Coking composite leaning agent and preparation method thereof

A technology of coal coking and thinning agent, which is applied in the field of coal chemical industry, can solve the problems of unfavorable coke mechanical strength, reduction of coke sulfur content, and large particle size of thinning agent powder, so as to improve coke mechanical strength, reduce coke sulfur content, The effect of the simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

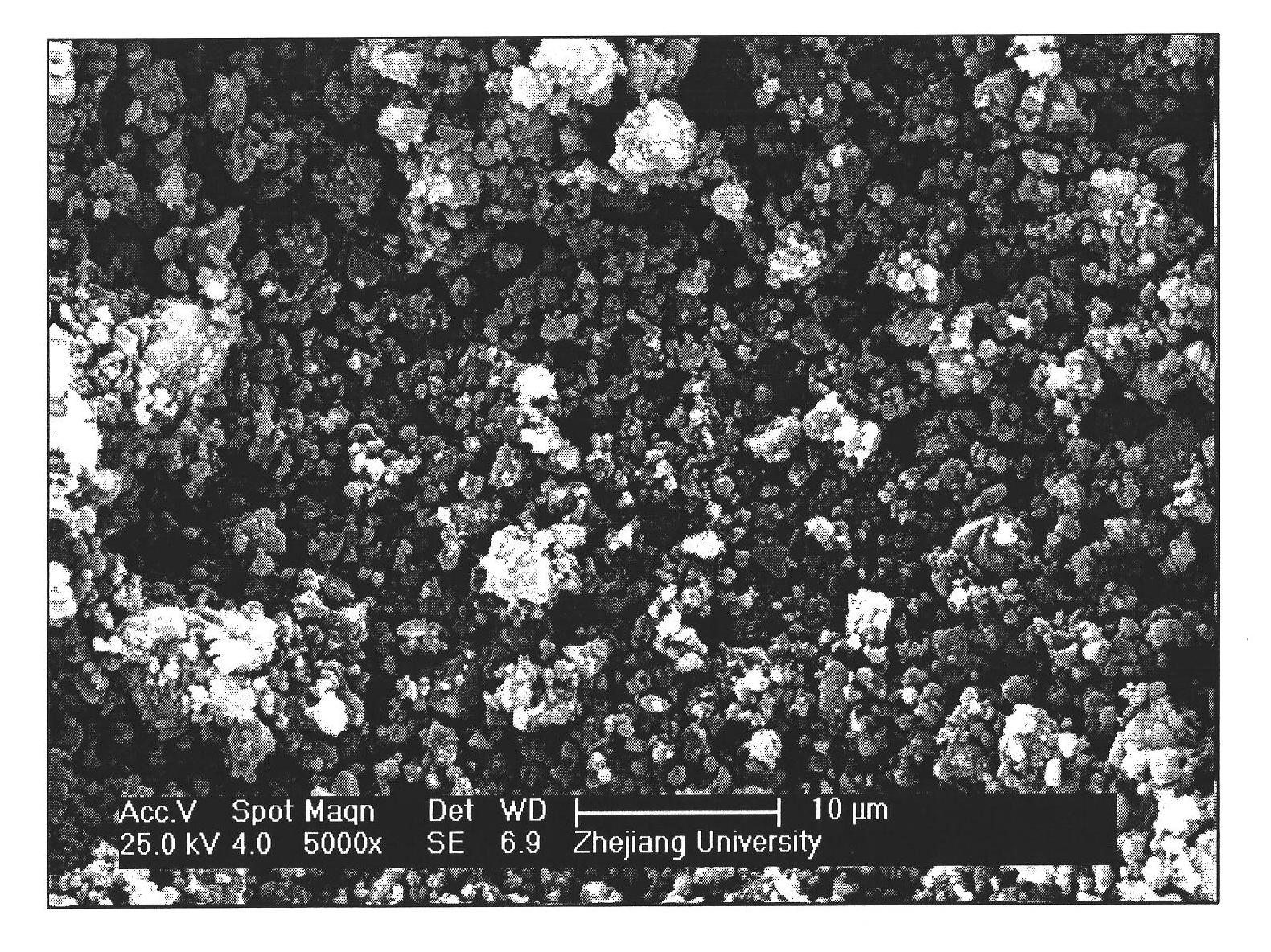

[0026] The magnesite ore (MgCO 3 content > 97%), anthracite from Jincheng Coal Mine in Shanxi (total sulfur S t,ad 0.51%, organic sulfur S org,ad 0.24%), coke powder (sulfur S t,ad 0.71%, organic sulfur S org,ad0.37%) and coal tar pitch (112° C. of softening point) as raw materials; the selected four kinds of raw materials are respectively crushed to a particle size of 25mm after 500 revolutions measured by a small drum 25 Characterization, abrasion resistance is measured by the mass percentage M of coke with particle size 10 Characterization; Determination of organic sulfur content S org,ad ; CO in the gas sample 2 and CO content were measured with an Austenitic gas analyzer. Experimentally measured, when no thinning agent is added, the organic sulfur content of coke S org,ad 0.29%, crushing strength M 25 90.3%, abrasion resistance M 10 6.9%, CO in gas 2 and CO content are 2.1% and 7.3% respectively; when adding 10% compound thinning agent, the organic sulfur conten...

Embodiment 2

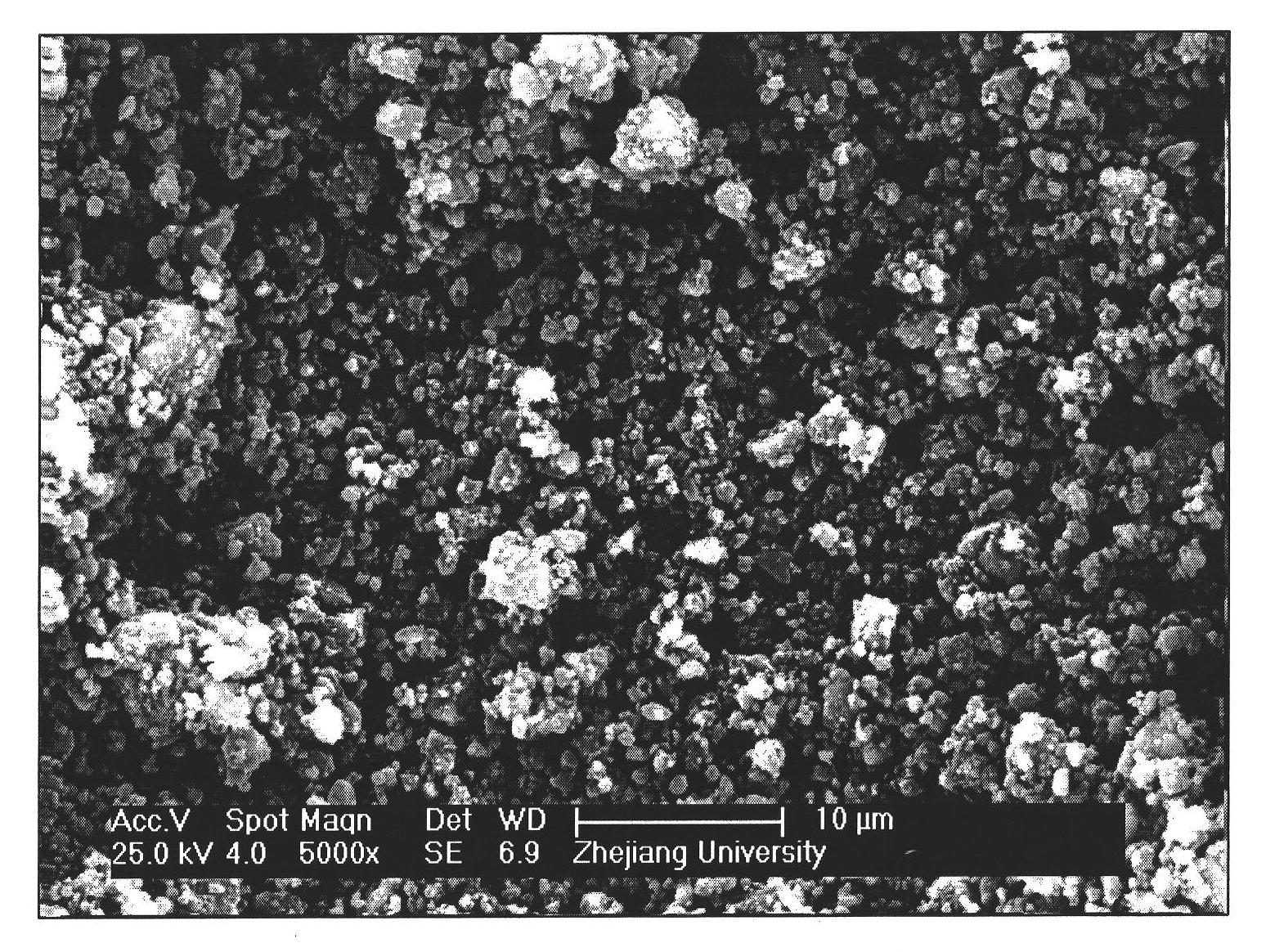

[0028] The difference from Example 1 is that the proportioning of the four raw materials for preparing the composite thinner is: 82% magnesite ore, 5% anthracite, 10% coke powder, 3% coal tar pitch; magnesite When the ore, anthracite, and coke powder are mixed and ball milled, the hydrogen atmosphere pressure is 0.2MPa, the ball milling time is 1 hour, and the ball milling time is 1.5 hours after adding coal tar pitch; the dosage of the obtained composite thinner in coking coal is 5%; According to the coking test, the organic sulfur content of coke S org,ad 0.24%, crushing strength M 25 91.2%, abrasion resistance M 10 6.5%, CO in gas 2 and CO content were 3.8% and 8.6%, respectively.

Embodiment 3

[0030] The difference from Example 1 is that the proportioning of the four raw materials for preparing the composite thinner is: 45% magnesite ore, 15% anthracite, 30% coke powder, 10% coal tar pitch; magnesite When the ore, anthracite, and coke powder are mixed and ball milled, the hydrogen atmosphere pressure is 0.5 MPa, the ball milling time is 3 hours, and the ball milling time is 0.5 hour after adding coal tar pitch; the dosage of the obtained composite thinner in coking coal is 7%; According to the coking test, the organic sulfur content of coke S org,ad 0.25%, crushing strength M 25 93.1%, abrasion resistance M 10 6.0%, CO in gas 2 and CO content were 3.1% and 8.2%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com