Aluminum-doped zinc oxide-based thermoelectric material and preparation method thereof

A zinc oxide-based, thermoelectric material technology, which is applied in the field of environmentally friendly new energy materials, can solve the problems of low Al solid solution and the influence of material synthesis process conditions, and achieve high density, good mechanical properties and thermoelectric properties, and easy doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

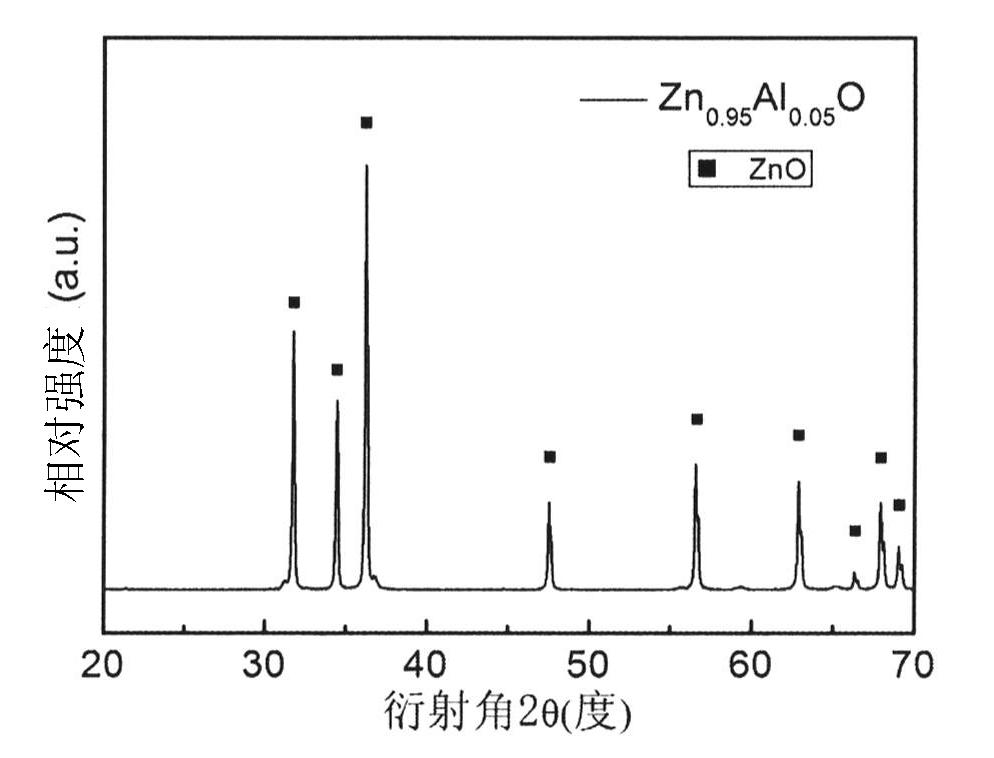

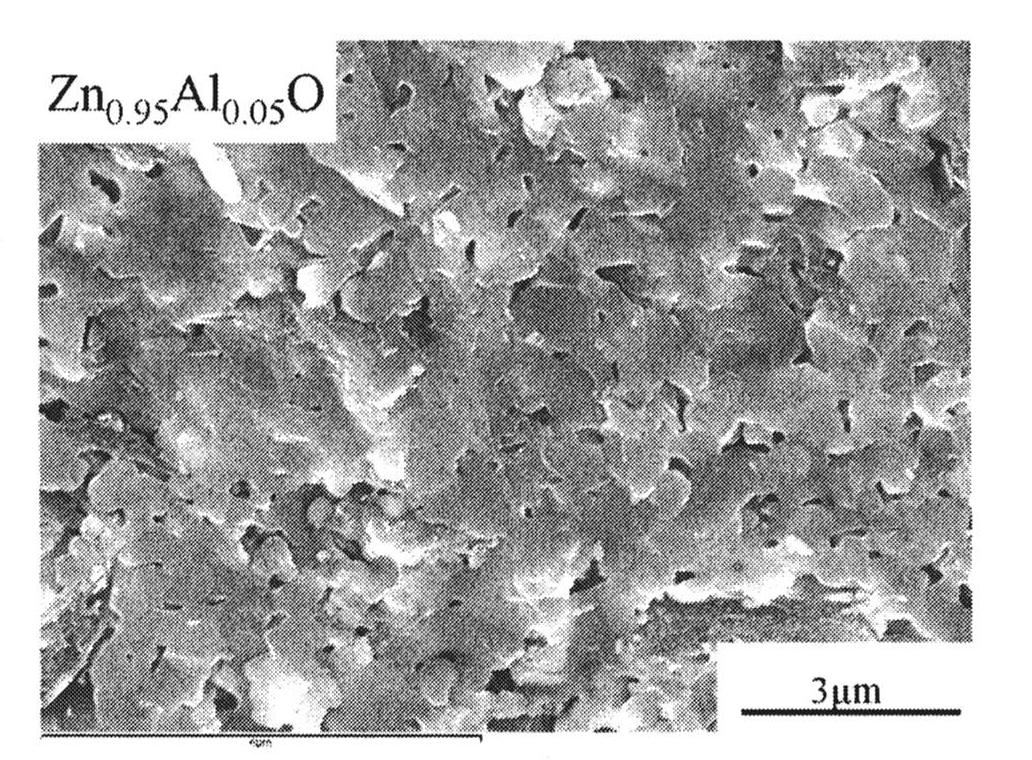

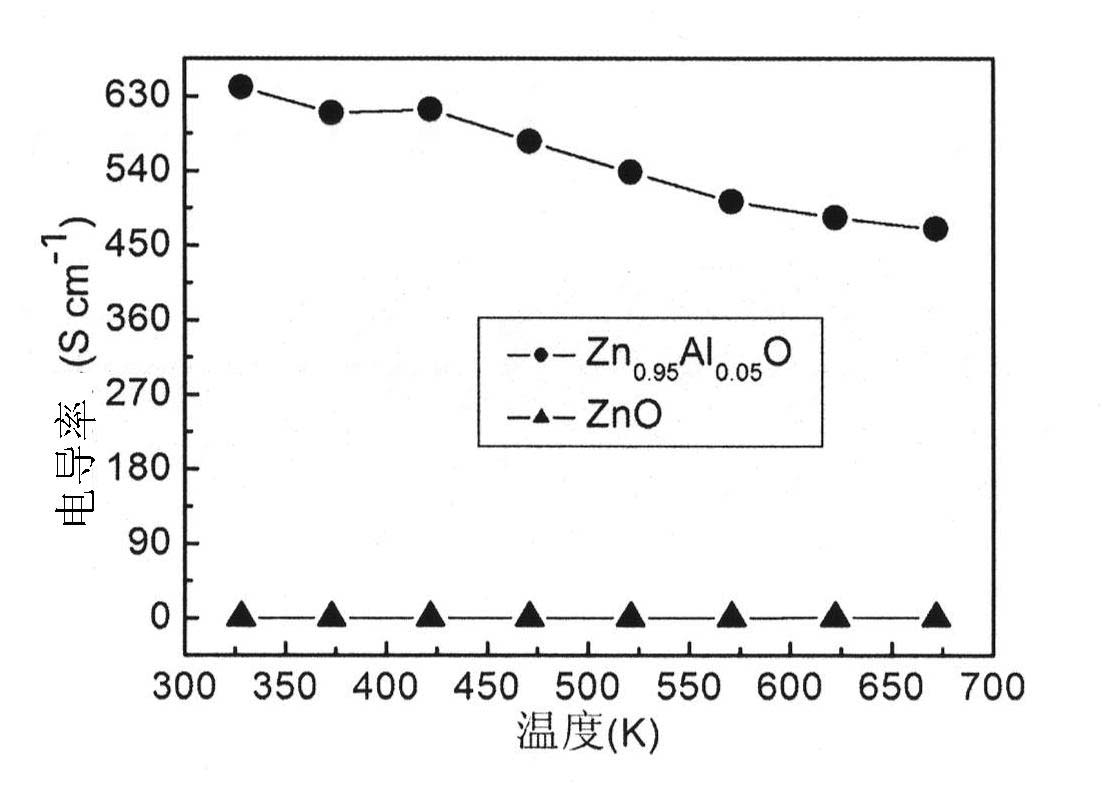

[0022] The present invention provides a technology mainly used for thermoelectric conversion, the chemical composition is Zn 1-x Al x O(0≤x≤0.20) oxide thermoelectric material, the material is Zn(OH) 2 And Al(OH) 3 As raw materials, use simple mechanical ball milling and roasting process for activation treatment, and then use spark plasma equipment to directly synthesize Zn 1-x Al x O material finally obtains a bulk material with high density, good machinability and thermoelectric properties.

[0023] The specific method steps for preparing the above include:

[0024] 1. Ingredients: use Zn(OH) 2 And Al(OH) 3 Powder according to Zn 1-x Al x O stoichiometric ratio, where 0≤x≤0.20, the weighed powder and a certain amount of deionized water are loaded into a ceramic substrate or a plastic ball mill tank.

[0025] 2. Ball milling: The ball milling tank is installed on the planetary ball mill for wet ball milling. The ball milling medium is deionized water.

[0026] 3. Baking: Put the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com