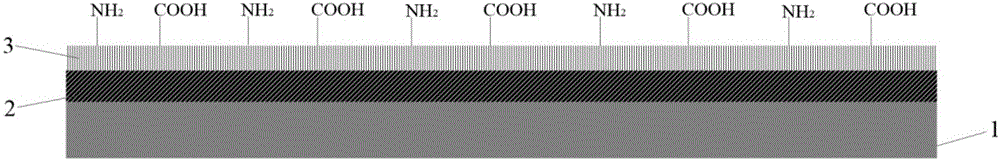

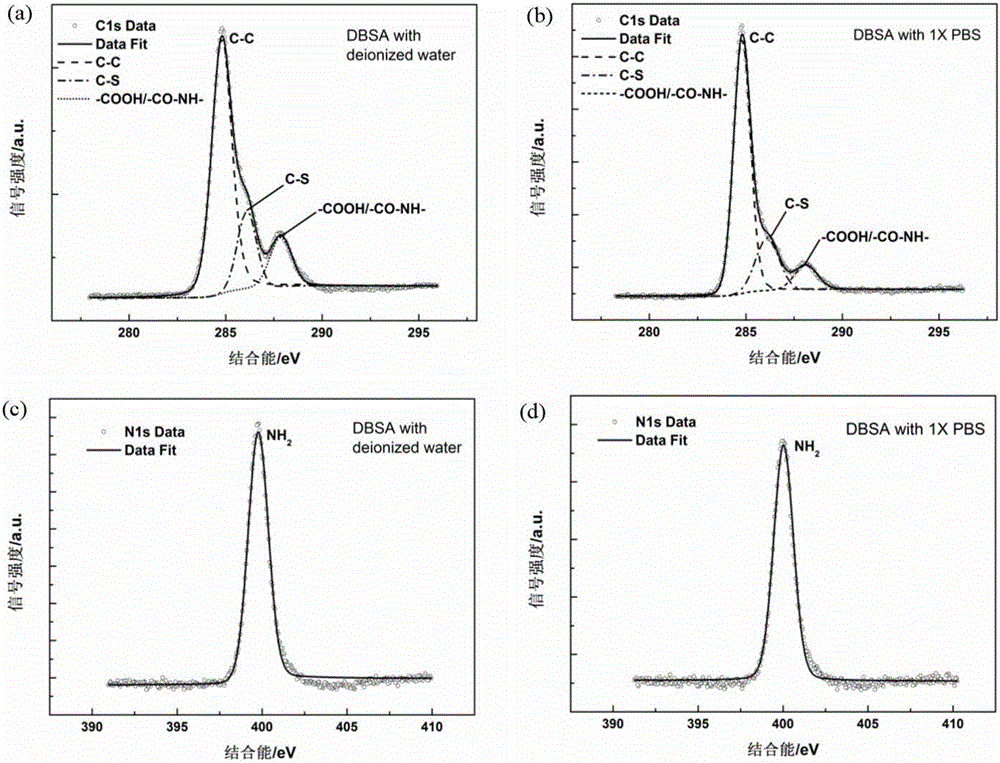

Graphene and protein composite film based on non-covalent modification and preparation method thereof

ActiveCN106335234AAchieve dopingEasy to operateMaterial analysis using wave/particle radiationLaminationComposite filmSingle layer graphene

The invention relates to a graphene and protein composite film based on non-covalent modification and a preparation method thereof. The composite film comprises a silica substrate, single-layer graphene and a protein film. The preparation method comprises the following steps: transferring the single-layer graphene film grown through chemical vapor deposition onto the surface of the silica substrate, removing a photoresist on the surface of the graphene film to leave single-layer graphene on the surface of the silica substrate; and dropwise adding the a protein solution onto the surface of the single-layer graphene and carrying out heat inactivation treatment at 60-90 DEG C for 1-10 min to form a protein film on the surface of the single-layer graphene. Non-covalent modification of the protein film is realized on the surface of graphene through the heat inactivation method. Thickness of the graphene-protein film can be controlled to nanoscale. The film is uniform. The preparation method is simple to operate and easy to realize. The protein film surface has amino group and carboxyl group and can be used as a platform for follow-up biomolecule diagnosis. The product has a good application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

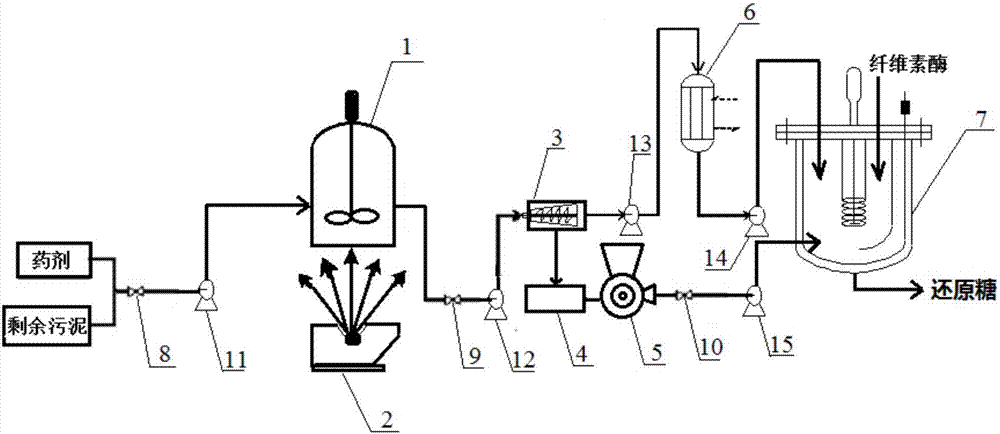

Efficient resourceful treatment device for residual sludge

ActiveCN107055994AAchieve crackingAchieve releaseSludge treatment by de-watering/drying/thickeningEnzyme production/based bioreactorsSludgeProcess engineering

The invention provides an efficient resourceful treatment device for residual sludge. The efficient resourceful treatment device comprises a chemical mixing unit, a liquid-solid separation unit, a liquid-phase concentration unit, a solid-phase grinding unit and a reaction kettle, wherein an outlet of the chemical mixing unit is connected with an inlet of the liquid-solid separation unit; a liquid-phase outlet of the liquid-solid separation unit is connected with an inlet of the liquid-phase concentration unit, and a solid-phase outlet of the liquid-solid separation unit is connected with an inlet of the solid-phase grinding unit; an outlet of the liquid-phase concentration unit and an outlet of the solid-phase grinding unit are both connected with the reaction kettle. According to the device, content of protein in the reaction kettle can be increased, utilization rate of cellulase is increased, heat inactivation rate of cellulase is reduced, and the use amount of cellulase is reduced.

Owner:JIANGSU OCEAN UNIV

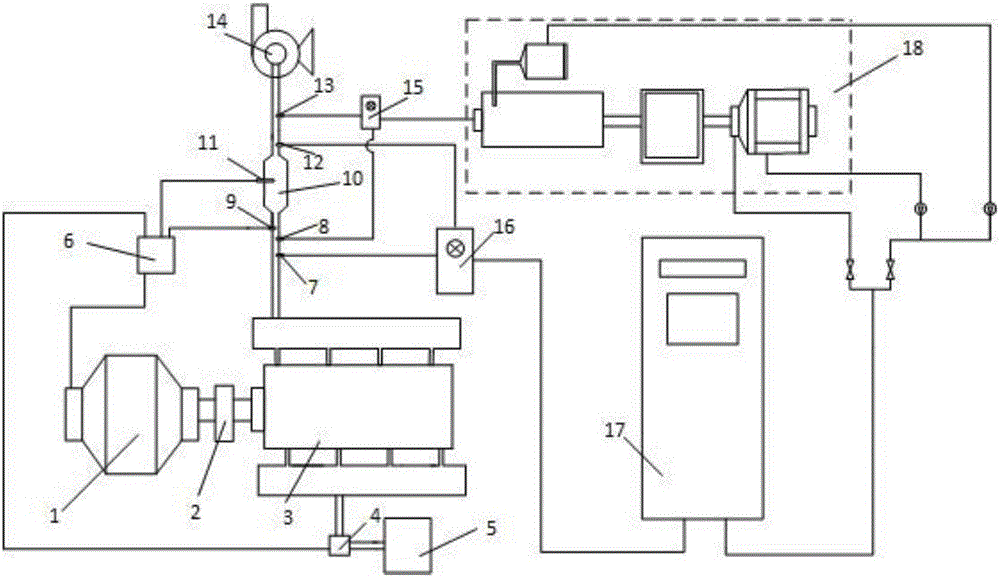

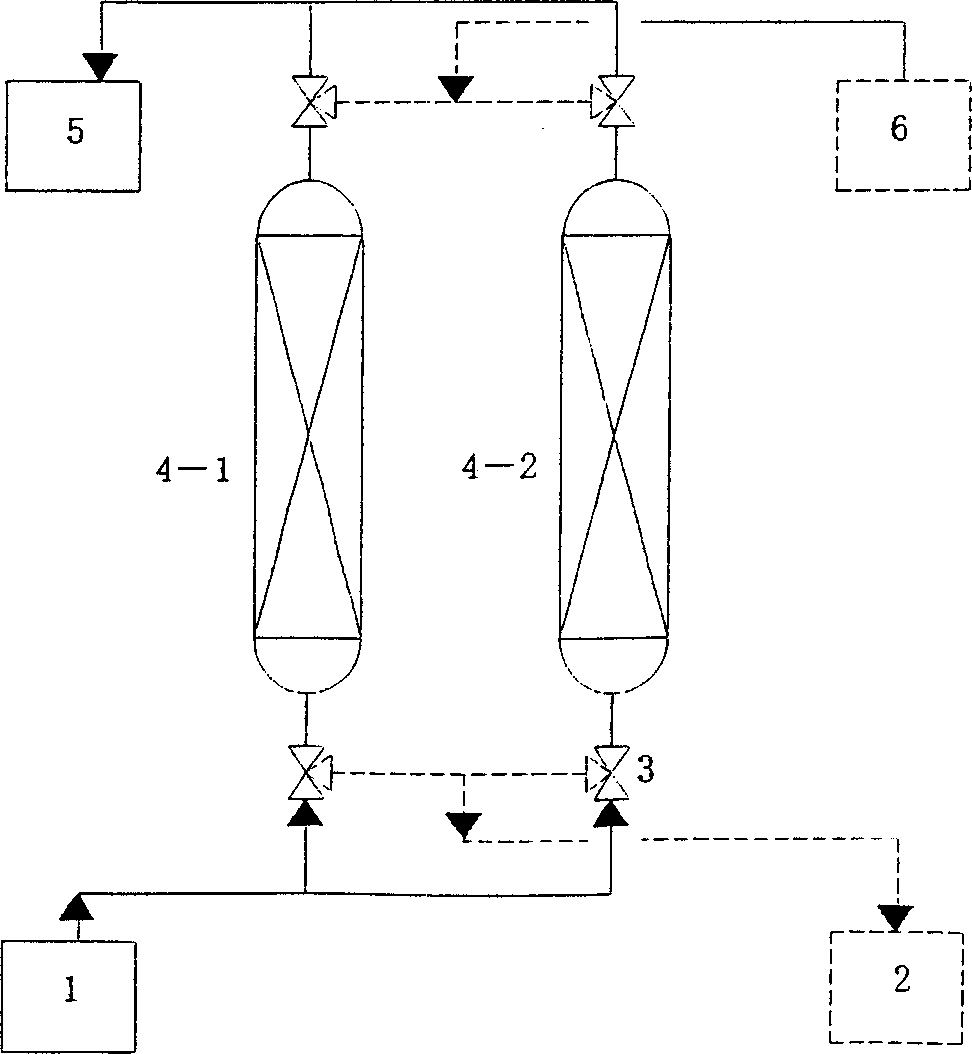

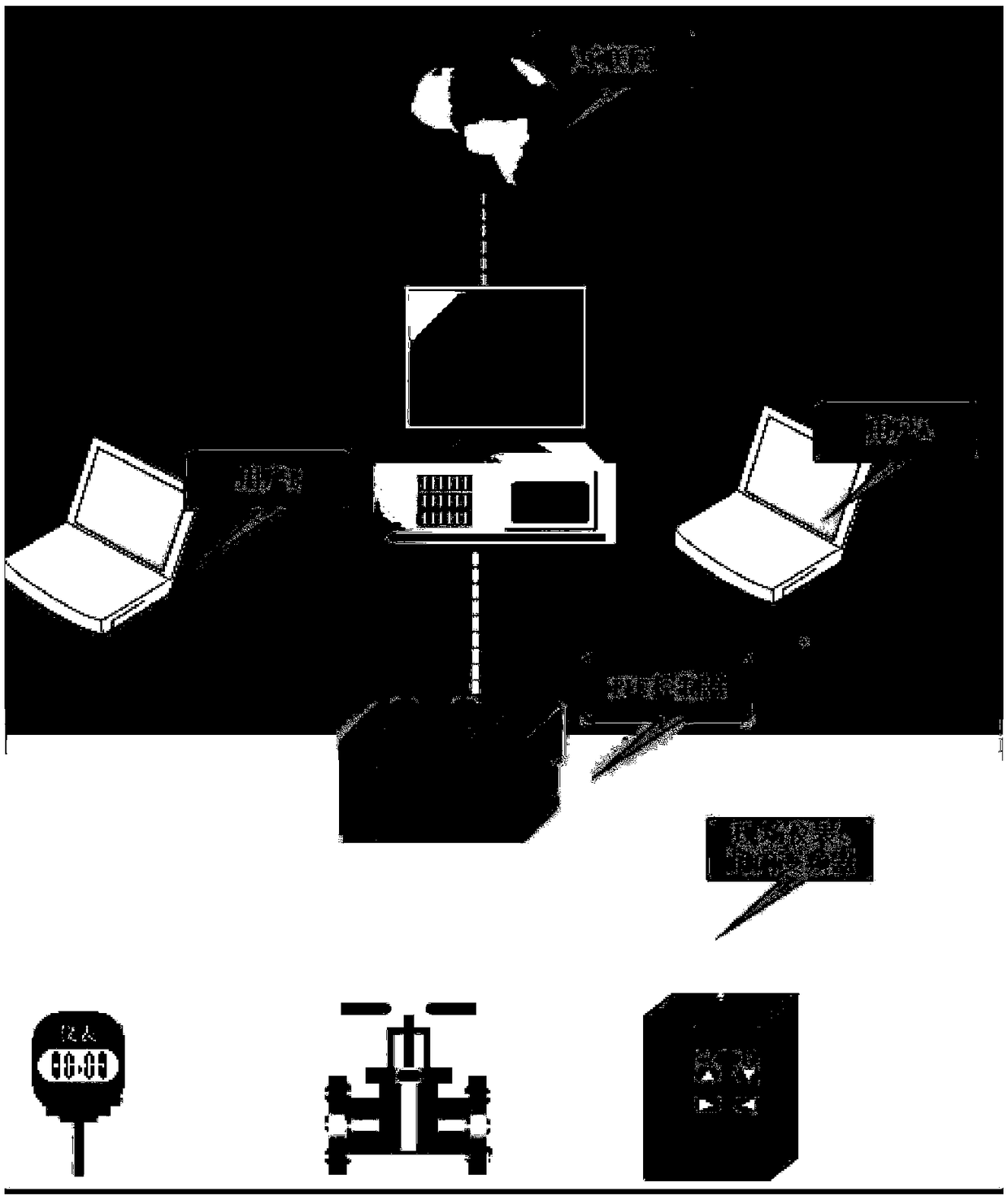

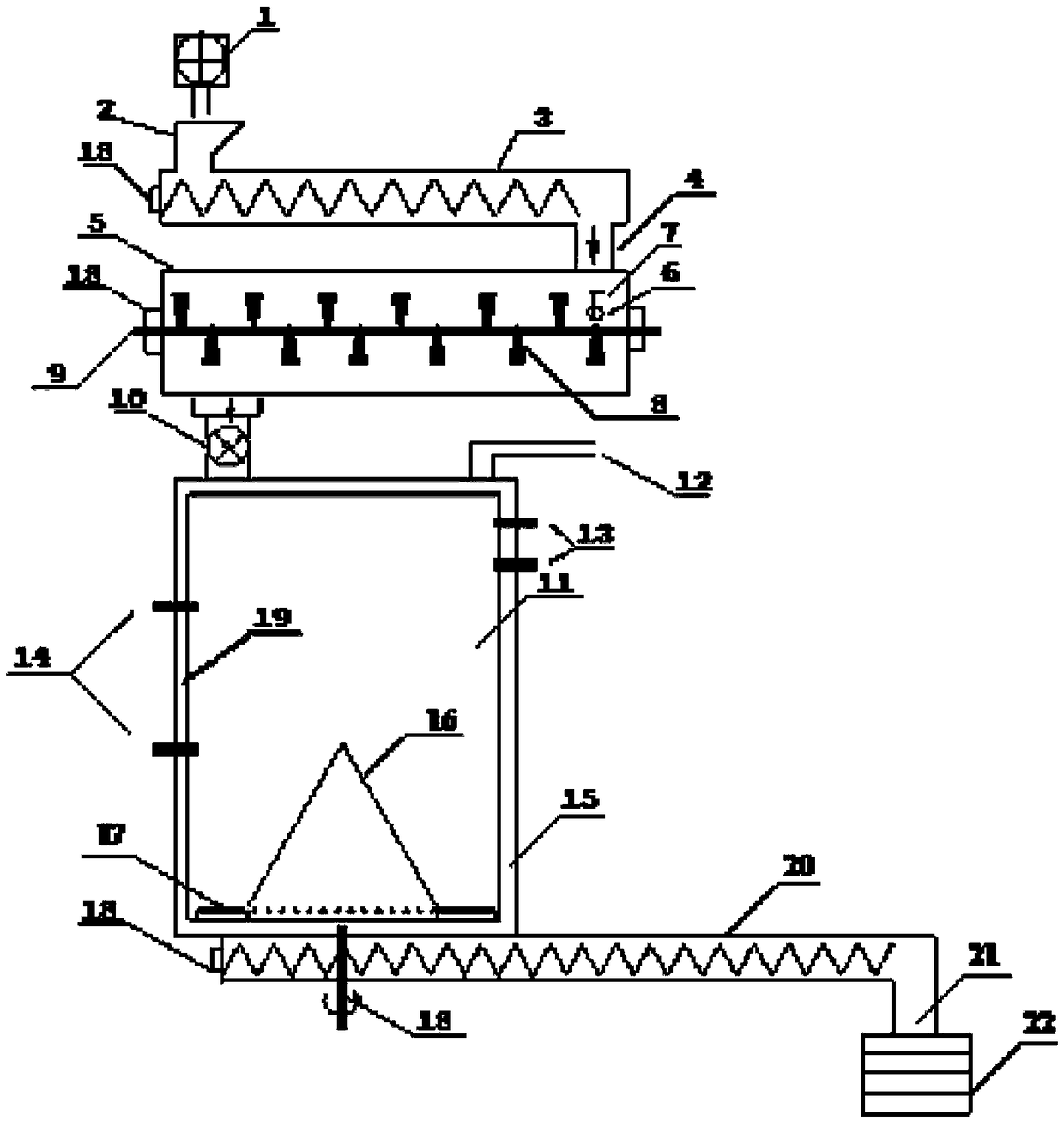

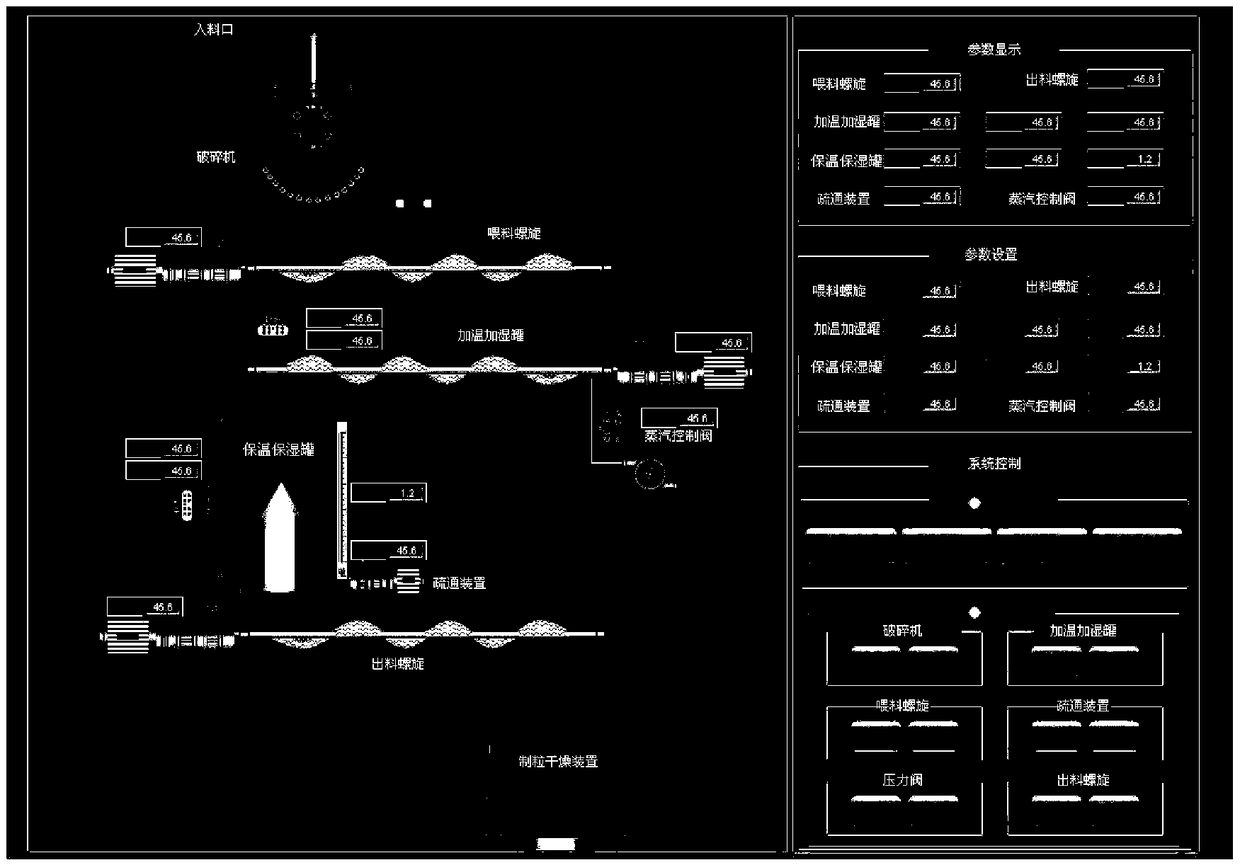

Computer-control heat inactivation treatment system for quarantine pests in imported grain processing by-products

PendingCN108845549ARealize automatic operationOvercome complicated proceduresMeasurement devicesTotal factory controlThe InternetQuarantine

The invention discloses a computer-control heat inactivation treatment system for quarantine pests in imported grain processing by-products. The system comprises the following steps: device managementsoftware at a computer end sends a processing request to a controller PLC to obtain processing parameters of a material processing device end and various control sensor data; the computer sends an operation command; the processing device achieves processing control index parameters and feeds the parameters back to controller for processing operation, and the computer records related data of processing in real time and sends the data to an Internet WEB terminal. when the material is insufficient, the controller sends out an operation stop command; a monitoring end performs supervision on parameters of processing in real time or not in real time; the computer achieves automatic management of inactivation treatment and supervisors perform real-time monitoring through the Internet, and interactive communication and coordination among three parties including processing plant production personnel, processing equipment and quarantine supervisors are realized. The invention solves a problem that the management level of system processing is low due to complex manual operation in prior processing equipment management.

Owner:郭成亮

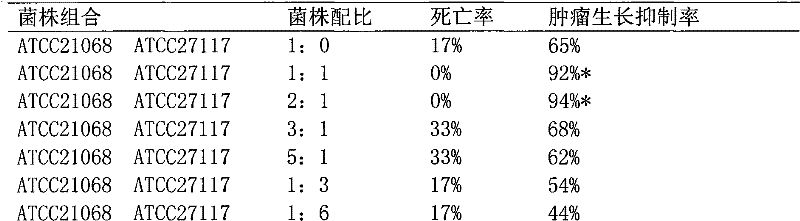

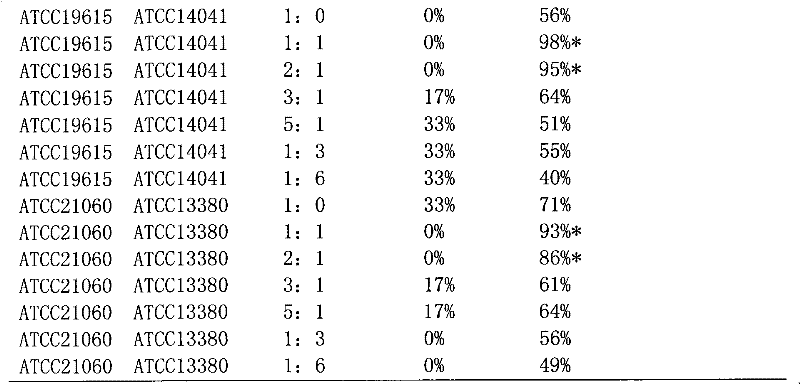

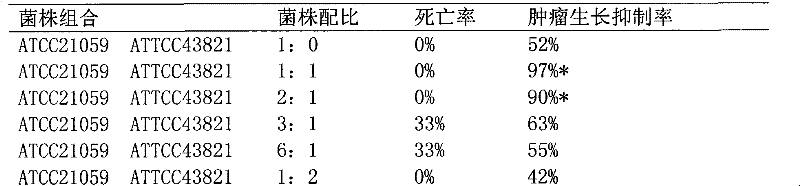

Preparation method of whole cell suspension of streptococcus pyogenes and serratia marcescens

InactiveCN102232972ASignificant effectPromote sheddingBacteria material medical ingredientsSolution deliveryStreptococcus pyogenesBacteroides

The invention discloses a preparation method of a whole cell suspension of streptococcus pyogenes and serratia marcesens, comprising the following steps of: respectively culturing streptococcus pyogenes and serratia marcesens to obtain whole cell culture solutions, then mixing the two bacteria according to the ratio of 1:1 or 2:1 as per the bacterial number, and after heat inactivation, diluting by a phenol normal saline of 1-3g / l containing phenol or resorcinol to obtain the whole cell suspension. In the whole cell suspension of streptococcus pyogenes and serratia marcesens prepared by the invention, the total number of bacteria of the streptococcus pyogenes and the serratia marcesens is 100000-3000000 per milliliter, and the whole cell suspension of streptococcus pyogenes and serratia marcesens can be used for treating tumor by the routes of administration such as intratumor injection, intracavitary injection or intramuscular injection.

Owner:SHANDONG UNIV

Crystallization process for extracting L-tryptophan from fermentation broth

InactiveCN106986808AUniform sizeIncrease the rate of crystallizationOrganic chemistry methodsUltrasonic cavitationUltrasound - action

The invention provides a crystallization process for extracting L-tryptophan from fermentation broth. The crystallization process comprises the following steps: continuously applying 50W ultrasound to crystallize concentrated fermentation broth at the temperature of 4 DEG C after the fermentation broth is treated by heating inactivation, microfiltration, ultrafiltration and rotary evaporation, wherein the ultrasound action time is 15-20min, so that tryptophan concentrated solution is quickly developed into minute crystals with uniform size from original crystal nucleuses with different sizes under the ultrasonic cavitation; then, allowing standing still for 1h at constant temperature of 4 DEG C, performing suction filtration on obtained suspension, and drying, so as to obtain a finished product. The parameters of crystallization rate, the conductivity change rate, the product yield, quality and purity and the like of the crystallization process and the existing common crystallization process are compared. The crystallization process provided by the invention mainly aims at solving the problems of multi-times of crystallization, long crystallization period, bigger crystals, non-uniform size, undesirable crystallizing quantity and the like existing in the traditional tryptophan extraction process, therefore, the crystallization rate is improved, the crystallization period is shortened, the L-tryptophan product yield is improved, and the purity is not influenced.

Owner:TIANJIN UNIV OF SCI & TECH

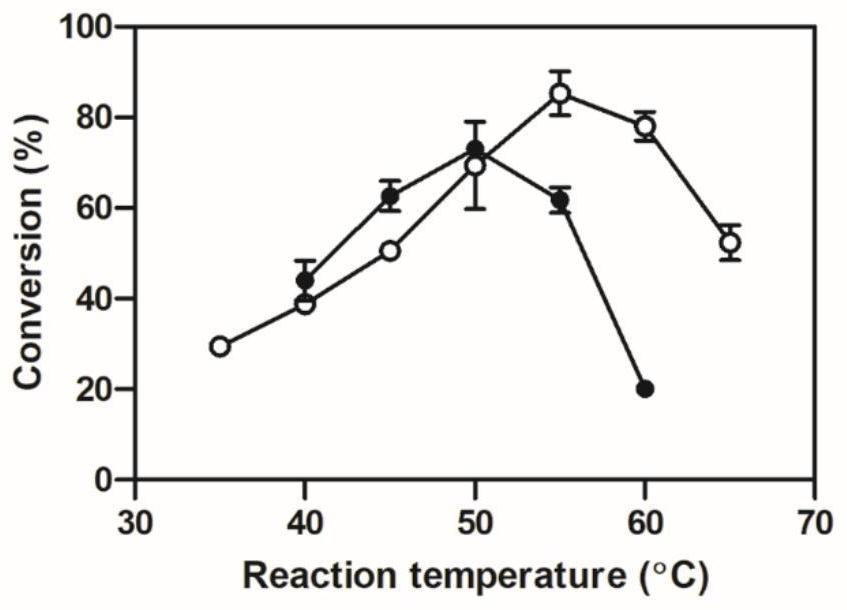

Method of converting RB to RD by using cutinase under stepwise changing temperatures

ActiveUS20180073049A1Increase conversion rateHigh speedSugar derivativesHydrolasesCutinaseReaction rate

The present invention provides a method to produce RD by using a cutinase to catalyze the esterification of RB under stepwise cooling temperatures, which is related to the field of biosynthesis of organic compounds. The method uses a cutinase from Thermobifida fusca to catalyze the esterification of RB and sophorose to produce RD. The stepwise cooling temperatures are used to reduce the heat inactivation of the enzyme as well as to improve the mass transfer. The method catalyzes the esterification of RB to produce RD in a solvent such as methanol, DMSO and DMF. The reaction is safe, efficient and highly selective. In addition, the method uses stepwise additions of substrate RB and cooling temperatures for the esterification reaction. In this way, it speeds up the initial reaction rate, increases the amount of solved RB as it is converted to RD, and improves the mass transfer to further increase the reaction speed. In summary, the method uses moderate reaction conditions, and has a high yield and a simple purification procedure.

Owner:JIANGNAN UNIV

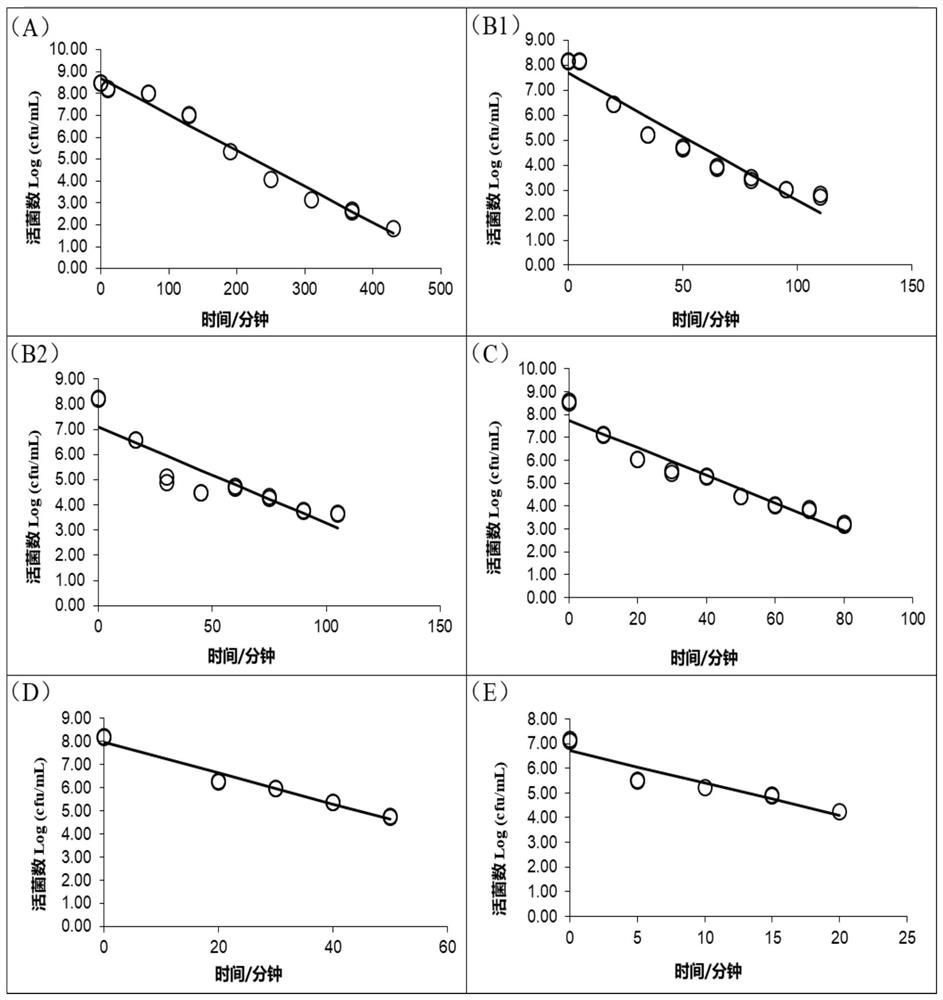

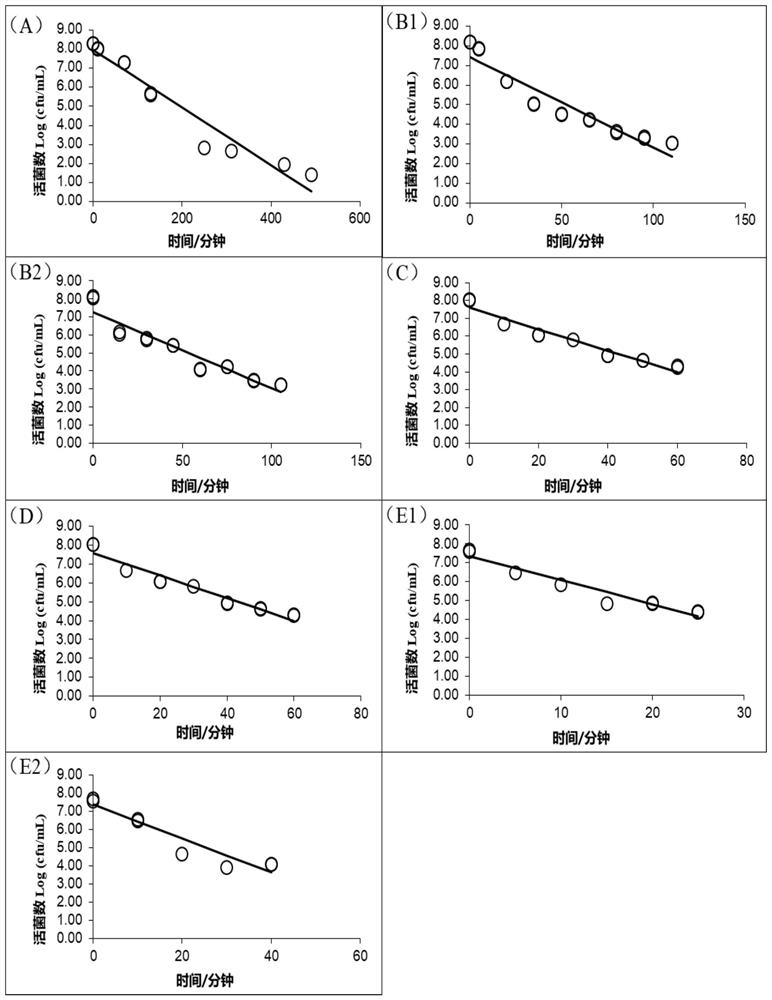

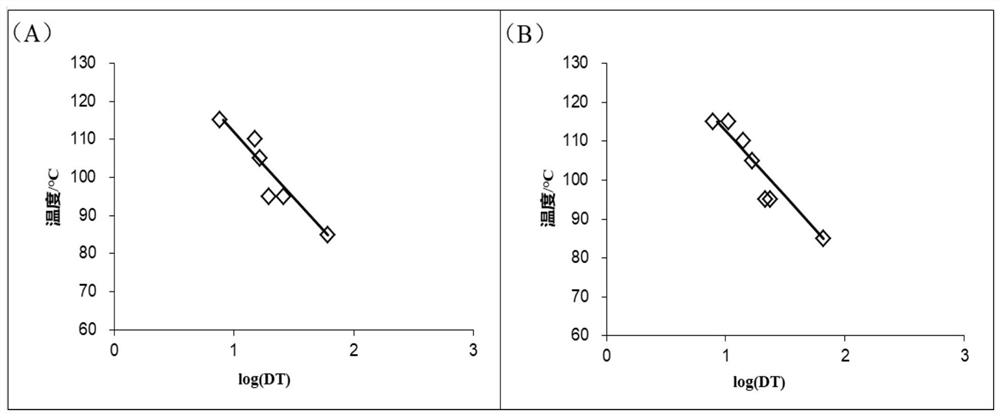

Prediction model for survival amount of probiotics in food heat treatment processing process

ActiveCN112259158AReal-time prediction of live bacteria countMicrobiological testing/measurementBiological material analysisBiotechnologyMicroorganism

The invention provides a model for predicting a viable bacteria survival amount of bacillus coagulans under dynamic temperature change in a food heat treatment processing process and application of the model, and the established model can predict the viable bacteria survival amount of the bacillus coagulans in the medium after thermal inactivation according to initial concentrations of the bacillus coagulans in different media and real-time temperature change conditions of the bacillus coagulans in a heat inactivation process. The method provided by the invention is suitable for the thermal inactivation process of bacillus coagulans in any food processing, and provides a rapid, simple and convenient technical method for evaluating the stability of bacillus coagulans in the functional foodprocessing process. According to the method, a traditional microbiological detection means is not needed, and the viable count in the functional food processing process can be directly predicted onlyby knowing the temperature change condition, the used time and the initial bacillus coagulans count in the functional food processing process.

Owner:QINGDAO VLAND BIOTECH INC +1

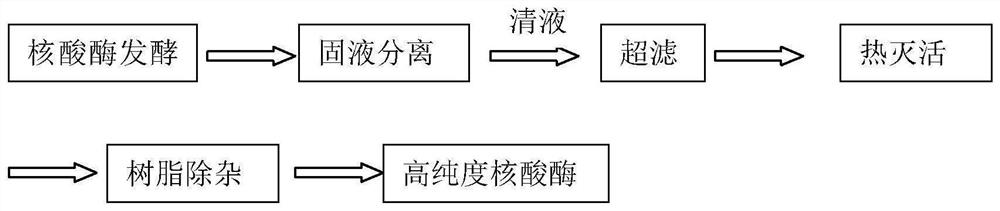

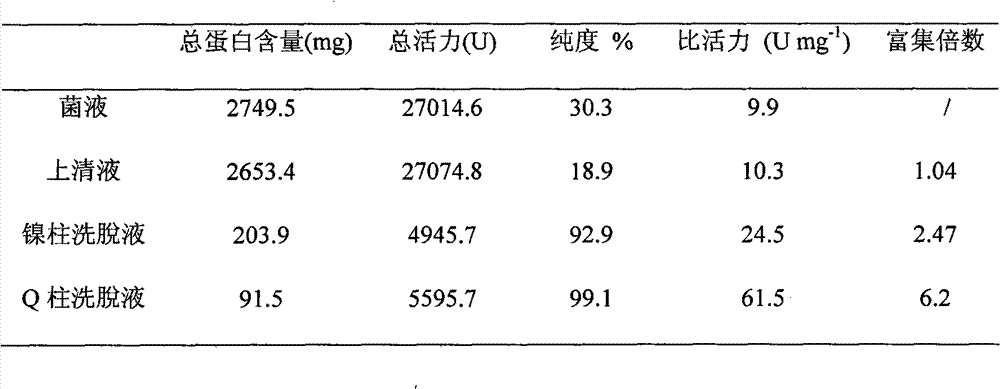

A method for multistage purification of nuclease p1

The invention discloses a method for multistage purification of nuclease P1, that is, performing multistage purification of nuclease P1 crude enzyme solution through ultrafiltration membrane ultrafiltration, heat inactivation and resin impurity removal. The method of the invention can efficiently separate and purify the nuclease P1, and the enzyme recovery rate of the nuclease P1 reaches 82.6 percent; and the method has low cost and is applicable to large-scale industrial production. At the same time, the purity of the nuclease P1 obtained by the method of the invention is greatly improved, the specific activity is 7.3 times that of the crude enzyme solution, and there are few impurities, so it can be used in the food industry.

Owner:NANJING TECH UNIV +1

Steam moist-heat inactivation method for soybean quarantine pests

The invention discloses a steam moist-heat inactivation method for soybean quarantine pests. When the method is used for production inactivation of main quarantine pests in soybean processing byproducts such as tofu skin, impurities and leftovers, the method comprises the following steps of: crushing the soybean processing byproducts such as the tofu skin, the impurities and the leftovers carrying the quarantine pests to the granularity of less than or equal to 3 millimeters through a crusher, putting the processing byproducts into equipment with temperature of more than or equal to 85 DEG C and relative humidity of more than or equal to 95 percent, and keeping the processing byproducts in the equipment for more than or equal to 4 minutes so that the quarantine pests are completely inactivated. The adopted steam moist-heat inactivation method is simple, convenient, economic and environment-friendly, and can be widely applied to the production inactivation of the quarantine pests in the imported soybean processing byproducts such as the leftovers, the impurities and the tofu skin and feed.

Owner:中华人民共和国秦皇岛出入境检验检疫局

Kelp beverage for lowering blood pressure and preparation method thereof

InactiveCN109287914AGreat tasteStomach mildYeast food ingredientsStrepto/lacto-coccusIntestinal structureNitrogen gas

The invention discloses a kelp beverage for lowering blood pressure and a preparation method thereof. The preparation method comprises the following steps: (1) crushing dried kelp, mixing the crusheddried kelp with clean water, heating and stirring the mixture, and draining the mixture to collect first leachate; (2) adding clean water, sodium carbonate, disodium hydrogen phosphate into a solid material obtained in step 1, uniformly stirring the mixture, carrying out ultrasonic treatment, and draining the mixture to collect second leachate; (3) merging the first leachate and the second leachate, introducing nitrogen, and keeping stirring; (4) inoculating kluyveromyces marxianus and streptococcus thermophilus into mixed liquid obtained in step 3, and carrying out fermentation and heat inactivation; and (5) filtering fermentation broth to obtain the kelp beverage. The kelp beverage for lowering blood pressure has characteristics of good mouthfeel, mild property to intestines and stomach,relatively light color and luster, etc., has a prospect of being further prepared into other beverages, and provides a good soft beverage for people who are not suitable for drinking alcoholic beverages, such as hypertensive patients, etc.

Owner:荣成石岛慧谷科技企业孵化器有限公司

A kind of preparation method of partially inactivated chymosin

The invention belongs to the technical field of protein renaturation and especially relates to a preparation method for partially inactivated chymosin. The preparation method comprises the following steps: (1) placing a chymosin solution containing ectoine under the temperature at 61-70 DEG C and treating for 1-20min, thereby acquiring the partially inactivated chymosin, and (2) quickly cooling the partially inactivated chymosin prepared in the step (1) to 4 DEG C, standing by and refrigerating for 0-42h, thereby acquiring the chymosin after renaturation. The method is different from the treating method for high concentration urea, and the like; a heat inactivation method is adopted for preparing the partially inactivated chymosin; the operation is simple and easy, the repeatability is high and the state of the partially inactivated chymosin is more approximate to the heat inactivation state of enzyme; the inactivated chymosin prepared according to the method has the characteristics of obvious renaturation effect, high enzyme activity after renaturation, and the like.

Owner:SHANDONG POLYTECHNIC

Application of 2', 5, 6', 7-tetrahydroxy dihydroflavonol for treating sepsis

InactiveCN101264075BLower LPS levelsImprove protectionOrganic active ingredientsAntipyreticEscherichia coliCell activation

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Low temperature alkaline phosphatase and preparation method thereof

The invention belongs to the field of gene engineering, and relates to novel alkaline phosphatase and a preparation method thereof. The cDNA sequence of low temperature alkaline phosphatase shown as SEQ ID NO 1 in a sequence table is cloned to a vector for genetic engineering, and expressed to obtain the low temperature alkaline phosphatase. According to codon bias of Escherichia coli, the DNA sequence of the TAB5 low temperature alkaline phosphatase is transformed, so that the DNA sequence is highly expressed in the Escherichia coli; the alkaline phosphatase is purified by nickel affinity chromatography and ion exchange chromatography; and more than 90mg of TAB5 alkaline phosphatase with the purity of over 99 percent is obtained from each liter of Escherichia coli liquid finally. The invention can be applied to research in the field of molecular biology of the field of life science, particularly multi-step reaction for heat inactivation of alkaline phosphatase, such as sample treatment before DNA sequencing and the like.

Owner:FUDAN UNIV

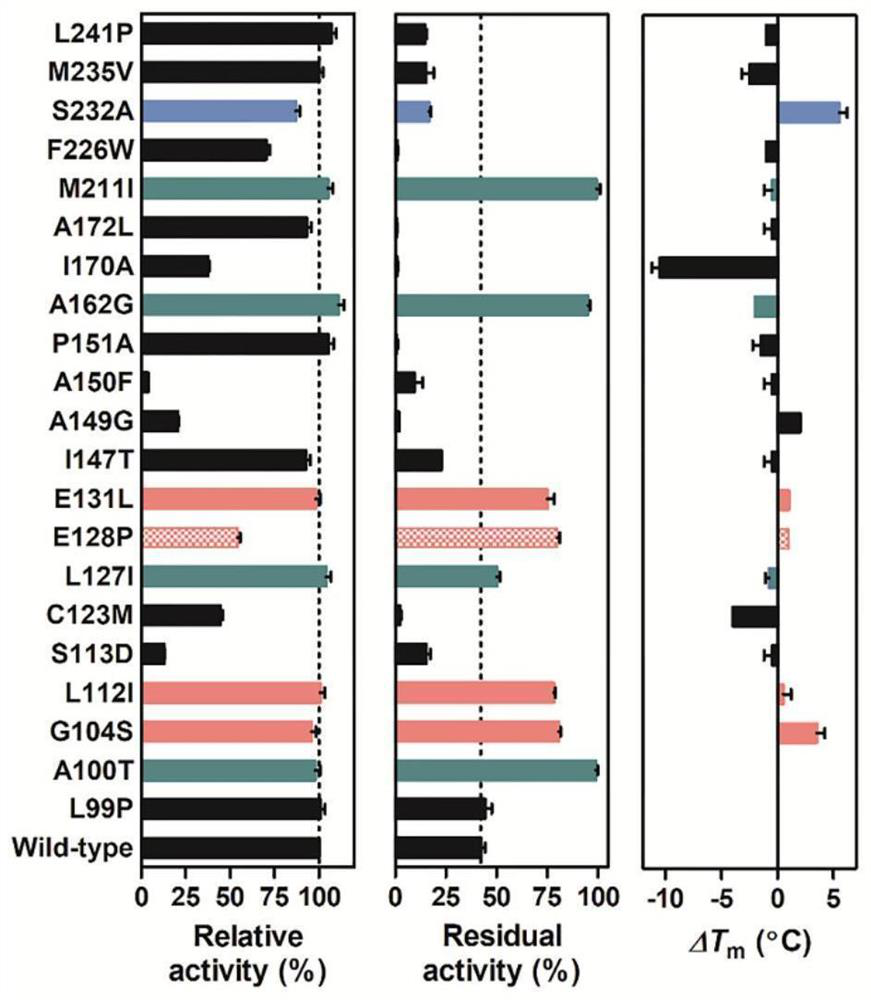

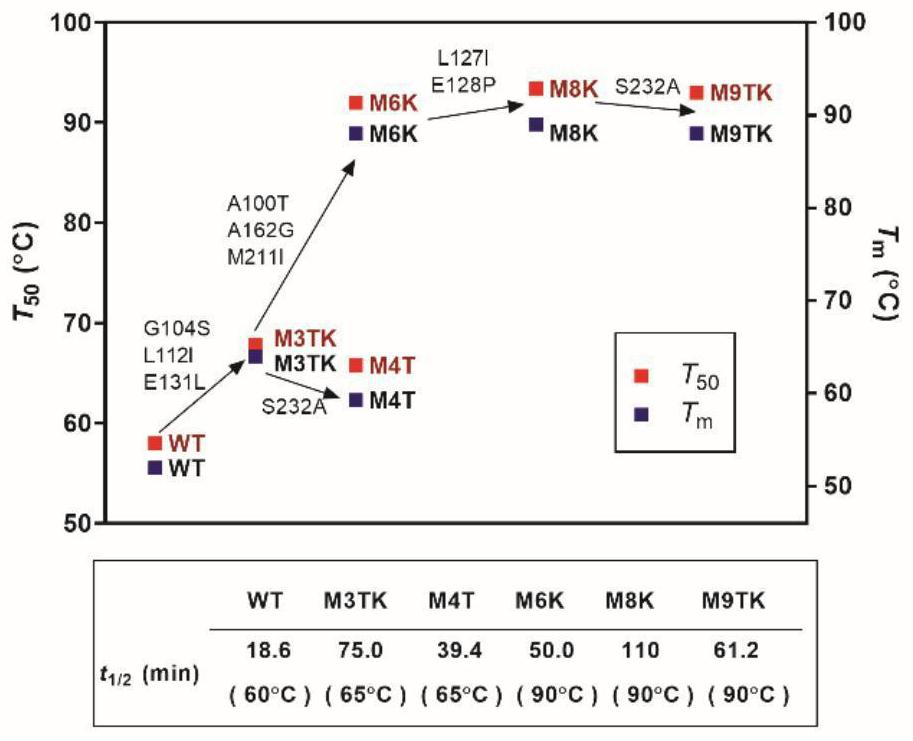

Carbonyl reductase mutant with improved thermal stability

PendingCN114774379AHigh catalytic efficiencyReduce manufacturing costOxidoreductasesFermentationCarbonyl ReductaseBiochemistry

The invention belongs to the technical field of gene engineering and enzyme engineering, and particularly discloses a thermal-stability carbonyl reductase mutant with high catalytic activity. Compared with a wild type enzyme, the mutant enzyme can tolerate higher temperature, and has higher catalytic efficiency at high temperature. The thermal inactivation half-life period of the combined mutant M8K containing 8 mutation sites at the high temperature of 90 DEG C can reach 110 min, the catalytic activity of the combined mutant M8K at the temperature of 50-60 DEG C is higher than that of a wild type enzyme, the optimal catalytic efficiency is achieved at the temperature of 55 DEG C, and the combined mutant M8K has wide industrial application prospects.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Preparation and application of an improved adenovirus vector system and its virus particles

ActiveCN103290052BOmit recombination reactionLow costViruses/bacteriophagesFermentationInfected cellEnzyme digestion

The invention discloses an improved adenovirus vector system and a virus preparation method. The system takes a pDONR221 vector as an initial vector to make improvement, and multiple cloning sites and an IRES-GFP fragment are inserted. The system combines enzyme digestion connection and recombination reaction technologies, can efficiently construct a vector, and also reduces the reagent cost. The invention also discloses an improved method of purification following after enzyme digestion of the virus vector. The method abandons traditional purification methods adopting phenol, chloroform and isoamyl alcohol, and uses a conventional DNA recovery column or direct heat inactivation method. The method is simple and feasible, shortens the operation time, reduces the material cost, and has no need for toxic phenol and chloroform reagents. The adenovirus system combining the two aspects has improved preparation efficiency and reduced cost, and still maintains high efficiency in infected cells.

Owner:上海诺百生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com