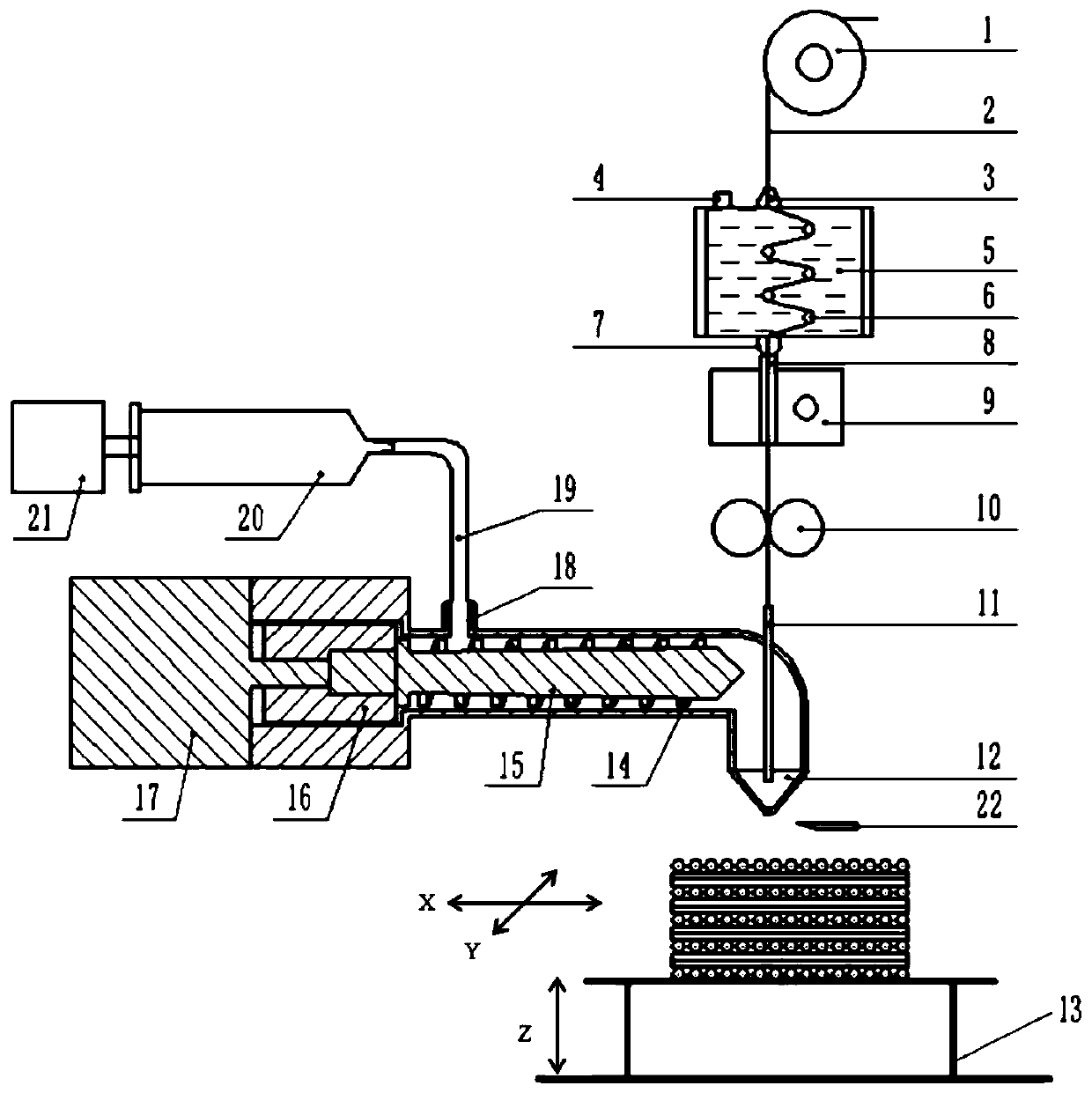

Three-dimensional (3D) printing device and method for bionic porous continuous carbon fiber reinforced ceramic bone scaffold

A 3D printing and carbon fiber technology, applied in the field of 3D printing, can solve the problems of low precision of scaffolds, difficulty in extrusion of slurry, poor mechanical properties, etc., and achieve the effects of improving biological performance, good wettability, and solving adhesion difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of continuous carbon fiber reinforced ceramic bone support comprises the following steps:

[0048] Step 1. Mix deionized water and glycerin according to the mass ratio of 7:3 to 8:2 to prepare a 100ml solution, place it in a magnetic stirrer, and stir evenly to obtain solution A.

[0049] Step 2, add polyammonium acrylate PAA-NH in solution A 4 , PAA-NH 4 The mass of the solution is 1-2% of the mass of the HA powder, stirred evenly, then measured its pH, adjusted its pH value to 9 with ammonia water, and stirred for 15 minutes to obtain solution B.

[0050] Step 3, mix solution B with HA powder, and prepare two kinds of HA suspensions with low solid ratio and high solid ratio respectively, and the solid ratio of the HA suspension with low solid ratio is 5% to 10% %, the solid ratio of the HA suspension with high solid ratio is 20%~30% (20% solid ratio, i.e. V 粉体 / (V 粉体 +V 溶剂 )=20VOL%), the two HA suspensions were ball milled at a frequency of...

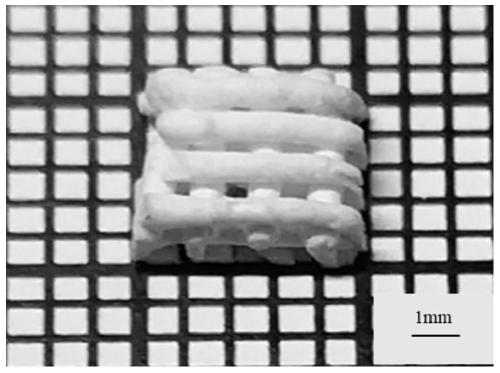

Embodiment 1

[0061] The preparation method of the continuous carbon fiber-reinforced ceramic bone scaffold will be further described below in combination with examples.

[0062] The matrix is made of hydroxyapatite (HA) powder, and the carbon fiber multifilament is composed of 10 carbon fibers.

[0063] Step 1. Mix deionized water and glycerol according to the mass ratio of 7:3 to prepare a solution of 100, place it in a magnetic stirrer, and stir for 15 minutes to obtain solution A.

[0064] Step 2, add polyammonium acrylate PAA-NH in solution A 4 , PAA-NH 4 The mass of the solution was 1.5% of the mass of the HA powder, stirred for 30 minutes, then measured its pH, adjusted its pH to 9 with ammonia water, and stirred for 15 minutes to obtain solution B.

[0065] Step 3, mix solution B with HA powder, prepare two kinds of HA suspensions with low solid ratio and high solid ratio respectively, the solid ratio of the HA suspension with low solid ratio is 7.5%, and the high solid ratio T...

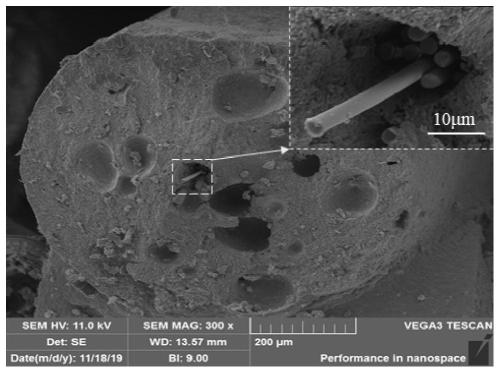

Embodiment 2

[0076] The ceramic material uses hydroxyapatite (HA) powder, and the carbon fiber multifilament is composed of 5 carbon fibers.

[0077] Step 1. Mix deionized water and glycerin according to the mass ratio of 7.5:2.5 to prepare a solution, place the mixture of deionized water and glycerin in a magnetic stirrer, and stir evenly to obtain solution A.

[0078] Step 2, add polyammonium acrylate PAA-NH in solution A 4 , PAA-NH 4 The mass of the solution is 1% of the mass of the HA powder, stirred evenly, then measured its pH, adjusted its pH value to 9 with ammonia water, and stirred for 15 minutes to obtain solution B.

[0079] Step 3. Mix solution B with HA powder, prepare HA suspensions with low solid phase and high solid phase respectively, the range of low solid phase is 5%, and the range of high solid phase is 20%. The two HA suspensions were ball-milled at a frequency of 30 Hz for 12 hours respectively. The purpose of ball-milling was to make the slurry more uniform and disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com