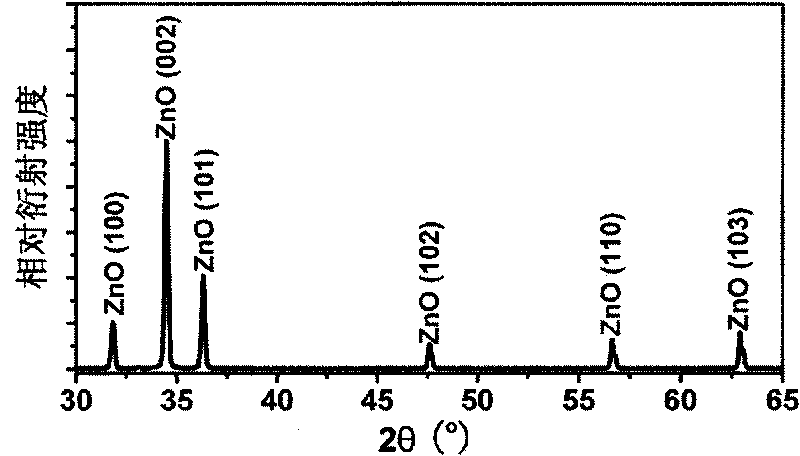

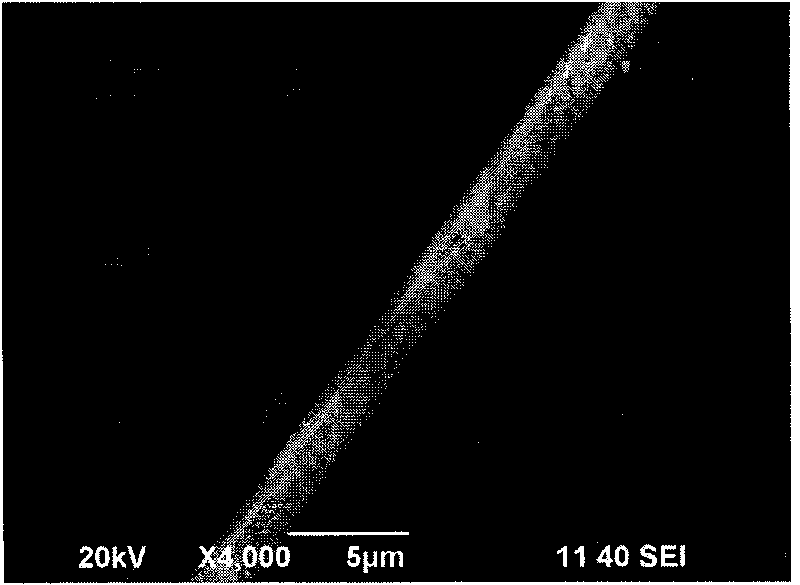

Preparation method of ultra-long stibium-doped zinc oxide micrometer line

A zinc oxide micron, antimony doping technology, applied in microstructure technology, gaseous chemical plating, microstructure devices, etc., to achieve the effects of reliable preparation, reduced preparation temperature, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The quality of the product prepared under the following experimental conditions is better. The experimental equipment is a horizontal tube furnace, specifications: length 75cm, tube diameter 45mm, maximum heating temperature 1000°C; quartz tube length 100cm, tube diameter 32mm.

[0015] Solution: First, ultrasonically clean the silicon substrate in acetone and absolute ethanol for 20 minutes, rinse it with deionized water, and then use magnetron sputtering to deposit 20nm of Au on the silicon substrate as a catalyst. Zn powder, Sb 2 o 3 Mix it with C powder at an atomic ratio of 5:1:4, ball mill it for 1 hour, mix well and put it in a porcelain boat as a raw material, and put the silicon substrate on the porcelain boat facing the powder. Then the ceramic boat is placed in the middle of the quartz tube in the tube furnace, and the flowmeter is adjusted to feed argon (98%) / oxygen (2%) mixed gas (300 sccm) into the tube. Keeping it warm for 10 minutes at a temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com