Steam moist-heat inactivation method for soybean quarantine pests

A technology for harmful organisms and soybeans, which is applied in the field of steam damp heat inactivation of soybean quarantine pests, can solve the problems of high cost, unsuitable inactivation treatment, and large impact of processed products, and achieves the goal of simple method and protection of agricultural production safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] It is used for steam damp heat production inactivation of soybean northern stem canker pathogen: the bean skin, leftovers and impurities carried by soybean processing by-products carrying soybean northern stem canker pathogen are crushed by a grinder to a particle size of ≤3mm, and then placed in damp heat inactivation In the device, keep the temperature ≥ 80° C., the relative humidity ≥ 95%, and the time ≥ 3 minutes, and the soybean northern stem canker pathogen is 100% inactivated.

[0054] In addition to being used for the inactivation of soybean northern stem canker pathogens, this embodiment can also be used for steam damp heat of soybean southern stem canker pathogens, North American soybean sudden death syndrome pathogens, South American soybean sudden death syndrome pathogens and soybean stem brown rot pathogens. production inactivation.

[0055] The damp heat inactivation device referred to in Example 1 is a damp heat inactivation device for quarantine harmful ...

Embodiment 2

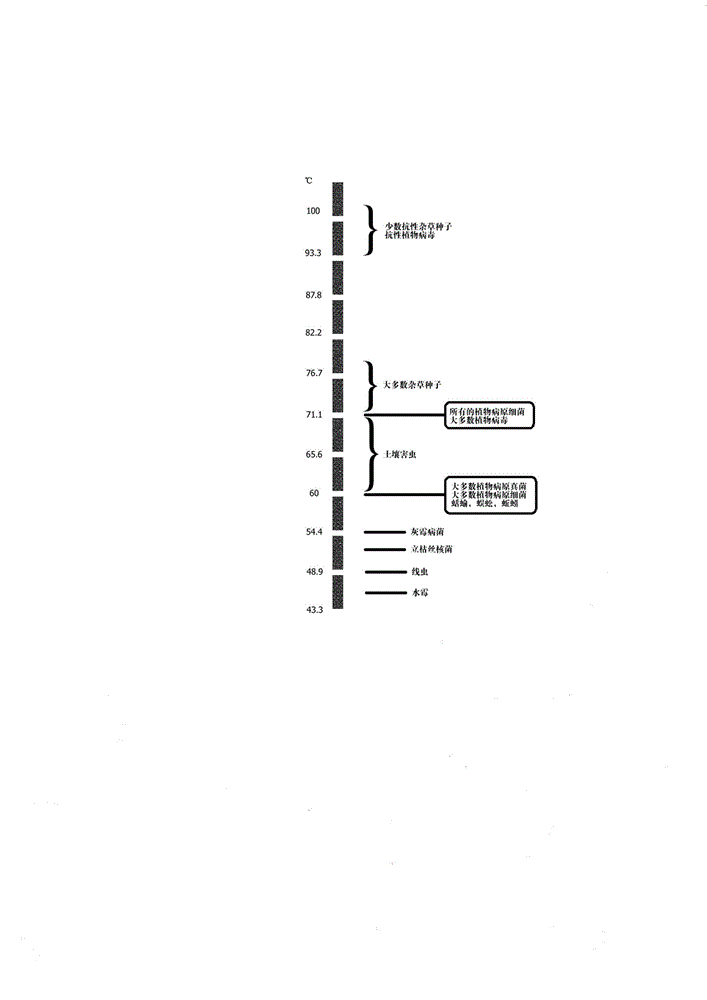

[0057] Weed seeds among the main quarantine pests of imported soybeans are steamed and inactivated by damp heat production: soybean hulls, leftovers and impurities, the by-products of soybean processing carrying quarantine weed seeds, are crushed by a grinder to a particle size of ≤3mm, and then placed in humid heat In the inactivation device, keep the temperature ≥ 85°C, the relative humidity ≥ 95%, and the time ≥ 3 minutes, and the main quarantine pests of soybeans are 100% inactivated.

[0058] The damp heat inactivation device referred to in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0060] Steam damp-heat production inactivation of main quarantine pests of imported soybeans: Soybean skin, leftovers and impurities carried by soybean processing by-products carrying major quarantine pests of soybeans are pulverized by a grinder until the particle size is ≤3mm, and then placed in a damp heat inactivation device During the process, keep the temperature ≥ 85°C, relative humidity ≥ 95%, and time ≥ 4 minutes, and the main quarantine pests of soybeans will be 100% inactivated.

[0061] The damp heat inactivation device referred to in this embodiment is the same as that in Embodiment 1.

[0062] In this example, the main quarantine pests of soybeans have been pointed out above, so the description will not be repeated in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com