Graphene and protein composite film based on non-covalent modification and preparation method thereof

A non-covalent modification and composite film technology, which is applied in chemical instruments and methods, lamination, coating, etc., can solve the problems that it is difficult to meet the actual needs of graphene, the adsorption amount is small, and the adsorption amount of coupled molecules cannot be controlled. , to achieve good application prospects, uniform film, easy to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

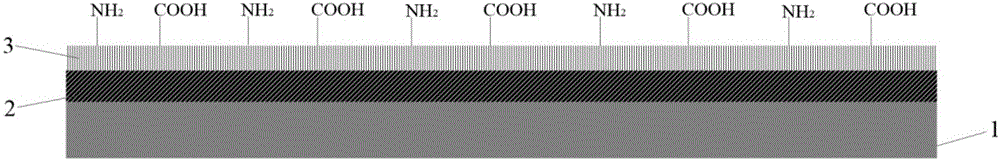

[0025] Such as figure 1 Shown is a schematic diagram of the structure of protein films with different nanoscale thicknesses formed on the surface of single-layer graphene on a silica substrate. Transfer the single-layer graphene film grown by chemical vapor deposition to the surface of the silicon dioxide substrate, remove the photoresist on the surface of the graphene film and leave the single-layer graphene on the surface of the silicon dioxide substrate; the protein solution Add it dropwise to the heat inactivation treatment of single-layer graphene to form a protein film on the surface of single-layer graphene, and obtain a non-covalently modified graphene-protein composite film.

[0026] Dissolve the BSA solution with a concentration of 1.8mM in deionized water, set the temperature of heating inactivation at 75°C, and control the time of protein inactivation at 2min, 4min and 6min, respectively, which can form different nanoscale thickness on the surface of graphene. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com