A method for multistage purification of nuclease p1

A technology of nuclease and nuclease crude enzyme, which is applied in the biological field, can solve the problems of small sample processing volume, low titer, and low sample recovery rate, and achieve the effects of efficient separation and purification, low cost, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

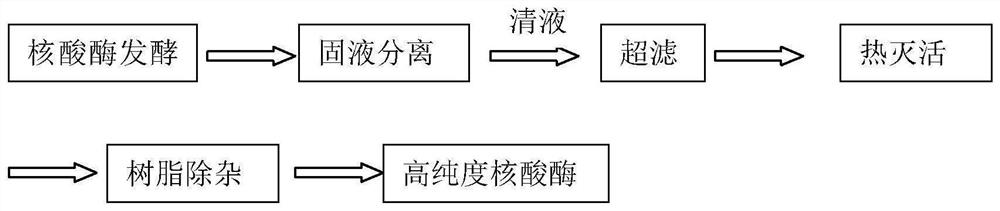

[0052] Purify nuclease P1 as follows:

[0053] 1. Prepare nuclease P1 crude enzyme solution by fermenting mold, the enzyme activity is 5600U / mL, and the specific activity is 852U / g.

[0054] 2. Separating the solid-liquid of the crude enzyme liquid obtained in step 1, collecting the filtrate, and ultrafiltering it with an ultrafiltration membrane with a molecular weight of 3KD; specifically, comprising the following steps:

[0055] (i) put the filtrate in an ultrafiltration membrane, and perform ultrafiltration at 30° C., and ultrafilter until the retentate is 1 / 4 of the volume of the filtrate, and collect the retentate;

[0056](ii) continue replenishing water to the volume of the filtrate described in step (i) in the retentate, then ultrafilter until the retentate is 1 / 4 of the initial volume, and collect the retentate;

[0057] (iii) Step (ii) is repeated, and the cycle ends for 2 times, and the retentate is collected.

[0058] 3. Transfer the retained liquid obtained in ...

Embodiment 2

[0062] Purify nuclease P1 as follows:

[0063] 1. Prepare nuclease P1 crude enzyme solution by fermenting mold, the enzyme activity is 5900U / mL, and the specific activity is 863U / g.

[0064] 2. Separating the solid-liquid of the crude enzyme liquid obtained in step 1, collecting the filtrate, and ultrafiltering it with an ultrafiltration membrane with a molecular weight of 6KD; specifically, comprising the following steps:

[0065] (i) Put the filtrate in the ultrafiltration membrane, at 32°C, perform ultrafiltration, ultrafiltration until the retentate is 1 / 4 of the volume of the filtrate, and collect the retentate;

[0066] (ii) continue replenishing water to the volume of the filtrate described in step (i) in the retentate, then ultrafilter until the retentate is 1 / 4 of the initial volume, and collect the retentate;

[0067] (iii) Step (ii) is repeated, the cycle is completed for 3 times, and the retentate is collected.

[0068] 3. Transfer the retained liquid obtained in...

Embodiment 3

[0072] Purify nuclease P1 as follows:

[0073] 1. Prepare nuclease P1 crude enzyme solution by fermenting mold, the enzyme activity is 6200U / mL, and the specific activity is 912U / g.

[0074] 2. Separating the solid-liquid of the crude enzyme liquid obtained in step 1, collecting the filtrate, and ultrafiltering it with an ultrafiltration membrane with a molecular weight of 12KD; specifically, comprising the following steps:

[0075] (i) put the filtrate in an ultrafiltration membrane, perform ultrafiltration at 33° C., and ultrafilter until the retentate is 1 / 4 of the volume of the filtrate, and collect the retentate;

[0076] (ii) continue replenishing water to the volume of the filtrate described in step (i) in the retentate, then ultrafilter until the retentate is 1 / 4 of the initial volume, and collect the retentate;

[0077] (iii) Step (ii) is repeated, the cycle is completed 4 times, and the retentate is collected.

[0078] 3. Transfer the retained liquid obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com