Low temperature methanol cleaning process

A process, methanol technology, which is applied in the field of methanol absorption and recovery of acid gas in mixed gas, which can solve the problems of reduced desorption amount, increase of system temperature, and reduced desorption refrigeration effect, so as to reduce production costs, reduce consumption, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

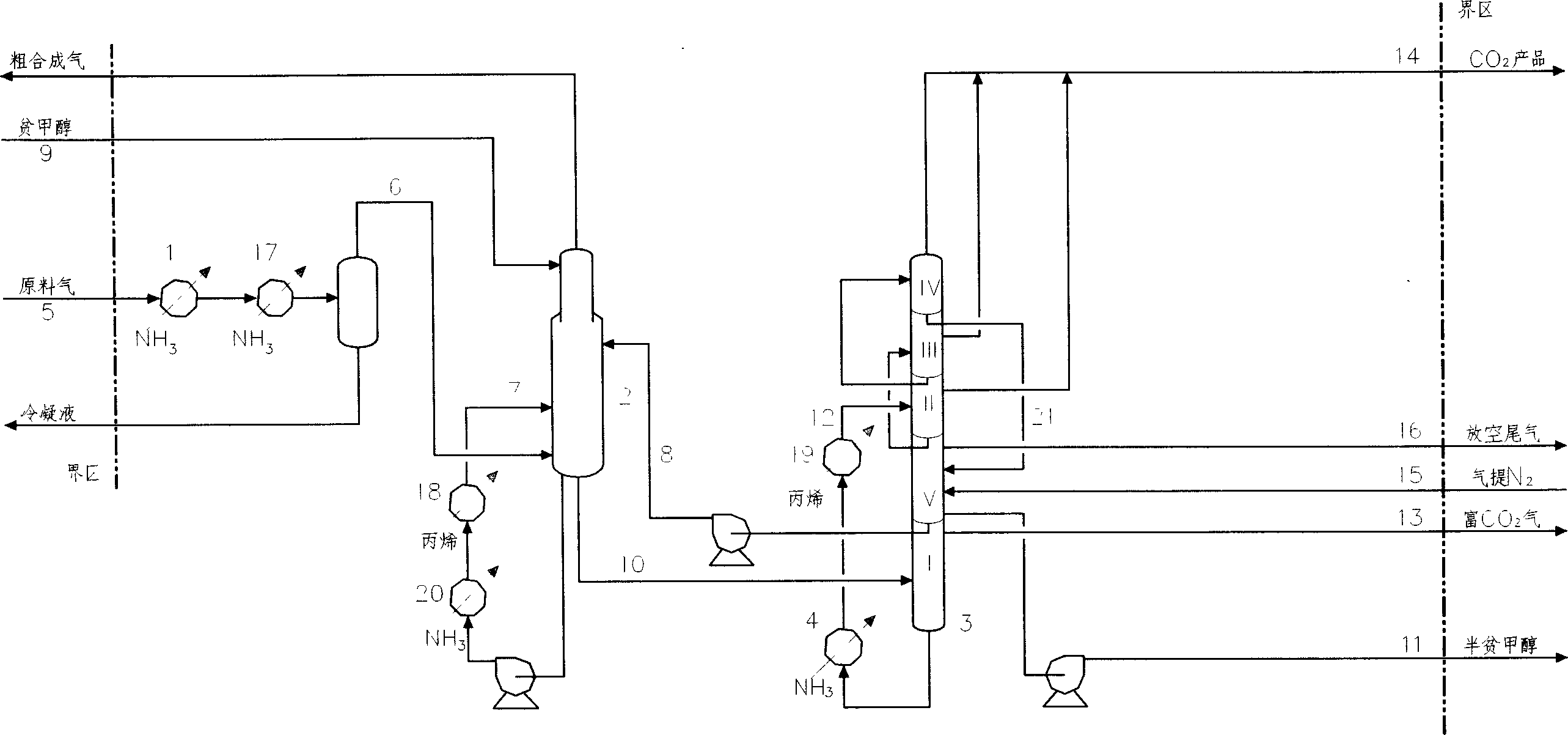

[0013] Accompanying drawing 2 is a kind of low-temperature methanol washing process of the present invention, and the temperature of feed gas (5) is 40 ℃, and pressure is 4.9MPa (A), and flow rate is 124450Nm 3 / h is cooled to about -27°C by the ammonia cooler (1) and the ammonia cooler (17), the condensate is separated, and the gas (6) is sent to CO 2 The absorption tower (2) uses the circulating methanol (7) of the circulation section, from the CO 2 The semi-lean methanol (8) in the V section of the regeneration tower (3) and the lean methanol (9) from the boundary area are washed and purified, and the methanol-rich solution at the bottom of the tower is divided into two streams, and one stream of methanol-rich solution (7) passes through the ammonia cooler ( 20) and the propylene cryocooler (18) are cooled to about -35°C and sent back to the bottom of the tower, and another stream of methanol-rich solution (10) is sent into the CO 2 Regeneration tower (3) section I flashes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com