Efficient resourceful treatment device for residual sludge

A technology for excess sludge and treatment equipment, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of high thermal inactivation rate, limited degree of resource utilization, and ineffective improvement of reaction The protein content of the kettle and other problems can be solved to achieve the effect of promoting breaking stability and not being easy to heat inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

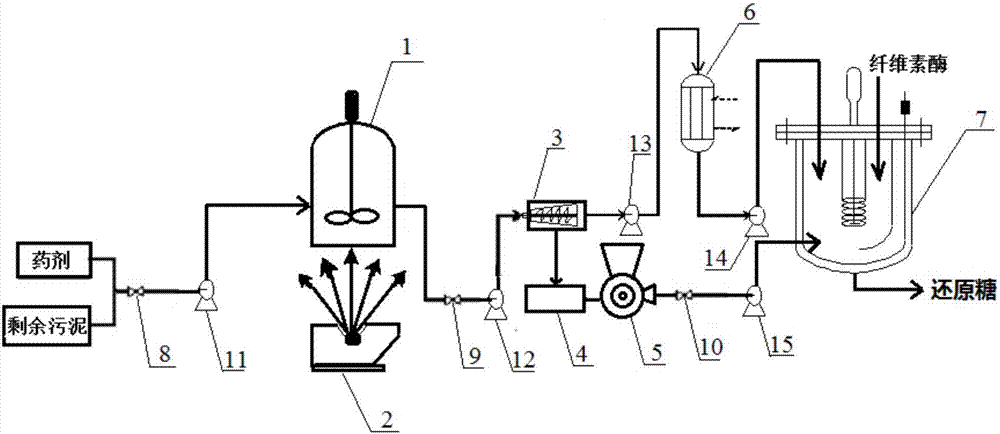

[0020] Such as figure 1 As shown, a high-efficiency recycling treatment device for excess sludge includes a chemical mixing unit, a liquid-solid separation unit, a liquid phase concentration unit, a solid phase crushing unit and a reaction kettle 7 .

[0021] Wherein, the medicament mixing unit includes a material-liquid mixer 1 and an electron accelerator 2 . The inlet of the feed-liquid mixer 1 is connected to the feeding centrifugal pump 11 and the feeding flow regulating valve 8 in turn, and the inlet of the feeding flow regulating valve 8 is connected to the chemical input pipeline and the remaining sludge input pipeline through a three-way valve; the feeding-liquid mixer The outlet of 1 is connected to the feed-liquid flow regulating valve 9 and the feed-liquid centrifugal pump 12 in turn, and the outlet of the feed-liquid centrifugal pump 12 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com