Activated carbon coating/foam silicon carbide structural catalyst and preparation method thereof

A foamed silicon carbide, structural catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of discontinuous opening, separation of catalyst and reaction product, poor heat and mass transfer effect and other problems, to achieve the effects of good oxidation resistance, reduced loss and improved ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

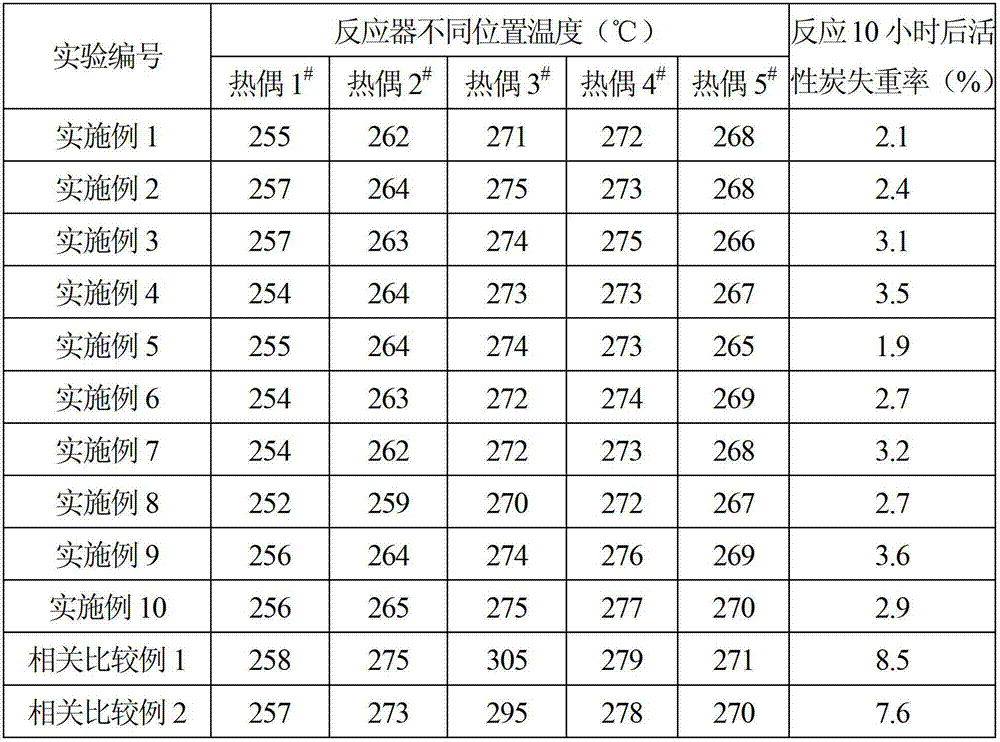

Examples

Embodiment 1

[0037] a. Soak silicon carbide foam ceramics with an average pore diameter of 1mm in NaOH or KOH solution with a concentration of 3 mol / L for 8 minutes to improve the surface roughness and remove oil and other impurities on the surface, then wash with water, and then store at 120°C Dry in air atmosphere for 3 hours;

[0038] b. In terms of weight ratio, the ratio of aminophenol-formaldehyde resin:activated carbon:curing agent:alcohol=100:50:2:100 was used to prepare suspension, and ball milled for 1 hour to obtain slurry. Wherein, the curing agent is hexamethylenetetramine.

[0039] c. Fully soak the foamed silicon carbide ceramics obtained in step a in the slurry in step b for 5 minutes, then take it out, blow off excess slurry with compressed air or centrifuge, and dry it in an air atmosphere at 100°C.

[0040] d. Repeat step c for the dried sample until the loading of the coating reaches 200g / L.

[0041]e. Put the sample obtained in step d into a muffle furnace or a vacuu...

Embodiment 2

[0046] The difference from Example 1 is that the weight ratio of the coating slurry in step b is phenolic resin:activated carbon:curing agent:alcohol=100:100:2:100. Wherein, curing agent is oxalic acid.

Embodiment 3

[0048] The difference from Example 1 is that the weight ratio of the coating slurry in step b is epoxy-modified phenolic resin:activated carbon:curing agent:alcohol=100:150:2:100. Wherein, curing agent is citric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com