Computer-control heat inactivation treatment system for quarantine pests in imported grain processing by-products

A technology for controlling management and harmful organisms, applied in general control system, control/regulation system, program control, etc., can solve problems such as complex process operation, low efficiency and management level, and achieve the goal of overcoming complex operation process and realizing automatic operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with drawings and embodiments.

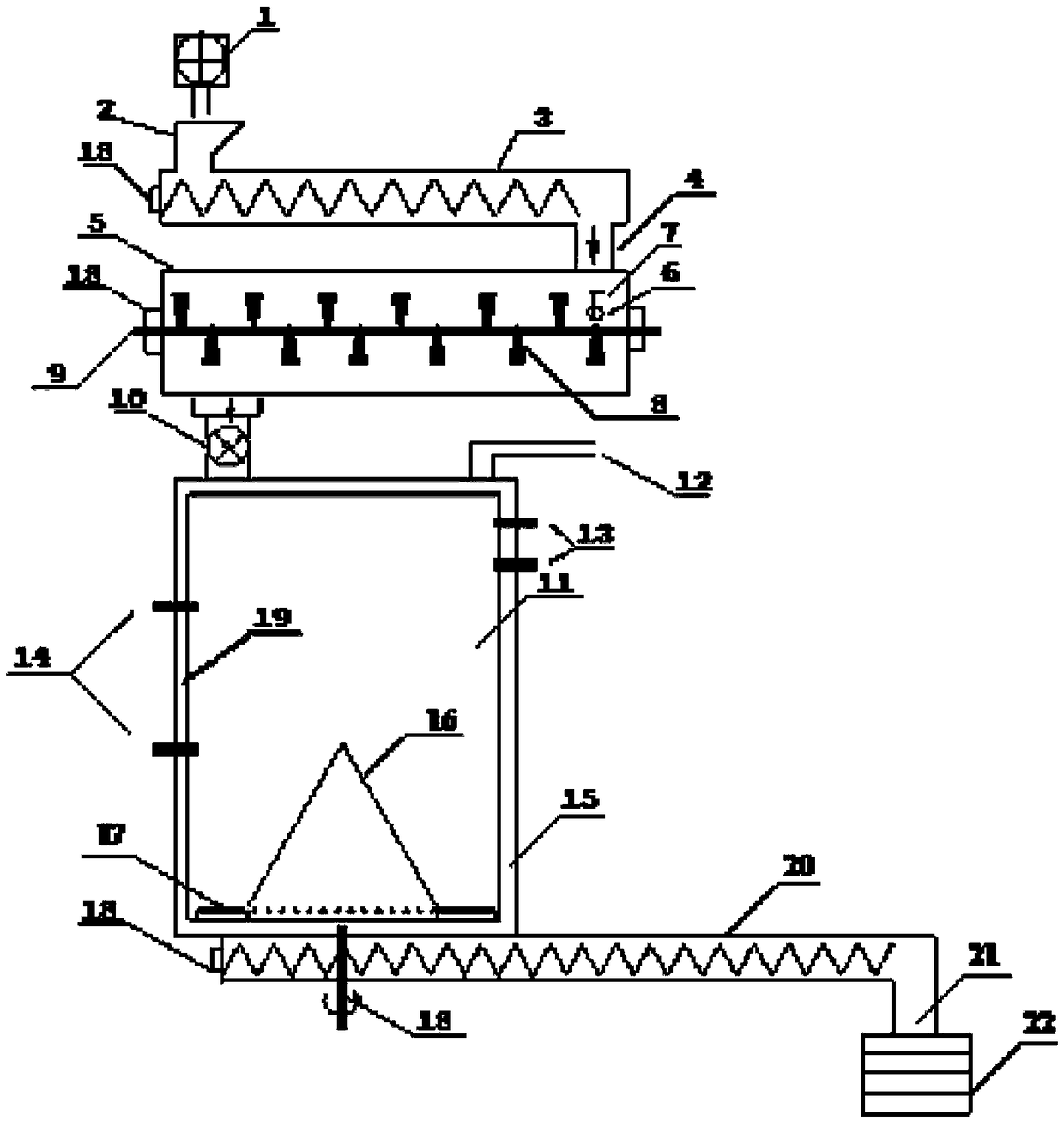

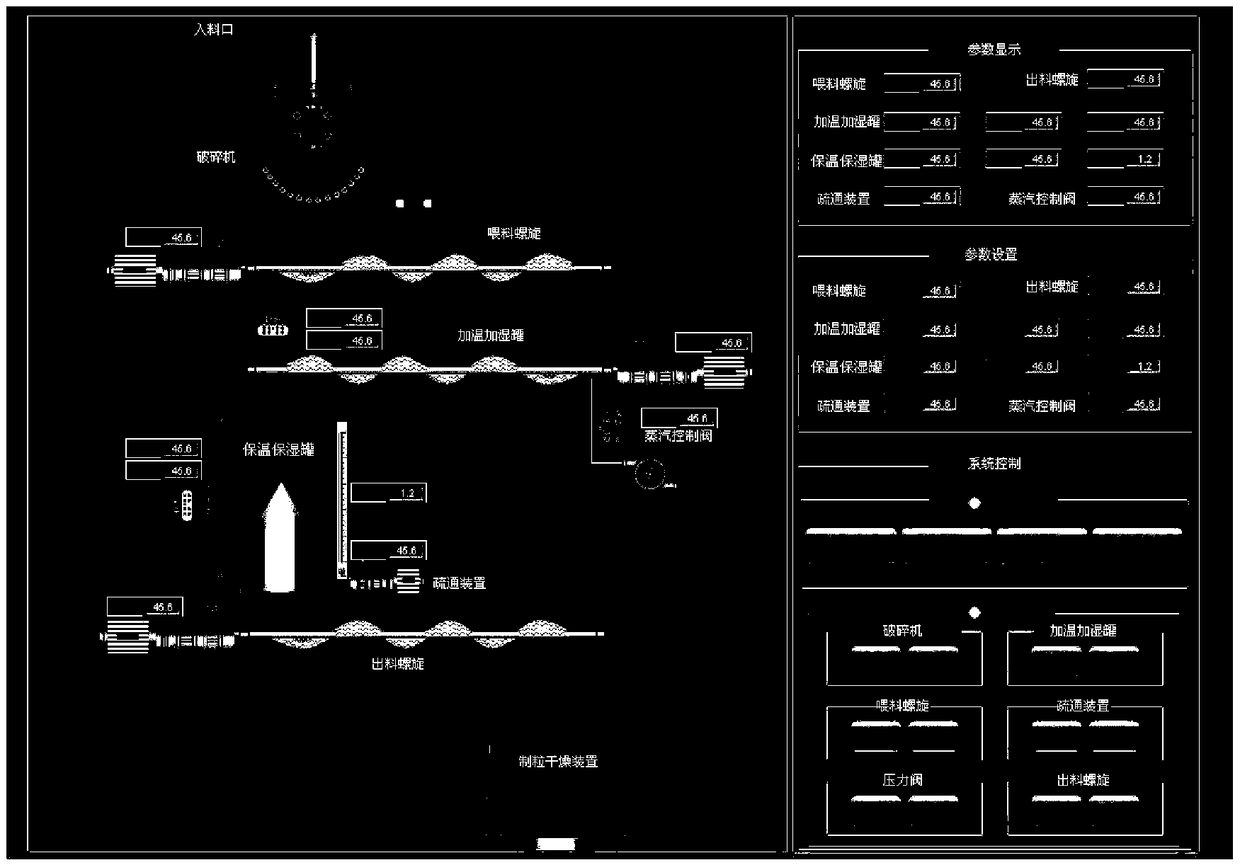

[0047] The basic principle of this system is to collect parameters such as temperature, humidity, time of steaming heat treatment, steam pressure of processing heat source, etc. through sensor electrical signals, as well as electrical signals of material level sensor and auger speed frequency sensor to control the stable operation of the assembly line production. While accurately and automatically controlling the inactivation parameters (temperature, humidity and time) and production capacity, the automatic record of each parameter and output is realized and the records cannot be modified, and remote real-time and non-real-time monitoring are realized through the Internet.

[0048] figure 1 A schematic diagram of a processing system for computer control management is given. In addition to the mechanical part of the processing device, the system also includes instrument...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com