Method for removing low-concentration heavy metal by embedding heat-inactivation activated sludge with sodium acetylide

A low-concentration heavy metal, activated sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc. Large-scale operation and other problems, to achieve the effect of strong adsorption of mixed heavy metals, simple immobilization process and good pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

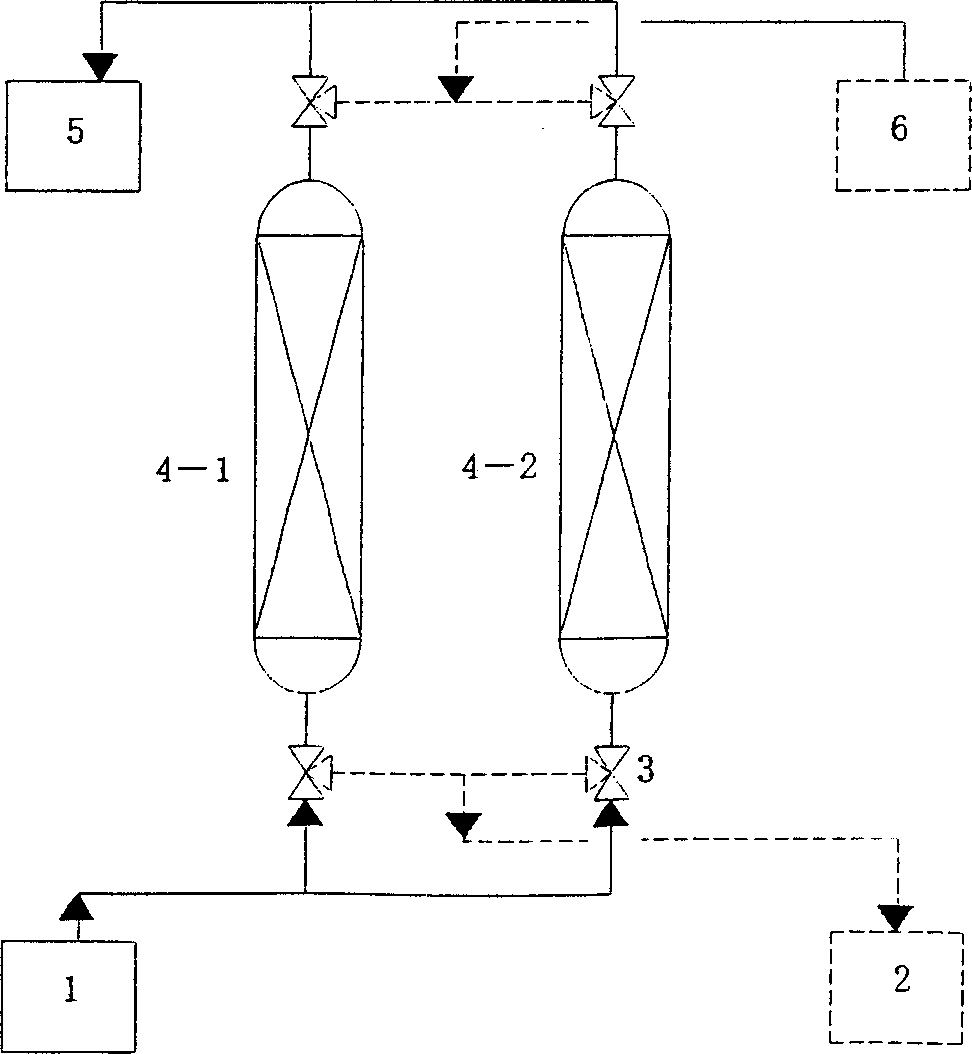

[0022] As can be seen from Fig. 1, the specific implementation method of the method of the present invention is:

[0023] 1. Heavy metal wastewater treatment

[0024] The fixed bed reactor consists of two reactors 4-1 and 4-2 running in parallel, alternately performing adsorption and regeneration operations. In the fixed-bed reactor, the spherical adsorbent (CA) is filled in the fixed-bed reactor in a fixed-bed manner, and the wastewater containing heavy metals is slowly pumped into the bed from the bottom to the top of the storage tank 1, and the adsorbent and the heavy metal ions The wastewater undergoes dynamic adsorption, and the adsorbed wastewater enters the storage tank 5 . Determination of the residual amount of various heavy metals in the water.

[0025] 2. Desorption of heavy metal ions

[0026] The fixed-bed reactor after adsorption is switched with a three-way valve, and then the hydrochloric acid eluent from the eluent storage tank 6 is used for elution regener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com