Thermostable vaccine with silica on surface and preparation method therefor

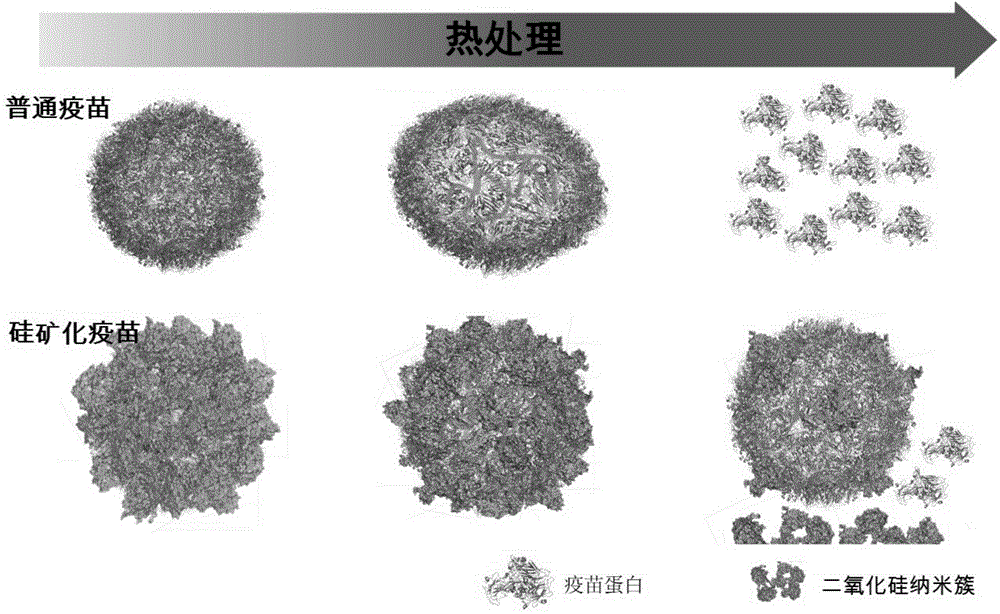

A silicon dioxide and heat-stabilized technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, can solve problems such as limiting effects and difficulty in storing vaccine liquids at room temperature, and achieve good Effects of immunogenicity and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1, preparation EV71 or OPV vaccine liquid

[0082]1. EV71 virus or OPV vaccine solution

[0083] 1. Infect RD cells or Vero (using DMEM culture fluid) with human hand-foot-mouth virus EV71 strain or poliovirus OPV vaccine strain, and cultivate in a cell culture box at 37° C. for 36-72 hours.

[0084] 2. The culture system obtained in step 1 is centrifuged (16000g, 10min), the supernatant is collected and filtered (using a filter membrane with a pore size of 0.22 microns), and the filtrate is collected, which is the virus vaccine liquid (after testing, the pH of the virus liquid is 7.2), it is named EV71 vaccine liquid or OPV vaccine liquid.

Embodiment 2

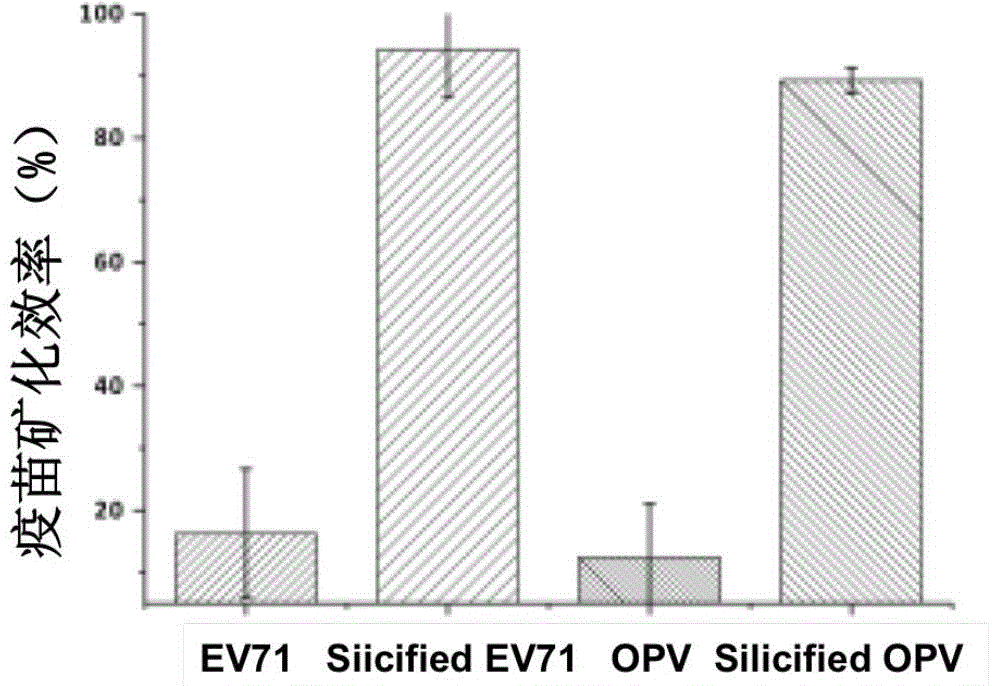

[0085] Example 2, using the EV71 virus liquid or OPV vaccine liquid obtained in Example 1 to prepare a silica mineralized vaccine liquid (that is, to prepare a thermally stable vaccine with silica on the surface through in situ silicon mineralization)

[0086] 1. Preparation of SilicifiedEV71 / OPV vaccine solution-A

[0087] Silicic acid can be prepared by acidification of sodium metasilicate or hydrolysis of alkyl silicate (TEOS or TMOS): dissolve sodium silicate with PBS or Tris buffer to a concentration of 30 mM, and adjust it to 8.0 by hydrochloric acid treatment; or The 1M silicate is prepared by shaking and hydrolyzing in 1mM hydrochloric acid for 15-30 minutes. In EV71 virus liquid or OPV vaccine liquid (the virus concentration is 1×10 8 PFU / mL, that is, 1×10 11 PFU / L) was added to the newly prepared silicic acid to make the concentration reach 2mM, and the pH was adjusted to about 5.5, which was the initial system; the initial system was incubated at room temperature ...

Embodiment 3

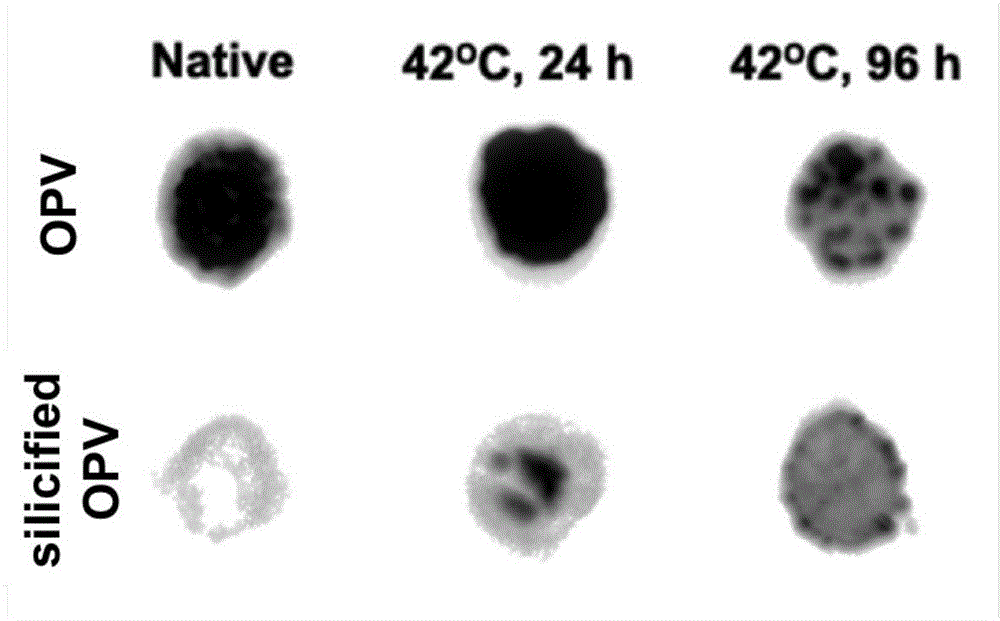

[0133] Embodiment 3, the biological characteristic experiment of SilicifiedOPV vaccine liquid

[0134] 1. Plaque characteristics

[0135] The SilicifiedOPV vaccine solution and the OPV vaccine solution were subjected to the following experiments respectively:

[0136] Diluted 10 times by volume (10 -1 、10 -2 、10 -3 、10 -4 , 10 -5 、10 -6 and 10 -7 ), and then seeded 300 μL / well on a monolayer of RD cells spread on a 12-well plate, placed at 37°C, 5% CO 2 Incubate in an incubator for 1-2 hours; then discard the virus solution, cover the cells with agar cover (i.e. low-sugar DMEM medium containing 1% agar and 2% FBS), place at 37°C, 5% CO 2 Incubated in an incubator for 3 days; then fixed with 4% formaldehyde solution at room temperature for 1 h, discarded the agar cover, and stained with crystal violet for 10 min at room temperature; observed plaque morphology and took pictures, and calculated plaque forming units (PFU); vaccine titer = (empty Plaque forming unit×diluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com